Category: Linen Frock Coat

Setting the Sleeves

It’s now time to finally set the sleeves into the armscyes. While in the past I’ve used several rows of shirring stitches to help gather the excess material into the armscye, I’ve found that this is slow and tedious, and with a little practice, it’s quite possible to set the sleeves without the shirring stitches, so that is what we will do here.

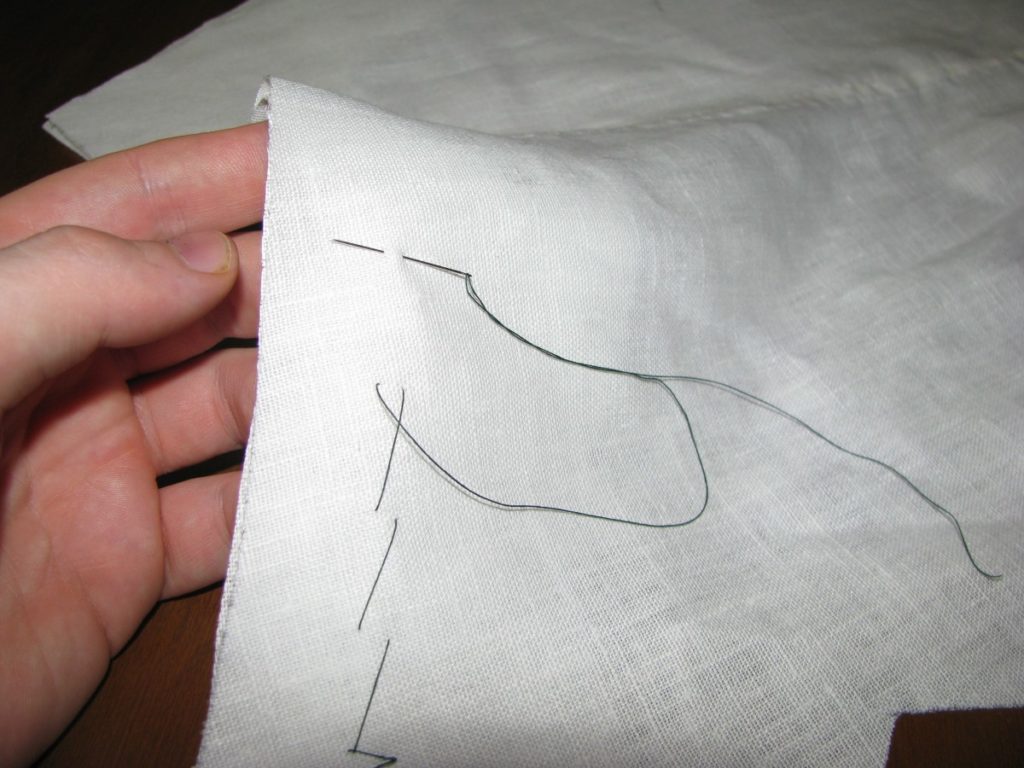

Begin by marking the back seam of the sleeve, 1/2″ from the armscye, on the right side. This will help you align the sleeve properly.

On the right side of the back of the coat body, at the armscye, mark the seam allowance and then make a cross hair exactly between the shoulder and side body seams.

Lay the coat armscye and the sleeve head right sides together, with the two cross hairs laying on top of each other. This ensures the precise alignment of the sleeve.

Baste the sleeve to the coat at this point only, making three or four stitches in place to hold everything securely.

Now turn the coat so that the wrong side of the body is facing you, and the sleeve is on the inside. This exposes the armscye seam area in a way that you can readily work on it.

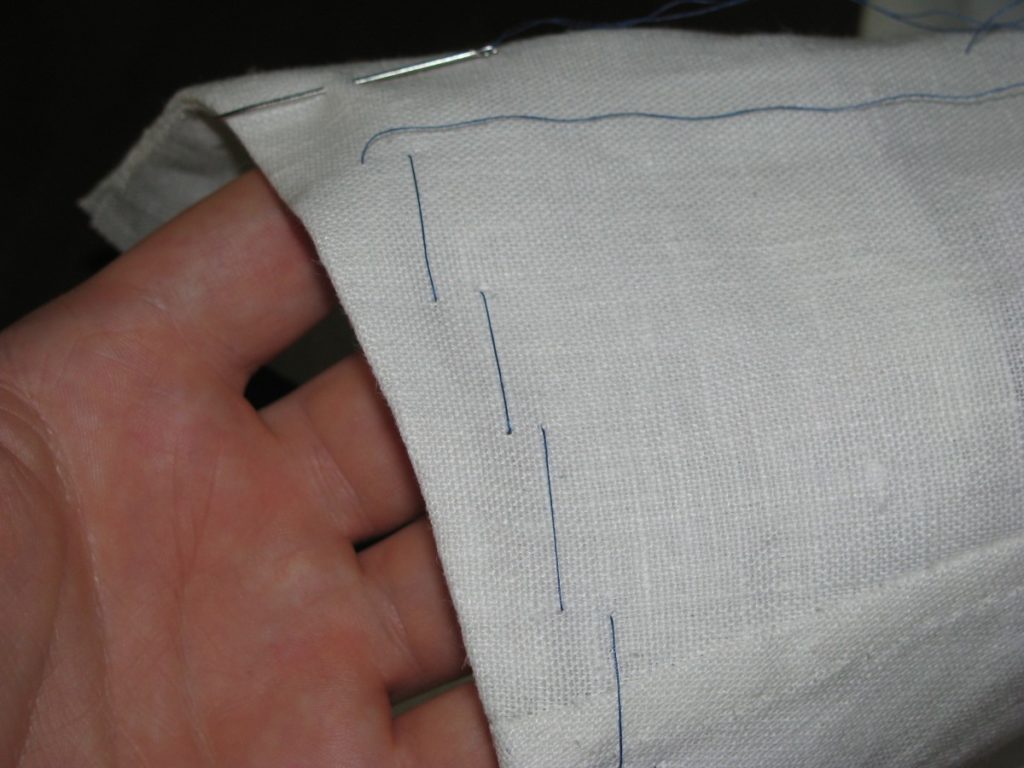

Starting at that crosshair, baste the undersleeve to the armscye using a running stitch.

As you approach the side seam of the coat, you can work a little fullness into the sleeve, using your fingers, in the same manner as described below. This being linen, I’d do maybe a 1/4″ of fullness at most.

Continue basting until you get to the front sleeve seam. Making one backstitch in place. It just so happened that the armscye dart on the coat body aligned with that seam, but this was completely unplanned.

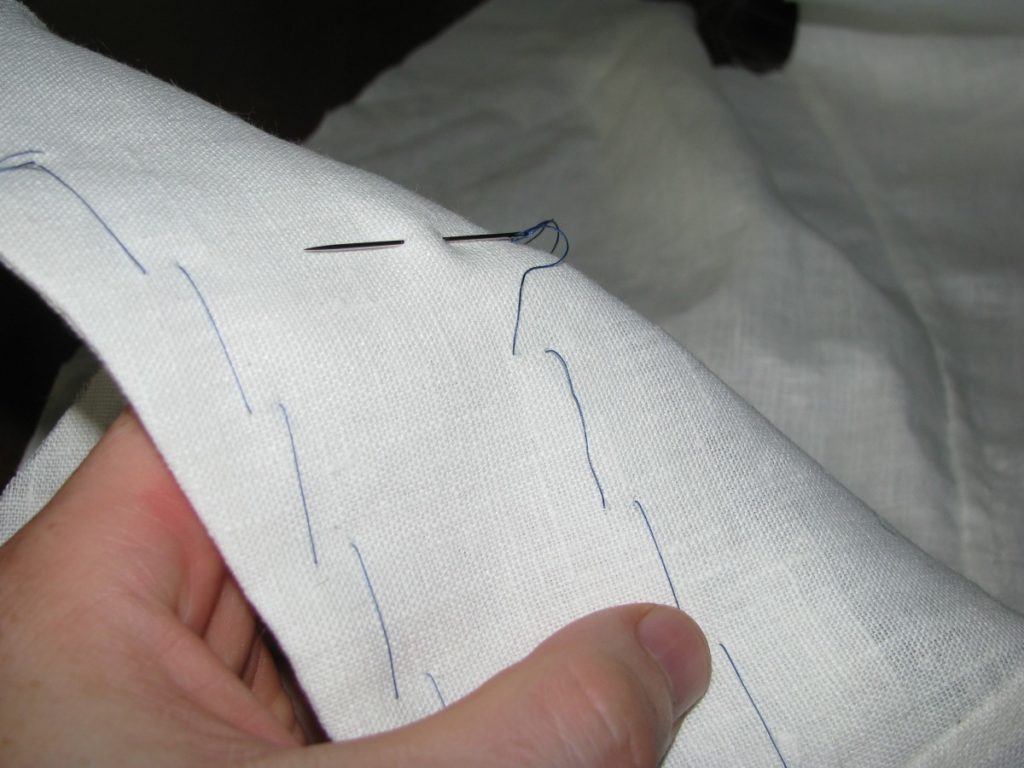

Now that we’ve reached the top sleeve section, you’ll notice there is a lot of excess material that must be fulled in. Using Devere’s system, I’ve found that excess to be about two graduated inches worth, but this can vary according to how full you drafted the sleeve, and any stretching that may have gone on during the construction process.

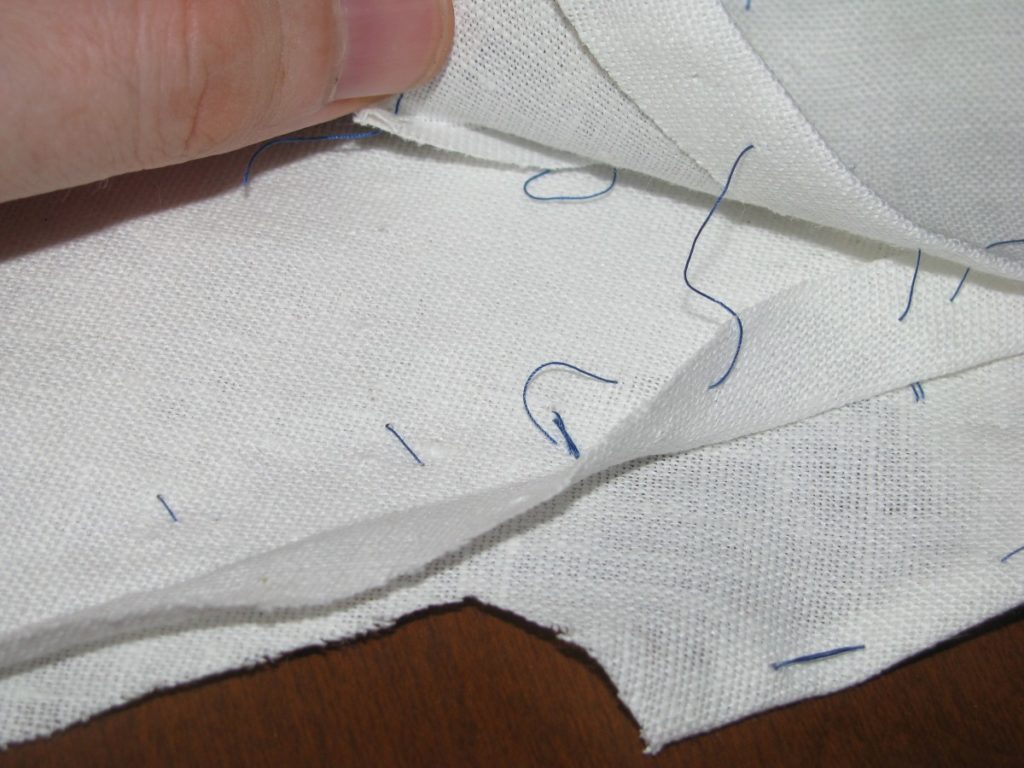

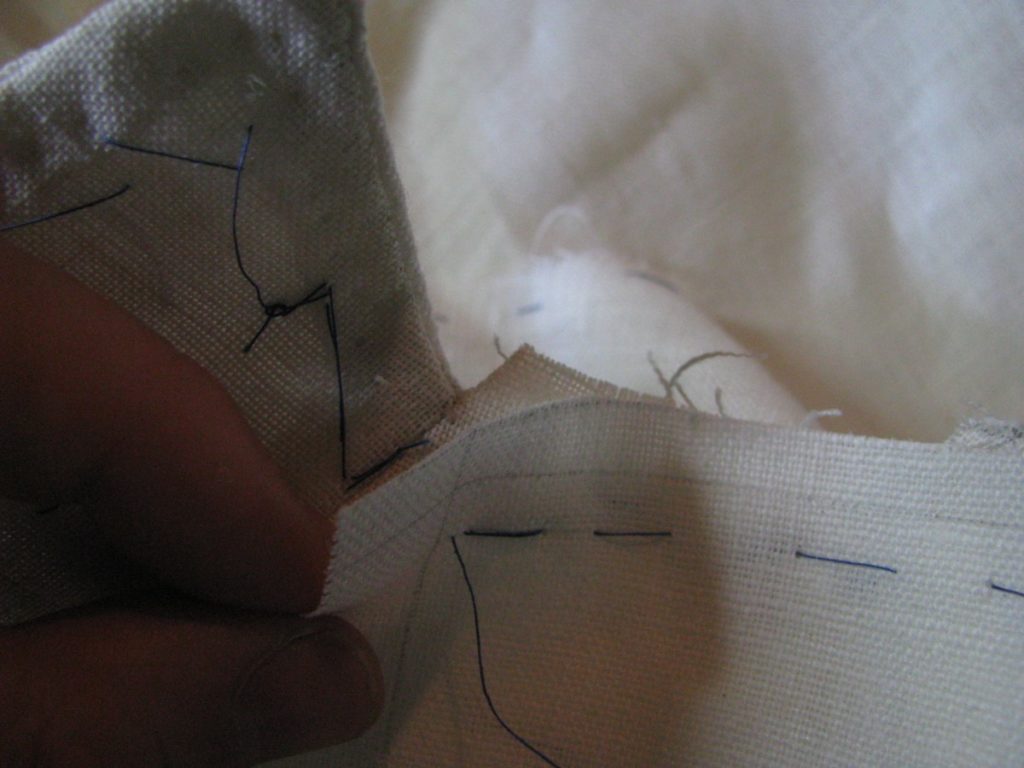

This fullness must be gradually worked in to the armscye. Hold both layers of fabric between your thumb and fingers, and leaving your thumb in place, gently move some excess fabric towards your last stitch with your fore finger. The amount should be about an 1/8″ per basting stitch, I used a huge amount in the photo just to clarify what is going on. As you move the fabric over with your fingers, take another stitch to hold it in place.

Continue this process towards the top of the sleeve. At the very top, you may notice that the grain of the fabric on the sleeve runs parallel to the edge, which means it cannot be properly fulled. For this inch or two, just lay the sleeve on with normal tension. Then continue fulling around the back of the top sleeve.

After you’ve successfully basted around the sleeve one time, turn everything to the right side and examine your work. The sleeve should lay relatively smooth and be free of unsightly puckers. It actually took me two and a half tries to successfully get to this point, so do not fear if you have to redo some of the fulling. Every fabric will full slightly differently, so that takes some getting used to.

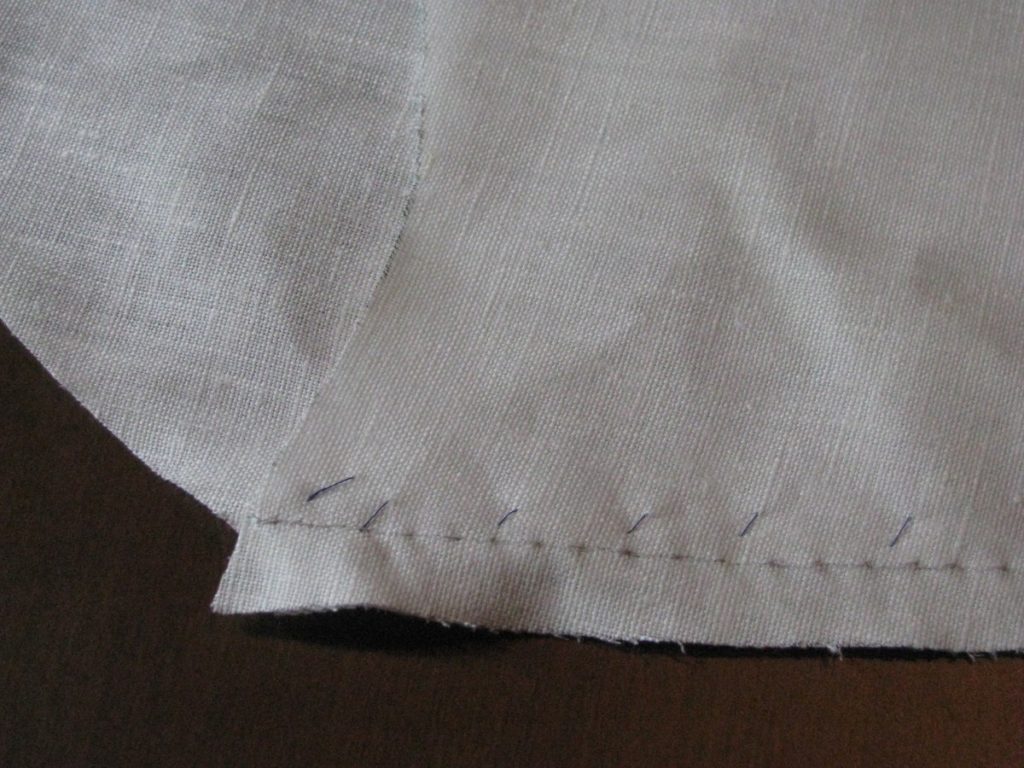

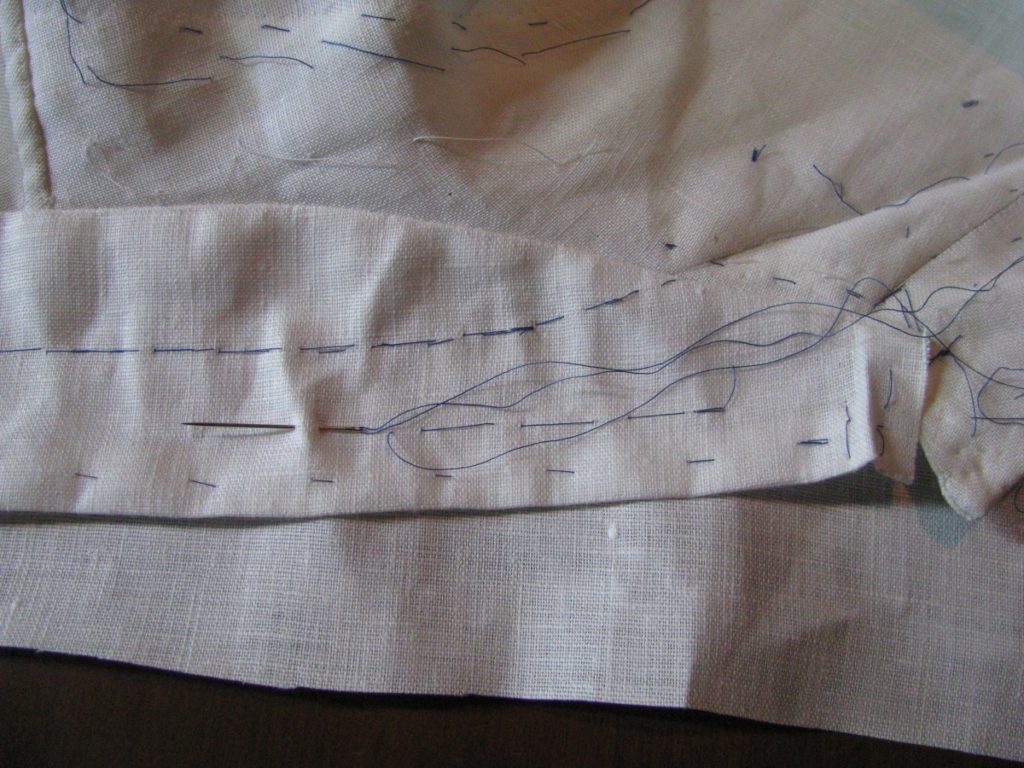

When you are happy, turn back to the inside and baste another row of running stitches around the armscye. These stitches should interweave with the previous stitches, affectively locking everything in place. As you get to the top sleeve, you can further refine the fulling with your fingers, subdividing the fullness in between each new stitch.

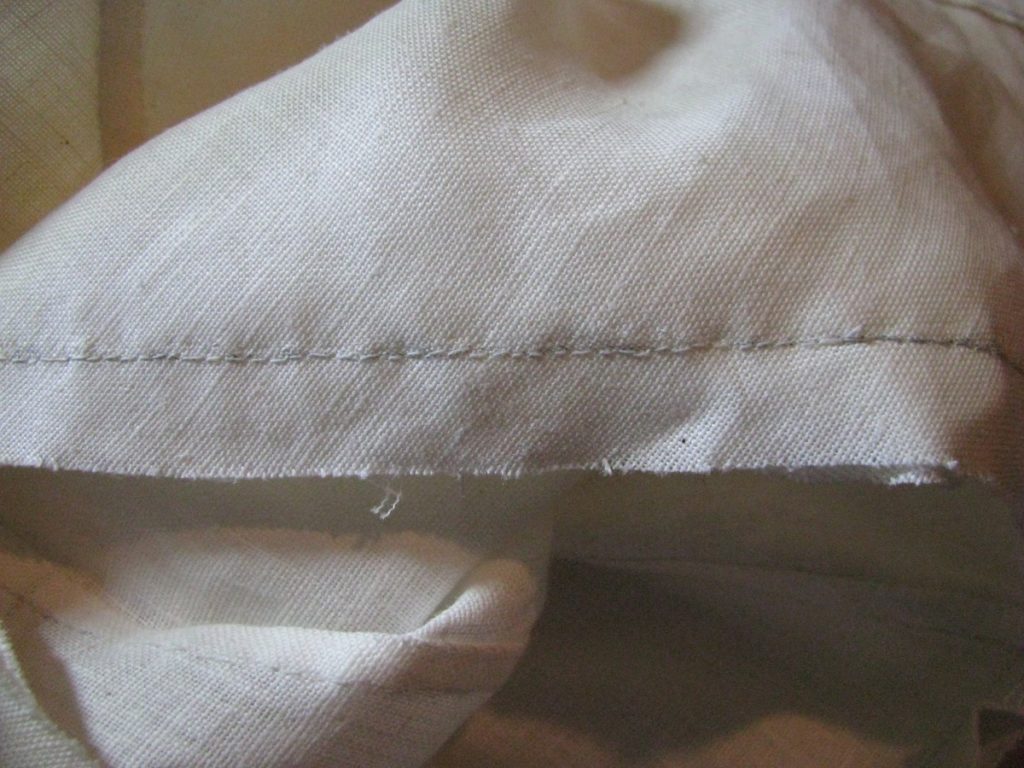

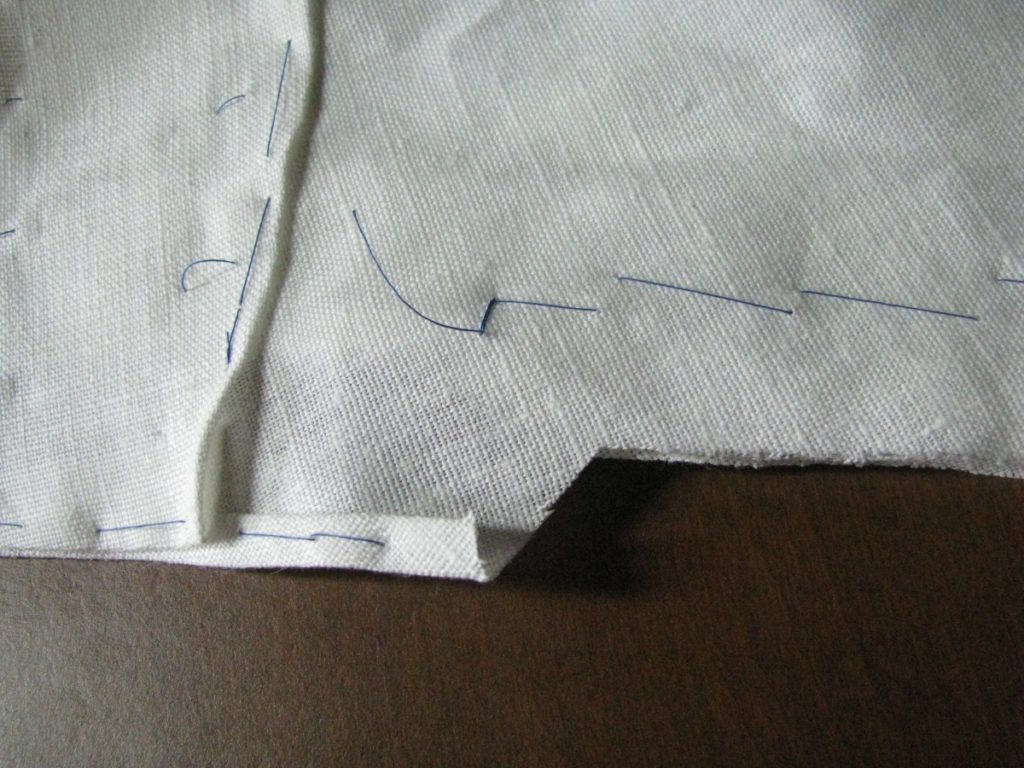

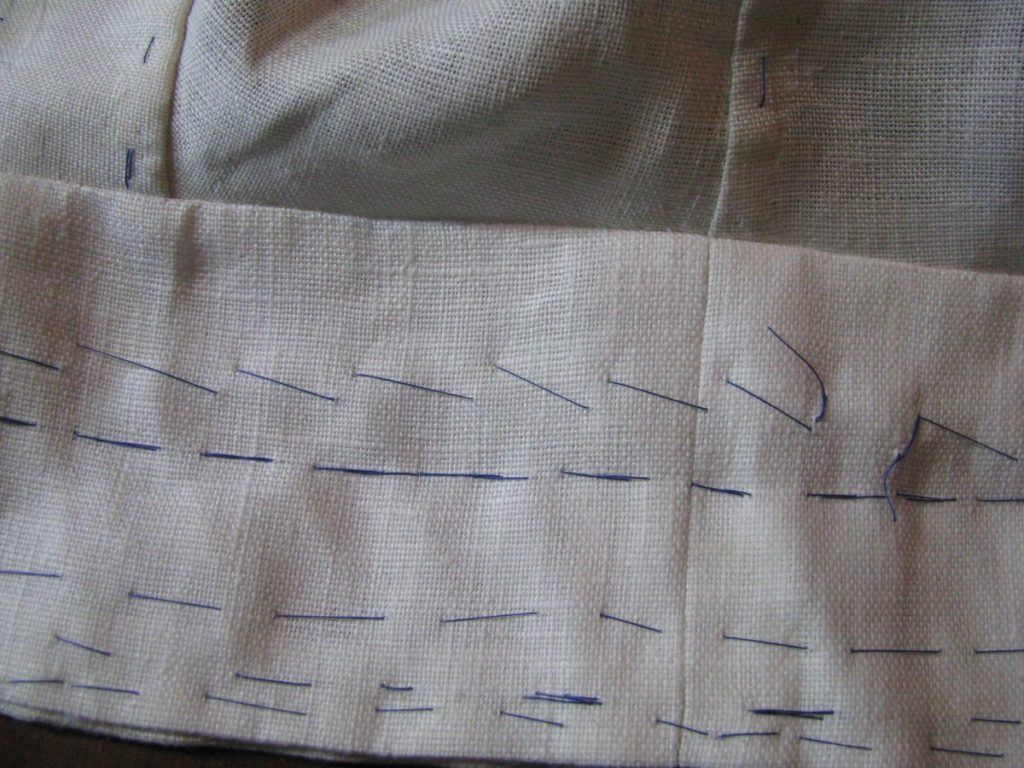

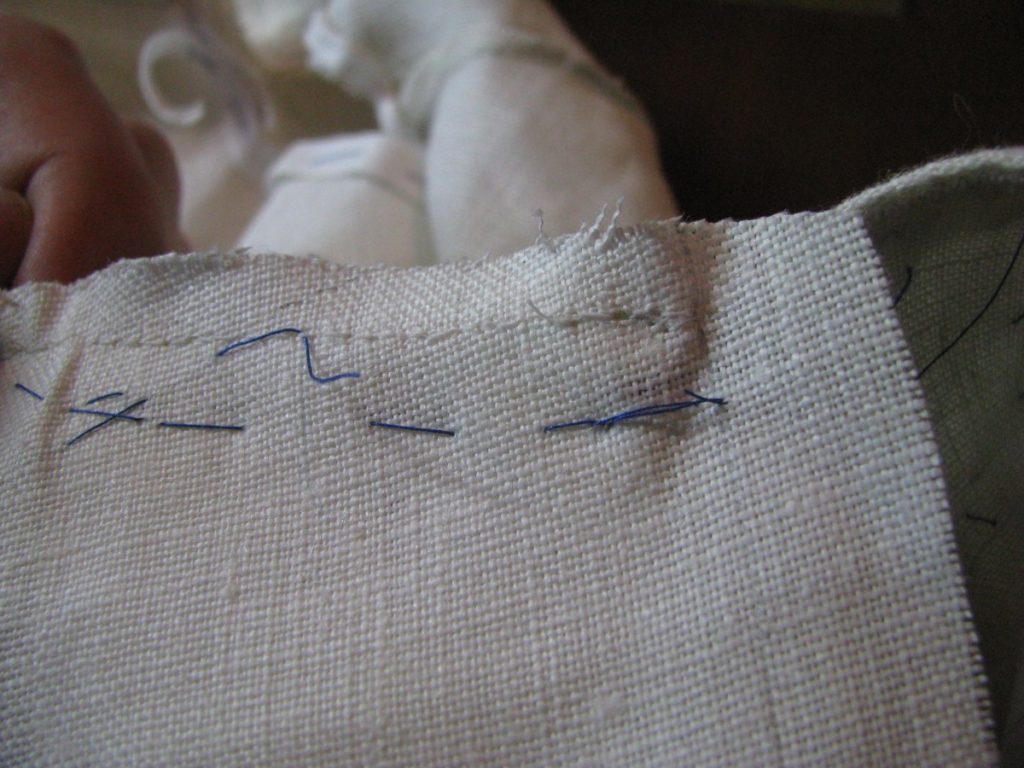

Here is what the basting should look like after the second round.

On the body side, mark and sew the seam using back stitches for strength, with a 1/2″ seam allowance. You can further refine the fullness in the top sleeve with each stitch, giving you a completely smooth sleeve head.

Do not trim either seam allowance.

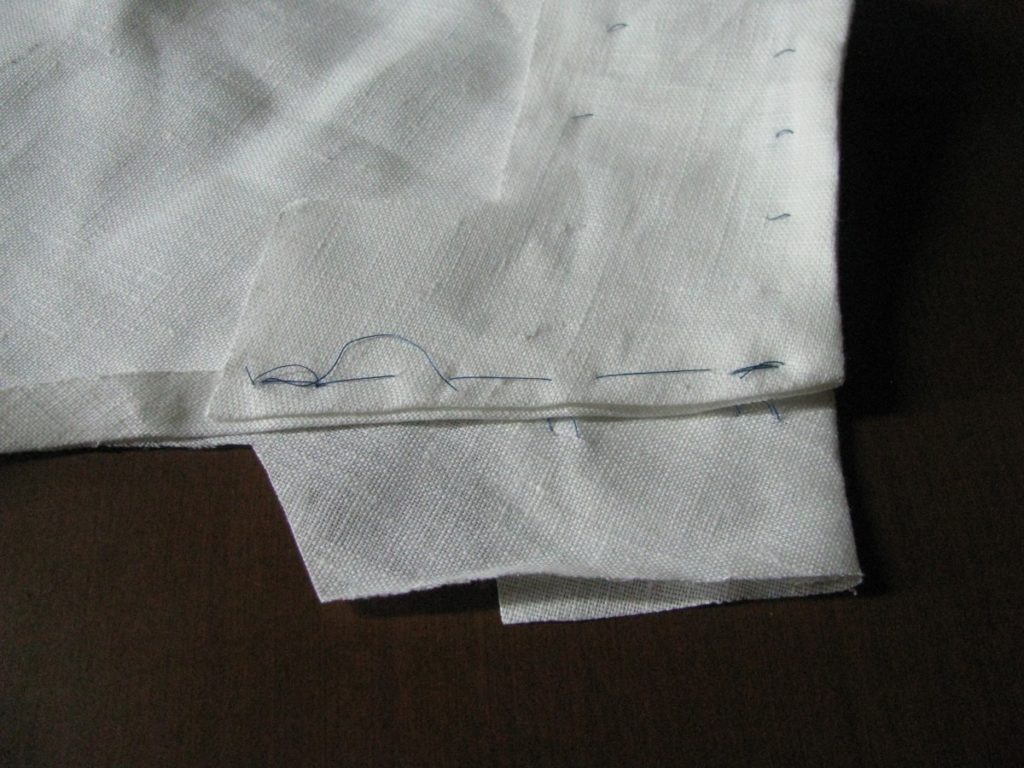

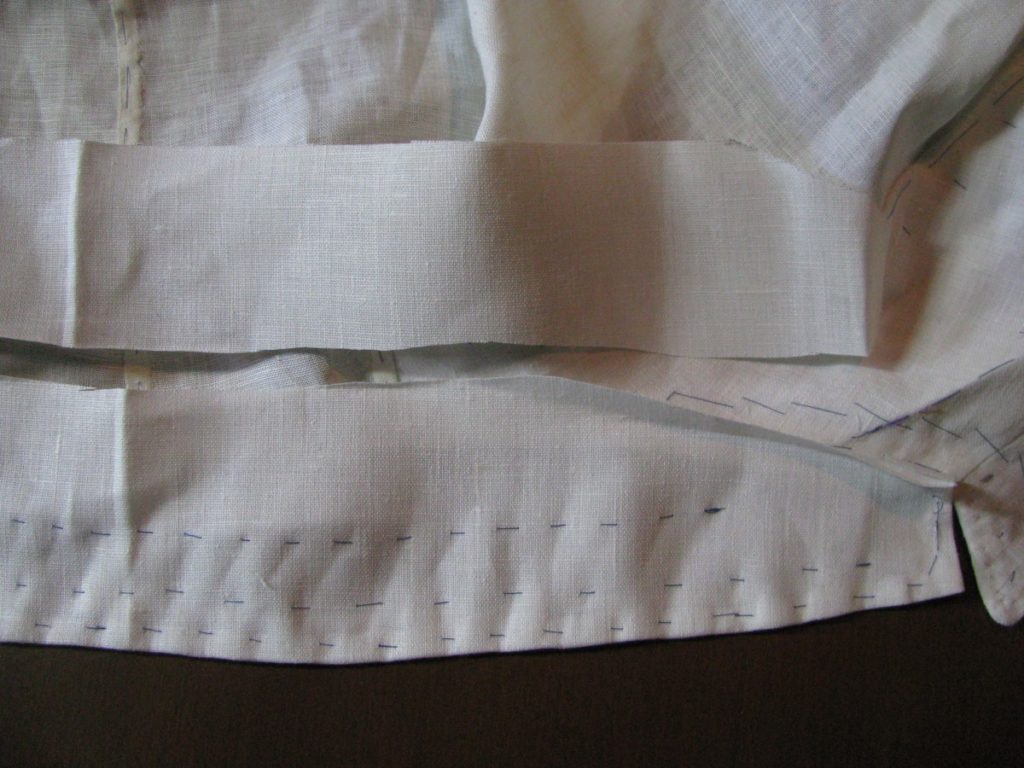

Rather, turn in both seam allowances to the inside, allowing the coat side of the seam to extend a 1/16″ past the sleeve seam allowance. Baste and then fell down. At the top sleeve area, there will be extra fullness, so try to work that in as best you can.

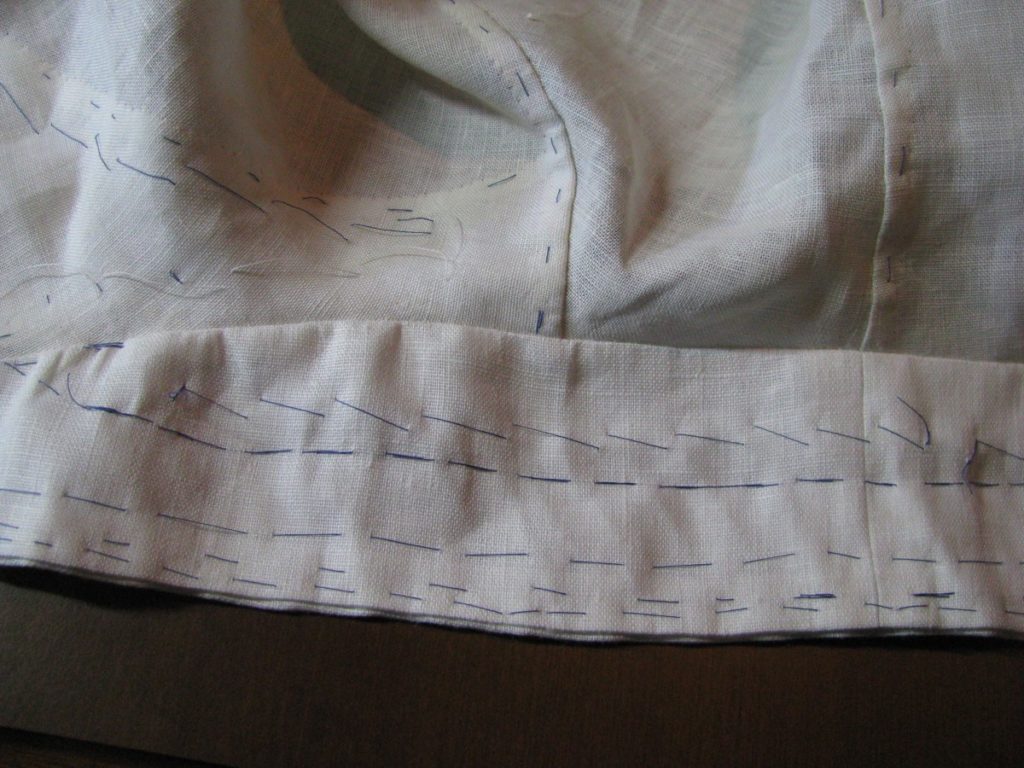

Here is the completed armscye seam, pretty much finishing up the coat except for buttons and buttonholes.

Completing the Cuffs

Now that we’ve got the cuff basted in place, we can now move on to sewing the rear sleeve seam. The right side of this stitch should be on the undersleeve, as shown, and with the usual 1/2″ seam allowance.

At the cuff end, the stitching stops 1/4″ beyond the start of the button inlay area. I marked it here for clarity.

As you’re sewing towards the cuff, make sure to move the cuff out of the way, taking out basting stitches if necessary. We don’t want it to get caught in the seam.

Turning the sleeve over to the topside, mark a 1/4″ line at the end of the stitching, perpendicular to the seam.

Note how the mark only goes half way towards the seam line. If we were to go all the way, it would weaken the sleeve at this point.

Carefully snip along the line, through the top sleeve layer only.

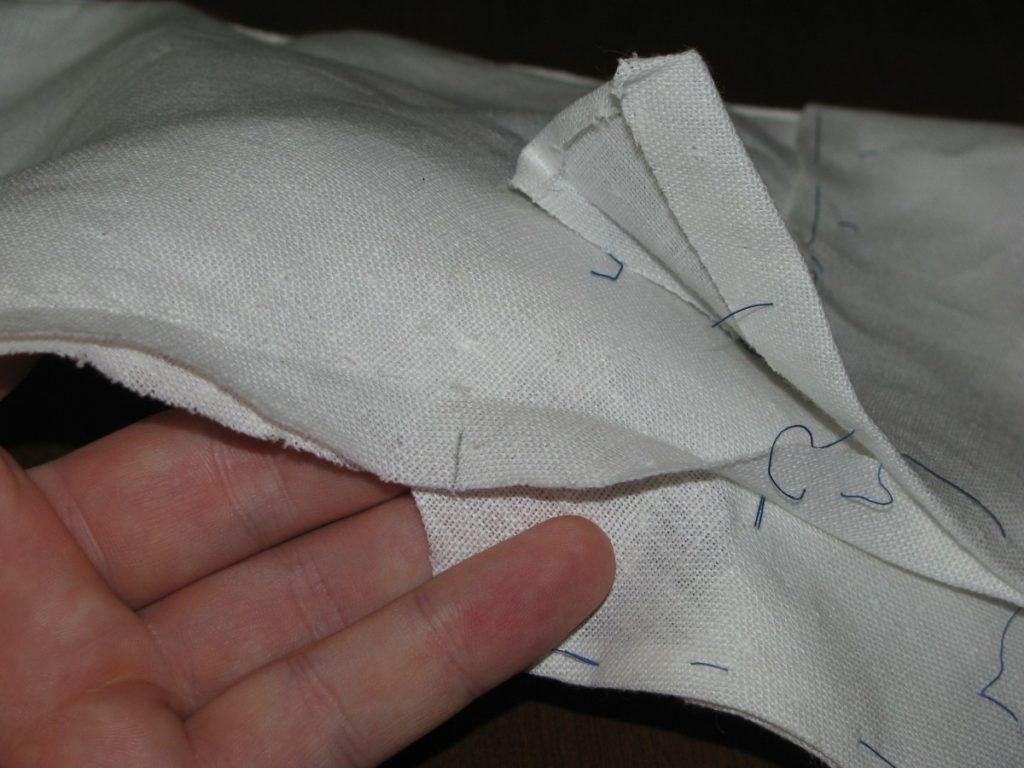

Now trim the seam allowance of the top sleeve from that snipped point to the armscye, as per the usual method.

Flipping back over to the undersleeve side, mark a line going from the end of the button inlay diagonally to the very end of the stitching.

Snip carefully along the line through the undersleeve layer only, just to the stitching. Make sure you don’t actually cut any of the stitching!

Fold over, baste, and then fell the seam as normal. Make sure the stitches catch only one or two threads of the sleeve itself, as they’ll be visible from the outside.

The appearance of the seam near the armscye.

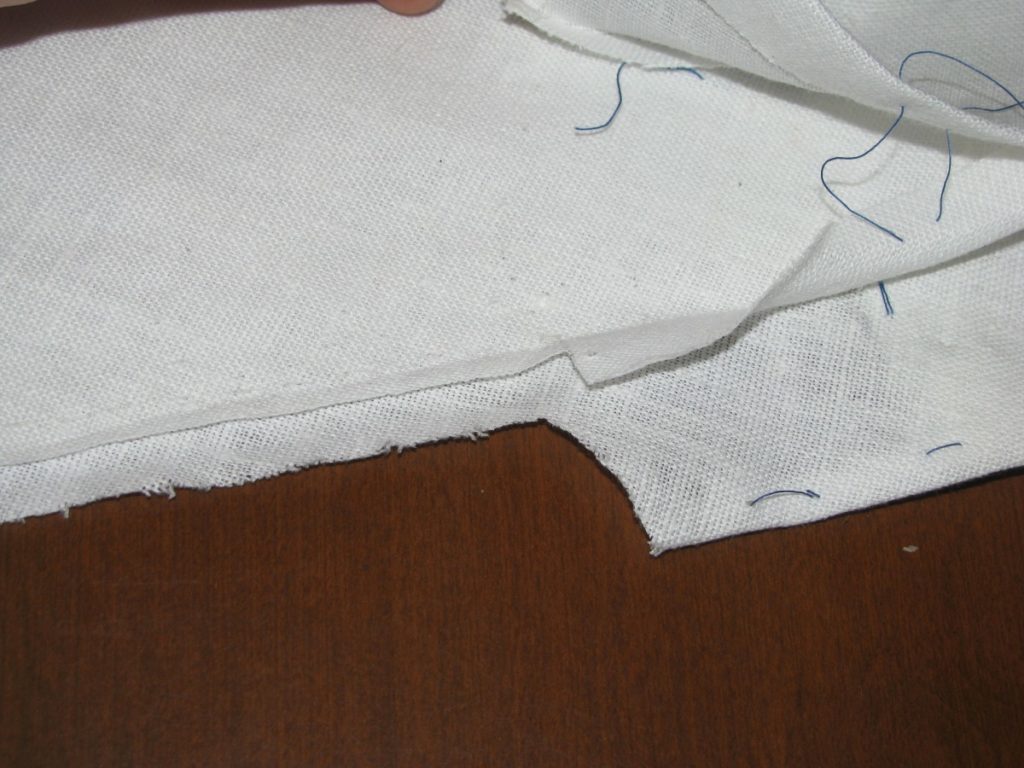

And the other end of the seam near the cuff.

Now that the seam is done, we can re-baste the buttonhole facing along the outer edge. Notice how it covers the snip we made in the top sleeve seam.

Fell the edge of the cuff along the edge of the buttonhole side.

Fell the other end of the cuff. Since the two edges go in different directions, I like to start by felling the 1/4″ seam of the button inlay, and then turn the work around and fell down the edge of the cuff. Note, we’re just sewing the ends of the cuff, not the inner edge.

Position the button inlay in place overlapping the buttonhole side of the cuff, and baste securely. You’ll want to make sure everything is properly aligned at this point because this is how the final cuff will look.

Fold under the raw edge at the top of the button inlay, and baste securely closed through all layers.

Turn the sleeve right side out and check the alignment of the cuff opening, making any adjustments if necessary.

This next step is extremely difficult to photograph, but starting at one end of the cuff, 1/4″ from the edge, top stitch using a side stitch to firm up the edge. This stitching goes all the way around the edge of the cuff to the other side.

You can just barely make out the tiny side stitches along the edge.

Turn the sleeve inside out once more, and along the top of the button inlay, fell down the folded edge, going through all layers. Try to catch only a stitch or two of the outside fabric.

About 1/4″ below, and parallel to the edge you just felled, sew a row of backstitches, catching the top layers, but not going through to the outside of the coat. This provides extra strength for the vent.

Turning to the right side out for the last time, top stitch a row of side stitches along the inside edge of the cuff, using your fingers to feel for the edge. The stitching starts at the rear seam and follows the edge of the facing beneath, about 1/8″ away from the edge. This is in place of felling from the inside, and gives a better finish to the cuff.

Here you can barely make out the stitching, which outlines the facing beneath it.

Remove all basting stitches, revealing the finished sleeve.

You can choose to put in the buttons and buttonholes now, or wait until the sleeves have been set.

The Cuffs

Now that we have the pattern issues straightened out, it’s time to begin the construction of the sleeves and cuffs. It’s actually quite involved, so this first section will cover up to the basting of the cuffs.

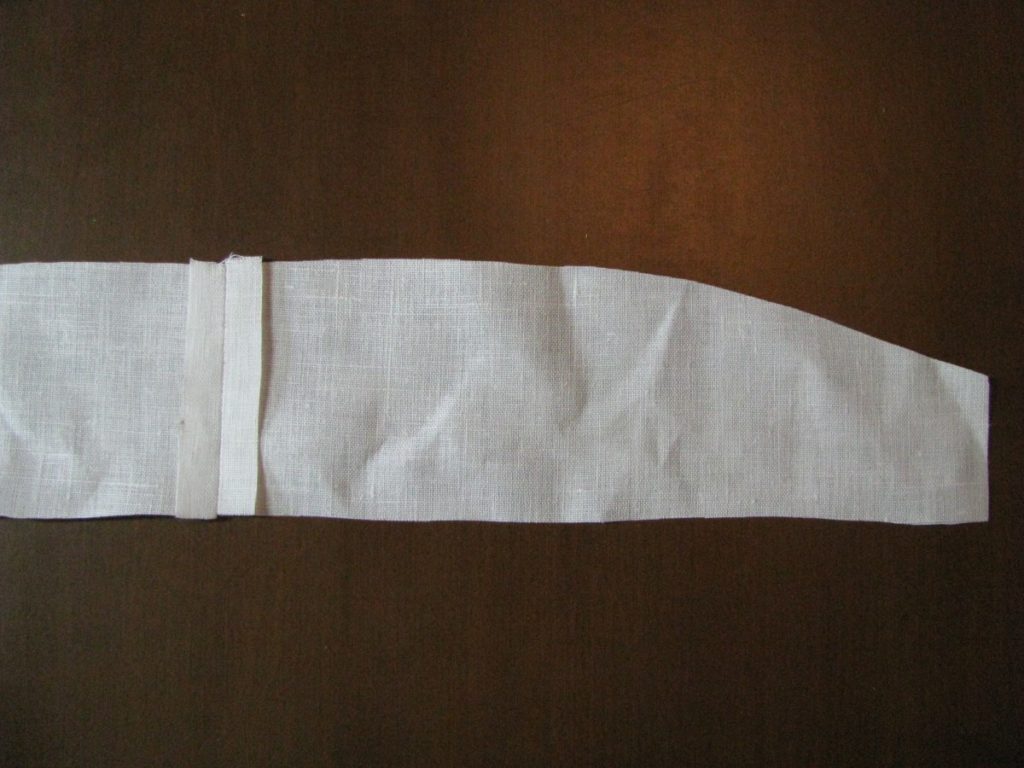

Begin by laying the sleeve pieces on the table, right sides together. Baste along the front seam, working in any fullness as you go along.

Stitch using a back and fore stitch and a 1/2″ seam allowance. It doesn’t really matter which side is the ‘right’ side, just be sure to be consistent with the other sleeve.

Trim one seam allowance to 1/4″.

Baste the raw edge over and fell securely.

Now that you have the sleeve halves together, I like to use them to cut out my cuffs. While it’s possible to do using the paper pattern, I find this method to be much easier and more accurate.

Lay the end of the sleeve on the linen, making sure that the grain lines are aligned with the center seam.

Trace around the cuff area, about 5 inches up each side.

Draw in the upper seam of the cuff, anywhere from 3 to 4 inches from the end of the sleeve. This includes a 1/4″ seam allowance. The seam does go all the way across, I had my sides mixed up which is why the line stops near the right side.

On the button hole side of the sleeve, extend the cuff upwards so that it is about 1/2 an inch higher than the button inlay on the other side of the cuff. The width of this section should be 1/2″ plus the width of your buttonholes, plus another 1/2″ and then a 1/4″ seam allowance. Generally this works out to about 2 to 2 1/2″.

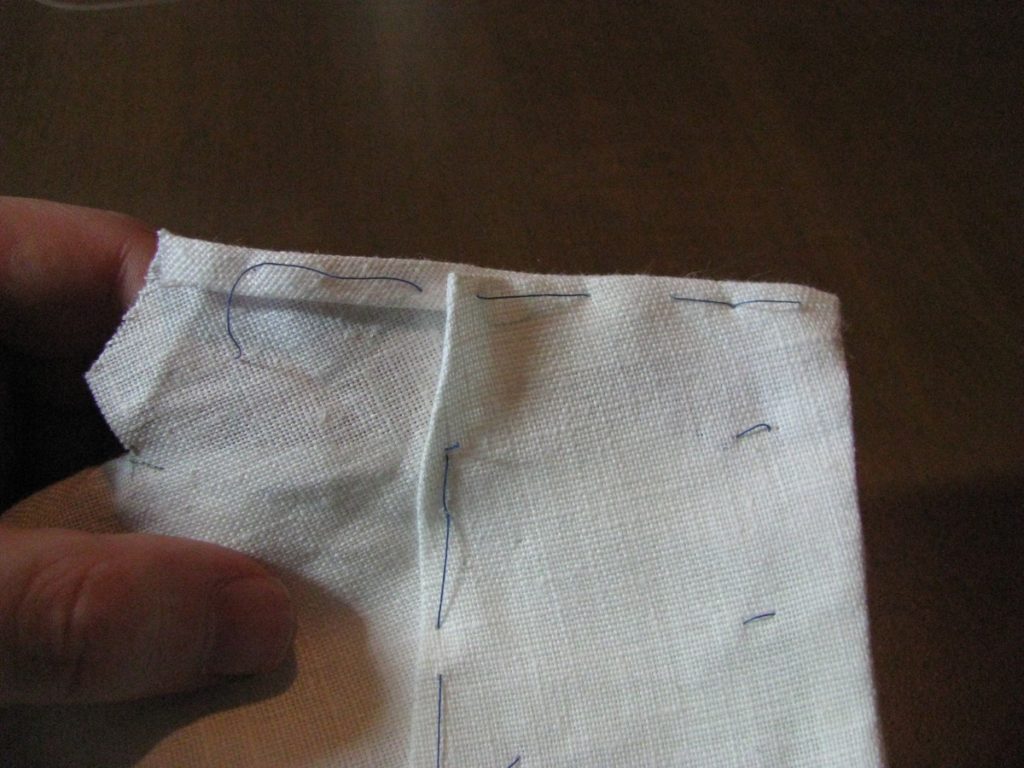

A close up shot of the buttonhole side of the cuff.

And the button side of the cuff. If you wish you can extend this side up as well to cover the entire inlay, which would also give additional support to the first button.

Lay the sleeve and cuff right sides together. Here’s a new technique I’ve developed for better shaping the cuffs. So often the cuffs, being on the inside of the sleeve, are bunched up and not very elegant looking. To prevent that, we’ll add some well-placed basting stiches. Start by turning over the sleeve and cuff, so that the cuff side is nearer the table.

Baste along the end of the sleeve, allowing the fabric to drape over your hand as you go. This makes the sleeve slightly longer than the cuff, and will prevent that bunching.

Working still with the sleeve side up, use a back and fore stitch and 1/4″ seam allowance to attach the cuff to the sleeve.

Remove the basting stitches, and turn the cuff to the inside of the sleeve. Again holding the sleeve with the sleeve side up, and draped over your hand, baste the cuff in position along the edge. As you’re working, make sure that the sleeve extends beyond the cuff by about 1/16″ to better hide the seam.

You can kind of see here how the sleeve wants to curve naturally, even when flat on the table.

Try to keep the basting stitches about 1″ away from either end. This last stitch here was actually too close and I ended up removing it later on.

Holding the sleeve in the same position, baste the inside edge of the cuff, about 1/2″ from the edge of the cuff, and 1″ from either end.

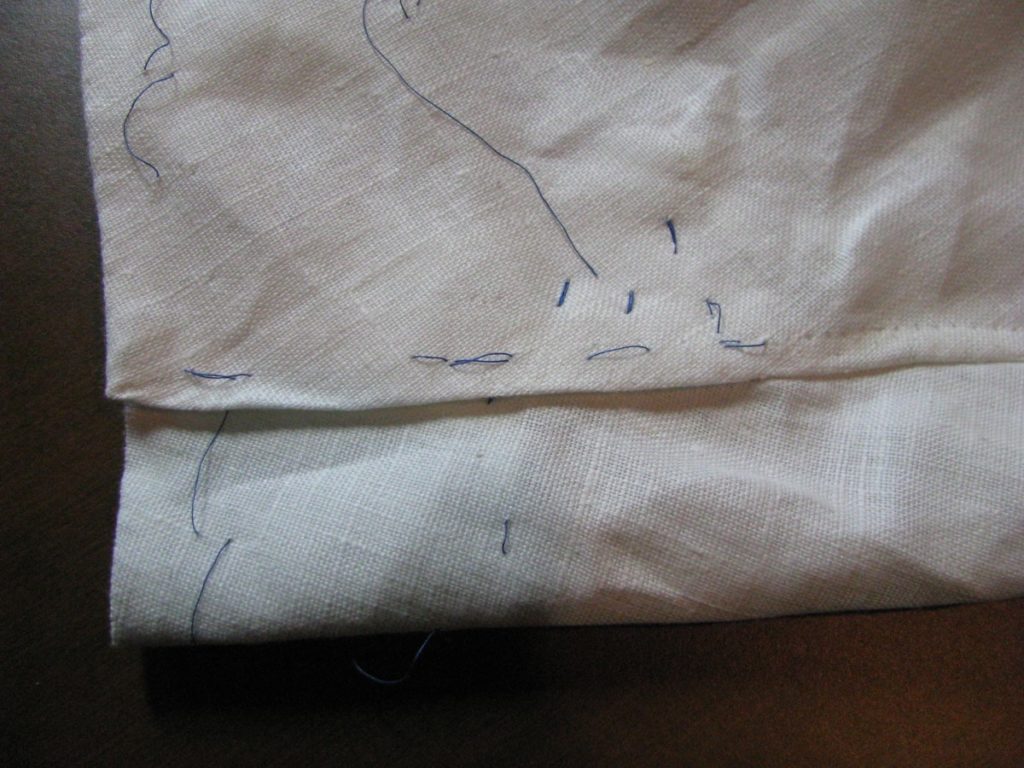

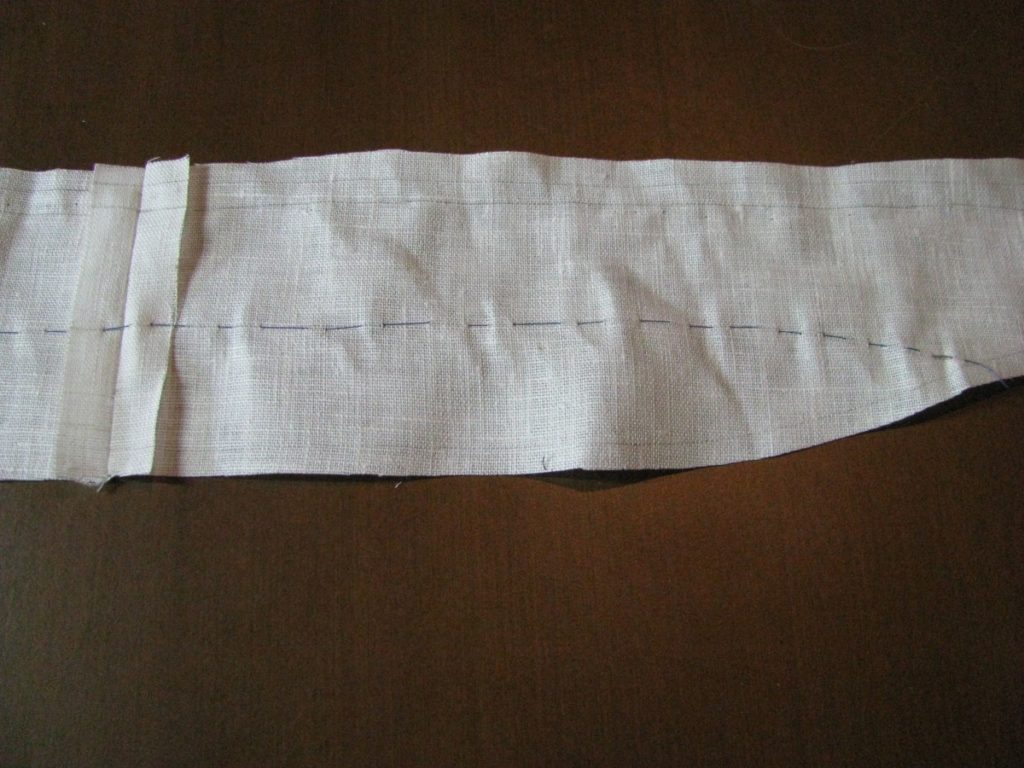

Here is what the basting looks like so far.

Now it’s time to worry about the two ends of the cuff. On the buttonhole side, the raw edges are folded in on both the cuff and the end of the sleeve by 1/2″, corresponding with the seam allowance of the sleeve itself.

Baste the folded edges. In the photo below, I’ve laid the buttonhole side on the button inlay, to ensure they are cut properly. Notice how the buttonhole facing extends 1/4″ beyond the button inlay.

Turn this seam allowance under at the top of the buttonhole facing.

At the inside corner where the facing and cuff lines intersect, draw a 1/4″ line at 45 degrees.

Snip the line and continue folding under the cuff seam allowance all the way to the other end.

Baste everything down. Note you will be removing some of these stitches near the buttonhole facing, but they’re helpful to make sure everything is aligned.

Here’s the button side. Note how I’ve stopped about and inch and a half from the edge.

Fold in the button inlay 1/2″.

Then tuck the raw edge inside so you have a 1/4″ fold and no raw edges showing.

Fold the cuff end in 1/2″ to match, and baste in place.

Before we start sewing down the cuff permanently, we’re going to baste the rear sleeve seam. Align the end near the armscye so that the 1/2″ seam allowance intersects. Pin the cuff end in place, and baste the seam, working in any fullness of the top sleeve in as you go, along the first 6 inches near the armscye.

Baste until about 1″ past the start of the button inlay, making sure the seams are properly aligned.

You’ll have to remove some basting stitches from the buttonhole facing so you can have room to work properly.

That concludes the basting up of the sleeves and cuffs. Next we’ll sew it all together.

Drafting the Sleeves

Following the instructions in my drafting tutorial, draft a basic sleeve. There are a couple of alterations to be made to the basic pattern.

First, we are going to assume the original pattern found in Devere’s includes the seam allowances in the draft. When drafted this way, the sleeve will have about 2″ of extra fullness than the armscye.

Since we are finishing the sleeves with a half inch seam allowance, we need to add 1/4″ all the way around the draft, except for at the cuff areas, which will be sewn with the included 1/4″ seam allowance.

We also need to add an inlay for the buttons to attach to. This is added at the rear seam of the under sleeve, and is about 5″ long by 1 1/5″ wide.

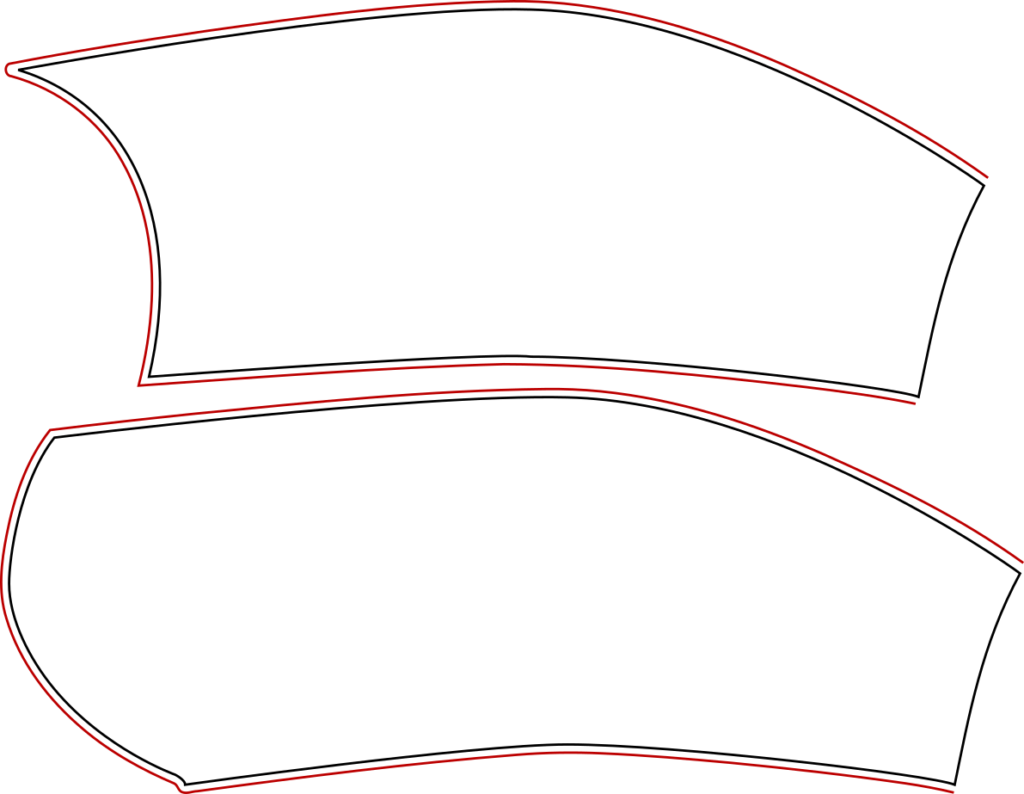

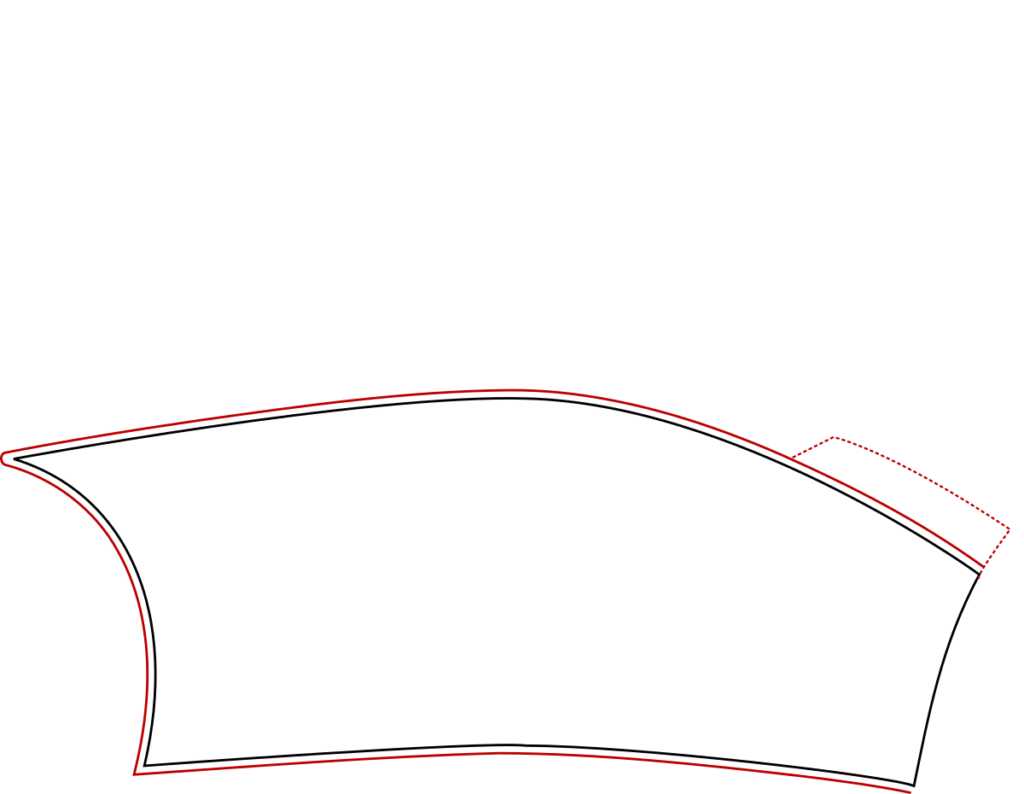

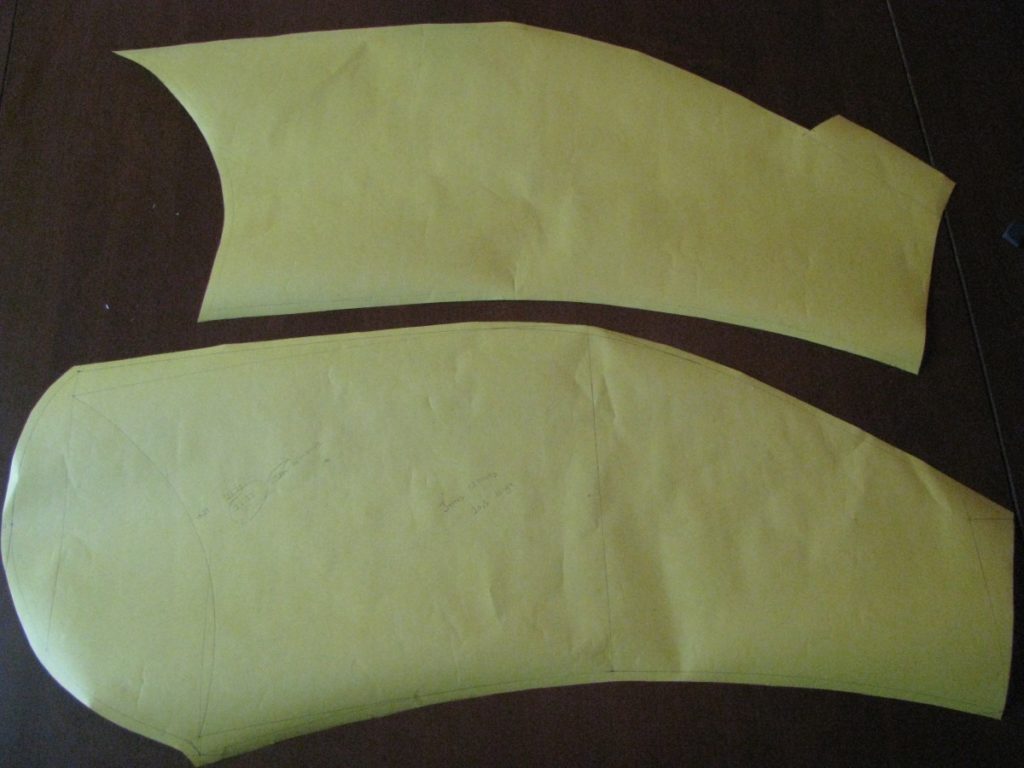

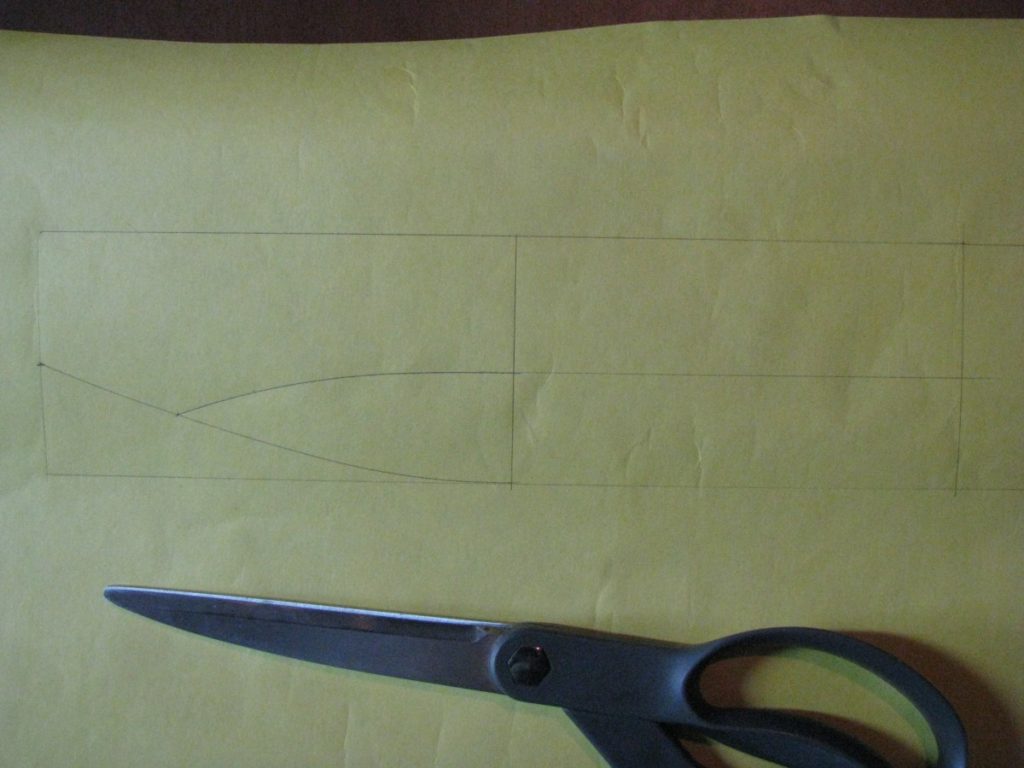

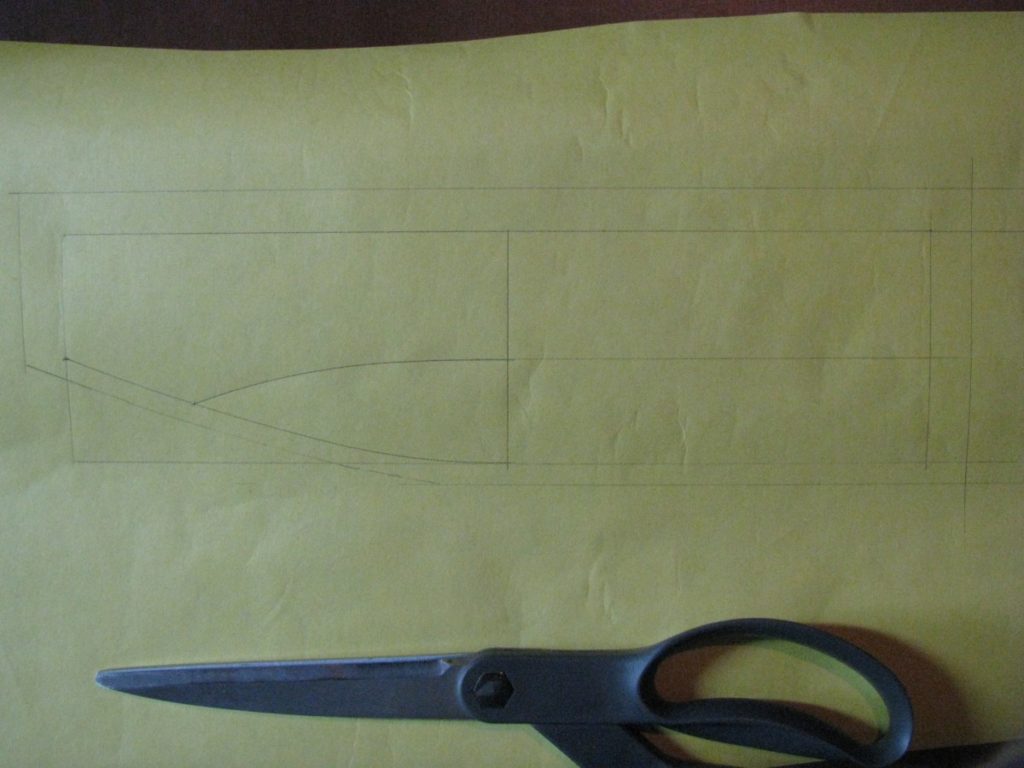

Here are my completed sleeve patterns. Note the inlay for the buttons and the additional 1/4″ seam allowance.

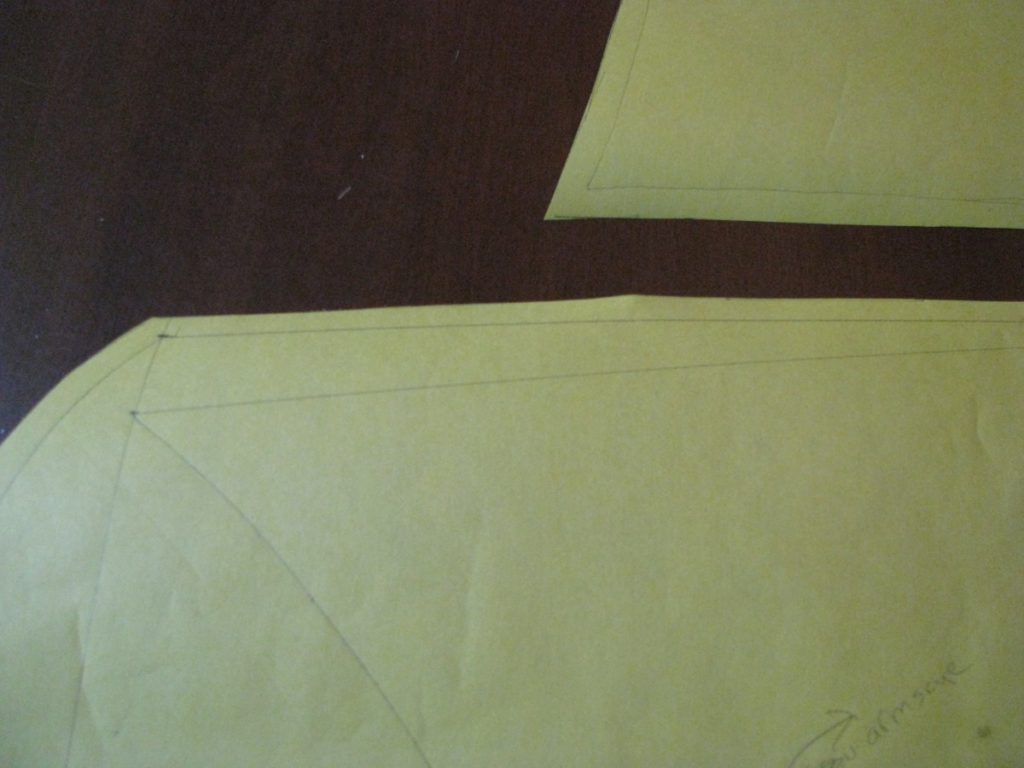

Closeup showing the added seam allowances. As you can see, I usually trace the under sleeve onto a new sheet of paper, and then cut the top sleeve pattern straight from the original. You may want to trace the top sleeve as well in order to preserve the original pattern. I was feeling confident though, so rarely do that these days.

I highly suggest cutting a muslin sleeve first. When you are happy with the fit, cut out your sleeves in linen.

The Top Collar

It’s now time to install the top collar, which must be basted into place much like the front facings were, in order to ensure that it drapes correctly.

Begin by pressing and basting the under collar seam allowance 1/2″ along the top edge.

Do the same thing to each end. By doing the ends second, you ensure that the folded seam allowance angles inward so that it will not be seen in the finished collar.

A view from the right side showing the seam allowances basted in place. You want this to be as neat as possible as it gives you the finished position of the collar.

Also note how the lapel, coat body, and collar all meet precisely at the same point.

It’s time to cut out the top collar, with the center line on the fold. Lay the pattern down, and then mark a line 1″ all the way around. Cut out the collar. This extra material gives you room to fit the top collar properly.

Lay the top collar wrong side up on the table and lay the coat wrong side down, on top of it. Make sure the flat edge of the top collar is positioned towards the top of the collar.

Not really much to photograph here, but starting about an inch from the edge of the collar, baste along the roll line of the under collar, catching the top collar underneath.

Stop 1″ from the other side.

Again, about 1″ from the end of the collar, and about 3/4″ from the folded seam edge of the collar, baste along the collar catching the top collar beneath it.

Keep the entire collar flat on the table as you work to ensure the correct tension.

Stop 1″ from the other side of the collar.

Now carefully trim the excess away, leaving 1/2″ at the edge of the collar, and 1″ at each end. The hidden edge of the top collar is not touched at this point.

Fold under the ends of the top collar and baste, leaving 1/8″ of the top collar showing underneath.

Do the same thing for the other end, then along the outer edge of the collar, keeping that same 1/8″ of the top collar visible.

Turn the coat over so that the top collar is fully visible. At each end, crease the top collar back along the gorge line just to give you an idea of where to trim in the next step.

After both gorge lines are creased, continue the crease along the middle of the collar, so both creases meet up.

Keeping 1/2″ away from the crease line, trim off the extra fabric from the top collar.

Now fold under the 1/2″ seam allowance at each gorge line and baste securely closed.

Turn the coat back over so that the top collar is next to the table again. On the inside of the roll line, beginning about an inch from the edge of the collar, baste across the under collar, again catching the top collar underneath. This row of basting is about 1/2″ from the roll line.

Continue all the way across.

Turn the coat over so that the top collar is again facing you, and fold under the remaining raw edge of the collar so that it aligns with the stitching holding the under collar in place. Baste securely.

Working from the underside of the collar, carefully fell the top collar to the under collar, beginning at the outside edge of the collar, across the top, to the other end.

At one end of the collar (depends on whether you’re right or left handed, your preference), make about 4 or 5 backstitches in place at the point where the collar meets the lapel. This just firms up the area and prevents tearing.

Pass the needle and thread through to the top side of the collar. We’re in position now to start the ladder stitch, which is used to close up the collar and lapel along the gorge line.

Here’s a video demonstrating the ladder stitch:

Start by taking a stitch just above the crease, on the top of the lapel.

Then do the same to the collar side, entering the collar just across from where the last stitch exited. Repeat the last two stitches.

Every four stitches or so, take a stitch through the under collar, in between the two folded edges that you are sewing together. This holds everything more firmly in place. Pull the thread taught (but not too tight), right after you make this stitch.

Continue the entire process until you reach the end of the gorge line (which is where that snip was made in the facing).

When you reach the end of the gorge line, simply continue by felling the top-collar down to the neck along the shoulders and back. Continue until you reach the other gorge line.

And then continue with more ladder stitching, finishing up with another bar tack on the underside, as before.

Here’s a photo of the stitches before they are pulled tight.

The last stitch before passing the thread to the other side for a bar tack.

Finish the collar by top stitching using a side stitch, 1/4″ from the edge, just as you did with the facing.

The Under Collar

If you have not done so yet, now is the time to draft your collar pattern using my guide in the Frock Drafting series. Here is my pattern, freshly drafted:

Before cutting out the pattern, add a 1/4″ seam allowance along the bottom curved edge (or whatever you used for the neck seam allowance). Add 1/2″ seam allowance along the top edge, and two sides. This simply makes it easier to finish later on.

Cut out the pattern, and then the undercollar, which is made of two halves. Draw in the 1/2″ seam allowance along the center back (which is the wider side).

Stitch the under coller halves together using a backstitch. The collar is often under stress so it’s best to use a back stitch.

Press open the seam allowance. This can be trimmed to 1/4″ if you wish.

Transfer all seam allowances to the collar. Note here I accidentally put the 1/4″ seam allowance on the top of the collar instead of the curved bottom seam where it belongs. Figured that mistake out as I was basting the collar onto the coat.

Also very important, is to transfer the roll line to the collar. I find it’s easiest to just cut the pattern in half along the roll line and use that to mark it on the under collar.

Mark the under collar more securely in thread, so that it shows through to the right side.

With right sides together, line up the curved bottom seam of the collar with the neck seam at the center back.

Baste securely together, starting at the center and working your way out (the direction depends on if you are right or left handed).

As you get to the curved part of the neck seam, you’ll find that the collar will naturally full itself in with about 1/4 – 1/2″ of extra fabric. This will help the collar roll properly.

The most crucial point of the entire process, you want to make sure that the roll line of the forepart and the collar align exactly, 1/4″ from the edge.

Continue basting to the front edge of the collar, aligning the cross hairs of the seam allowance with the top of the lapel dart directly underneath.

Repeat the basting process for the other half of the under collar. Here’s what the entire under collar should look like when basting is complete.

Beginning on one edge of the collar, at the crosshairs formed by the seam allowance, use a back stitch to secure the collar to the neck of the coat. At each end, it’s a good idea to reverse the back stitching on itself to give an extra secure finish to the ends of the collar.

Backstitches continued along the center back.

And finishing up at the other side.

Using a tailor’s ham, press the collar upwards along its entire seam. Note here how the roll lines align perfectly between collar and lapel. If they’re off, you’ll have issues trying to get things to lay properly.

Here’s a view of the inside of the coat showing the back seam, shoulder seam, and center back of the collar, and how the seam is pressed up towards the collar – not opened up.

The Back Facing

Before moving on to the collar and sleeves, it’s a good idea to get the back facing out of the way. This facing hides the top of the plait pockets and the vent, and also provides a little structure and stability to the back of the coat.

Begin by measuring the inside of the coat, from the center back, to the far edge of the plait pocket. Add 2″ or so to this measurement for seam allowances and for some extra room to work with. Also measure the height of the area that needs to be covered and add two seam allowances to that measurement.

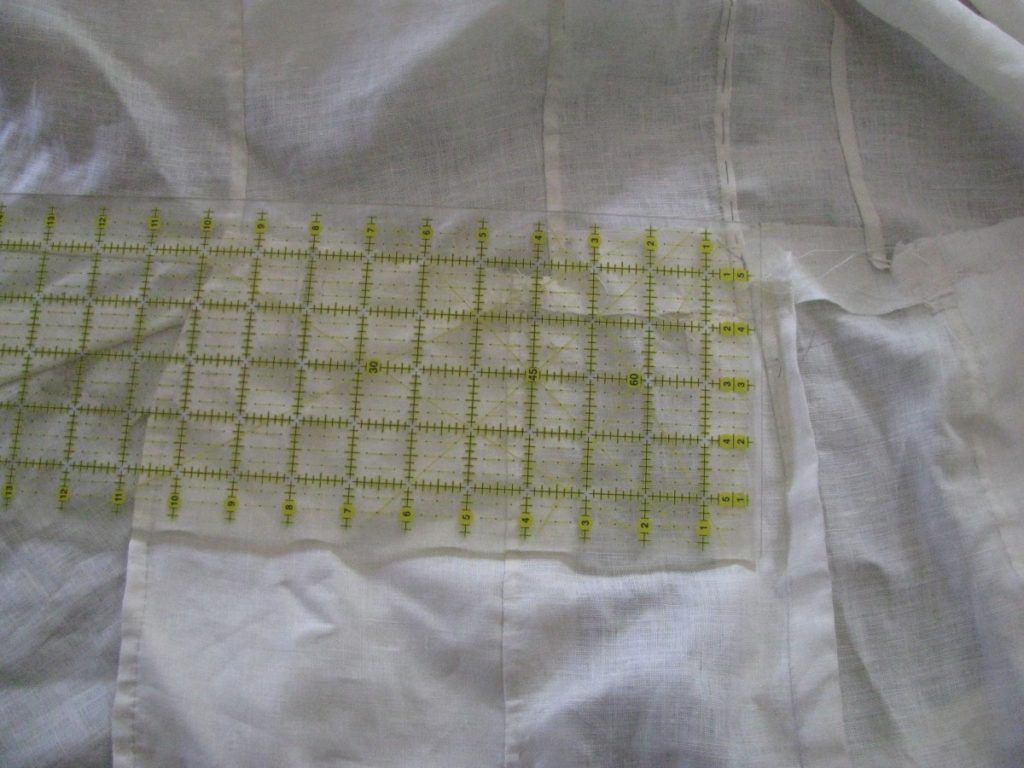

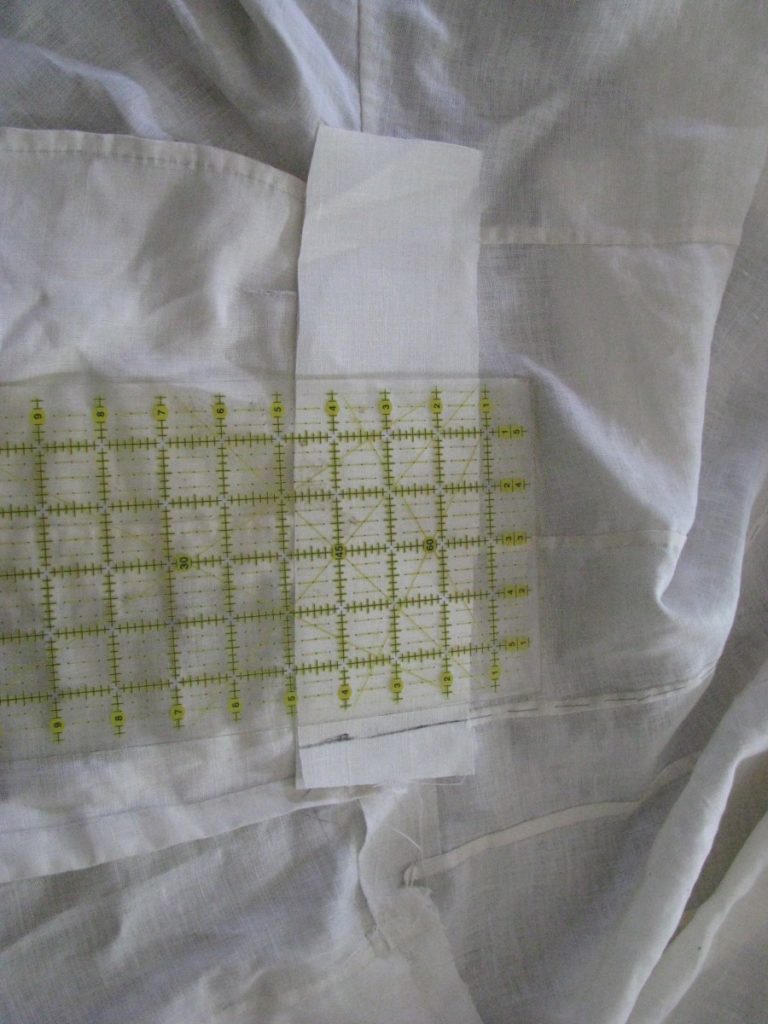

Using these measurements, cut out two facing pieces, one for each half of the coat. Mine turned out to be 3″ by about 13″ in length.

Place both halves together, and lay them on one half of the coat, covering the messy raw edges. When you’re happy with the positioning, lay a ruler along the back seam, and draw in the seam line for the back waist facing. It will most likely be at a similar angle to mine.

Stitch along this line with a back stitch, for extra strength.

Trim the seam to 1/4″.

Press open the seam.

Lay the facing, wrong side down, on the inside of the coat, aligning the center line with the center back seam.

Baste from the center line, along the middle of the facing, towards one end.

Repeat for the other side.

Fold under the raw edges and baste the facing down along the entire edge.

Using a felling stitch, fell the facing to the coat all the way around. Make sure you are only catching a couple of threads of the coat, as these stitches are visible from the outside.

The Back Vent

As soon as you finish the back seam, you’ll want to immediately begin work on the back vent, to prevent any tearing in the area. The left vent should overlap the right side of the coat. The exact position can be very difficult to figure out. It depends on the wearer’s posture and sometimes the default position will leave gaps in the vent. So I highly recommend doing a fitting and getting the position exactly. You want both halves of the vent to fall parallel to each other.

When you are happy, pin the vent in place and then remove the coat in order to baste more securely. Baste up the right side of the vent.

Across the top, and down the other side.

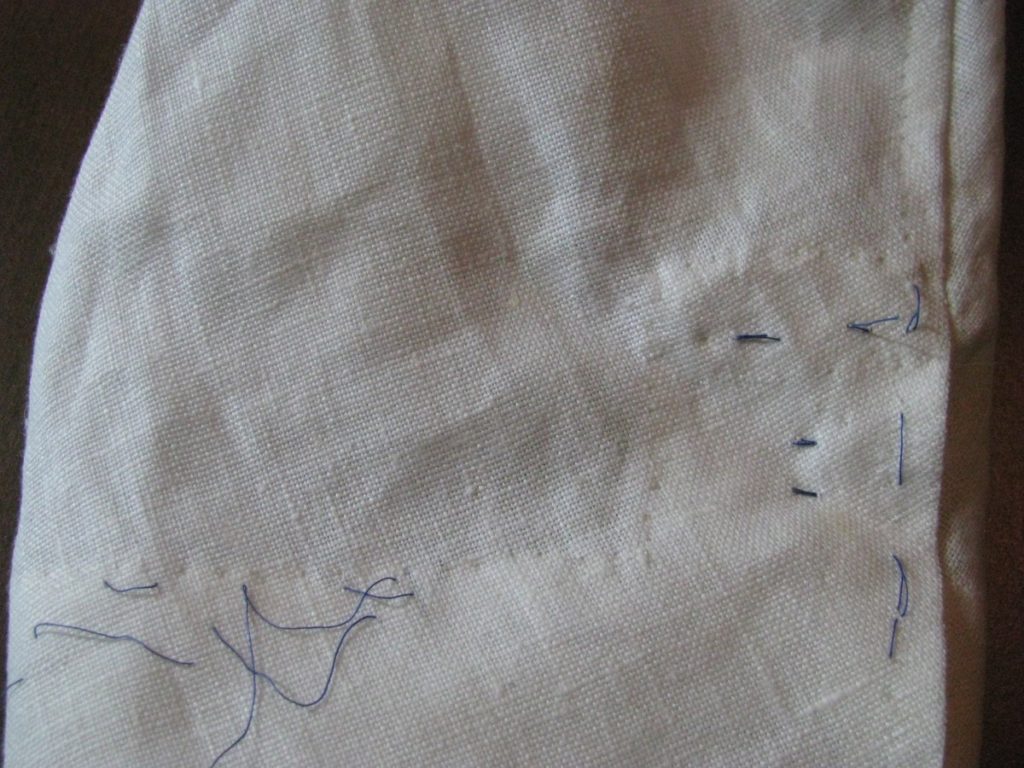

If you look closely, you’ll notice a little fraying at the inside corner of the vent. This is due to fraying during the construction process and not being accurate enough while sewing the back seam.

To fix this, and help secure the top edge of the vent, fell across the top edge of the vent, hiding any loose threads as you go. You can continue a short ways up the back seam if necessary.

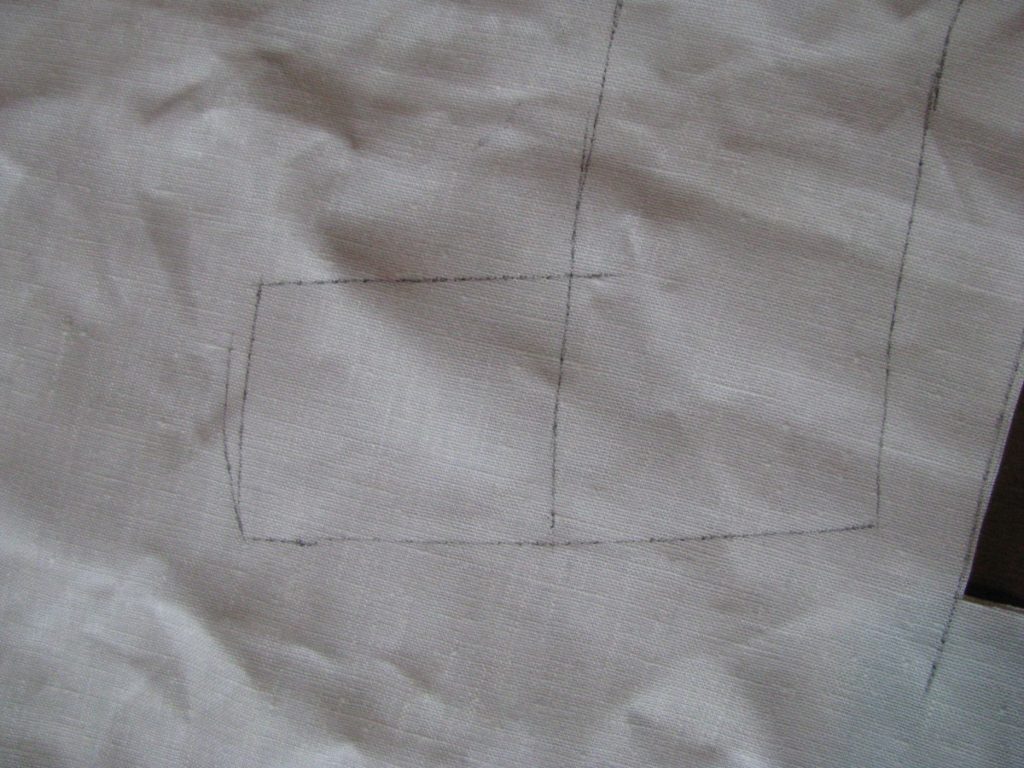

The back vent must now be top stitched to permanently secure it. I’m going to use a box stay here, which is probably most secure. Draw a rectangle just below the top of the vent. Mine is about 1/4″ in depth and slightly narrower than the vent in width.

Using a side stitch, secure the back vent around the rectangle you just drew, using stitches about 1/8″ apart at most. On the right edge of the vent, fell the right edge of the vent from the top to the depth of the box stay.

Completing the Back Seam

It’s now finally time to sew the two halves of the coat together. Lay the two halves, right sides together, on the table and align the back seam.

Baste along the seam about 5/8″ from the edge, just outside of the seam allowance.

At the bottom near the vent area, the top of the diagonal cut on one half of the back should align with the square edge of the other coat half.

The inside point of the angled cut is the precise location that you want to end the stitch line on.

Transfer that point to the other half of the coat and mark the point with cross hairs. This should correspond with the 1/2″ seam allowance of the back seam.

Continue drawing the seam allowance along the edge of the coat to the neck.

With the ‘right’ side of the stitching on the half of the coat without the diagonal cut, sew the back seam using a back stitch or back and fore stitch.

As you get to the bottom two inches, switch to a back stitch. This is one of the most stressed areas of the coat, and so any extra strength in this area is most welcome. Note how the stitching stops at that point.

Here’s the view of the back vent area from the other side. I was off with my stitching by about 1/32″, which is workable. The fraying linen sure doesn’t help!

Trim the seam allowance of the back to 1/4″ inch on the side with the diagonal cut.

Turn the coat over and make a small diagonal cut, this time just a hair over 1/4″ in depth. This will allow you to fold the seam over, baste, and whip stitch as with the other seams. For some reason I did not photograph the felling, but you should be able to figure it out by now.

The Shoulder Seams

It’s finally time to move on from the facings! We’ll begin sewing the shoulder seam by first removing any unnecessary inlays. Feel free to have a fitting beforehand if you want to fiddle with the fit more closely.

With right sides together, line up the neck edge of the shoulder seam on the forepart with the corresponding point on the back. You want the seam allowances at the very edge of the neck. to meet perfectly. Hold in place with a pin. If you’re feeling brave and want to experiment with techniques, you can hold this between your pinkie and the palm of your hand, allowing your other fingers to manipulate the fabric – this takes some practice though.

Line up the other edge of the shoulder seam and the armscye of the back at their seam allowances, and baste across the shoulder seam. You’ll notice that the back seam is longer than the forepart, which will give added room for the shoulder blades. Just gradually ease it in as you are basting.

On the back, mark in the .5″ seam allowance if you wish. The right side of the stitching should be on the back of the coat body, so that the seam allowance can be folded towards the forepart.

Sew the shoulder seam with a back stitch or back and fore stitch, and then turn the coat to the forepart side and trim the forepart seam allowance to 1/4″.

Fold over the remaining seam allowance and fell in the usual method. Note that by folding the seam allowance towards the forepart, we preserve the width of the back at the armscye. If we had gone the other way, it would look much narrower.

Repeat for the other shoulder.