Month: February 2021

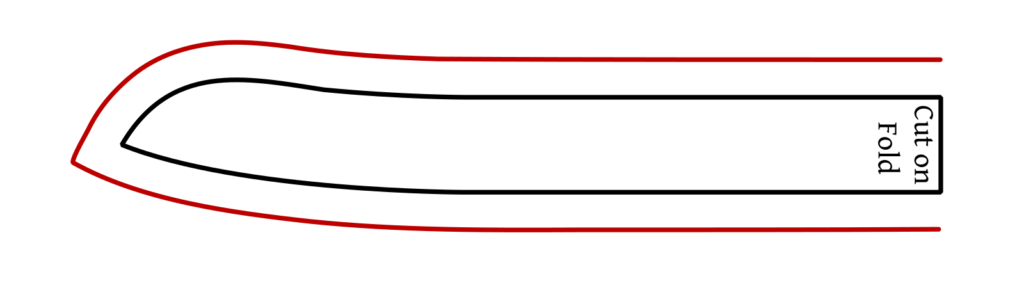

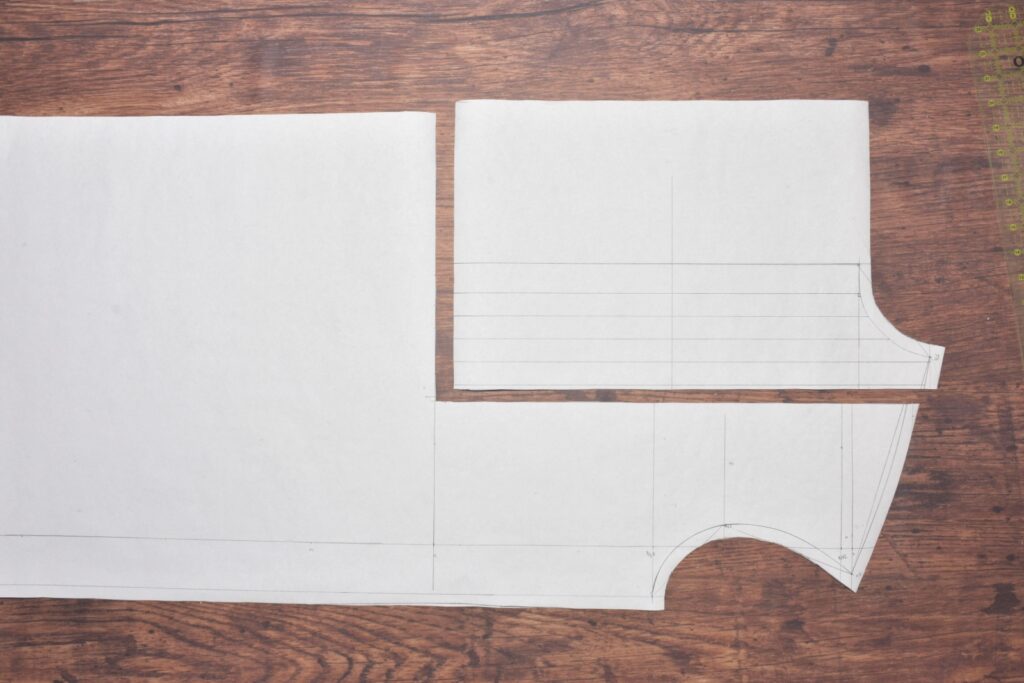

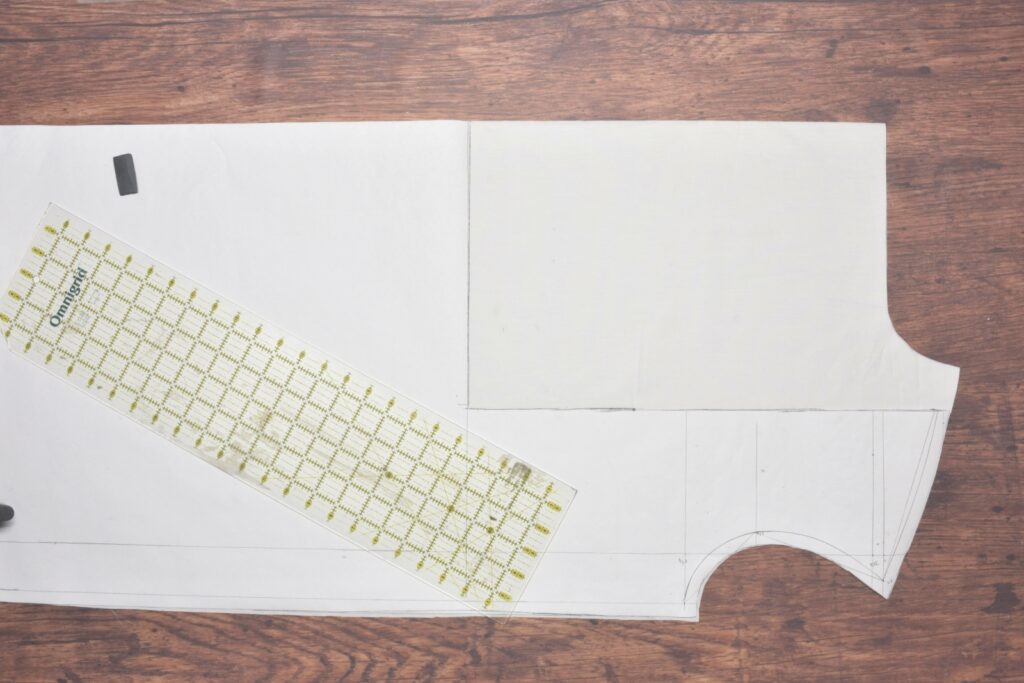

Drafting the Collar

The pattern for this collar comes directly from Devere’s draft with very little explanation. From what I can tell, and based on other original garments, it makes a one piece stand up collar. You could also perhaps turn the pattern into a two piece collar with the stand and fall by drawing a line parallel to the bottom edge, 3/4″ from the bottom, but that’s beyond the scope of this project.

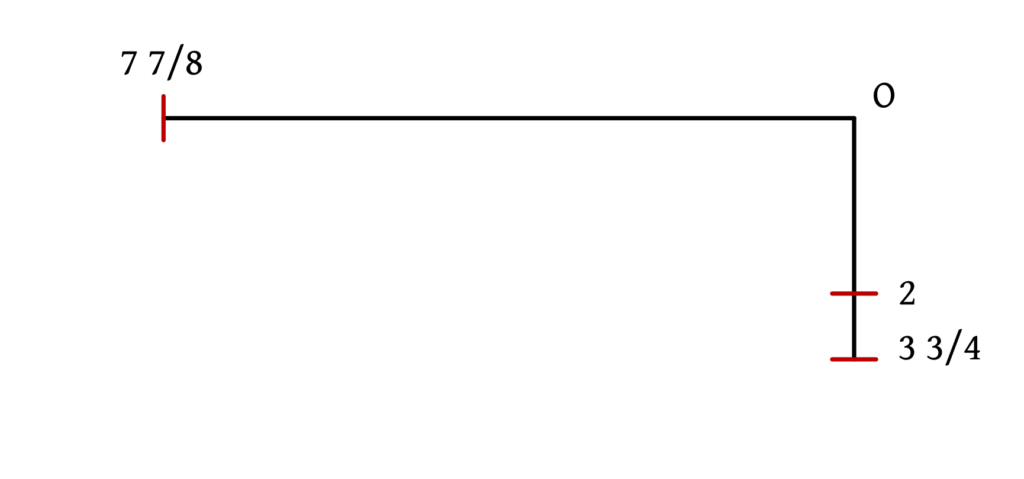

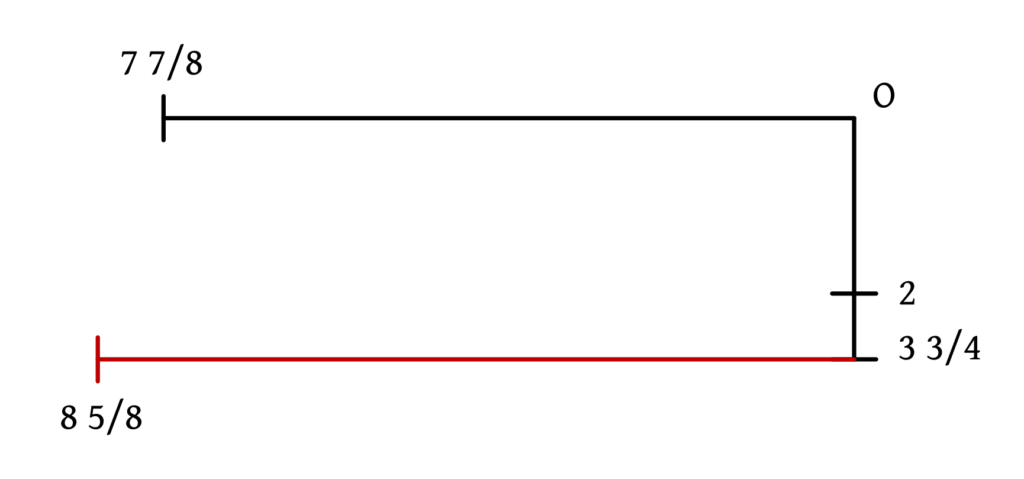

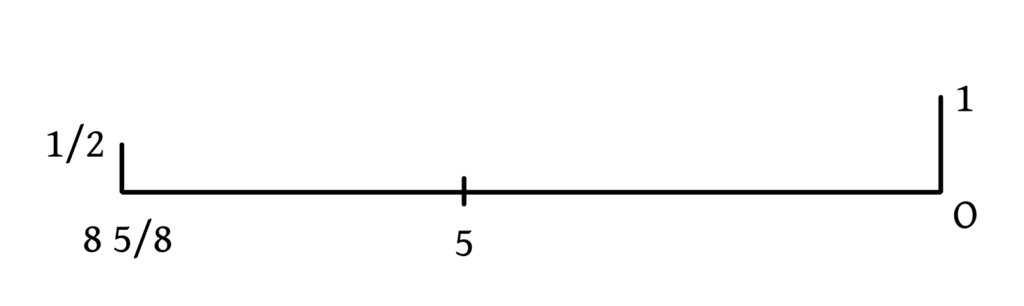

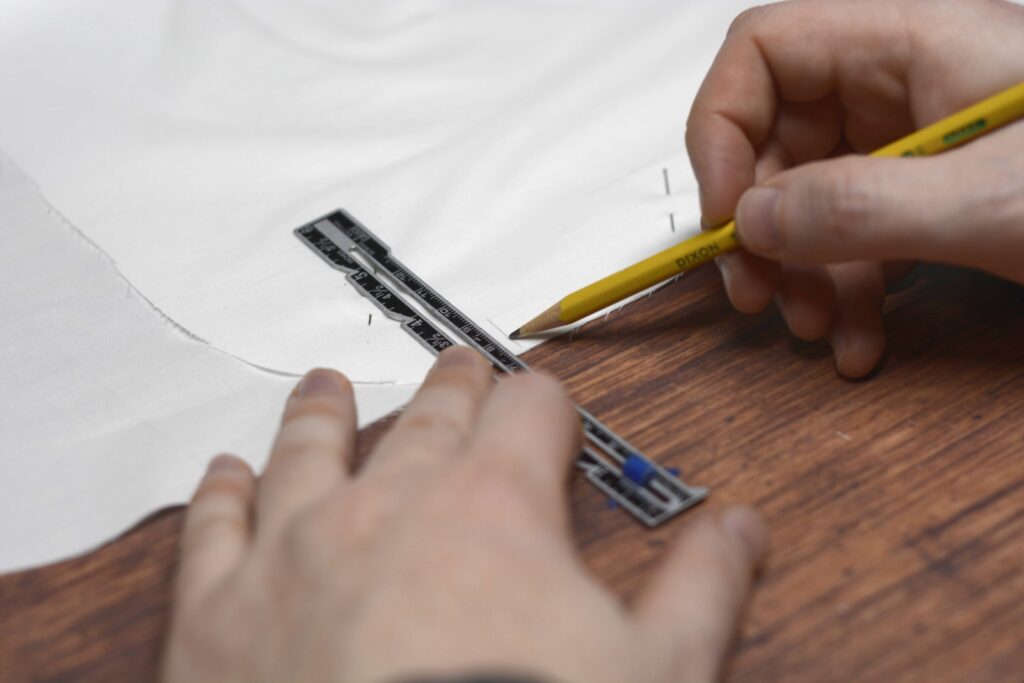

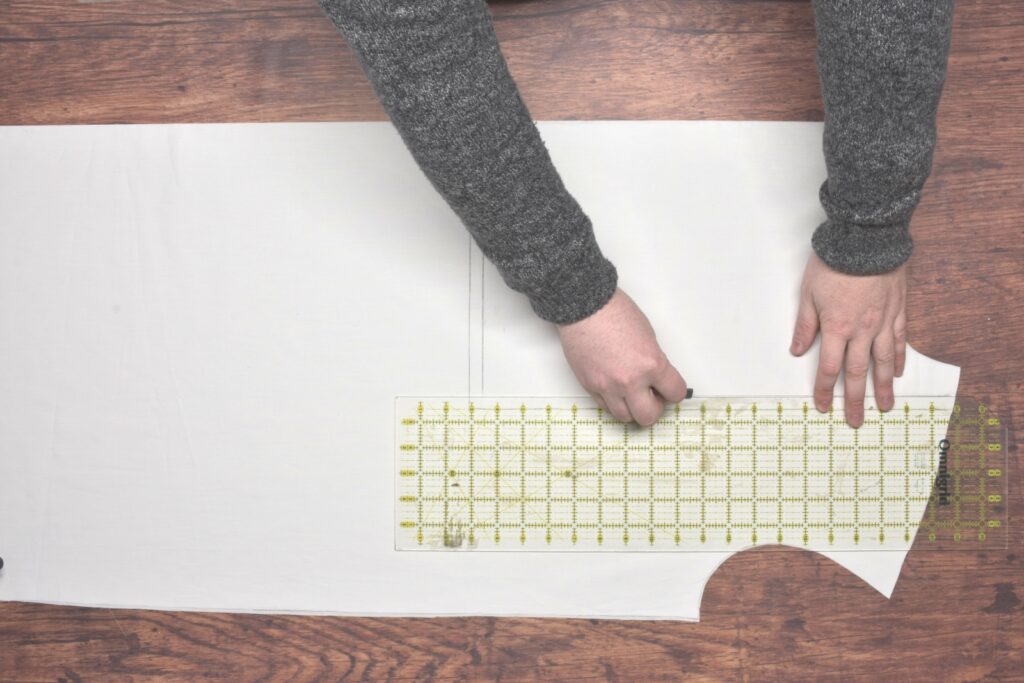

Begin by squaring out the following points from 0 using the appropriate graduated ruler:

- 2 from 0

- 3 3/4 from 0 (total height of collar)

- 7 7/8 from 0 (length of the top edge)

Square out from 3 3/4 to 8 5/8. This gives the length of the collar.

I would recommend measuring this afterwards with a regular ruler, doubling it and comparing it to your neck measurement. Then compare to the length of the neck and back neck on your pattern. Hopefully they will all be close but if there are large discrepancies it would call for a little investigation.

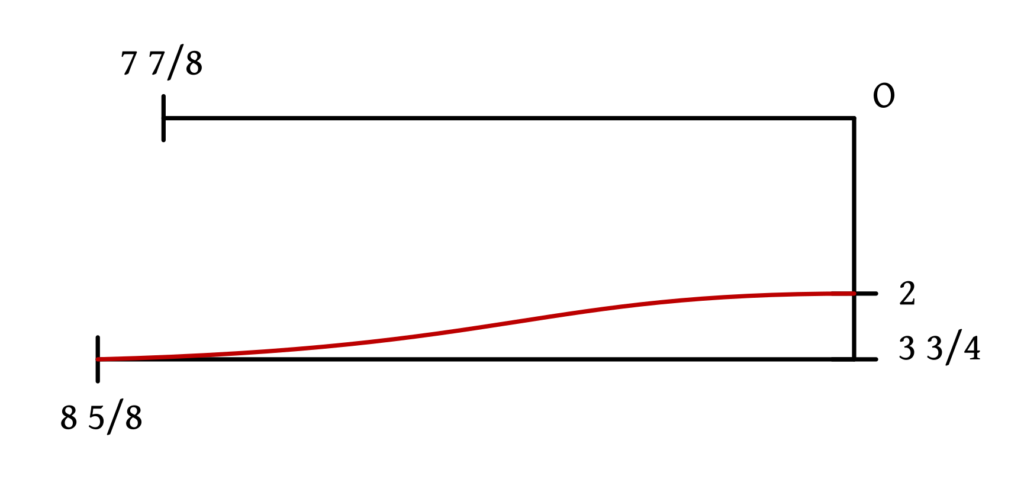

Draw in the bottom of the collar with a gentle ‘s’ curve beginning at 2. Start parallel to the baseline before slowly curving down into point 8 5/8 (which doesn’t need to be parallel to the baseline).

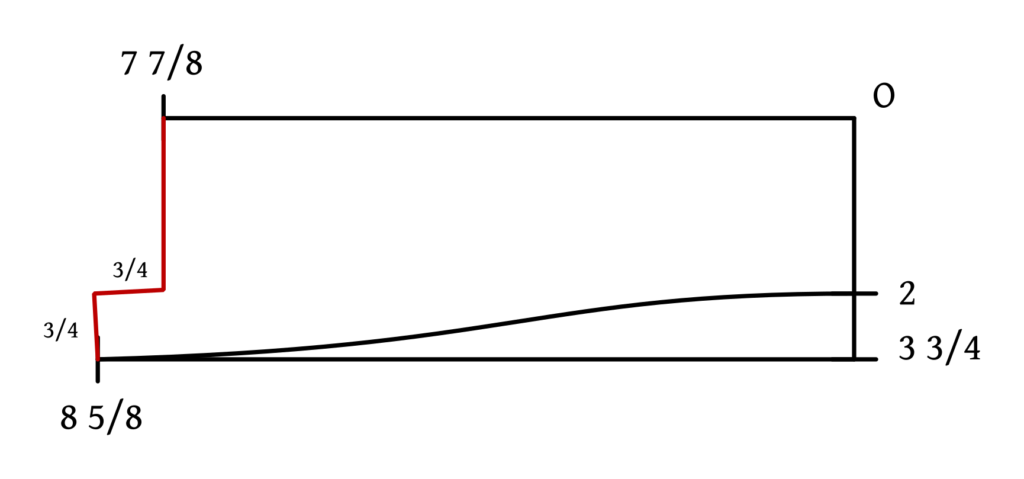

Devere doesn’t give measurements for actually finishing the collar, so this is as close as I could come up with with the given information. Square up 3/4 from the bottom of the collar (not the baseline). If you look closely you can see that the front edge of the collar is on a very slight angle.

Square out from this line another 3/4, meeting up with a line drawn square from 7 7/8.

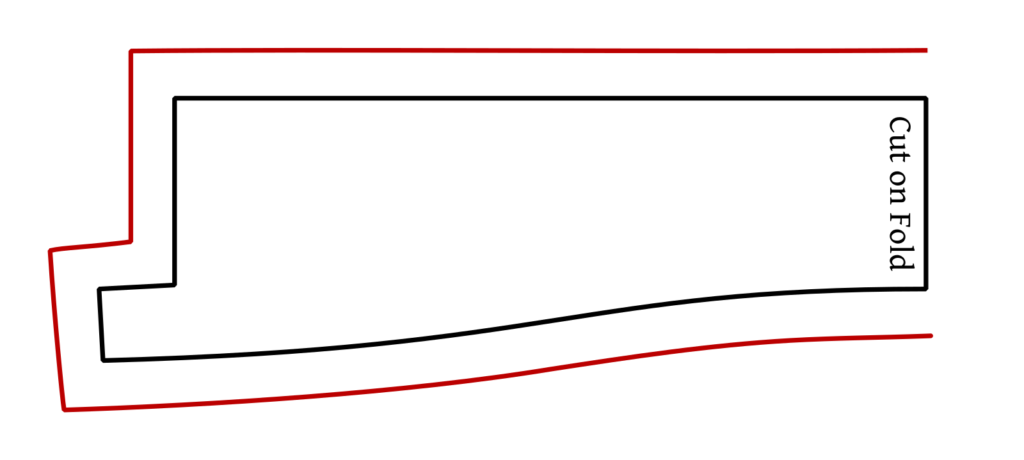

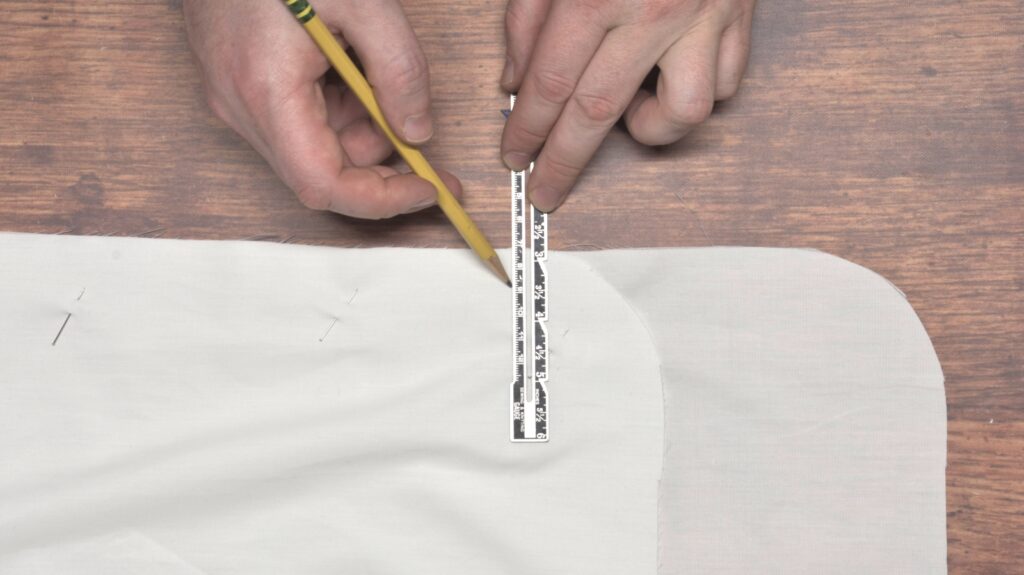

Finally, add a 1/2″ seam allowance all around except for the center back, which is cut on the fold.

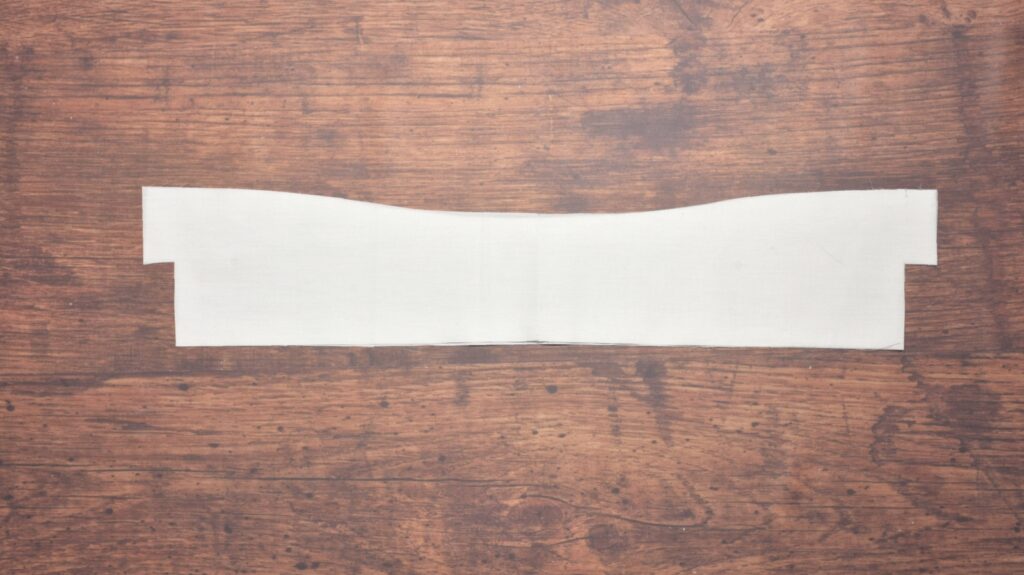

Banded Collar

If you prefer, you can make a banded collar for your shirt. These were often used in conjunction with a detachable collar so that you could vary your style without owning yet another shirt. We’ll be going over the detachable collar construction in the next project when this shirt is done. This is my own personal draft, so feel free to alter the pattern.

Begin by squaring out the following points from 0 using a graduated ruler.

- 1 from 0 (height of the collar)

- 8 5/8 from 0 (width of collar, adjust if necessary as explained above)

- 5 from 0

- 1/2 from 8 5/8

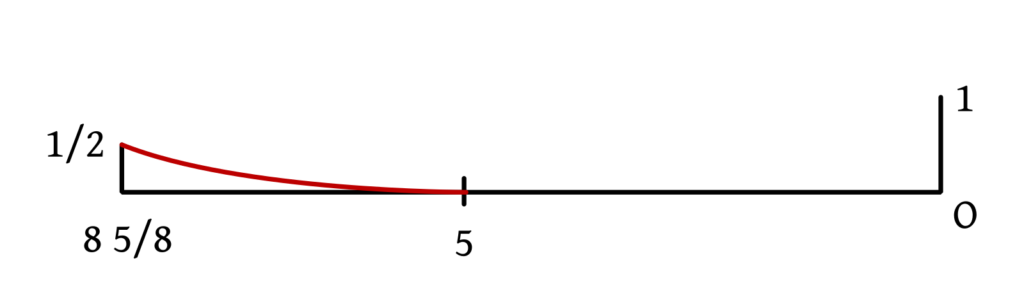

Draw a curve from points 1/2 to 5. This helps the collar lay smoothly around the neck.

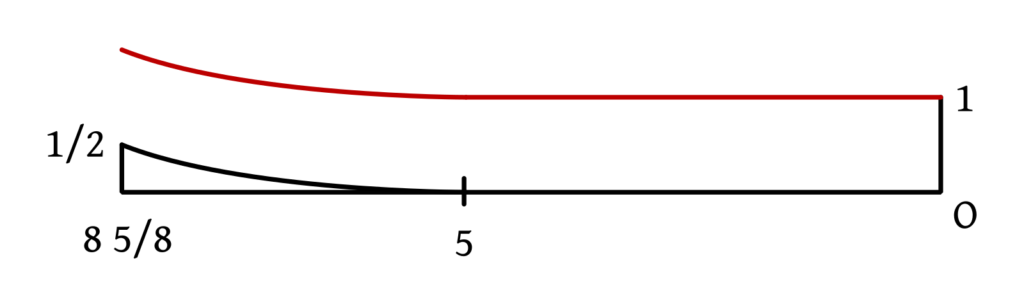

Draw a line parallel to the baseline, 1 (graduated) inch away, following the curve carefully.

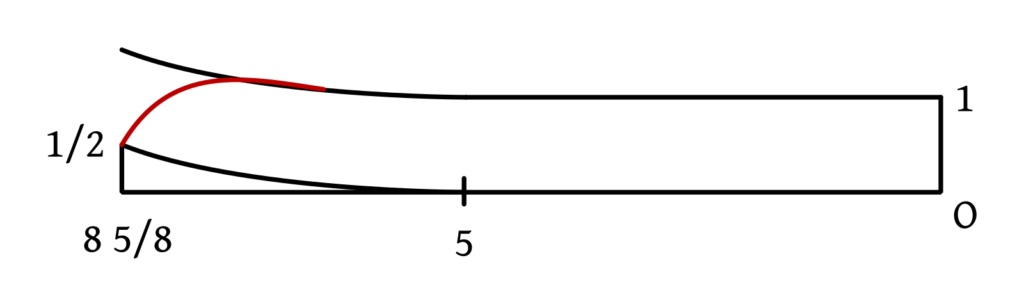

Draw in the shape of the front as desired. This can be a curve as I’ve drawn, with varying radii to match your preferences, or even be kept square to the curved line below.

Finally, add a 1/2″ seam allowance except for the center back, which is cut on the fold.

Your Progress

[columns gutter=”0″]

[col]

1 | Draft the collar. |

[/col]

[col align_text=”center, middle”]

[/col]

[/columns]

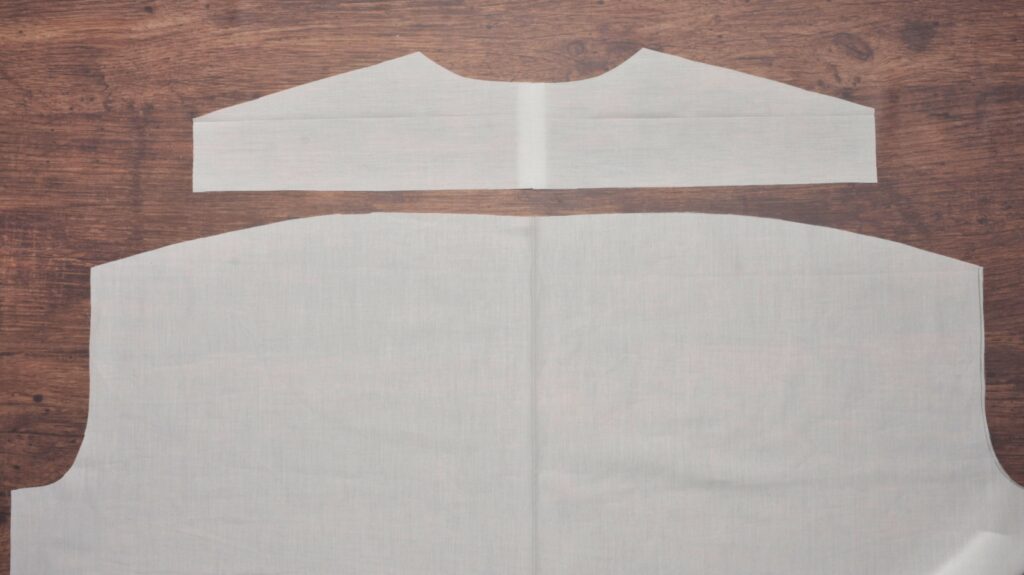

The Collar

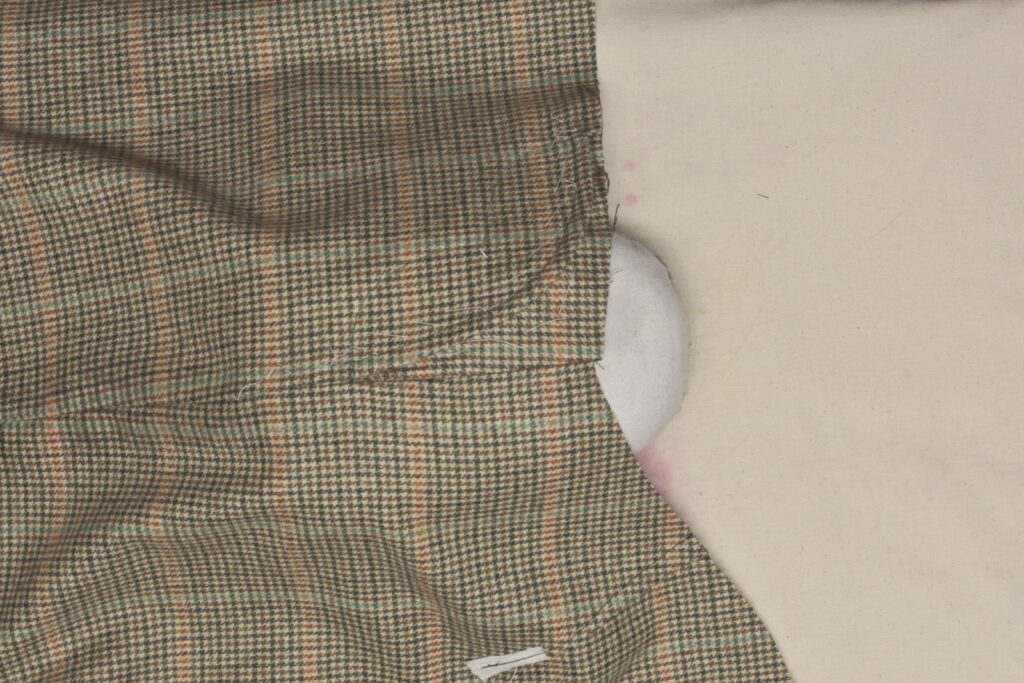

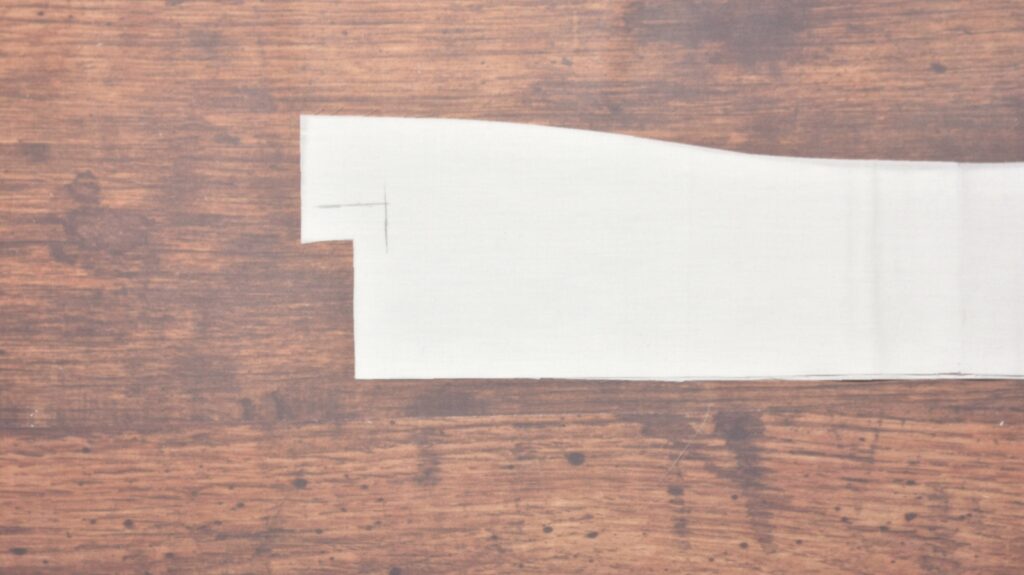

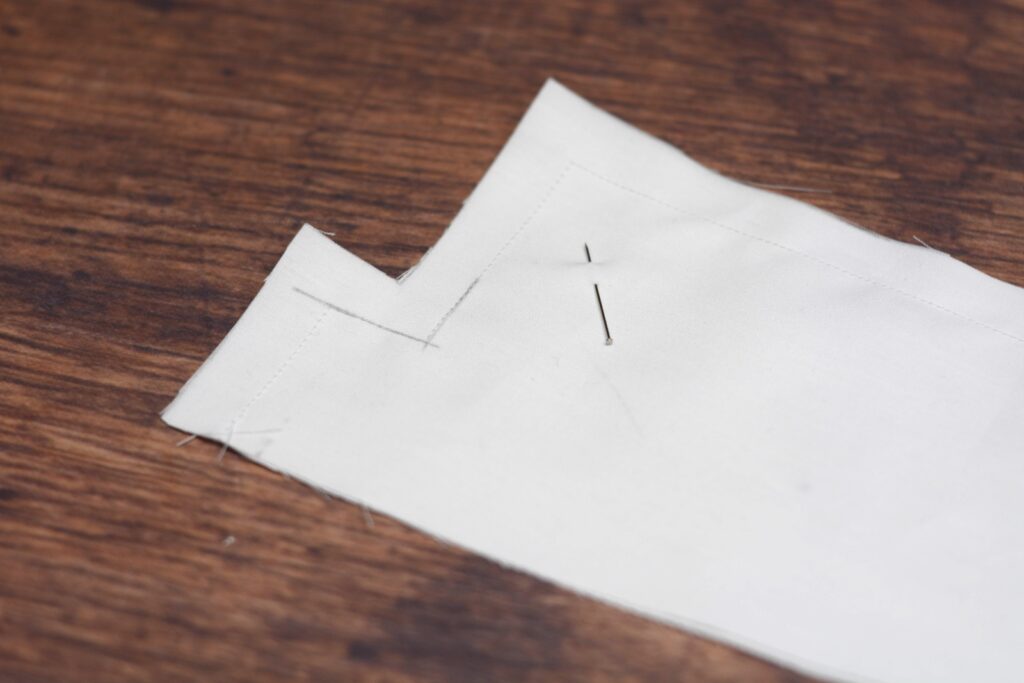

Now that the shirt body is complete, we can construct and attach the collar. The process is similar whether using a banded collar or this fancier style. Begin by laying both collar pieces right sides together.

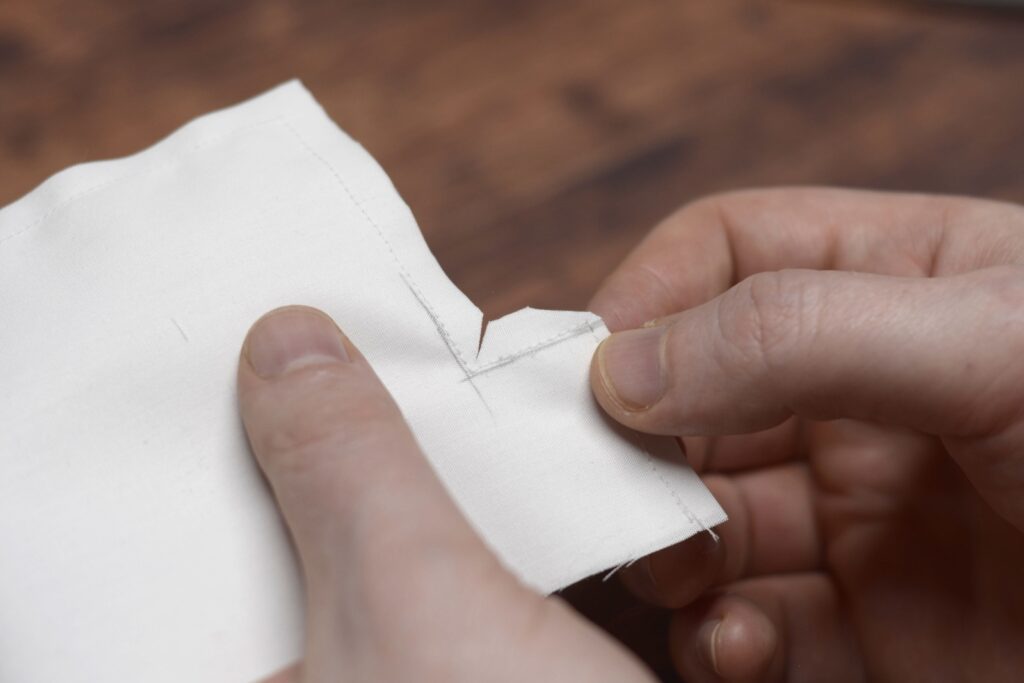

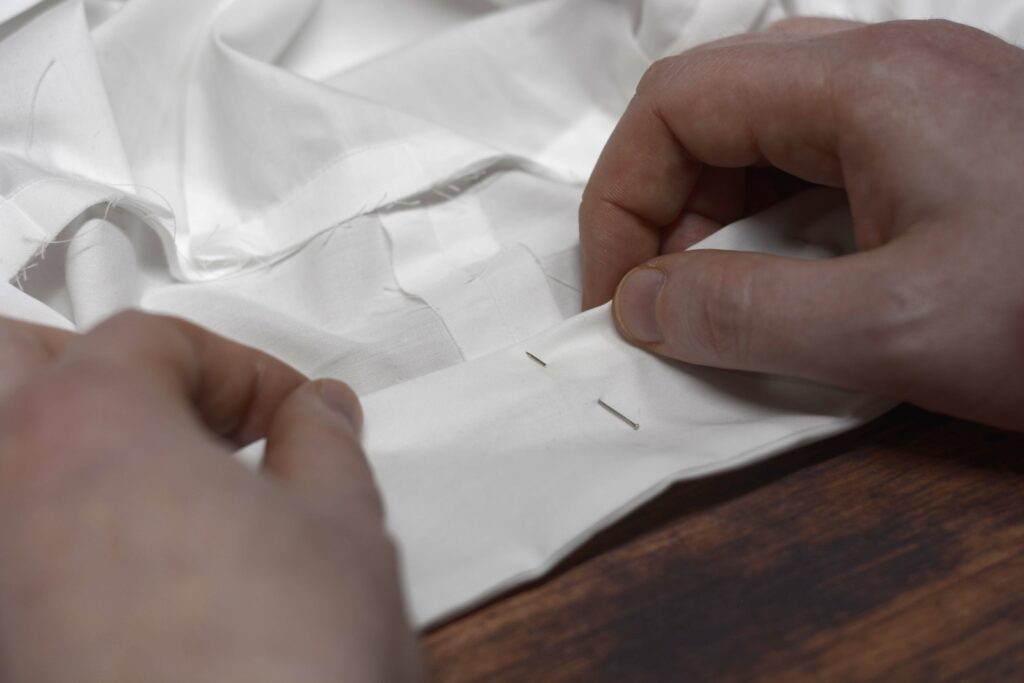

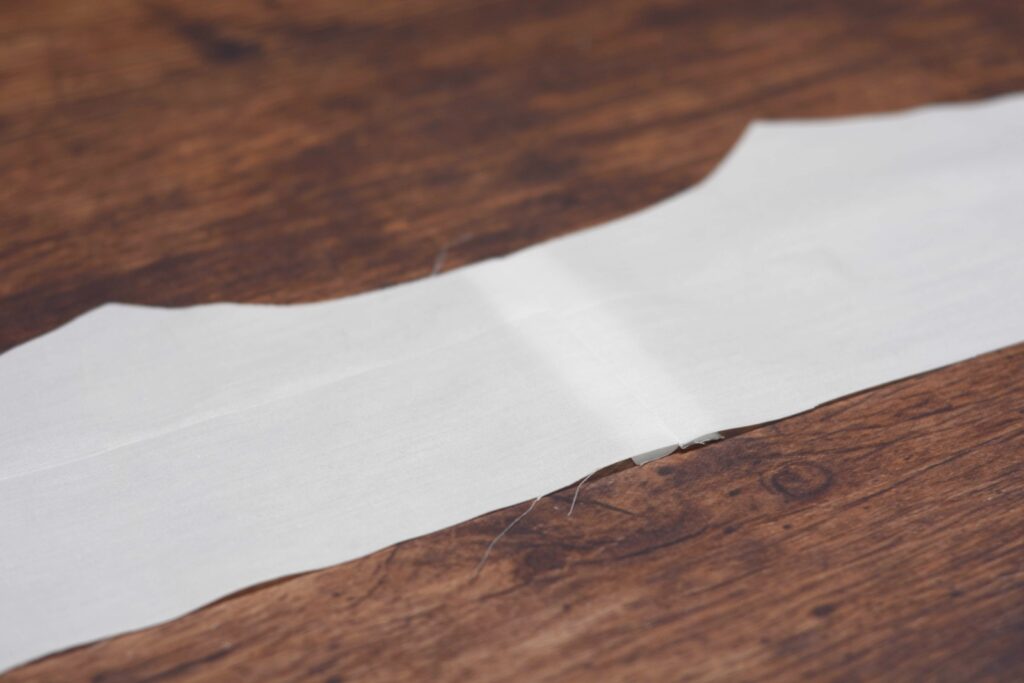

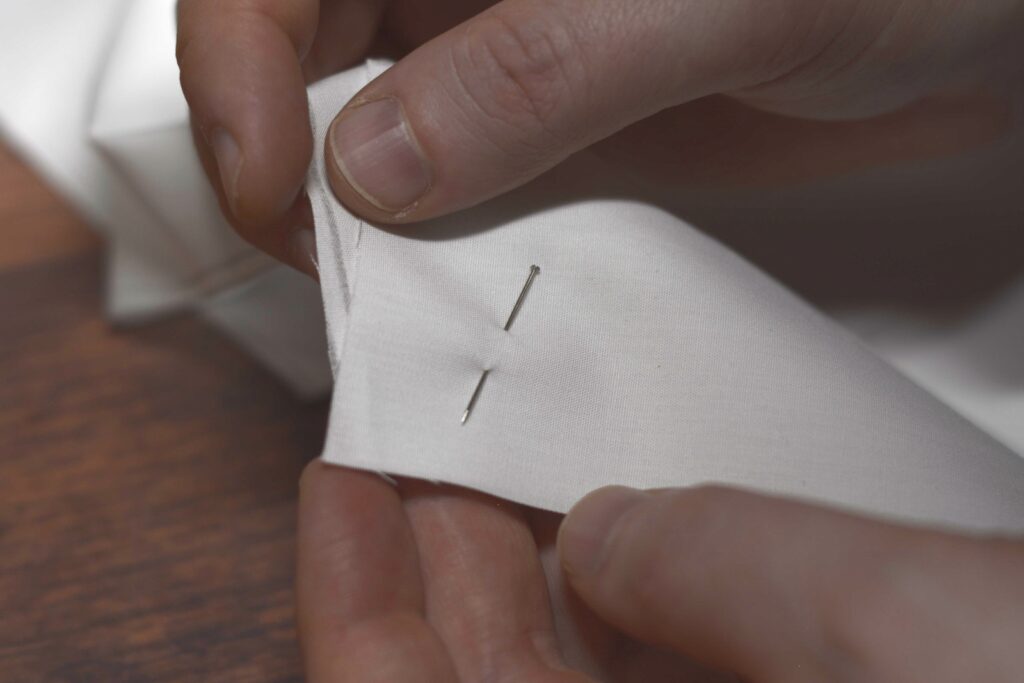

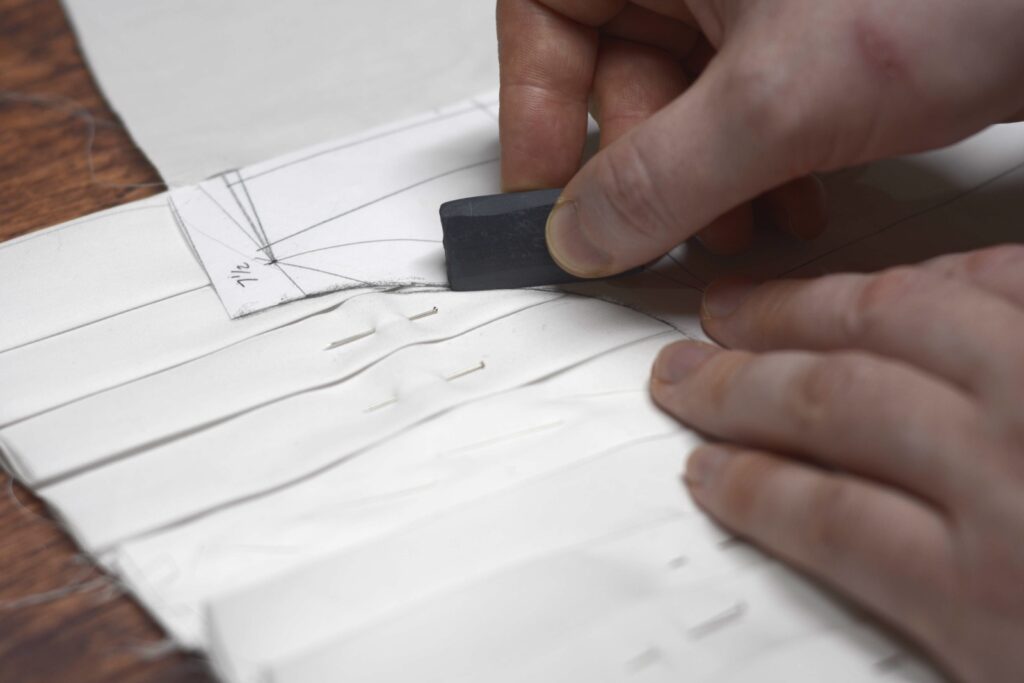

On the sharp corners, you can mark the seam allowances to help you turn the corners more accurately if you wish. I just did these two inside corners.

Starting at one end of the collar, sew the ends and top of the collar together with a 1/2″ seam allowance. Do not close up the bottom seam. You can pin the collar halves together before sewing if you want a little extra stability.

Here’s part of my sewn collar. I should have made a single diagonal stitch at each of the corners but it slipped my mind. It doesn’t really matter for this toile though.

Trim each of the seam allowances (except for the unsewn bottom seam) down to 1/4″.

Trim the outside corners down to about 1/16″ to 1/8″ depending on how stable your fabric is.

Clip the inside corner as well as close as you can without cutting into the seam itself.

Turn the collar right side out, using a point turner or even a pencil to ensure your corners are sharp.

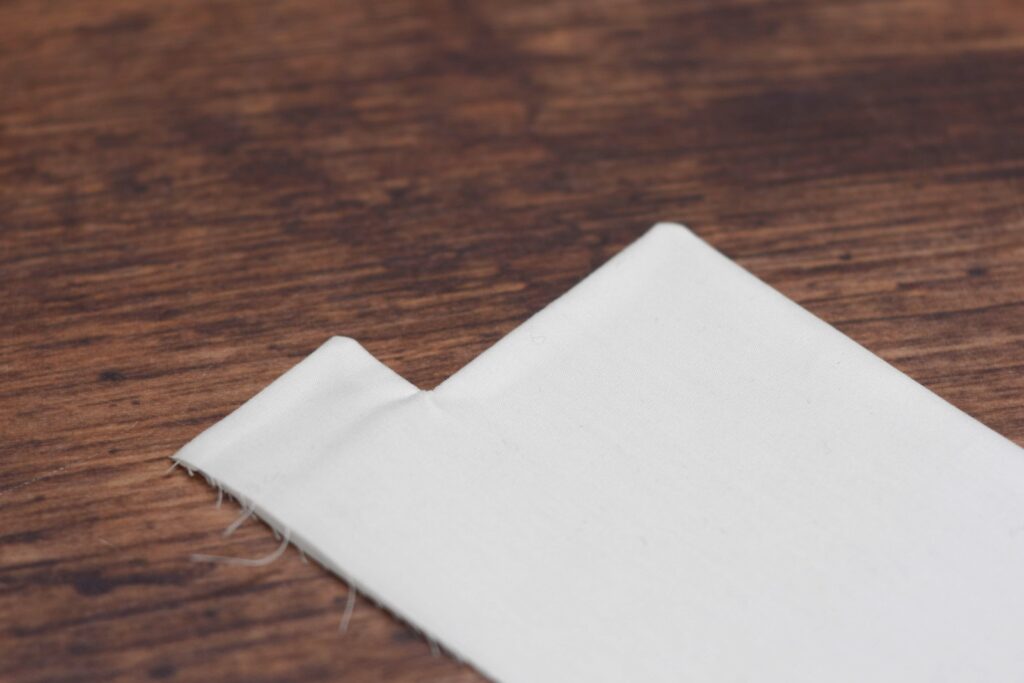

Press the collar well. Here’s what the collar should look like afterwards.

Attaching the Collar

Before attaching the collar, remove the small bit of machine stitching and the hand basting that are holding the shirt’s front placket together.

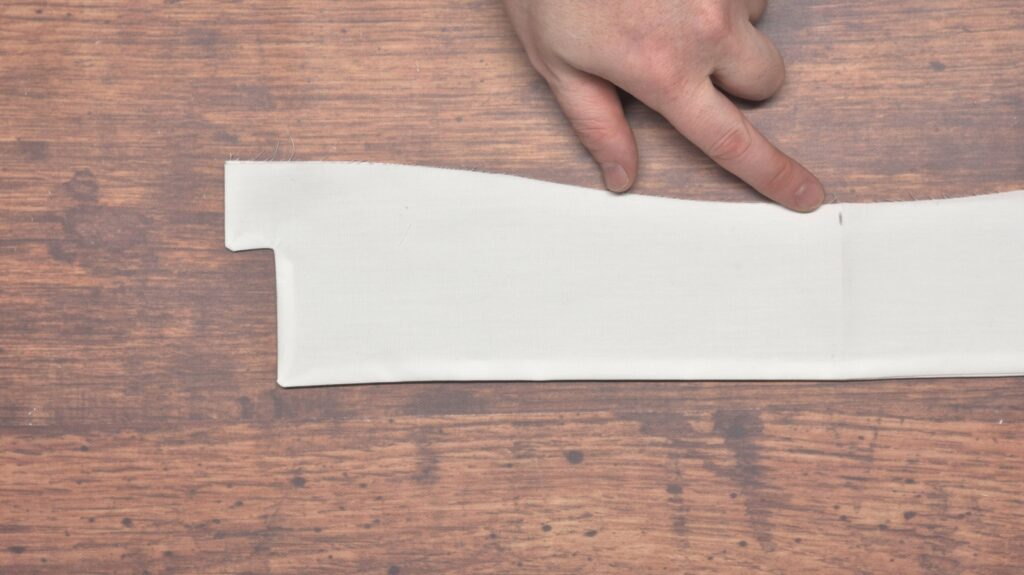

To attach the collar to the shirt, begin by folding the collar in half and finding the middle. Give it a crease with your fingers.

Mark the center with chalk or pencil.

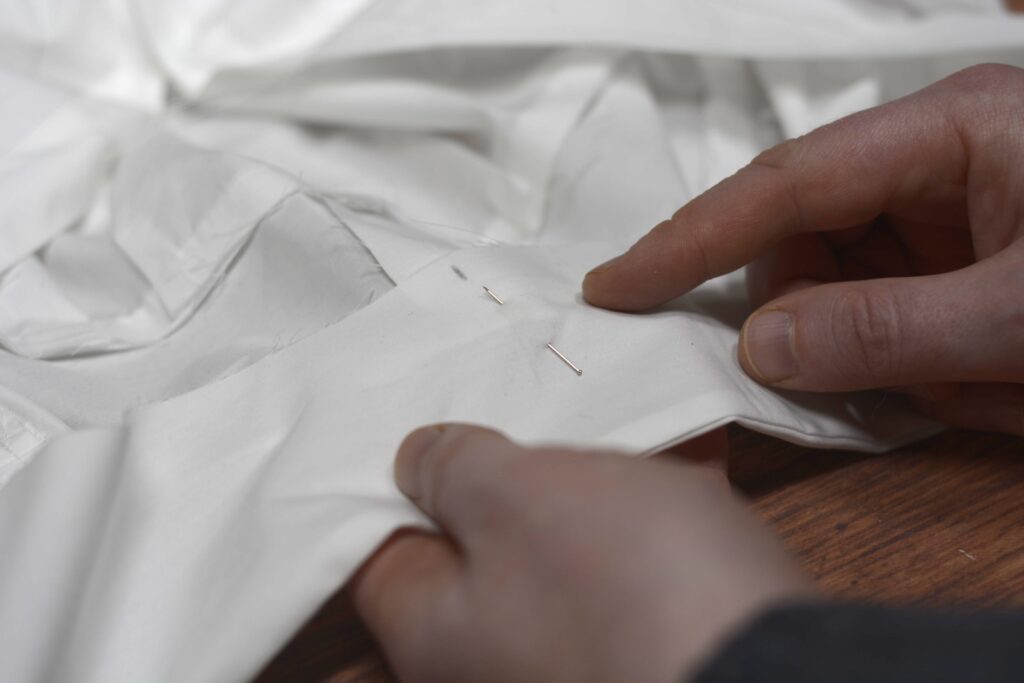

With right sides together, align the center back of the collar with the center back of the shirt and pin. Fold the top (inner) inner layer of the collar out of the way as you pin.

Now pin one end, carefully aligning the end of the collar with the placket beneath it. Continue folding the top layer of the collar out of the way (it gets tricky near the end). Repeat for the other end of the collar.

Here’s what it looks like without folding the top layer of the collar back.

Working from the center of the collar to one side or the other, gradually pin the rest of the collar, working any fullness as you go. Repeat for the other half.

Here’s the collar fully pinned to the shirt. You could also baste this by hand for a bit more control, with the added benefit of not having to worry about running over pins with your sewing machine.

Sew the collar to the shirt using a 1/2″ seam allowance from end to end. Carefully hold the top half of the collar out of the way as you sew, and be sure to take everything slowly, as the neck and collar seams have a tendency to want to get out of alignment, due to the curves involved.

Here’s the completed seam showing the collar from the inside, the back yoke on the left, and the pleated front on the right.

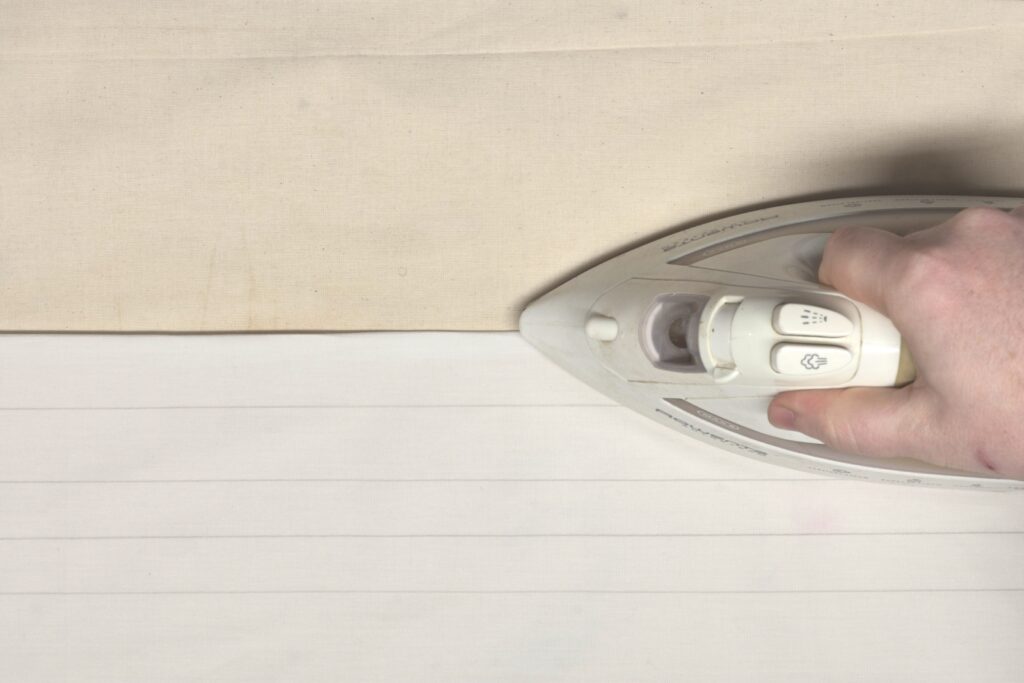

Press the collar and seam allowances up towards the collar. This will allow all the seams in this area to be hidden. Use a tailor’s ham to help with pressing the curved seams.

Turning to the inside of the collar and shirt, pin the inner collar to the undercollar at the center, evenly distributing the fabric, about 1″ from the edge.

Pin the rest of the inner collar as well.

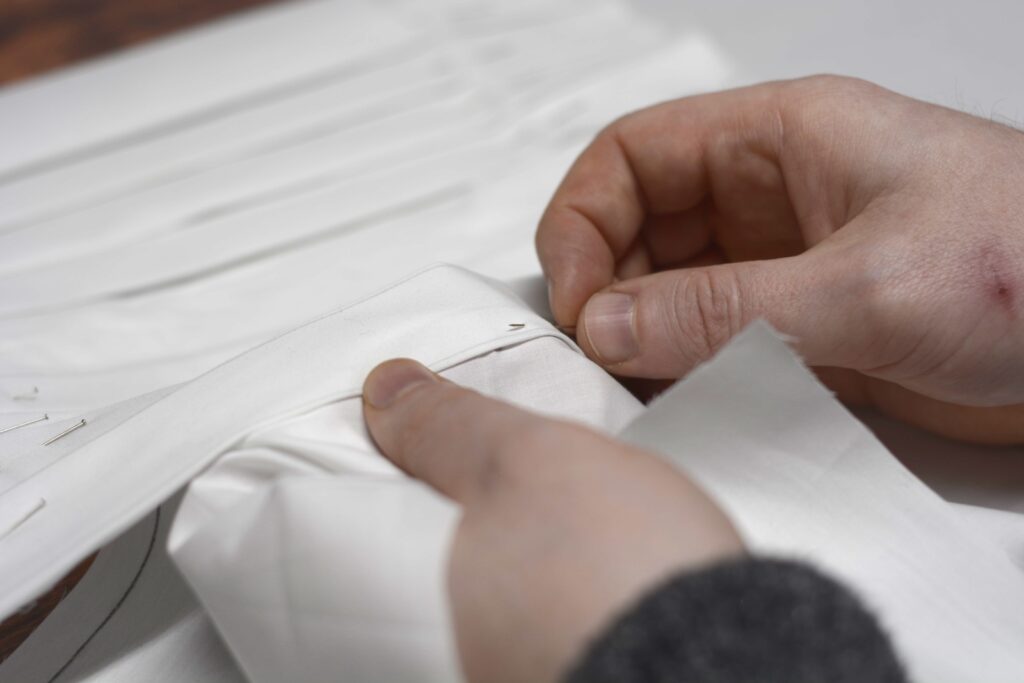

Now fold under the raw edge and seam allowance, allowing it to extend beyond the collar seam line by about 1/8″. Crease firmly with your fingers as you go.

Now baste the collar closed by hand along the neck seam.

Finally and optionally, you can top stitch across the base of the collar.

And around the front area and across the top.

Not very happy with how my collar turned out, but it is a mockup, after all.

Shoulder and Side Seams

Now that the front and back pieces are complete, we can go ahead and join them together at the side and shoulder seams. Begin by pinning the fronts to the backs at the sides, right sides together. Start at the top, aligning the armscyes, and keep even tension on both until you get to the bottom of the seam.

Mark the bottom of the stitch lines just at the point where the front piece begins to curve inward.

Sew the side seam using a 1/2″ seam allowance.

The Shoulder Seams

Pin the shoulder seams together at either end. Note how the seam lines themselves are aligned at each end, and not the corners of the fabric or some other point.

Pin the center of the shoulder seam, distributing the excess fabric of the front equally on both sides. Then pin between each of these pins for a total of five pins.

Sew the shoulder seam, front side down to help distribute the fabric with the feed dogs, using a 1/2″ seam allowance.

Pressing

Press the side seams towards the back and the shoulder seams up towards the yoke using a tailor’s ham to maintain the slight shape.

Your Progress

[columns gutter=”0″]

[col]

1 | Sew the side seams. | |

2 | Sew the shoulder seams. |

[/col]

[col align_text=”center, middle”]

[/col]

[/columns]

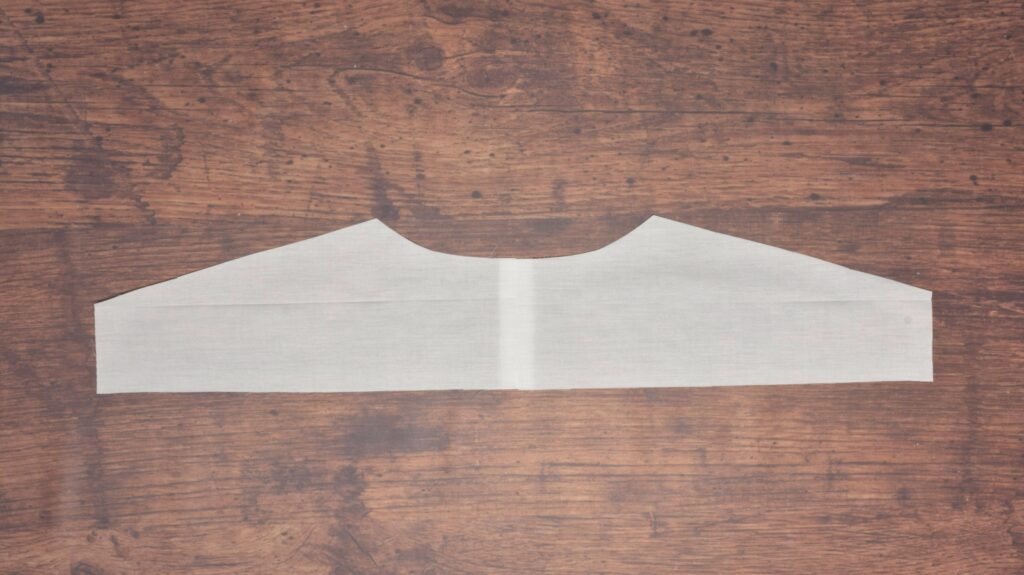

The Back

Work on the back begins with sewing the two halves of the yoke together at the center back, using a 1/2″ seam allowance.

Press open the seam.

Lay the yoke and back pieces into position, right sides up. The excess fabric will need to be gathered or pleated in, though it’s not as much as on the fronts.

Flip the yoke down into position, right sides together, and pin the center of the yoke to the center of the back.

Now pin both ends together.

Now form a series of pleats on each half of the back until all of the excess fabric is used up, in a similar manner as the front. Ideally these will be all the same size and spaced equally, but as you can see, I didn’t quite do that here. Again the fit is more important than the look at this stage.

I pinned each pleat from the yoke side so that the feed dogs on the sewing machine would aid in taking up any excess fabric that I may have missed.

Now sew the yoke to the back with a 1/2″ seam allowance.

Press both the yoke and the seam allowances up towards the neck.

By pressing the seams upward, you avoid extra bulk from the pleats or gathering, as well as the possibility of hiding the seams beneath the lining later on.

Your Progress

[columns gutter=”0″]

[col]

1 | Sew the halves of the yoke together. | |

2 | Pleat and sew the back to the yoke. |

[/col]

[col align_text=”center, middle”]

[/col]

[/columns]

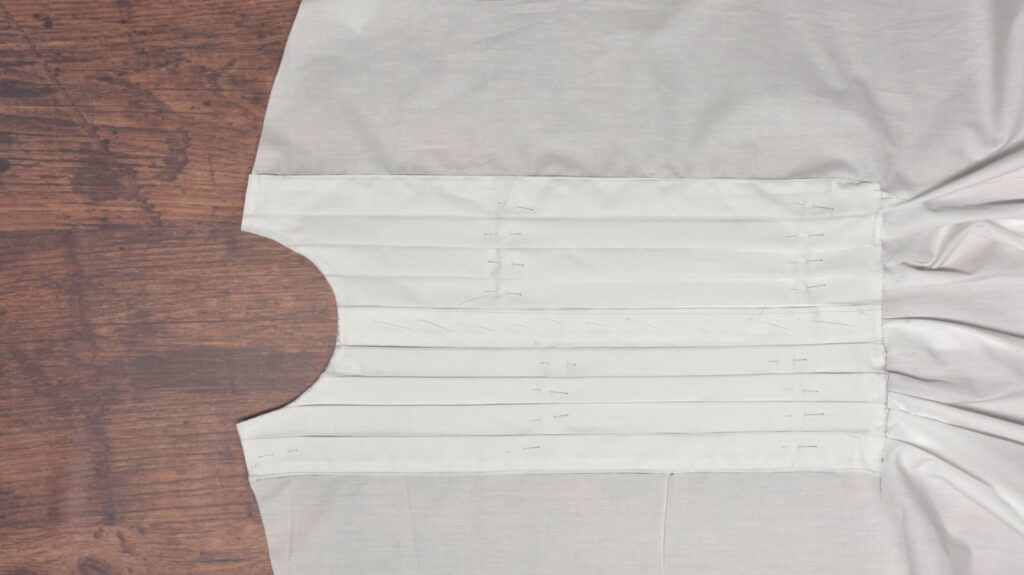

Attaching the Pleated Front

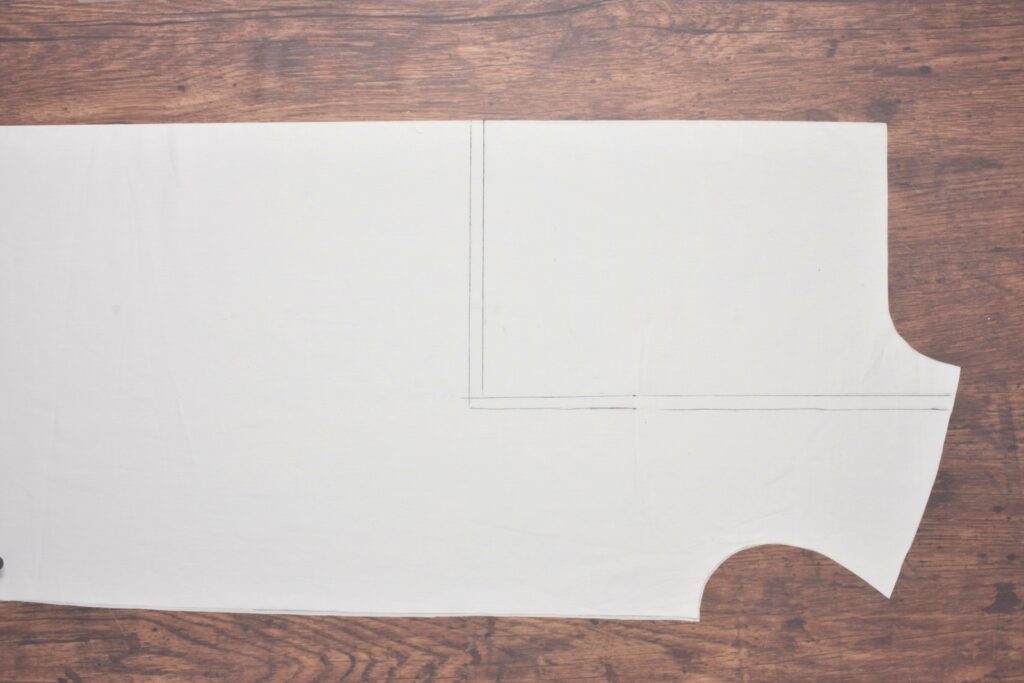

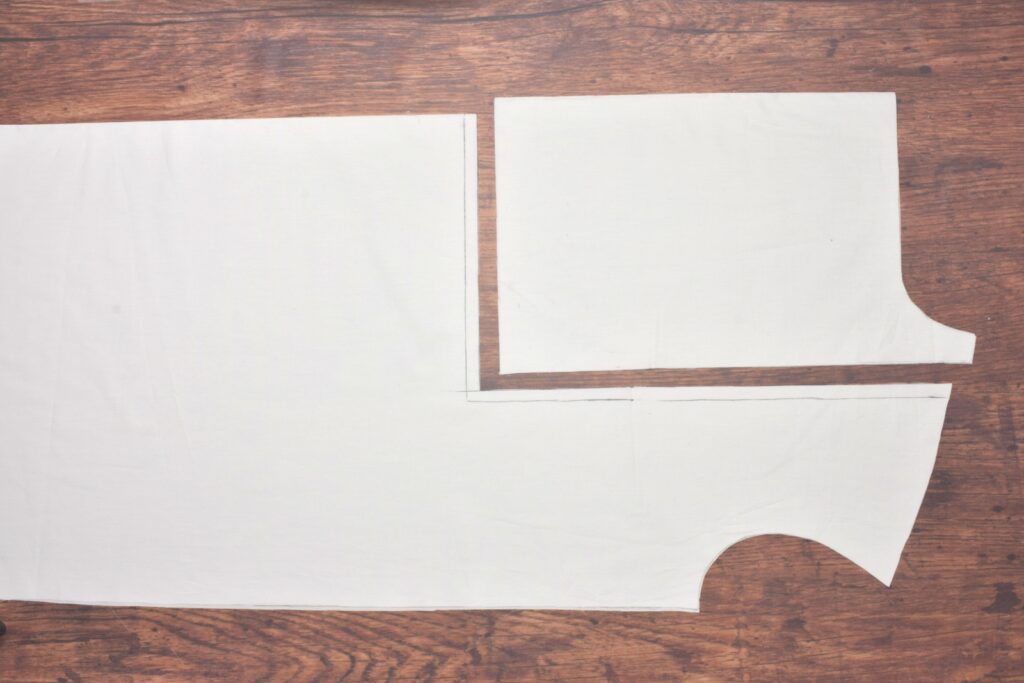

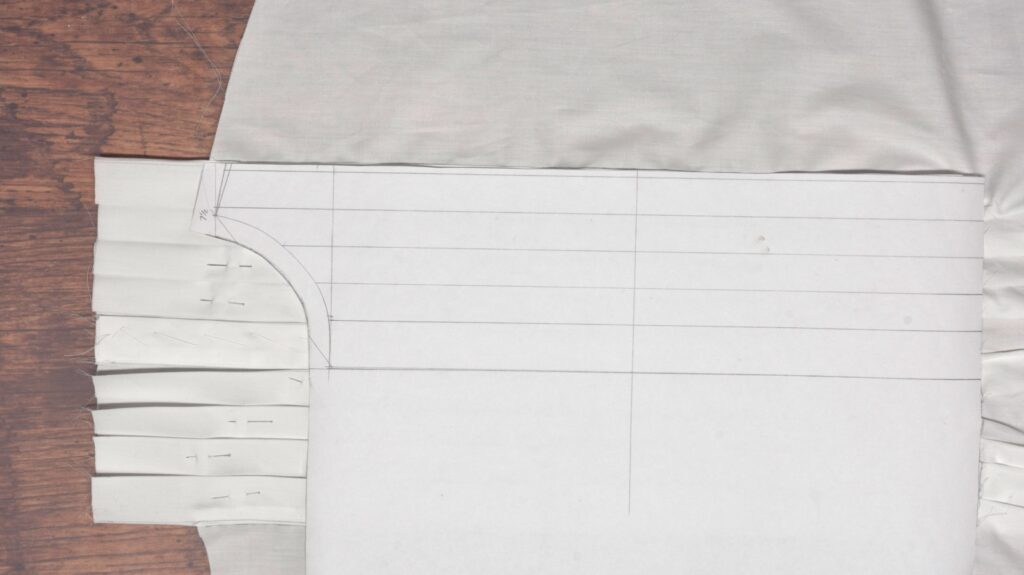

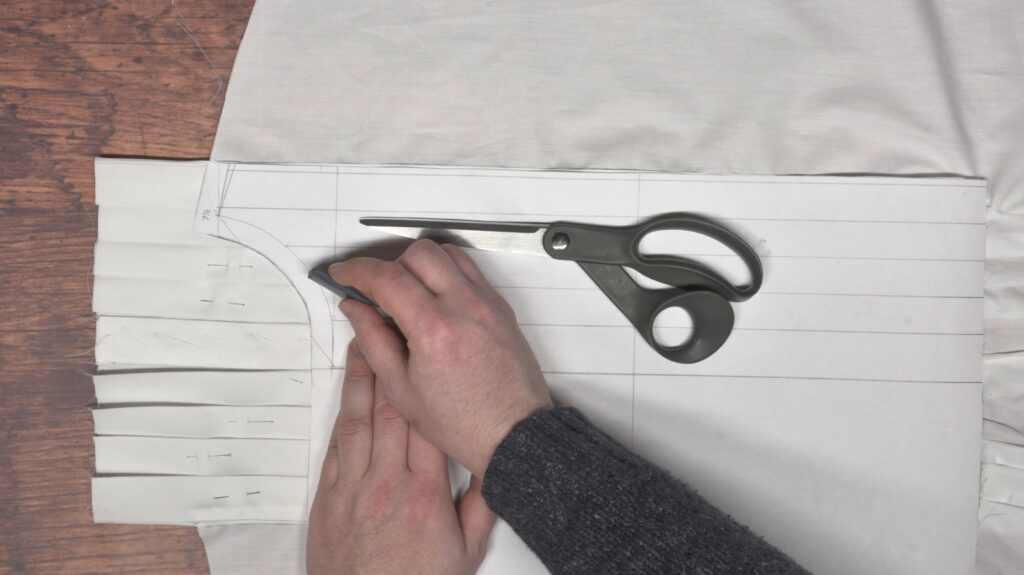

Attaching the pleated front to the shirt front begins with some work on the front pattern piece. I’ve found the most accurate and stress-free way to do this step is to cut out the pleated portion of the pattern and the extra bit we added to the front area. You can simply tape the two pieces again later before cutting out the shirt from your nice fabric.

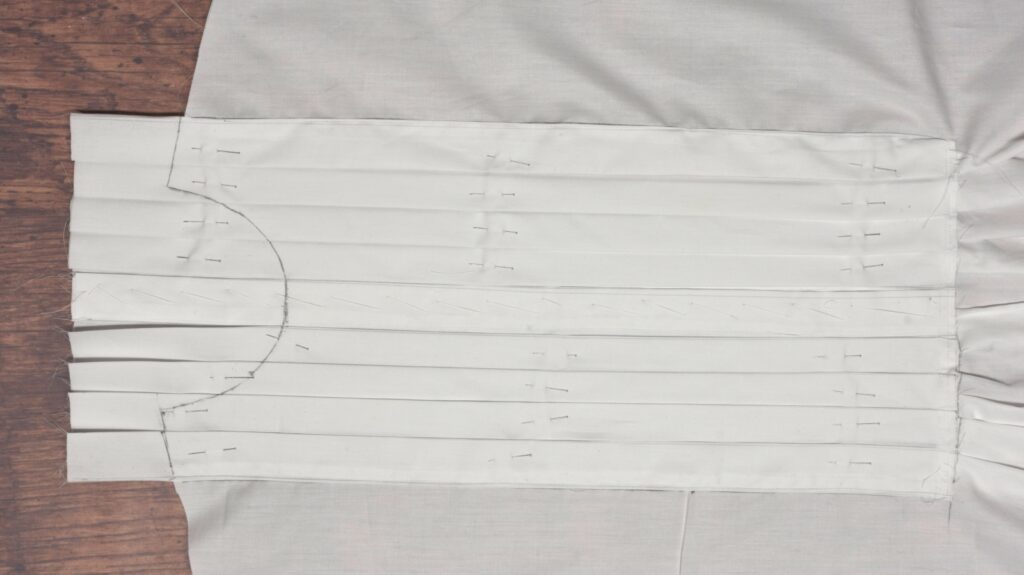

Lay the shirt front pattern on the shirt front, aligning the edges as closely as possible. Draw a line indicating the inside edge and bottom edge of the pleats.

Along the vertical, inner edge of the pleats, add a 1/2″ seam allowance. At the bottom add 3/4″ or 1″ seam allowance. Note that I did a 1/2″ seam at the bottom of the pleats, which I don’t think will give us enough room to work with on the actual shirt. For this muslin toile, it will work just fine.

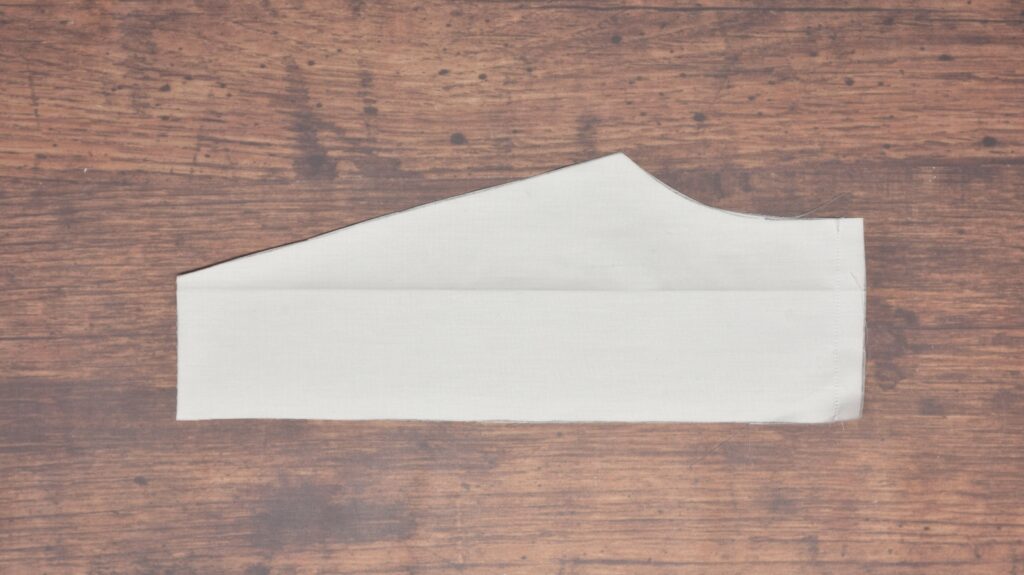

Cut out the rectangular piece along the added seam line. This piece can be used for another project as it’s not used in the shirt.

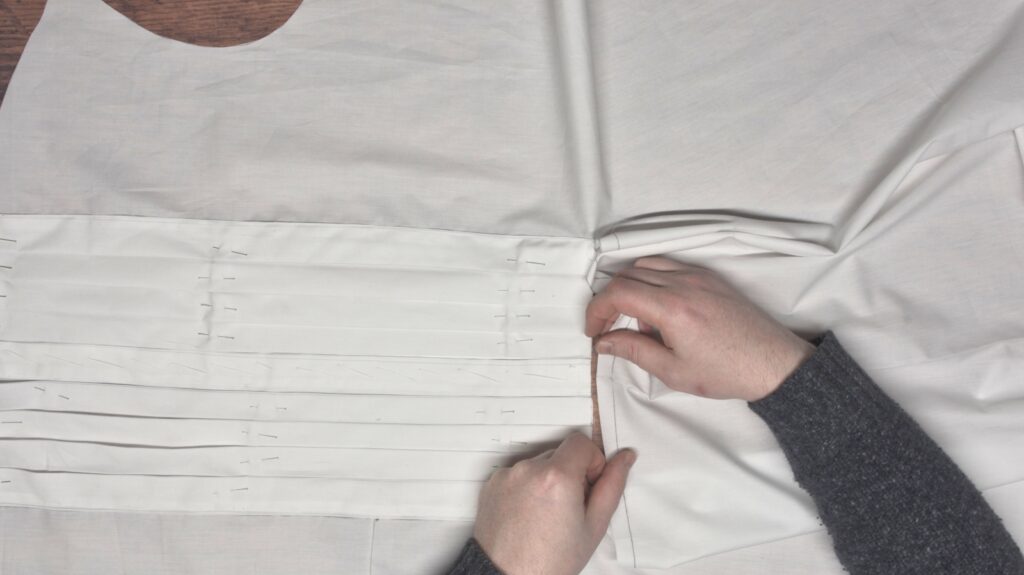

Pin one half of the pleated front to the shirt front, aligning the folded edge of the pleats with the seam line you drew earlier. Be sure the bottom of the pleats aligns precisely with the bottom seam line.

Very important! Make sure that your pleated front is arranged so that the left side overlaps the right! I completely forgot about that and ended up with a woman’s shirt-style opening.

Repeat the process with the other side of the pleated front. At this point, the bottom of the shirt is still hanging freely.

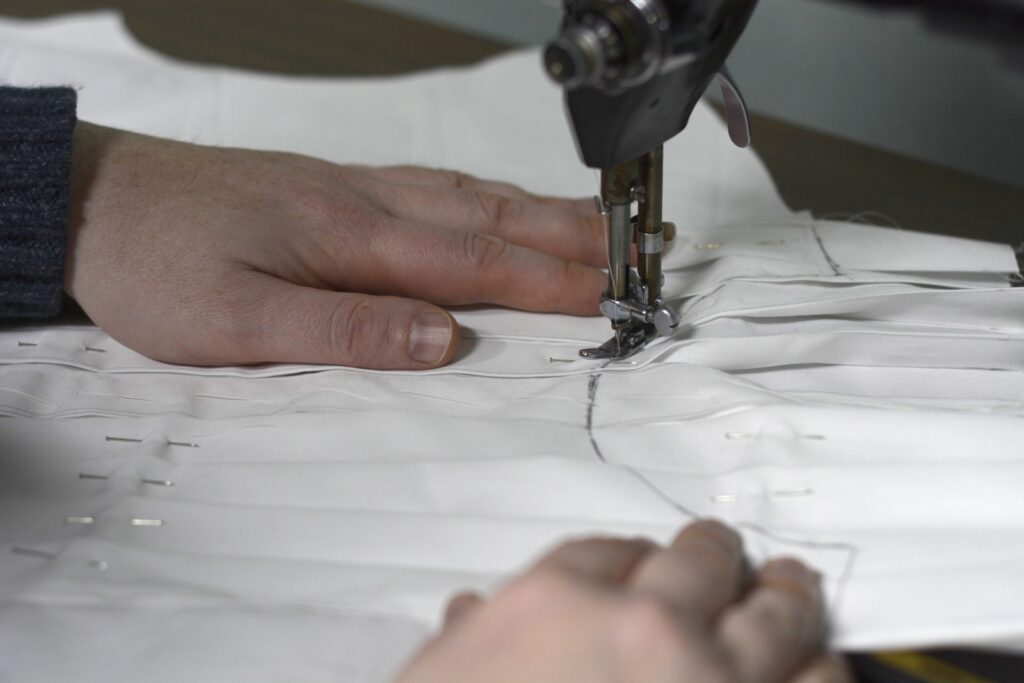

Now sew along the vertical edge on each side of the pleated front, about 1/8″ from the folded edge, removing the pins as you go.

Closing the bottom of the pleats

To close the bottom edge of the pleated front, first find the center front of the shirt itself – it will probably have a creased edge from being on the bolt.

Pin the center front of the shirt to the center front of the pleats, aligning the bottom of the pleats with the seam line you drew in earlier.

You’ll have noticed that there is a large quantity of fabric on the shirt as compared to the pleated front. This excess must be gathered in nicely for the real shirt – for this toile, I chose to just use some unmeasured pleats.

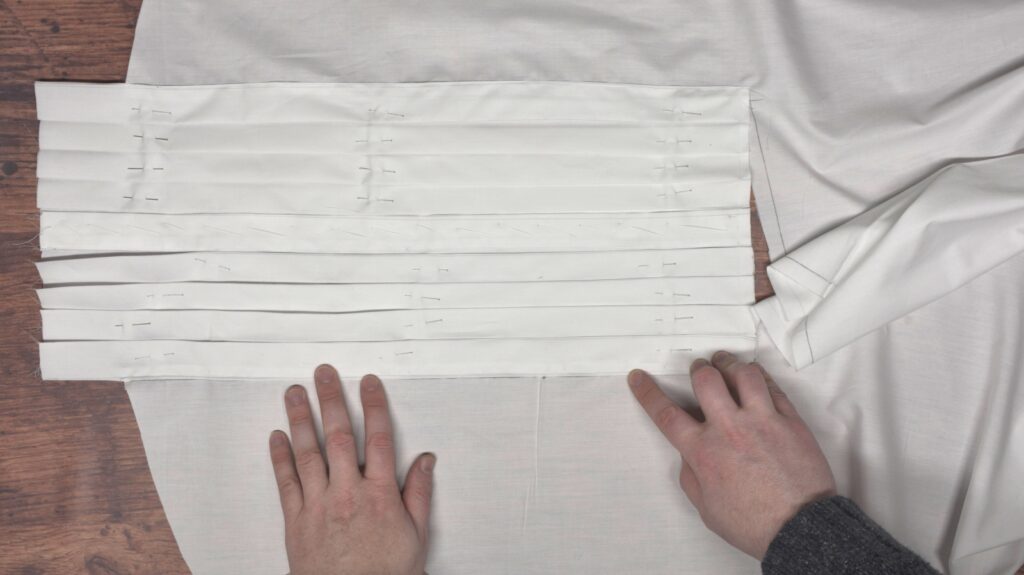

Form the pleats with your fingers in the shirt fabric, aligning the seam allowance line, and pinning them to the pleated front as you go. Work on one side of the shirt at a time.

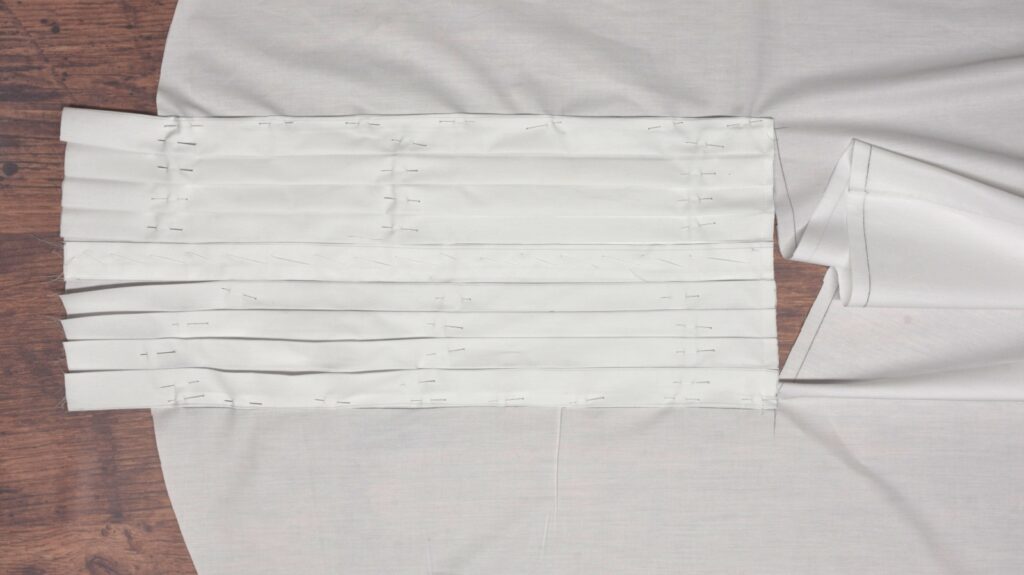

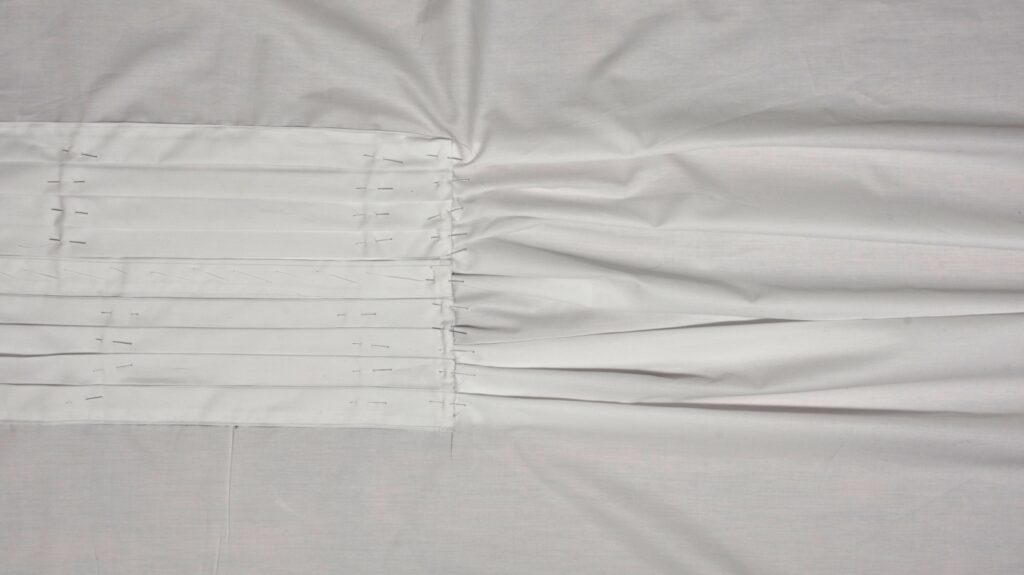

Here are half of my pleats done. As you can see they’re not the same size. It doesn’t really matter for the toile, as we’re more worried about the fit here than the appearance.

Repeat the process for the other half of the pleated front.

Now sew across the bottom of the pleats through all layers, about 1/4″ from the bottom. This will secure the pleats well enough for our purposes.

Trimming the Neckline

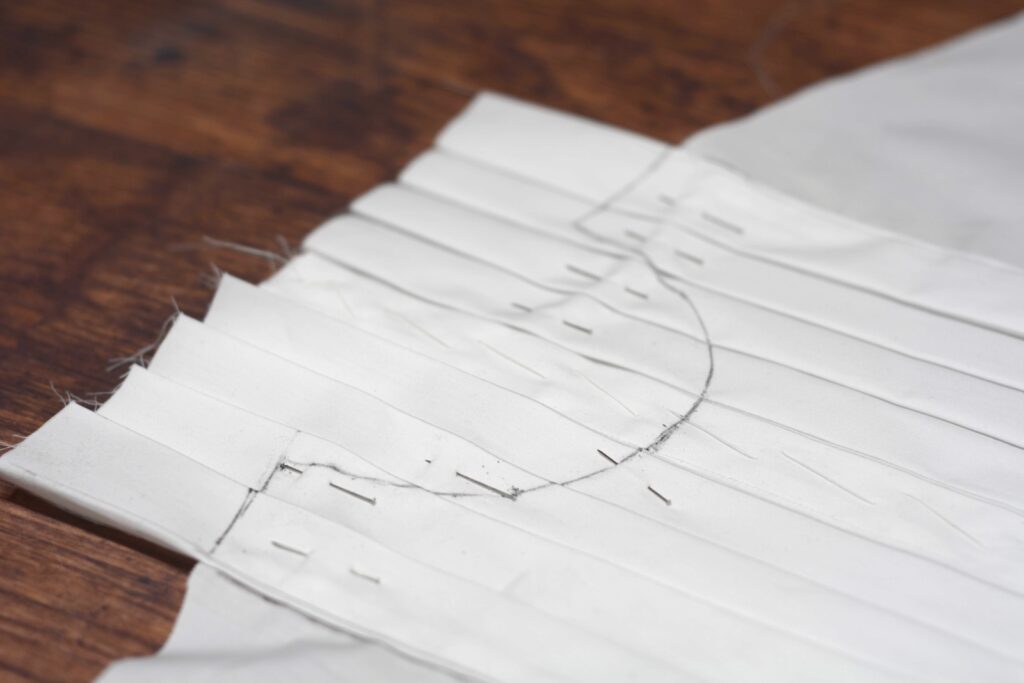

We now need to trim the neckline to fit the pattern. Line up the pleated front portion of the pattern on top of your shirt, aligning the edge and bottom of the pleats. If you’ve worked accurately the shoulder lines should line up as well. If not, you may need to move the pattern slightly to get the shoulders to align.

Mark a line across the shoulder area and around the neck to the edge of the center placket.

Flip the pattern piece over and repeat the process for the other side. Hopefully everything aligns nicely in the neck area!

To secure the top edge of the pleats, stitch a line about 1/8″ to 1/4″ (doesn’t really matter) below the chalked neck line. Be careful that the pleats stay in position as you sew.

Finally, trim the pleated front along the new neck and shoulder lines. This completes the front of the shirt.

Your Progress

[columns gutter=”0″]

[col]

1 | Attach the pleated front to the toile. |

[/col]

[col align_text=”center, middle”]

[/col]

[/columns]

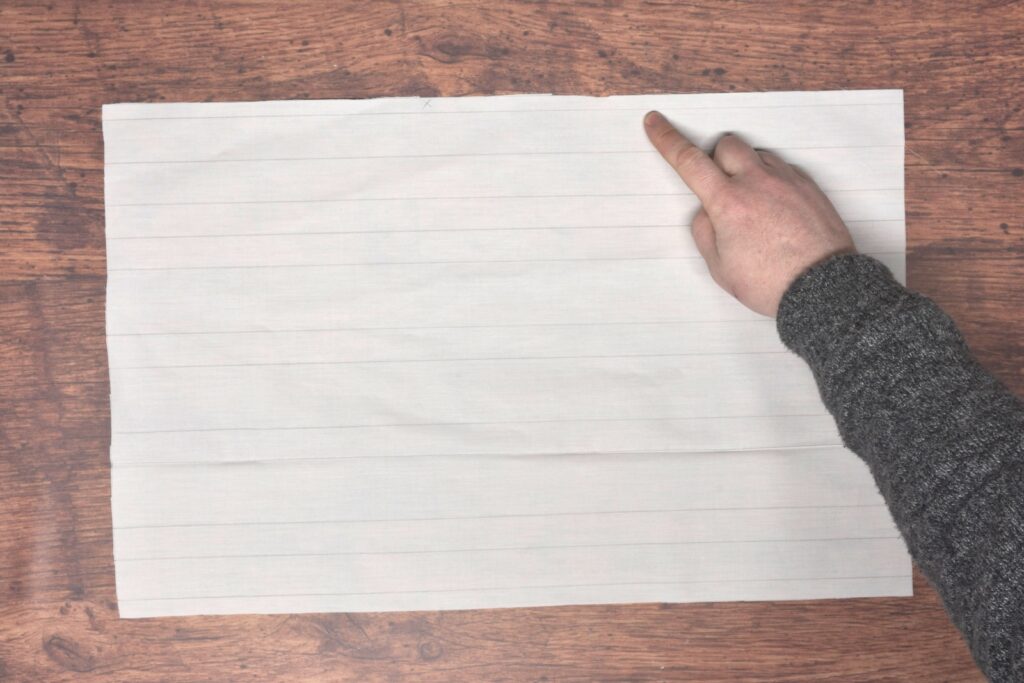

Pleated Front

I hadn’t planned on adding a section on making a toile for the shirt, but decided to include one just in case, as it’s good practice for those who have never made a shirt before, and for those who are working with odd or larger sizes. It’s up to you though, the muslin fabric I bought ended up being more expensive that the cotton I’ll be using for the shirt!

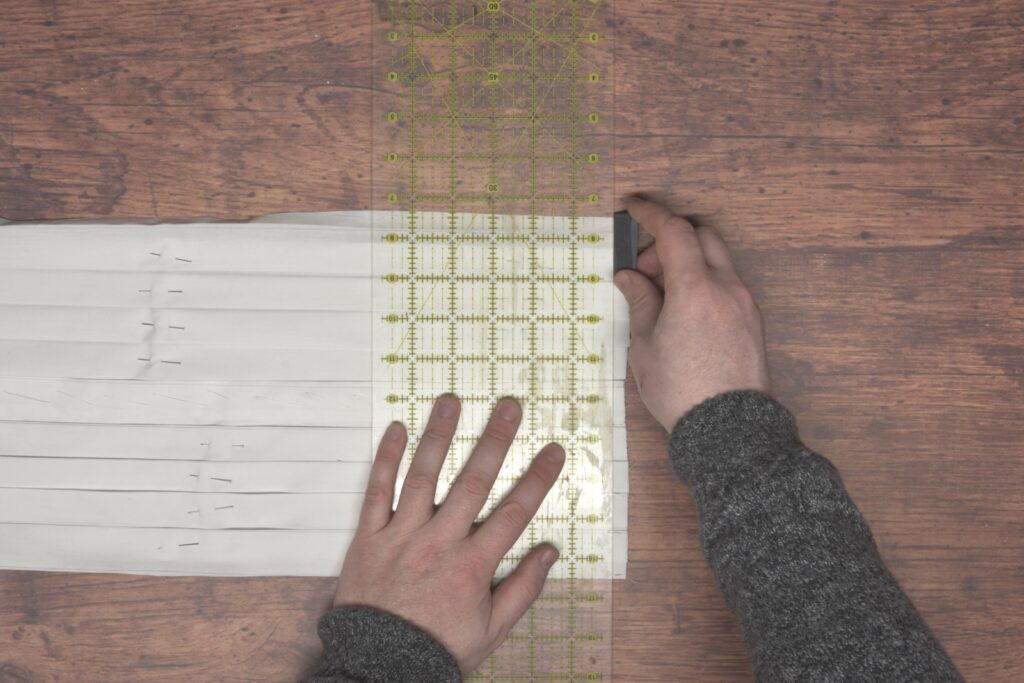

I’d highly recommend transferring the lines to an 8 1/2″ x 11″ sheet of paper and making a test run with that so you can figure out any errors as well as have something to refer to as you go along.

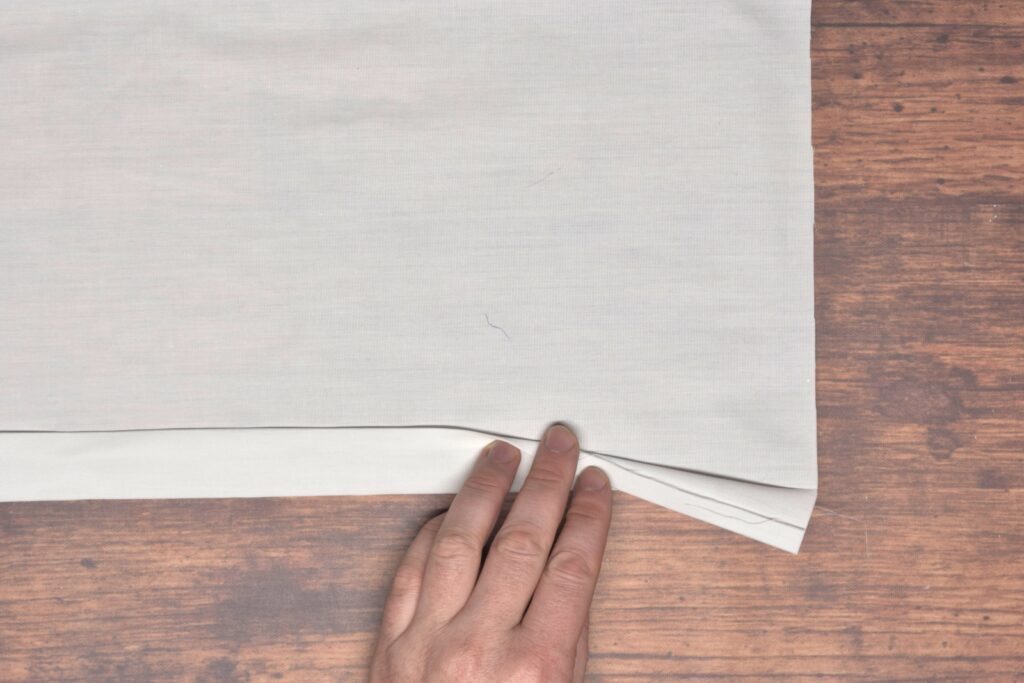

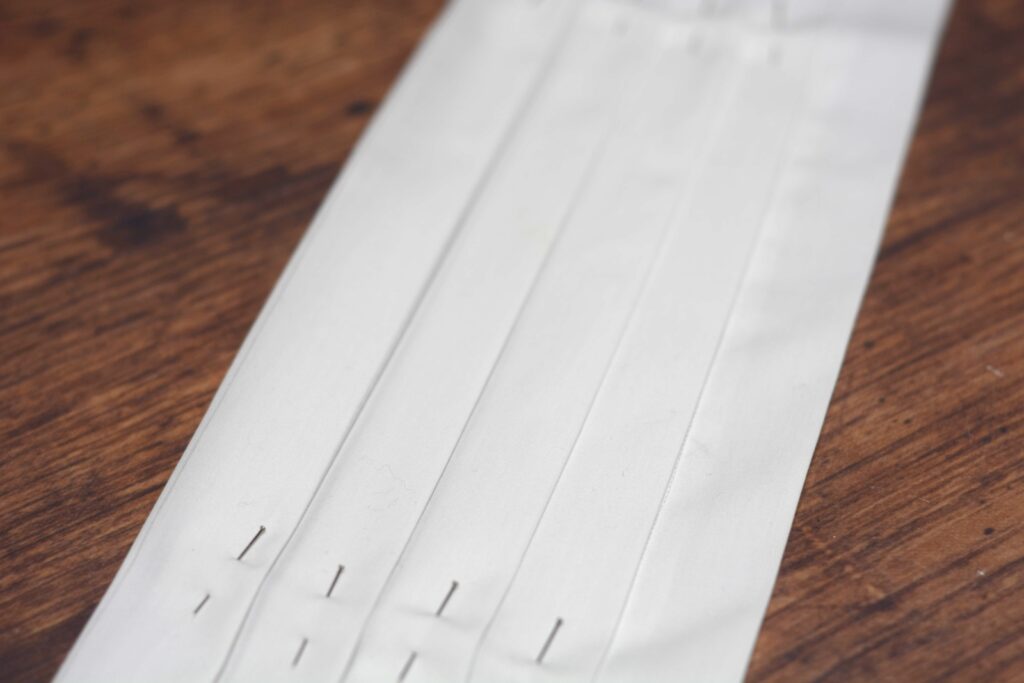

Construction begins with the pleated front and laying out all the lines on your piece of cotton. I’ll be starting from the center front placket area with the 3/8 seam allowance.

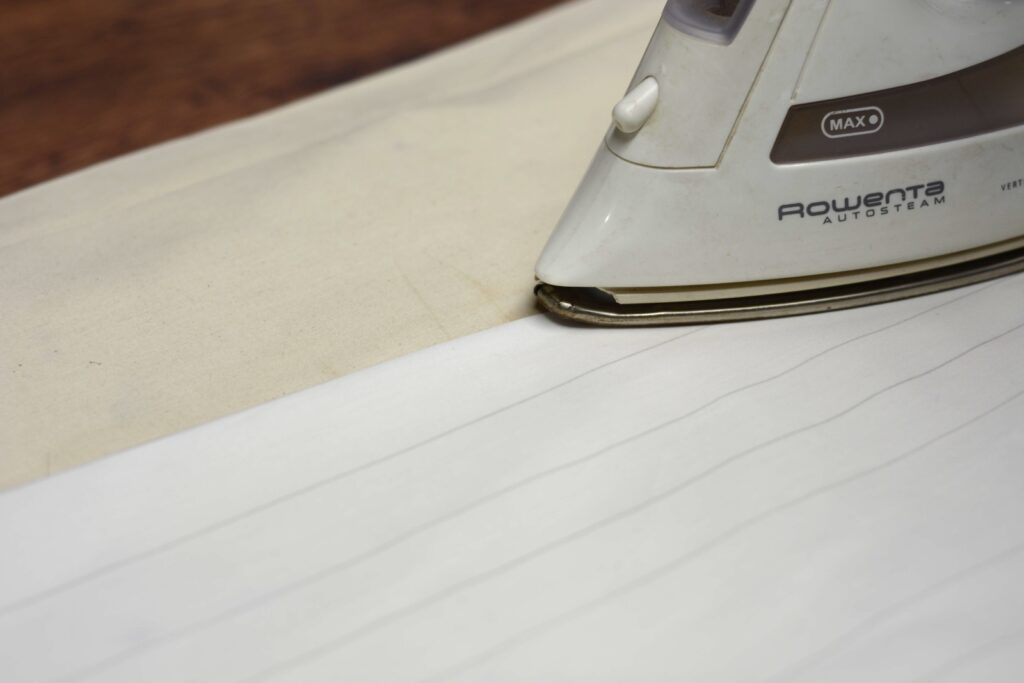

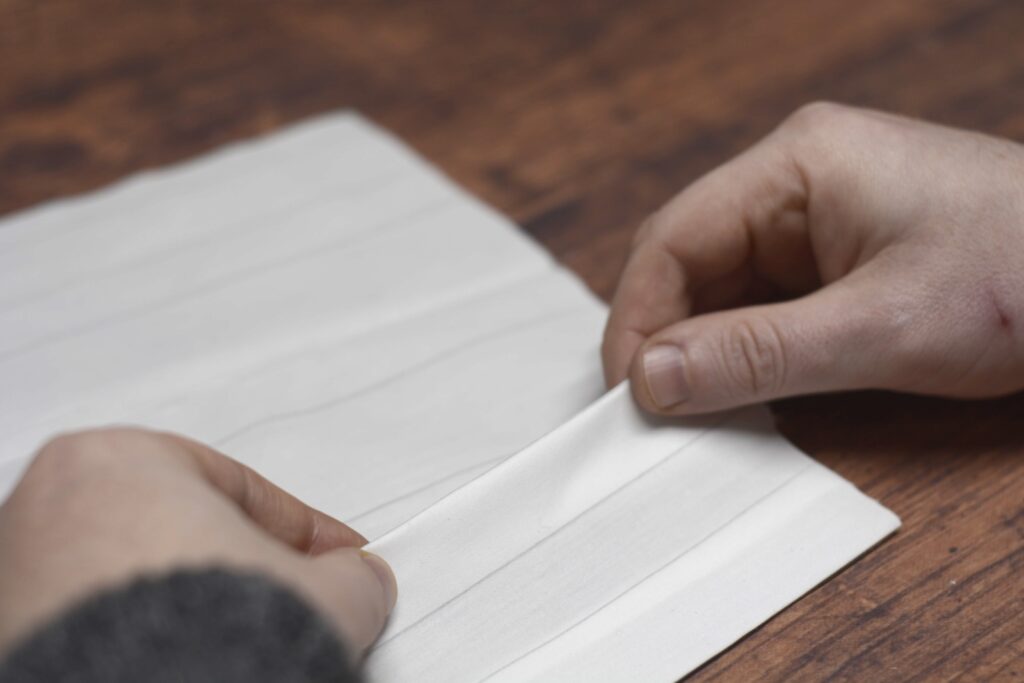

Turn the seam allowance under and crease firmly with your fingers. It’s important to be as accurate as possible here and in all of the following steps.

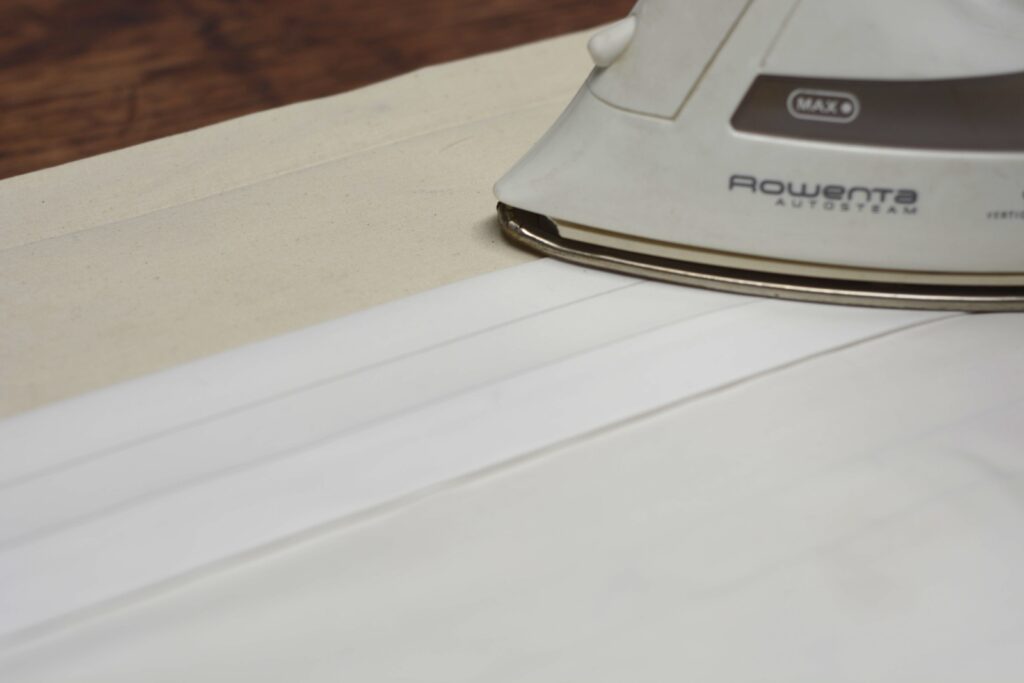

Press firmly with a hot iron and a little steam if necessary. This general method of using the fingers and the iron is used throughout.

Now fold and press the fabric at the second line, forming the shirt placket.

This is the view from the underside.

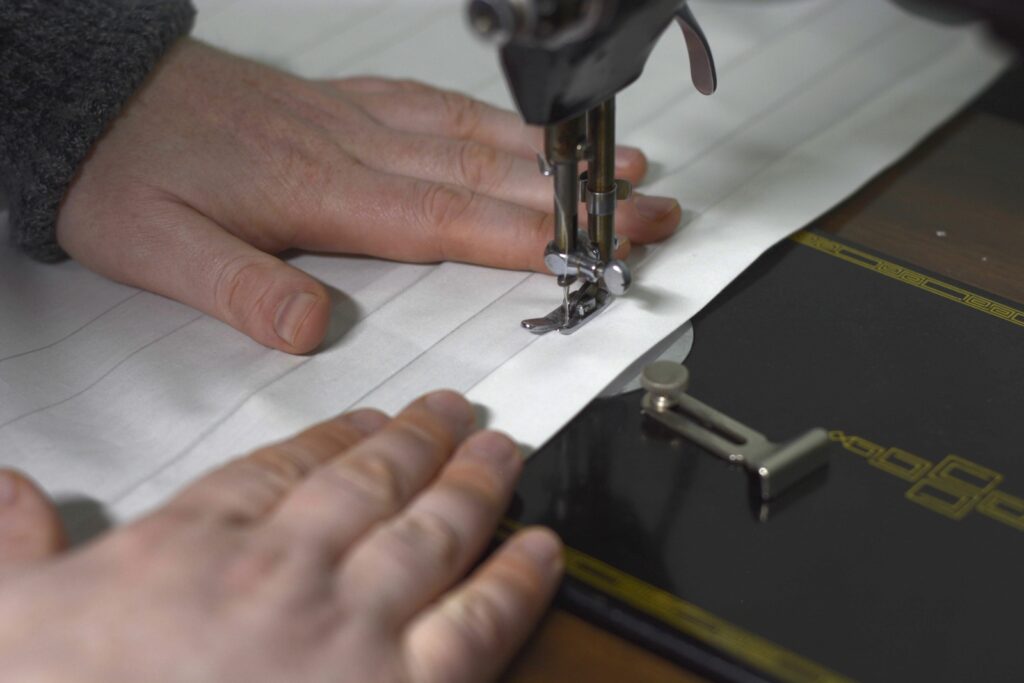

Sew along the inner edge of the placket about 1/8 from the edge. I recommend pinning the placket first – it will keep the fabric layers from shifting as you sew.

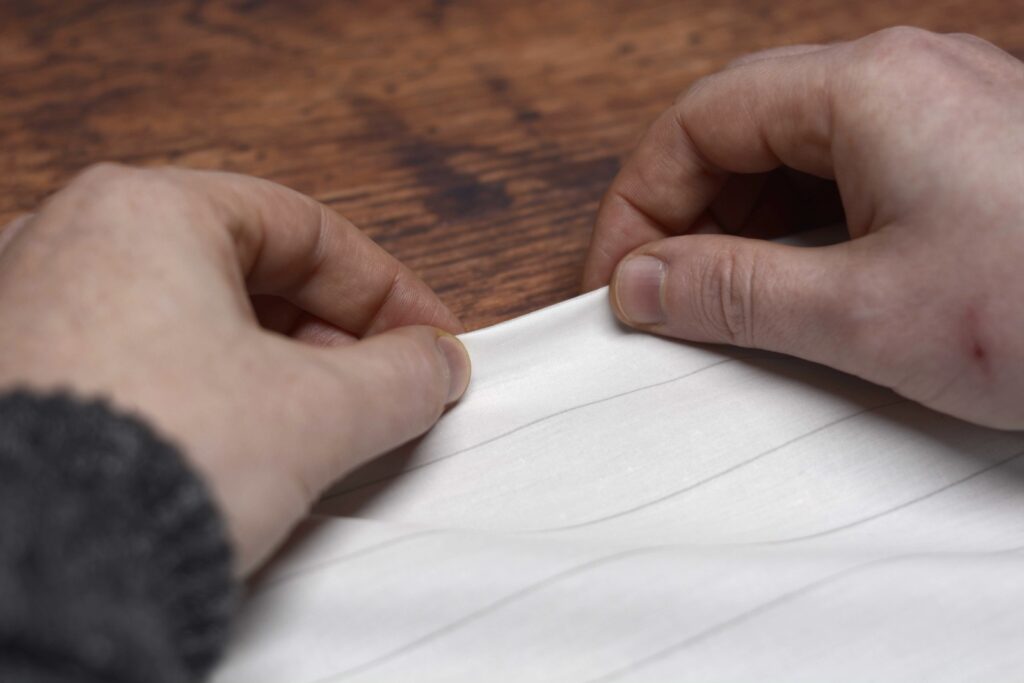

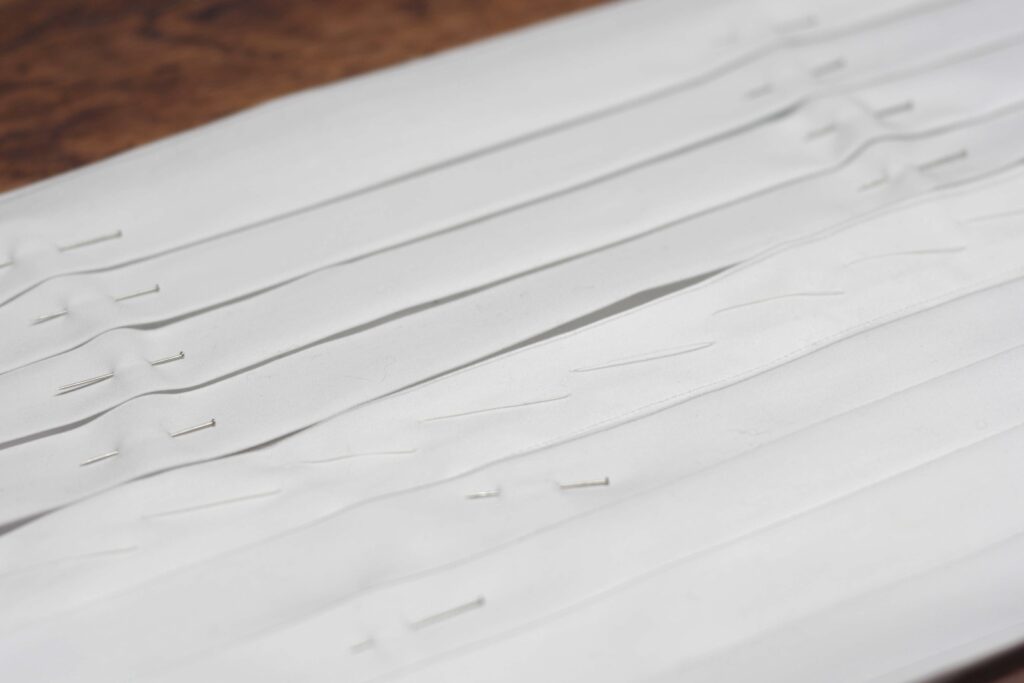

Now we’ll begin forming the pleats using the following process. The size of your shirt and the pleats themselves determines how many pleats you will have, so you may end up with more or less than my four.

Take the second line from the placket as shown.

Fold and press this line, forming the outer edge of the new pleat.

After pinching the fabric along the line, I like to press it as shown below.

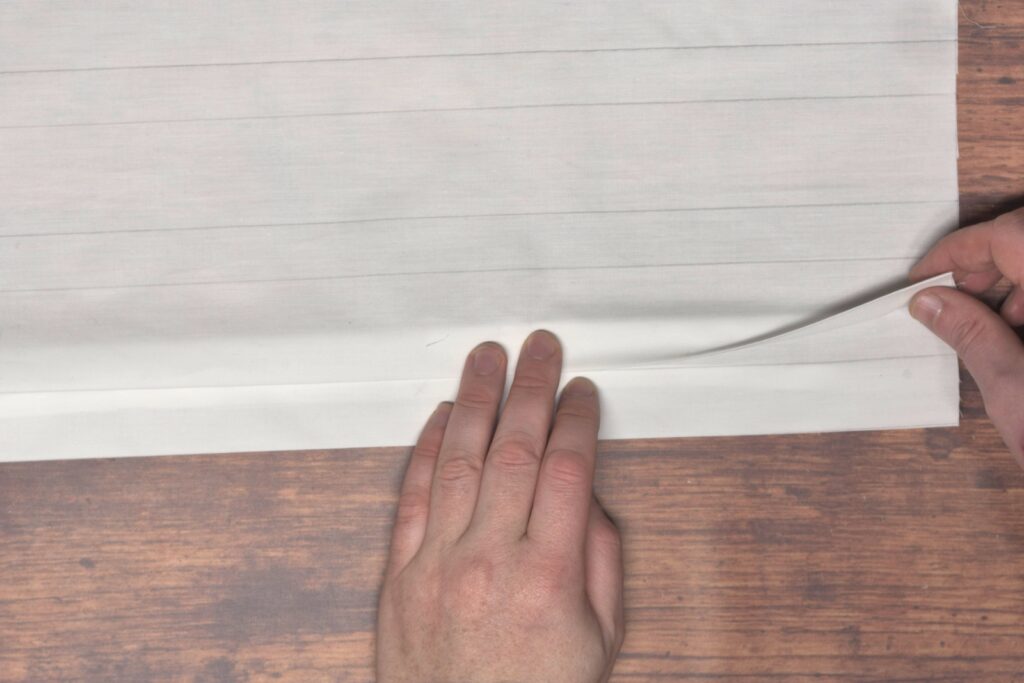

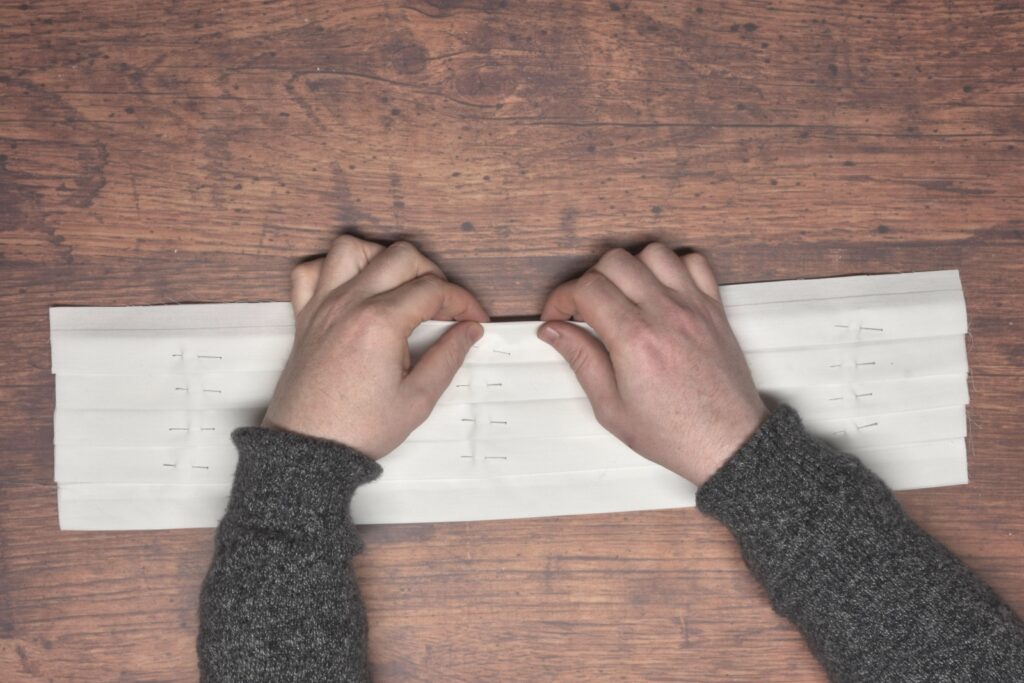

Then lay the pleated front out on the table again, taking the folded edge you just made.

Drag the pleat into position, lining it up with the edge of the placket.

Give it a firm, careful press and then secure with pins at the top, center, and bottom.

This completes the first pleat.

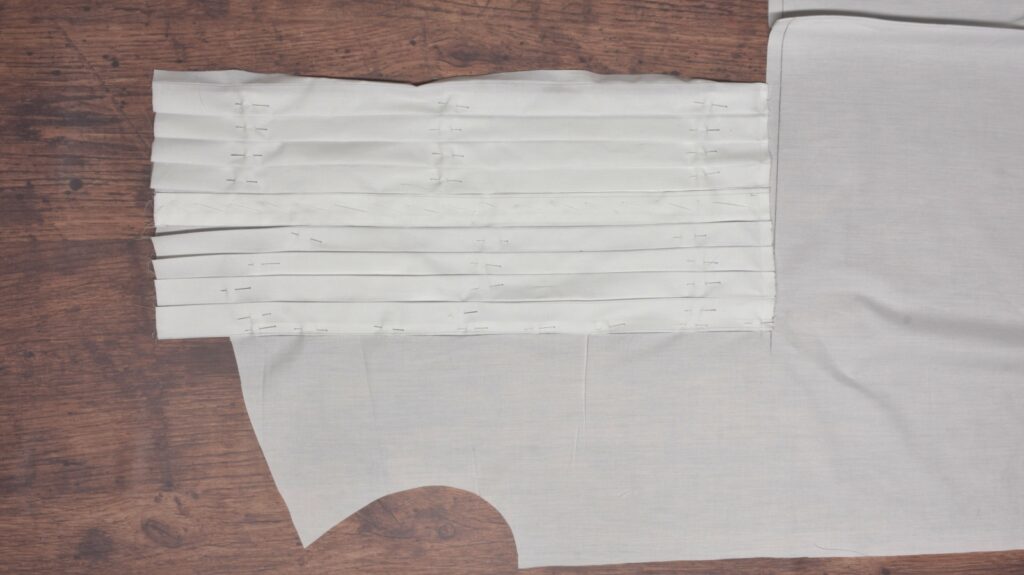

Continue the same process for the other pleats, pressing every second line, folding it into position, and pinning.

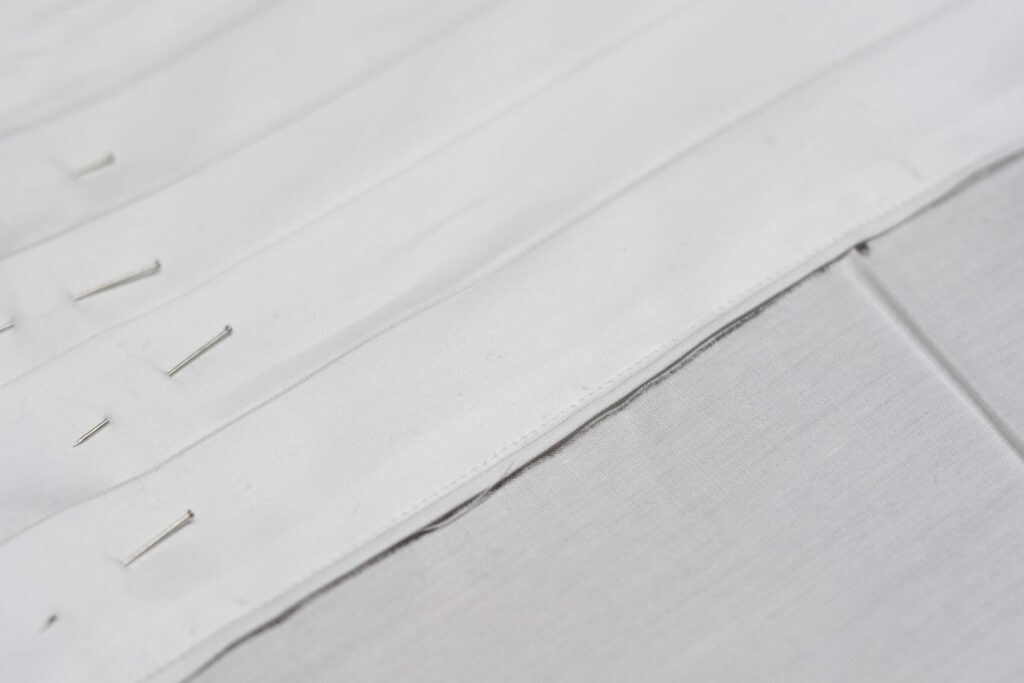

Next, fold over the remaining line to form the outer edge of the pleated front. The seam allowance folded underneath should be 1/2″ and this folded edge will later be sewn (felled) down to the shirt front.

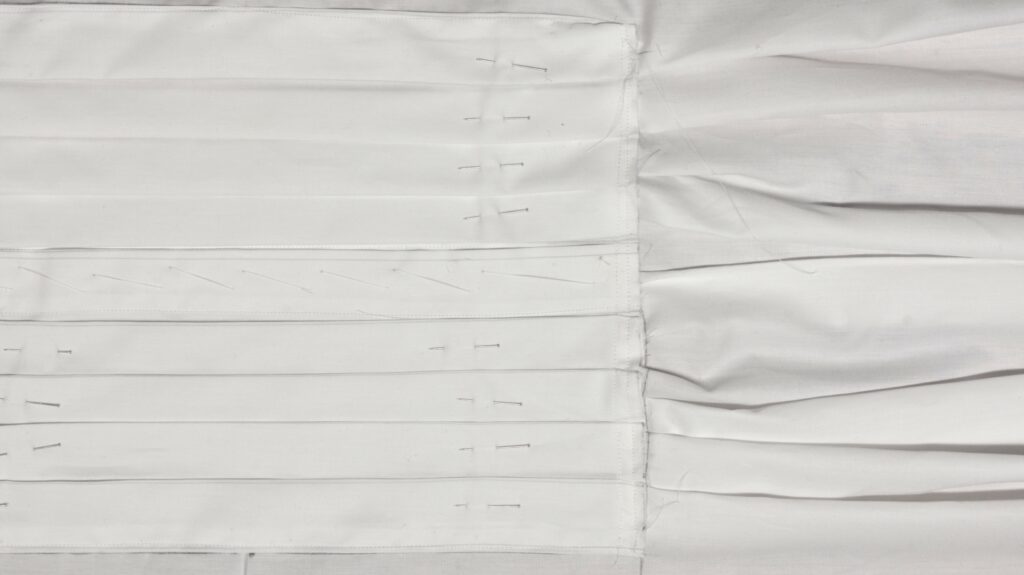

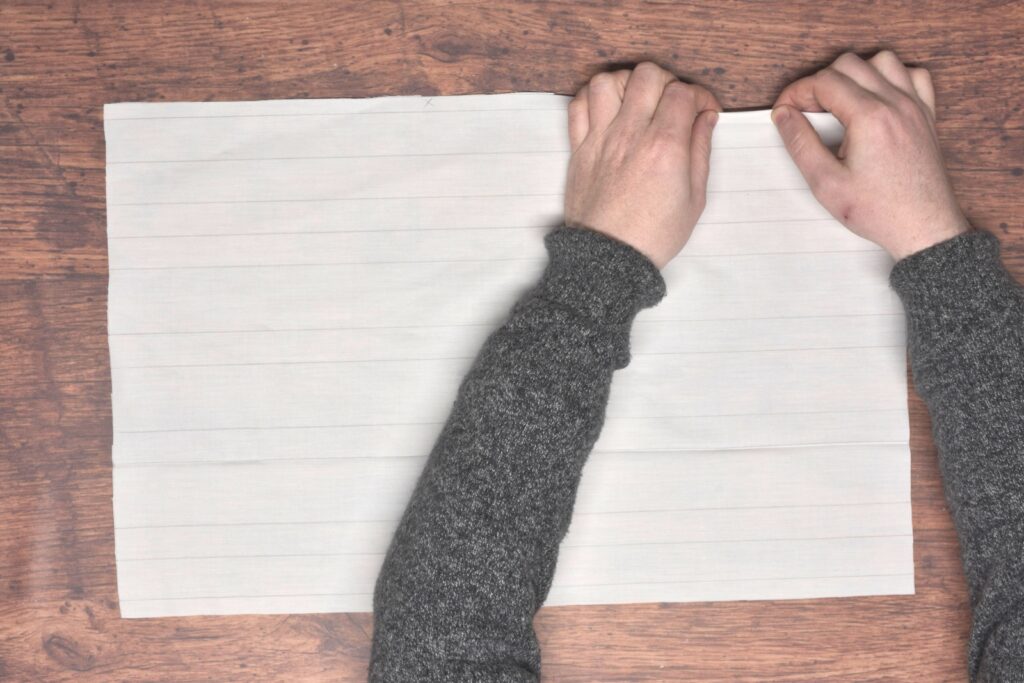

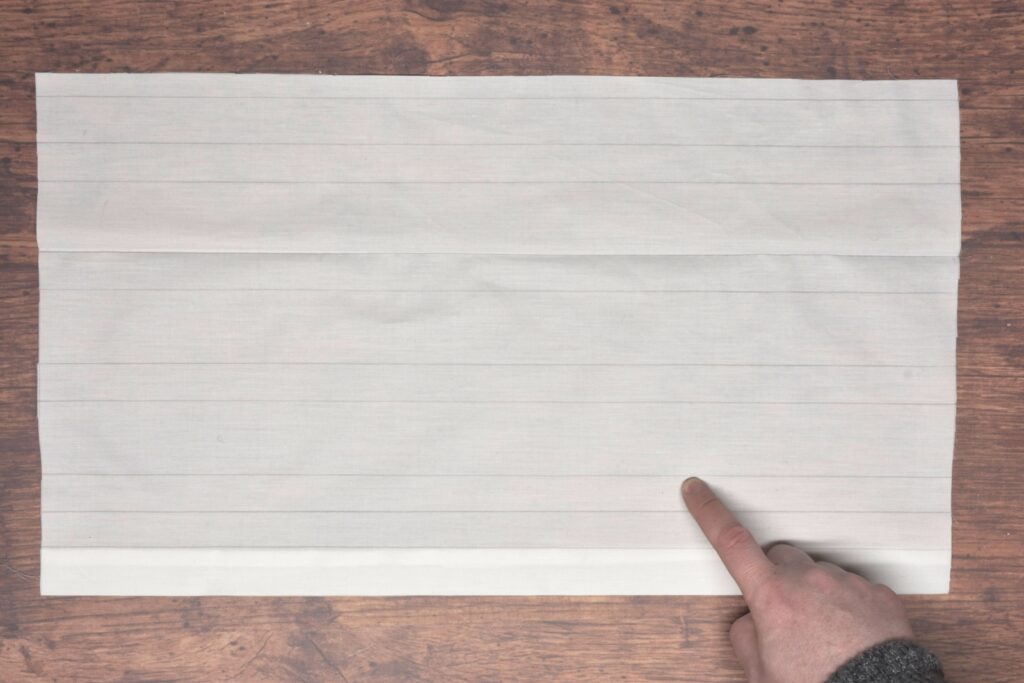

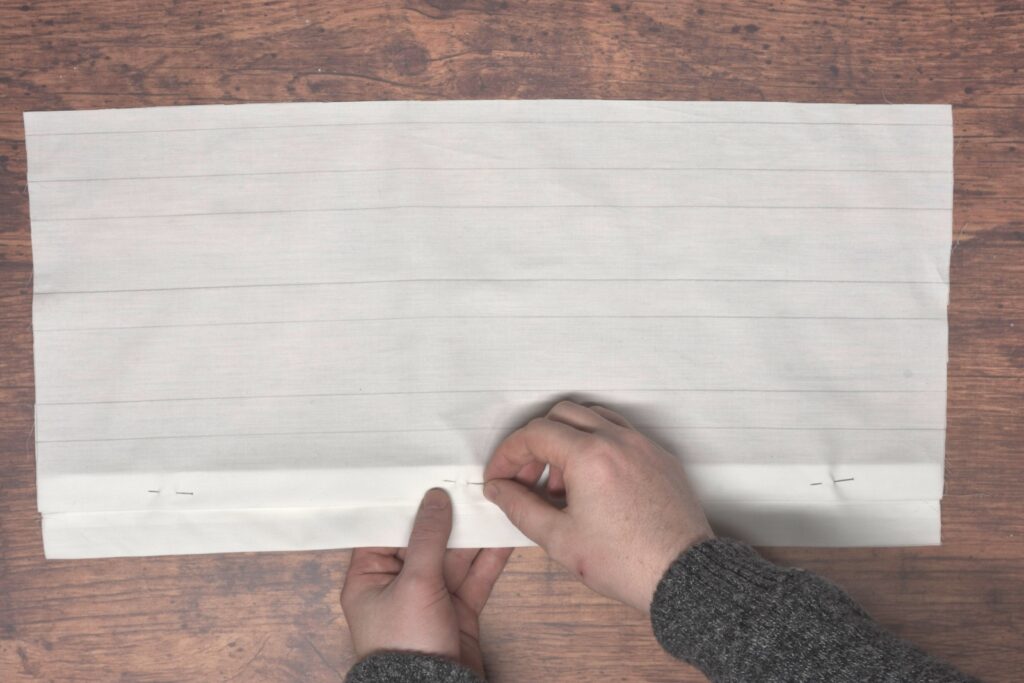

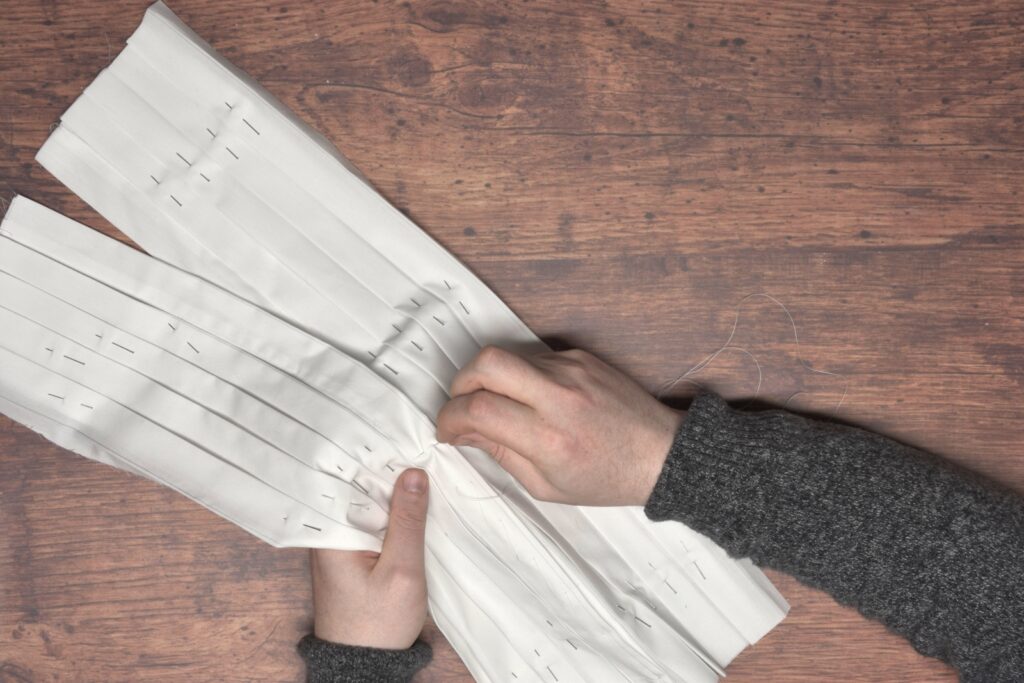

Here’s one completed half of the pleated front. I like to give everything a firm press at this point.

You can check your accuracy by laying one half of the pleated front directly on the pattern. I was surprised at how accurate mine was, from my past experiences. If you’re more than about 1/4″ off I’d recommend redoing the pleats and checking your work carefully.

(Note: I cut out the pleated section from my shirt front pattern. Don’t worry about doing this yet, it will be explained in the next section.)

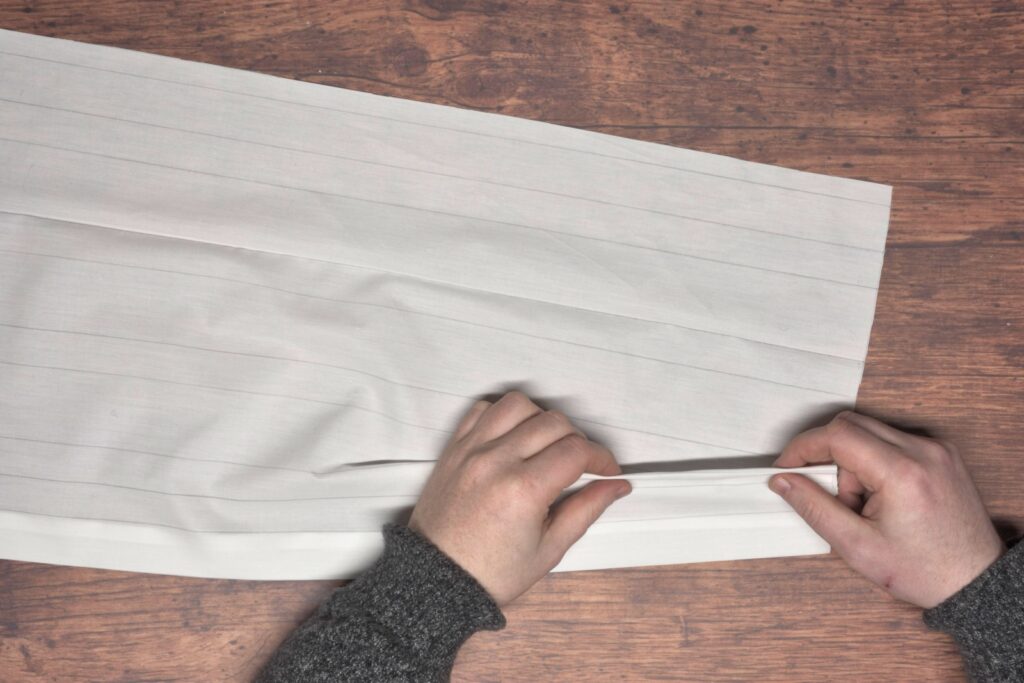

With both halves complete, lay them together, left side on top (Oops, I just realized I did mine backwards!).

Baste the two halves together along the center front placket by hand. These stitches will stay in the shirt for most of the construction just to make things a little easier to work with.

Orienting the pleated front so that the left side is on top, square off the bottom of the pleats with a line.

Sew a line about 1/4″ – 1/2″ above this line just to keep everything in place. Be careful while sewing as it’s easy for the pleats to be moved around by the presser foot.

Now trim the bottoms of the pleats with the line you drew square across.

This completes the construction of the pleated front! With a bit of practice you should be able to get it down to about ten minutes per side (not counting any hand stitching).

Your Progress

[columns gutter=”0″]

[col]

1 | Form the pleated front. |

[/col]

[col align_text=”center, middle”]

[/col]

[/columns]

Waistband with Watch Pocket II

With the waistband and pocket facings all basted into position, we can begin to sew everything down permanently. Begin by sewing the pocket bag to the trouser front using a 1/4″ seam allowance, beginning and ending precisely at the pocket opening marks. Be sure to keep the side seam pocket bag out of the way by folding it back.

Sew the pocket facing to the waistband in the same manner, using a 1/4″ seam allowance, keeping between the pocket opening marks. The stitching ends should line up as close as possible to those of the pocket bag.

Remove the basting stitches from the facing and pocket bag. You should end up with something similar to this.

Now sew the waistband with a 1/4″ seam allowance from the back of the trouser, to the third mark you made earlier.

Remove (for the last time!) the basting stitches holding the pocket in place.

Fold the side seam pocket out of the way. Baste down the waistband again if necessary.

Carefully sew the waistband to the trouser front from the rear pocket opening to that third mark (it’s just an inch or so), or as close as you can to the folded back pocket edge without actually catching it in the stitches.

Just before sewing, be sure to move the seam allowances of the pocket facing and bag out of the way. We don’t want them caught in the seam at all.

Ideally, the stitches should meet at the pocket opening mark. It turns out my seam allowance was slightly off when sewing on the pocket bag, so they met about 1/8″ apart. I’ll be able to make it work, but it’s not ideal.

Finally, sew the front end of the waistband using a 1/4″ seam allowance from the front pocket opening to the front edge of the waist. Be sure to move the seam allowance of the pocket out of the way again.

The seams lined up much better this time!

Here you can see how I’ve kept the 1/2″ seam allowances of the pocket bag and facing out of the waistband stitching.

You can see how I sew the waistband straight across the button catch rather than following the slight upward angle. It seems to align with the other half of the waistband just a bit better.

Pressing

With the wrong side of the trousers facing up, lifting the pocket so that the linen is exposed, clip the seam allowance of the trouser and linen pocket stay to the end of the stitch lines.

Press open the pocket bag seam as shown.

Now flip the pocket down into position, and press open the pocket facing seam.

Flip to the outside and press the inner pocket facing seam from the right side. It’s not really worth pressing the outside seam yet as the exact crease line has yet to be determined accurately.

Finally, press the remaining parts of the waistband seam up towards the waist as you did for the other waistband. This will enclose all the raw edges and make the seam stronger.

Waistband with Watch Pocket I

Adding a watch pocket to a waistband (usually on the right side) is not too difficult, but is somewhat involved with a lot of steps, so I will break the watch pocket into three sections. This first section will go over basting the pocket facings and waistband into place.

I’m adding this pocket to the trousers with side seam pockets. If you want one to trousers with the open top pockets, I’d suggest making a sample of each and then figuring out how best to combine them. I’ll try to add a tutorial for that combination sometime.

Besides the waistband, you’ll need the following pieces to construct a watch pocket. I like to make mine 3 1/2″ wide when finished, so all pieces should be cut 1″ wider, to give a 1/2″ seam allowance on either side. So for the pieces:

- 1 pocket facing 4 1/2″ x 1 1/4″

- 1 linen stay, 4 1/2″ x 1″

- 2 pocket bags, polished cotton 4 1/2″ x 4 1/2″

- 1 length of 1/4″ stay tape (not pictured) 4 1/2″

- Waistband

The pocket placement must first be marked – there are three marks total. The first two indicate the position of the pocket and are spaced 3 1/2″ apart (indicated by the two marks coming from the left). I like to place my pocket just in front of the hip bone so there is no interference. To the right (or towards the side seam, in other words), make a third mark an inch or two away from the pocket. You’ll be basting and sewing to this third mark, so it is fairly important.

Flipping to the wrong side, remove the basting stitches holding the pocket in place from the mark to the inside folded edge. Reinforce the basting at the mark with a couple of stitches in place if necessary.

Baste the linen pocket stay in place on the wrong side along the waist seam, flipping the pocket out of the way. Be sure to align it properly with 1/2″ allowance on either side of the pocket opening marks.

Baste the pocket back in place from the third mark to the edge of the pocket, keeping the stitches at least 1/2″ from the edge to give you some room to work with.

Baste the waistband into position in the same manner as the pocketless waistband, again keeping the stitches about 1/2″ from the edge. However, stop your stitching at the third mark, make a couple of stitches in place, and start a new thread to continue the rest of the basting.

I’m pointing here to the position of the third chalk mark, where I’ve started and stopped my basting stitches. This is so we can move and manipulate the pocket bag underneath without the entire waistband falling off.

If you made the side seam pockets earlier, this method will look very similar. Open up the waistband seam, exposing the right sides in between the layers. Transfer and mark the pocket openings on all pieces if you haven’t already.

With right sides together, place the pocket facing into position on the waistband. Be sure that 1/2″ allowance extends beyond the pocket opening marks on both sides.

Baste the pocket facing into position with a straight basting stitch, keeping the stitching out of where the seam will be sewn (1/4″ from the edge).

So far, you have the pocket facing basted right sides together to the waistband.

Now fold the pocket facing and waistband out of the way, exposing the right side of the trouser front underneath.

Place the pocket bag into position, right sides together with the trouser front, aligning it as you did the facing.

Holding the pocket bag half in position, fold the top of the side seam pocket that’s underneath out of the way.

Baste the pocket bag half to the trouser front, being sure not to catch the pocket that’s underneath. Mark the pocket openings.

This completes the basting process for the waistband and pocket facings. If you open yours up it should hopefully look similar to mine!

Attaching the Waistbands

Finally, it’s time to attach the waistbands, which close up the top of the pockets, in a sense completing them. If you are planning to insert a watch pocket on one side, please see the next section on attaching the waistband with a watch pocket.

Lay the waistband, wide end at the front of the trousers, right sides together. There should be two or three inches of extra fabric at either end to turn back later on. Baste securely.

As you get to the center of the waistband at the side seam, you’ll have to full in a little excess of the waistband fabric to help it get around the curved seam.

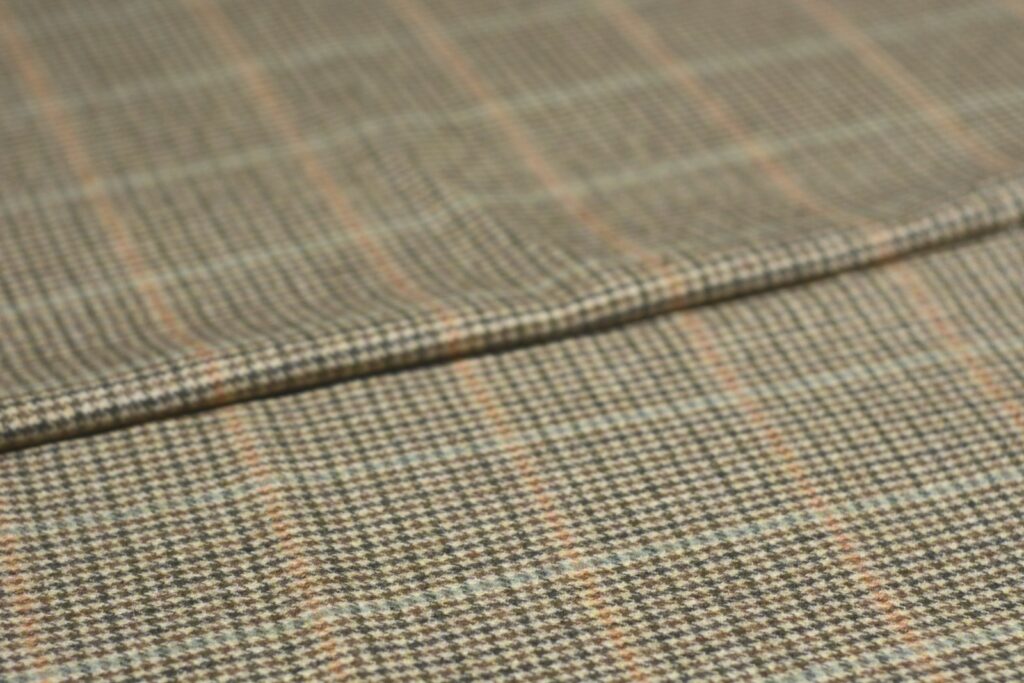

As you baste, check to make sure that the stripes are aligned between the waistband and the front of the trousers. As you get to the back of the trousers, it becomes impossible to match the stripes due to the angle of the cut.

From the underside, make sure the basting stitches catch the pockets and all layers, and that everything lays flat.

Sew the waistband seam through all layers with a 1/4″ seam allowance from end to end of the trousers.

Now, when you get to the end of the waistband at the button catch side, I like to go straight across with my stitching rather than following the slight upward angle of the button catch. It seems to give a better fit with the left side of the trousers.

Press the waistband up. The seam itself is not opened, rather the seam allowance and the waistband should both be pressed towards the top of the trousers.

Around the side seam area I like to use a tailor’s ham since there is usually a bit of excess fabric here.

A final view of the underside showing the seam allowance pressed towards the waistband. This gives the strongest possible seam to the waistband.

The Side Seam

It’s now time to attach the trouser fronts to the backs. Lay out the front on the table, and lay the back over the top, right sides together.

Now pin the very top of the side seam at the waist, ensuring that when we baste the side seam, the tops will be aligned properly.

Now, starting from the bottom hem, baste to the position of the knee (you can be precise about this and lay it out on the pattern, or just estimate).

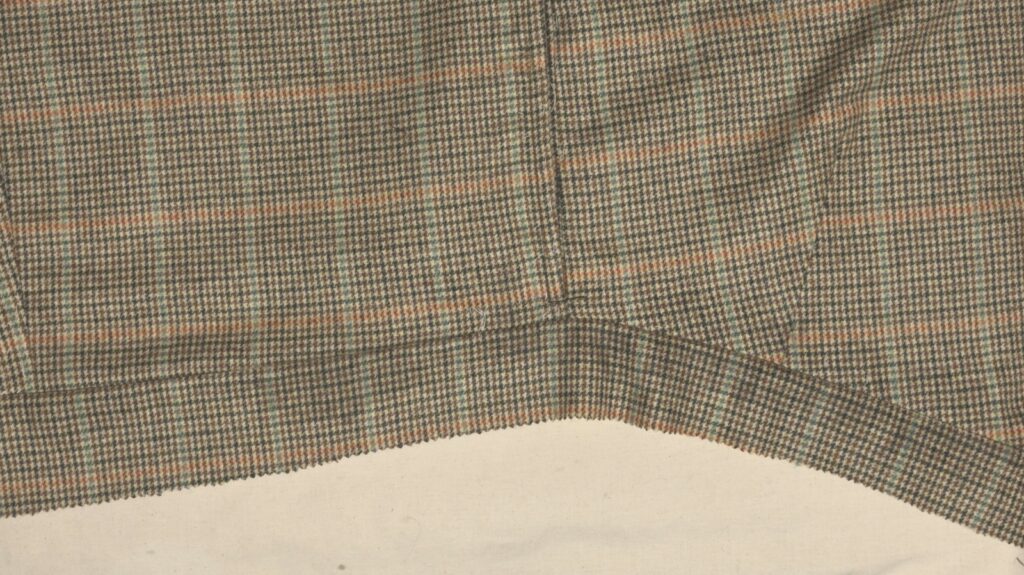

Be sure to match the plaids as you’re going, if necessary.

Now baste from the knee to the waist, positioning the trousers so that the back piece is underneath and in an orientation that is most comfortable for your you.

As you’re basting, you’ll notice that the underside has a bit more fabric than the top side. This needs to be distributed evenly, moreso around the pocket opening, with the remaining excess distributed just below the pocket and tapering off to an even tension by the time you get to the knee.

When you get to the pocket, baste through all layers, ensuring the pocket notch is properly aligned 1/4″ from the edge.

It’s a good time to check how the plaids are aligned, and if necessary, redo them. Really depends upon how fussy you want to get. Also check that the pocket is properly aligned.

When you’re happy with how everything looks, sew the side seam using a 1/4″ seam allowance. Take care near the pocket area, as the presser foot has a tendency to skew off course due to all of the layers.

Remove the basting stitches, open the seam up, and press.

My plaids got slightly out of alignment here, alas. Hopefully yours turn out better!