Category: Selvedge Jeans

Sewing Machine Tips

Before getting started with sewing the jeans I just wanted to share a few tips I’ve learned along the way regarding sewing machine needles, tension, and a test to make sure your machine can handle the modern construction methods (disregard if you’re doing the 1873 jeans).

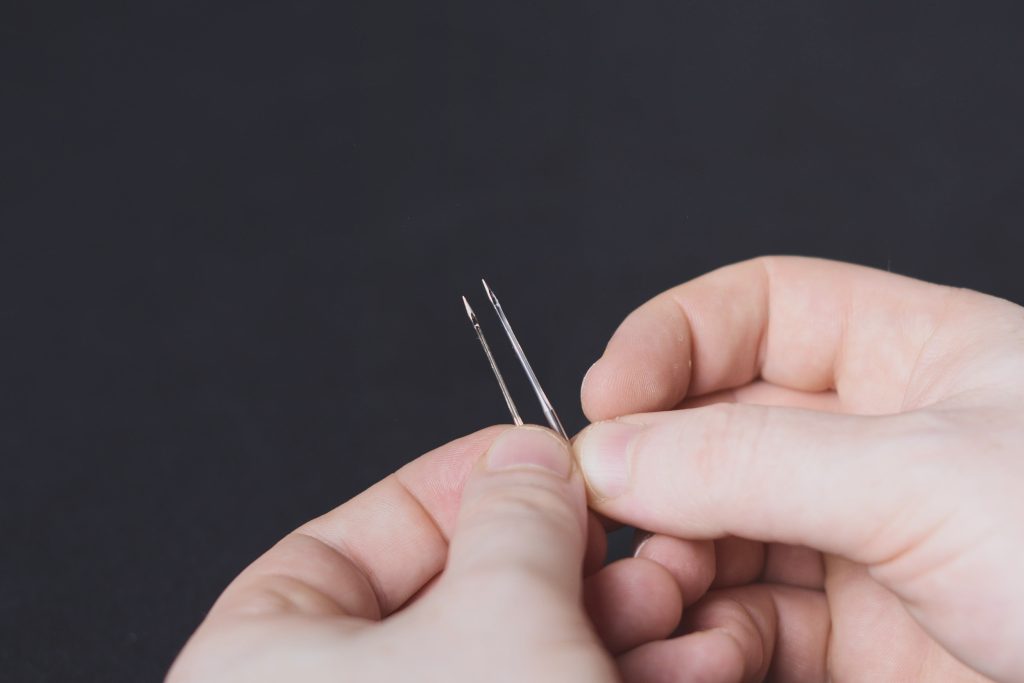

Needles

First, choose the largest needle for your machine you can find. On the left is a size 110/80 heavy duty needle which I’m pretty sure is the largest size you can get for a regular home sewing machine. The needle on the right is a size 130/21 industrial sewing machine needle, which you can see is much thicker and stronger looking. Both have a groove along the back side to allow the thread to more easily enter the fabric without breaking.

I’ve done the modern construction jeans on a home machine (Singer 201-2) but it was definitely a struggle in parts, most especially the seam intersections at the yoke and the crotch areas. But as long as you are using a denim below around 12oz and are prepared to struggle with your machine a little, you should be able to manage. Anything higher in weight you’re going to need an industrial machine at least for the modern construction method.

Thread

Here’s the thread I’ll be using, a 100% cotton thread. The thinner thread is a #30 and is used for the bobbin thread to help reduce friction, while the slightly thicker #20 thread is used for the upper thread in the machine. If you’re using something like a Gutermann polyester jeans thread, just go ahead and use the same thread both for the upper and bobbin.

It’s hard to see but you can definitely feel a difference in thickness and weight between the two threads.

If you have trouble threading the needle (I sure did!), just wax the end of it with a bit of beeswax to consolidate the fibers.

Bobbin Tension

People tend to be afraid to adjust their lower bobbin tension, but I’m afraid it’s a necessity when working with the denim and thicker threads. You’ll have to figure out what works best for your machine, but generally, you want the bobbin thread to move freely out of the bobbin casing, and for the bobbin casing to drop a little when you let it fall from your hand when holding the thread.

To adjust the bobbin tension, just turn the tension screw very slightly 1/4 turn at most in the direction needed – most likely counter clockwise to loosen it. The danger really comes when you start unscrewing it too much – the spring will shoot the tiny screw into the far corners of your sewing room never to be seen again. So just take care!

You’ll also want to adjust your upper tension to match the lower. I find that after getting familiar with a sewing machine you can almost do this by feel, followed by some testing with scrap fabrics to dial the tension in perfectly.

Testing Your Machine

For those doing the modern construction method, I’d highly recommend following the quick tutorial below to ensure your machine can handle sewing through the 16 layers of the yoke and crotch junctions. For the 1873 jeans, I’d do something similar but you only have to get through 9 layers I believe.

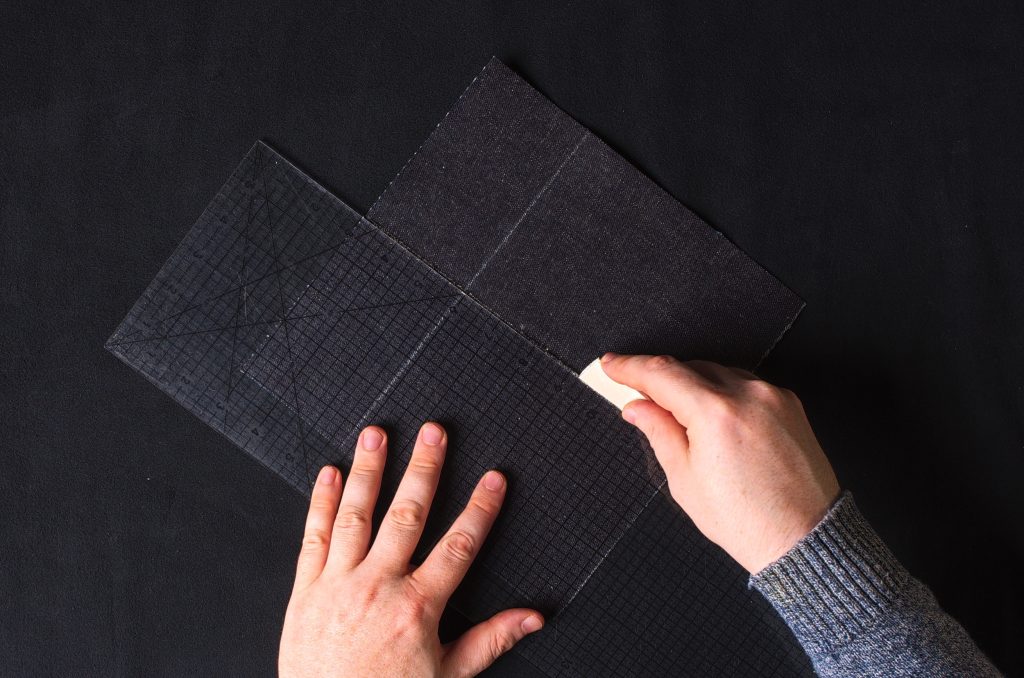

First, take a square of scrap denim and draw a line down the center (ignore the other line please).

Cut the piece in half along this line.

Mark a 3/8″ seam along one side of the pieces you just cut.

Align both pieces, right side up, the left overlapping the right side, with the raw edge against the chalk line.

Sew along the length of the seam, keeping the stitches centered between the overlapped area as best you can.

Now fold the denim piece in half, wrong sides together along the the cut edge underneath. You’ll have to go by feel here to get it just right. The press firmly.

Fold the top layer of denim back, again aligning the fold with the cut layer underneath, and press.

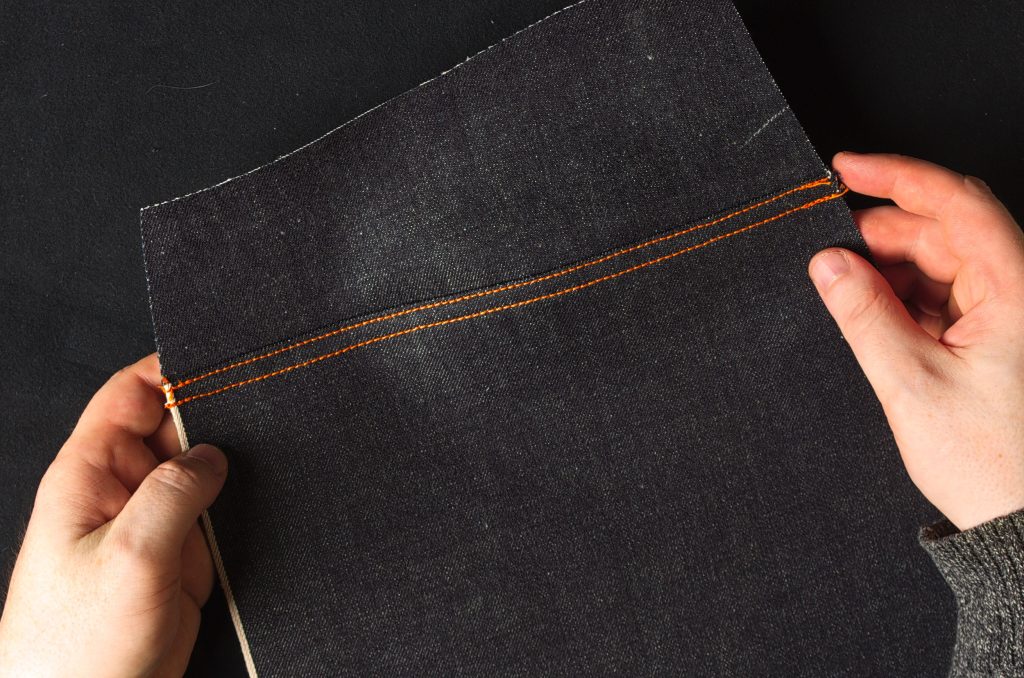

Top stitch through all layers about just under 1/8″ from the edge. You’ll have to determine the exact spacing you want to use and make that consistent throughout your project.

Sew a second row of top stitching, just under 3/8″ from the first row. You’ll want to make sure you’re still catching all of the layers underneath – it’s very easy to slip off and not realize it.

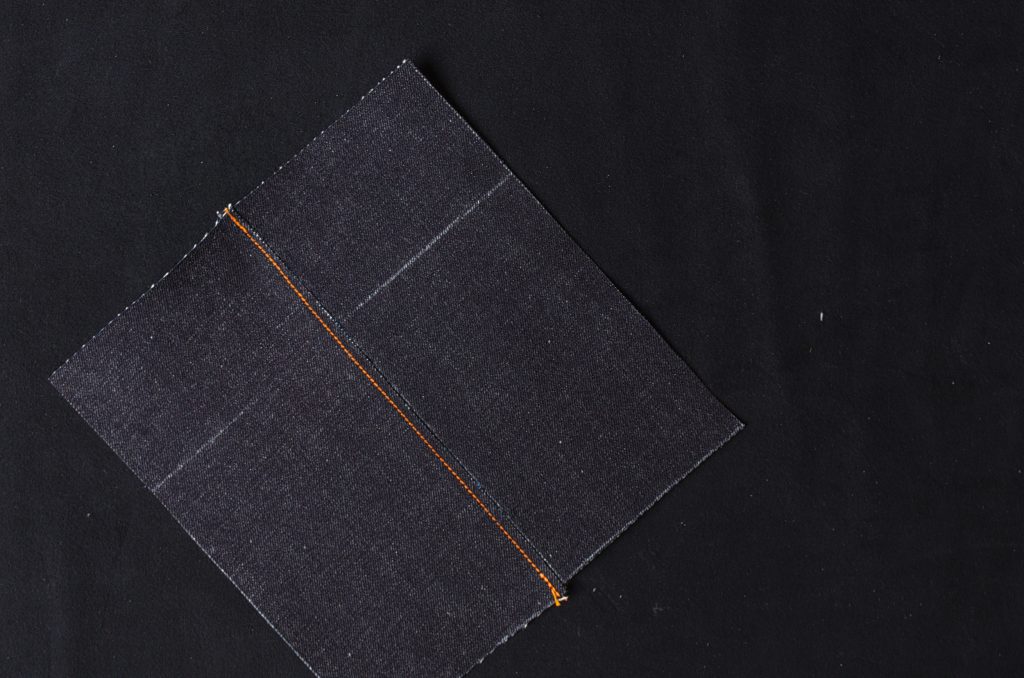

And here’s the work so far. As you’re going, be constantly checking and fine tuning your tension. This is the place to experiment.

Second Seam

We’re basically going to repeat the process now. Cut the piece in half again, perpendicular to the seam.

Add the seam 3/8″ seam allowance again to one piece.

Sew the two halves together, right sides up, aligning the pieces as before. When you get to the junction of the seams, I recommend using the seam jumper here to get a better stitch quality. Place it under the foot just as you get to the junction.

Sew over most of the junction, then move the seam jumper to the other side to ease the transition.

Here’s the seam so far.

Press the seam as before, only this time you’re dealing with 12 and then 16 layers. It gets pretty thick!

If you have one, I like to use my 16 pound goose iron here after heating and steaming with the regular iron. The extra weight really helps.

Open the piece up, folding along the remaining seam to get the full 16 layers in the middle.

Press with your fingers to keep everything in place.

Then move in with the steam iron and the goose to really get that thick junction to stay in place.

Then place the seam over a block of wood and gently but firmly hammer the seam junction to really flatten it. It helps if the area is still hot from the iron.

The seam after pressing.

Finally, go and top stitch in the same manner as before, first about 1/8″ from the edge.

Definitely use the seam jumper here at the junction. If your machine can make it through these 16 layers, breathe a sigh of relief – you’ve made it! I’m using 14oz denim here which proved to be too much for my Singer 201 to handle, hence having to go out and buy the industrial Juki machine. But don’t do that unless you plan to sew professionally.

Here are my seams after sewing. You can see a little unevenness in my stitching, I think from not putting the seam jumper in place at the right moment. And one of the stitches is a little longer than the others. You’ll probably notice some similar issues with your own work, but it really is a matter of practice to truly master this type of thing.

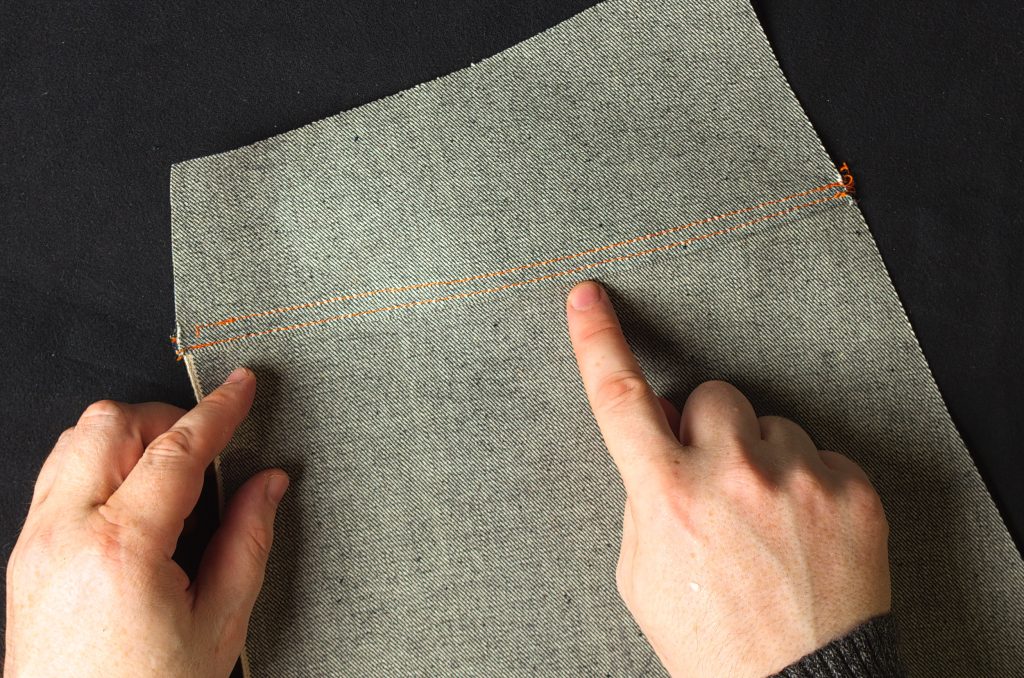

Turning over to the back, my stitches seem a little too far away from the folded seam. This again is a matter of getting a feel for the material you’re working with. Also beware of going off the edge as you’re top stitching. You’ll have to take out the seam and try again if that happens, at least with the actual jeans construction.

If you’re happy with the results here, you can move on to sewing your jeans with confidence!

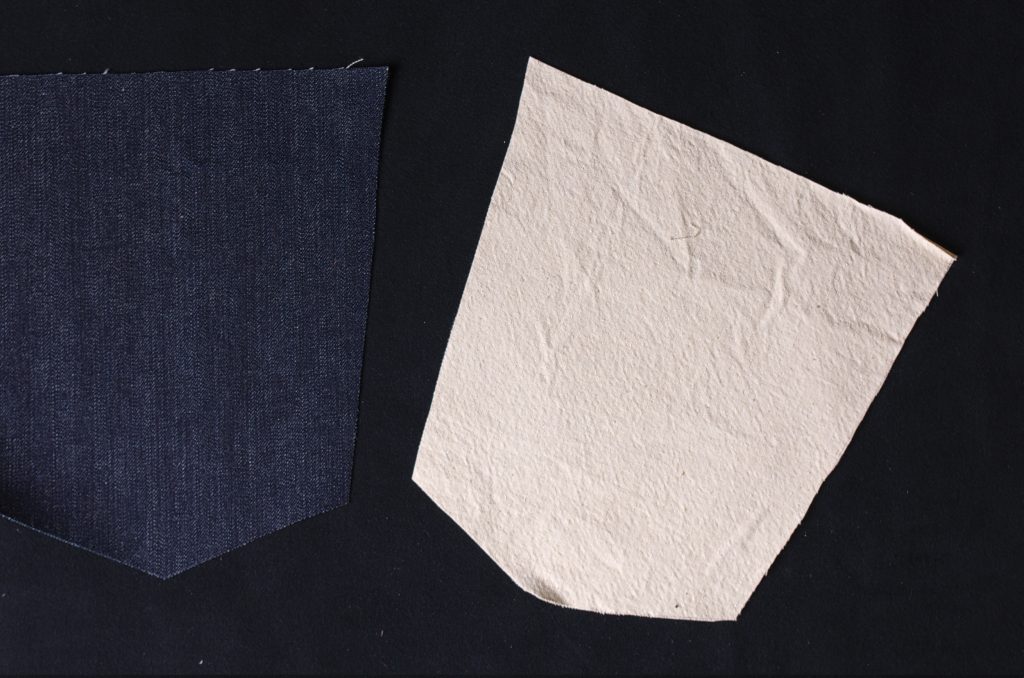

The Back Pockets

Moving on to the back pockets, you’ll need a single pocket and optional lining for the 1873 pair, and two of each for the modern jeans. It’s possible the 1873 jeans used a pocket lining, but it’s not visible from any of the videos or images I’ve seen. I like to include it for additional strength but feel free to leave yours out if you prefer.

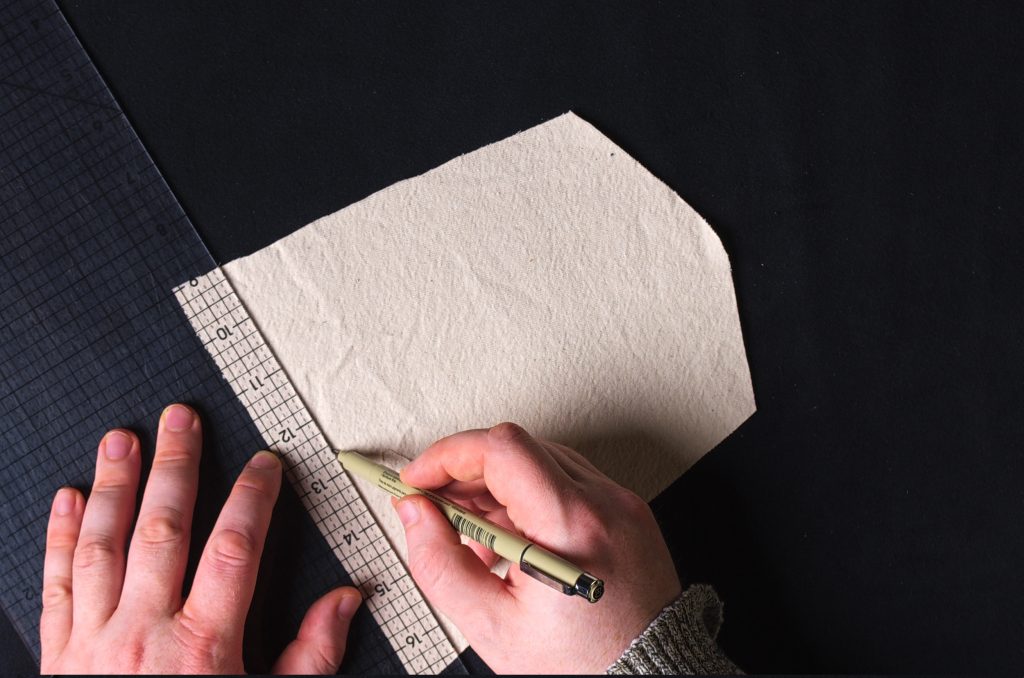

First, mark out a 7/8″ along the top of the pocket lining. Note I’m using a pen here for clarity but I’d recommend a sharp pencil for this.

Then mark out 1/2″ seam allowances around the sides and bottom of the pocket. We’re using 1/2″ here rather than the 3/8″ seam allowance to ensure the pocket seam allowances will turn under cleanly.

Trim away the seam allowances from the pocket lining.

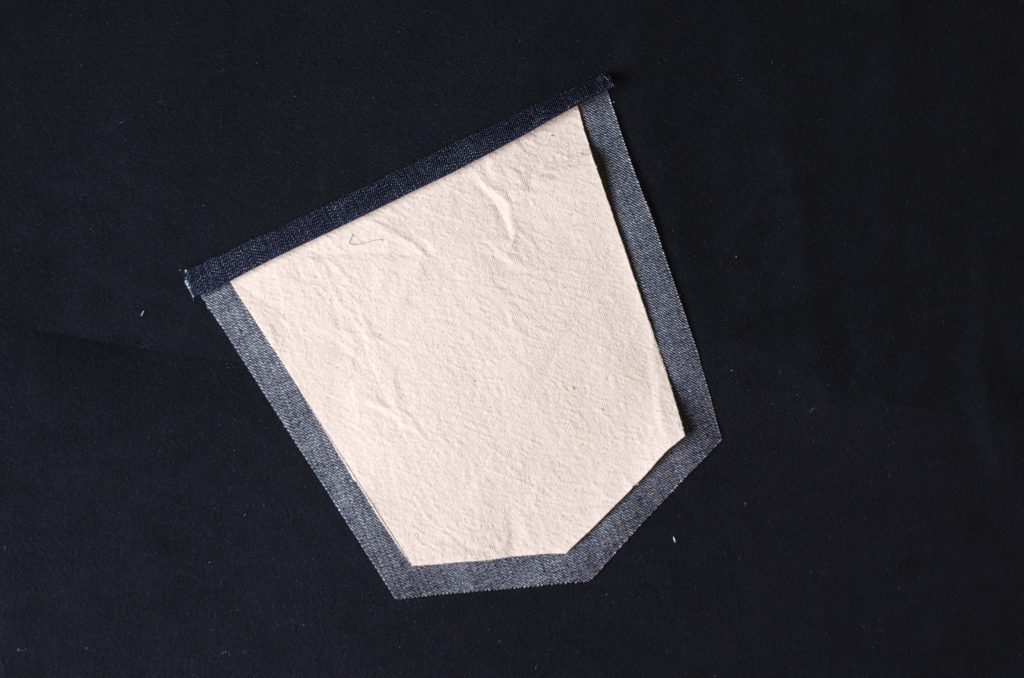

Here’s how the lining should fit on the wrong side of the pocket after trimming.

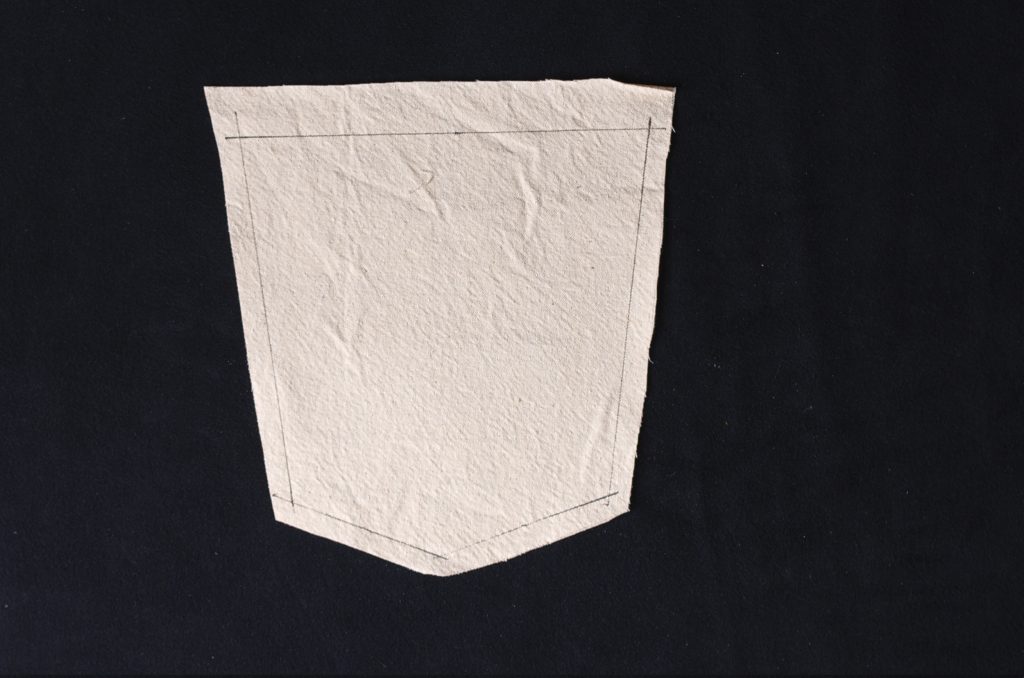

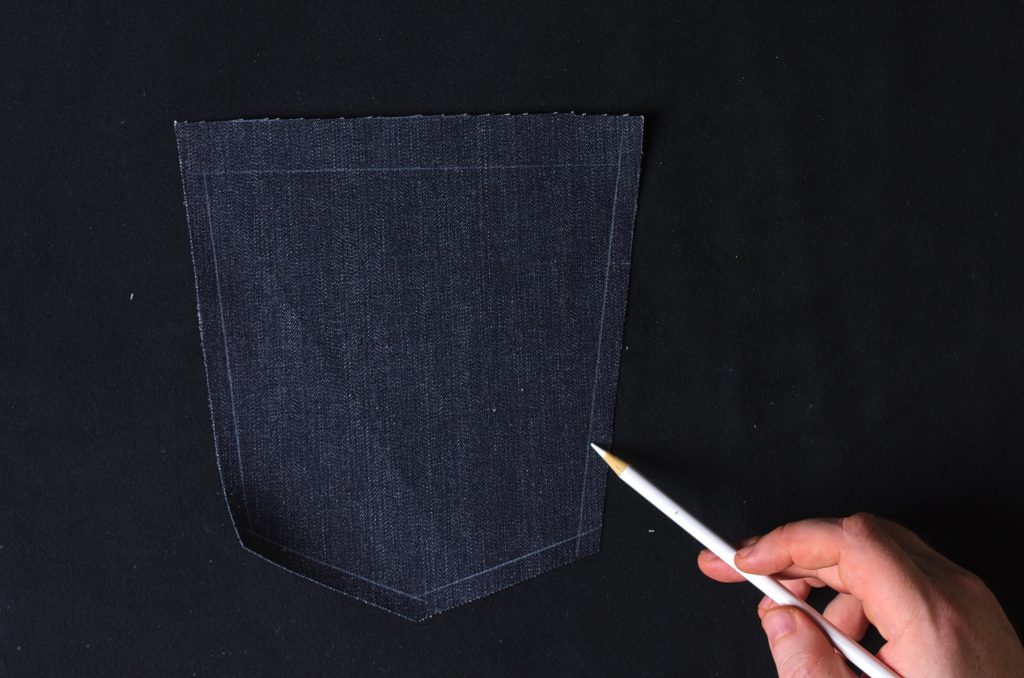

On the right side of the pocket, trace out the seam lines in a similar manner, only this time using 7/8″ along the top and 3/8″ along the sides and bottom. I like to use a colored pencil here for more precise work.

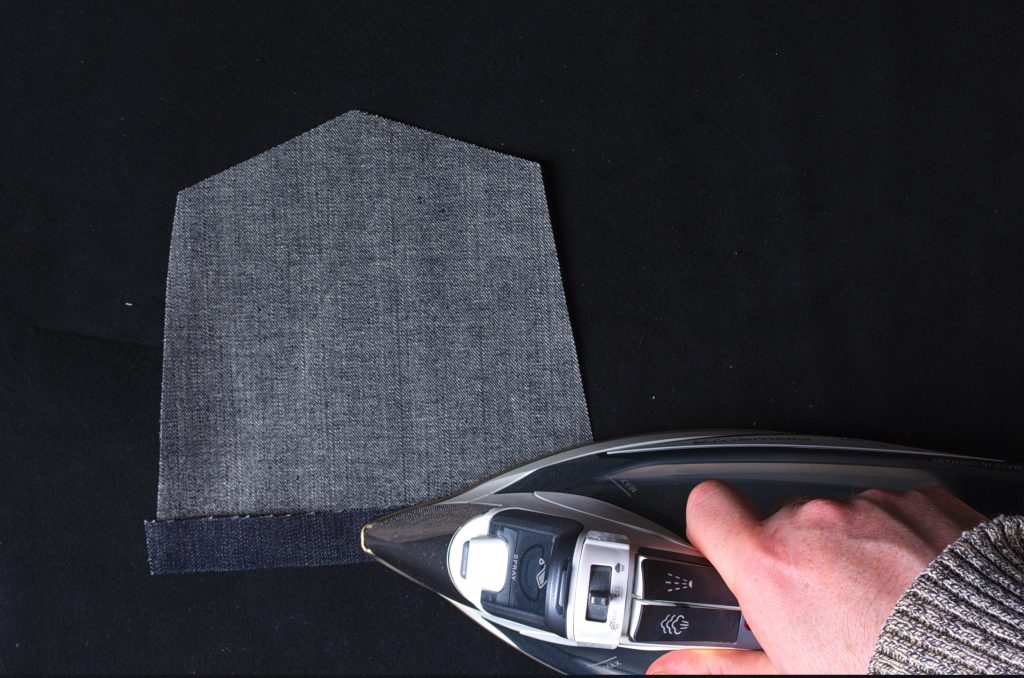

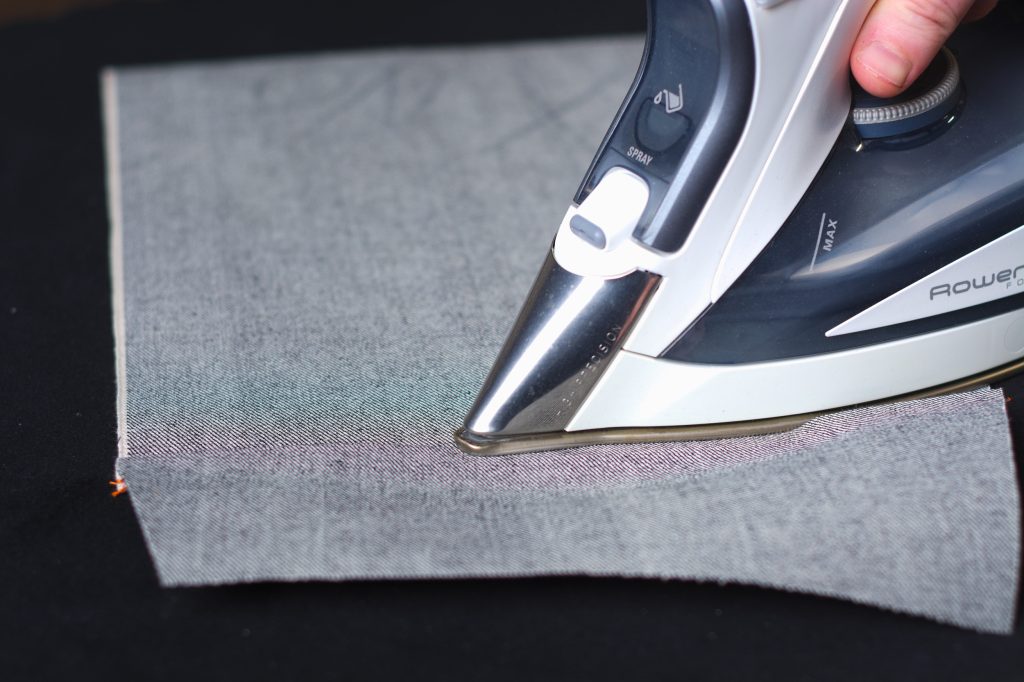

Working from the wrong side, press the top edge over along the seam line.

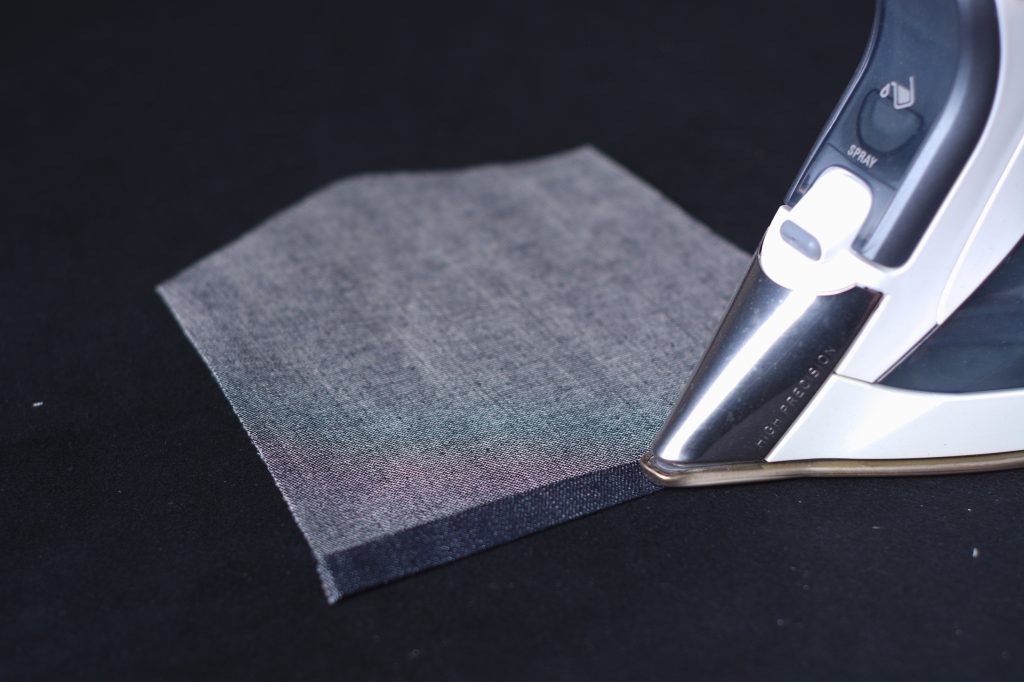

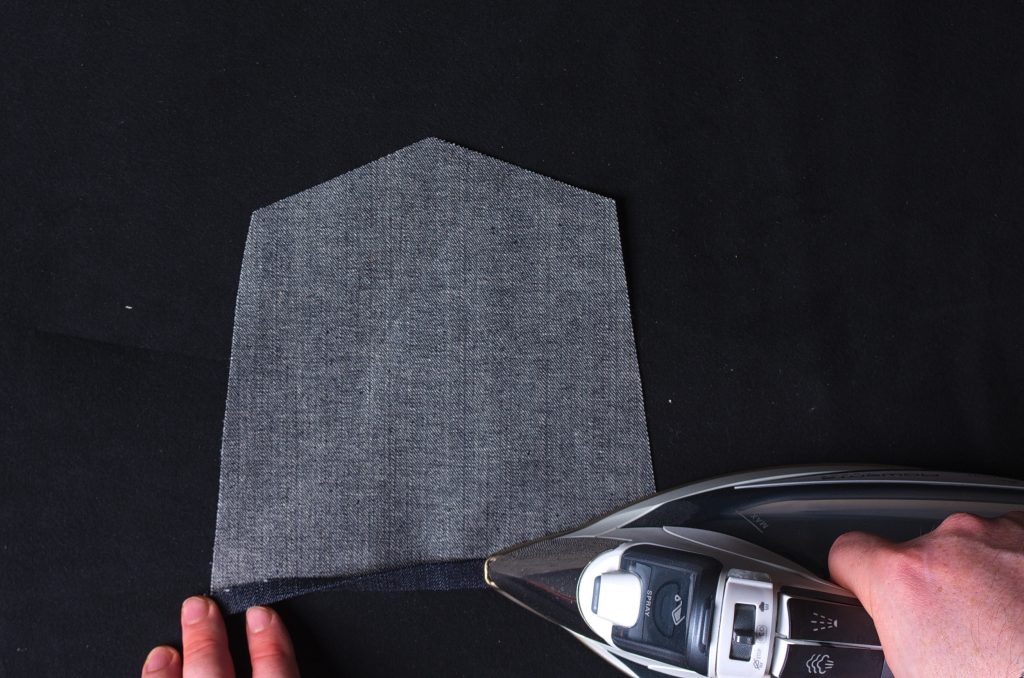

Tuck the raw edge under forming a nice finished 3/8″ seam (slightly over is fine), and press.

Here’s where you’d add in any arcuates or patterns to the back. I’ll be adding an entire lesson on that in the future, but for now I’m just going to stick with a basic line roughly centered across the pocket.

Again, I did not see these in the original 1873 pair, they seem to have been added a few years later, but I’m including them in my reproduction just for strength of the pocket.

For modern pairs, feel free to go as simple or as complex with your designs as you’d like.

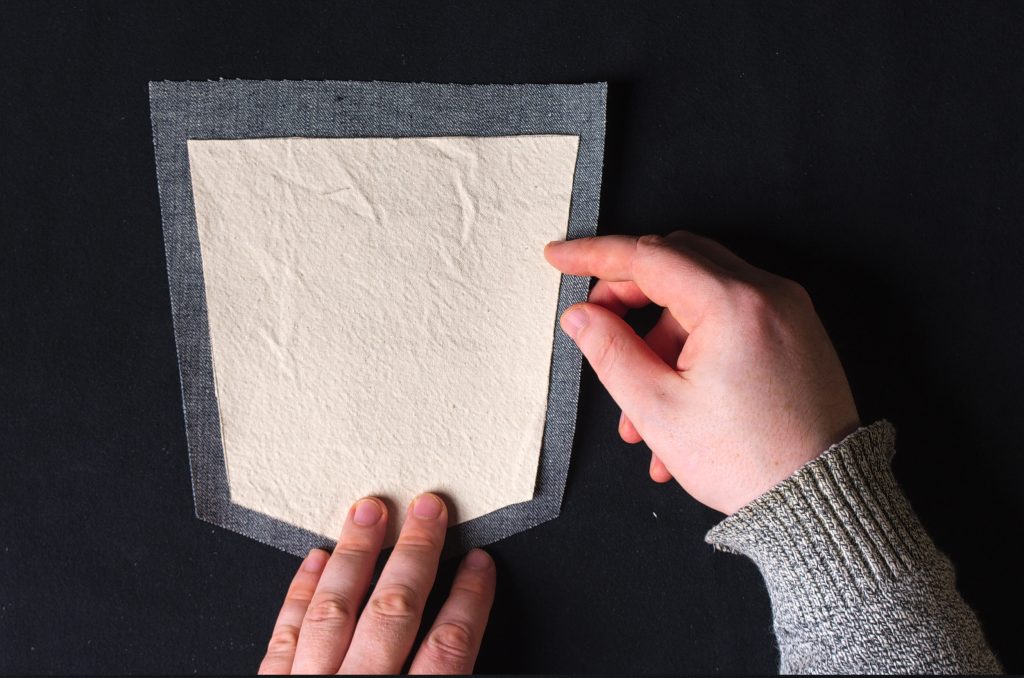

Center your lining on the wrong side of the pocket, tucking it closely under the top seam.

Stitch your arcuate from edge to edge, beginning and ending your stitching in the seam allowances.

Here’s my pocket after stitching. I used a thin, matching thread to keep it subtle for the 1873 pair, but feel free to be as bold as you’d like here.

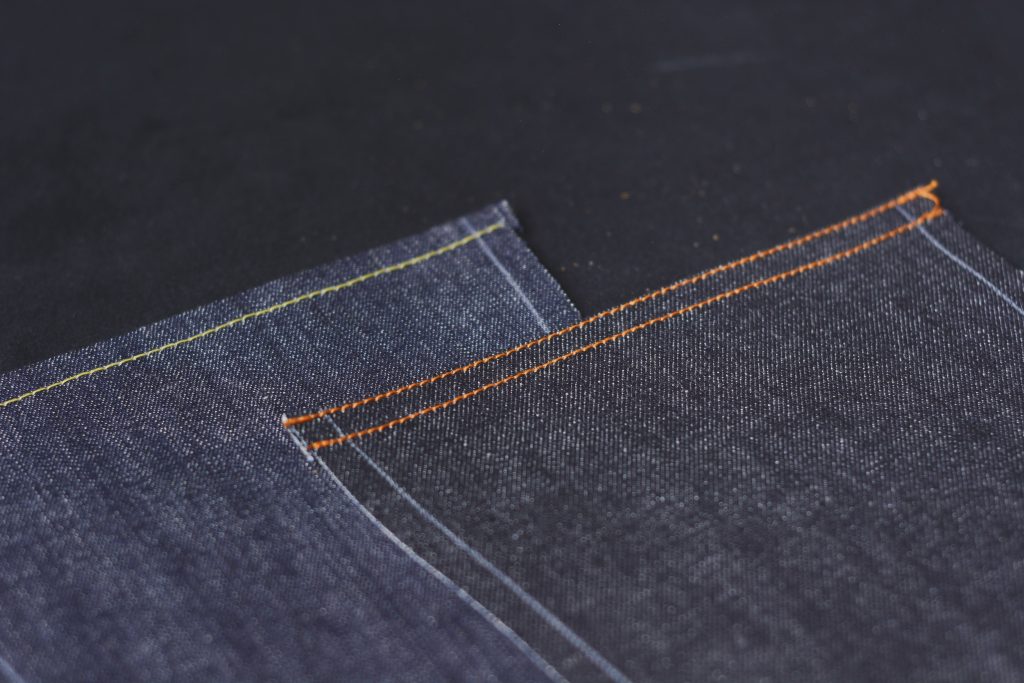

Now stitch across the top of the pocket, 3/8″ from the edge if making the 1873 jeans.

For the more modern jeans, two rows of stitching are used, the first about 1/8″ from the edge, the second about 1/4″ to 3/8″ from the first row of stitching. Try to match the spacing you used for the yoke seam.

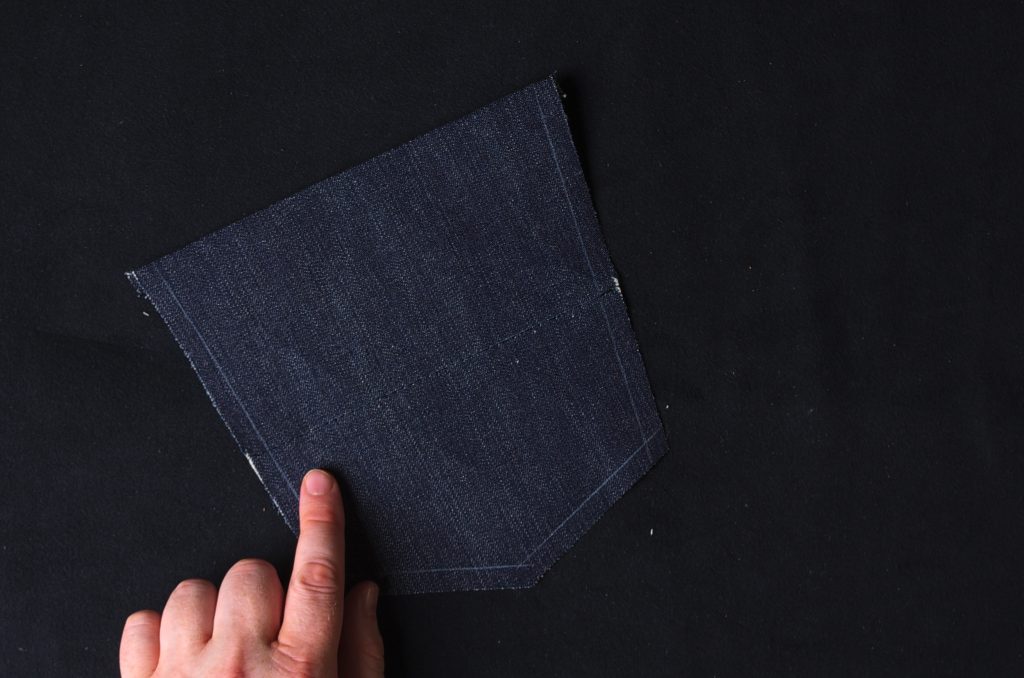

Here’s the wrong side after top stitching.

Now firmly press the sides and bottom edges of the pocket towards the wrong side, following the lines you drew in as closely as possible.

If you did not line your pocket you’ll end up with something like this.

After pressing, you’ll notice this little bit of fabric poking out from the top edge due to the angles of the pocket. You could trim this slightly (don’t trim too close to the folded edge or the pocket will come undone!), fold it under, which may make it difficult to sew through all the layers, or just tuck it under after top stitching the pockets in the next section, which is what I chose to do.

Here’s how you might trim the seam allowance. I’d recommend doing this after the first row of top stitching though in the next section.

The Back Yoke – Modern

This is the construction method for the modern style jeans with flat-felled seams. Be sure your machine can handle up to 16 layers of denim before moving on with this method.

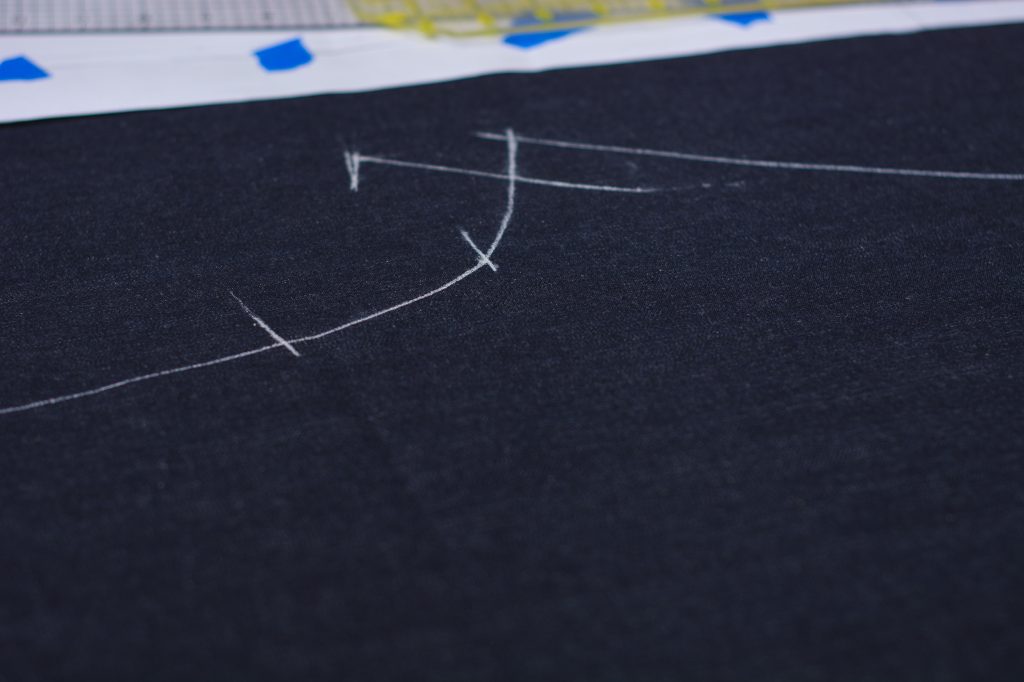

First, along the bottom of the yoke, draw in the 3/8″ seam allowance.

Moving over to the sewing machine, lay the back leg on top of the yoke, right sides up. Overlap the back leg so that it’s just touching the seam line you just marked in. Since it’s a curved seam, you’ll only be able to align a bit at a time.

Sew down the middle of the overlap, about 3/16″ from the edge. It’s not really critical though, the main focus should be on aligning the denim.

Continue aligning and sewing down the yoke seam until you reach the end of the seam. Ideally, seat seam should align perfectly between the two pieces, but you may have to trim some excess.

Here’s the seam so far, showing the shape built into the seam thanks to the curved yoke.

Pressing

Lay the back leg with the yoke facing you, wrong side facing up.

Fold over the yoke along the edge of the yoke seam that’s now underneath. You can kind of feel when the pieces are folded correctly when the fold his the edge of the yoke. Press with your fingers.

Press with the iron and a bit of steam, keeping the iron on the seam itself and not onto the leg and yoke.

Now fold the yoke back into its final position, again feeling for the cut edge now hidden between the layers. Press with your fingers and then the iron in the same manner.

Turn everything over and press from the right side.

Top Stitching

Holding the seam in place as you sew, top stitch the yoke seam through all layers, about 1/16″ from the folded edge.

I did okay here but got a little too far from the edge near my left hand.

Then sew another row of stitches about 5/16″ (just under 3/8″) away from the first row of stitching. You’ll want to figure out what works best for your sewing machine in regards to aligning the stitching with the foot and so on.

Also keep in mind that you don’t want to accidentally run off the edge of the seam underneath as you sew. This really just comes with practice and if you’re like me, you’ll probably have to unpick some stitches as you’re learning.

Here’s the finished yoke seam.

I’m just a little inconsistent with my stitching here, getting a little too far from the edge at the left side, and then overcompensating by narrowing the top stitching in that area. If this were an actual pair of jeans I’d probably unpick these stitches and try again.

From the wrong side of that same leg, you can see how far I was with the second row of top stitching from the edge – worried too much about running off of the seam.

Turning to the underside, you can see I failed to catch a part of the seam. So I’d definitely undo this seam as well.

The Back Yoke – 1873

This lesson is intended for those making the 1873 reproduction jeans, or for those making the modern pair but who lack a powerful enough sewing machine to get through the thicker seam junctions. For the modern pair, use the curve modern yoke – you’ll just not have any excess fabric to ease in here.

Begin by laying out your back legs and yokes, ensuring you get the correct pieces corresponding to each side. The long side of the yoke is part of the seat seam.

Lay the yoke on top of the back leg, right sides together, pinning the end farthest from you.

Be sure that the seam lines up properly at the edge.

From the side nearest you, align the seam allowances and edges, and take three stitches in places with basting thread to secure this end.

Using a diagonal basting stitch, baste the yoke seam together, keeping about 1/2″ away from the edge. As you baste, work in some of the fullness from the back leg below, evenly distributing it as best you can along the length of the yoke.

Here you can see some of that fullness I’ve basted into position.

Here’s what the yoke looks like after basting across the seam. There’s a little too much fullness under those two points – I probably should have gone back and fixed that, but it worked out well enough.

When you’re happy with your basting, sew across the length of the yoke seam on the machine using a 3/8″ seam allowance. Keep the leg side with the fullness down here and the yoke on top. The feed dogs will help distribute the fullness even further, giving you a better finish.

Remove the basting stitches.

Press all of the yoke seams under and down towards the leg, away from the yoke. I forgot to take a photo of the underside but it’s in the video for clarity. Try not to let the iron extend too far down the leg away from the yoke – you don’t want to shrink away that fullness you just built in.

After pressing, top stitch the yoke seam with a single row of stitching, keeping the stitches just under 1/8″ away from the edge (you’ll have to use your judgement here as to what looks good to you and keep it consistent the rest of the project).

Here’s the completed yoke from the right side.

You can see the fullness that was worked in here.

From the underside you’ll see the hand overcasting, as well as two rows of stitching.

And repeat the process for the other leg. You can see here I got a small pleat in one area (if you look really closely). Normally that would bother me but the originals I have seen have various pleats like that themselves. I suspect these were simply done in a rushed fashion without too much care about making it look perfect.

Finishing the Raw Edges

If you’re using the 1873 construction methods, either for the reproduction, or due to having a weaker sewing machine (explained more in the previous section), you’ll need to serge or overcast the raw edges of your jeans in order to prevent fraying. While using a serger is outside the scope of this class, feel free to use one especially for the modern versions. Otherwise, we’ll be overcasting by hand.

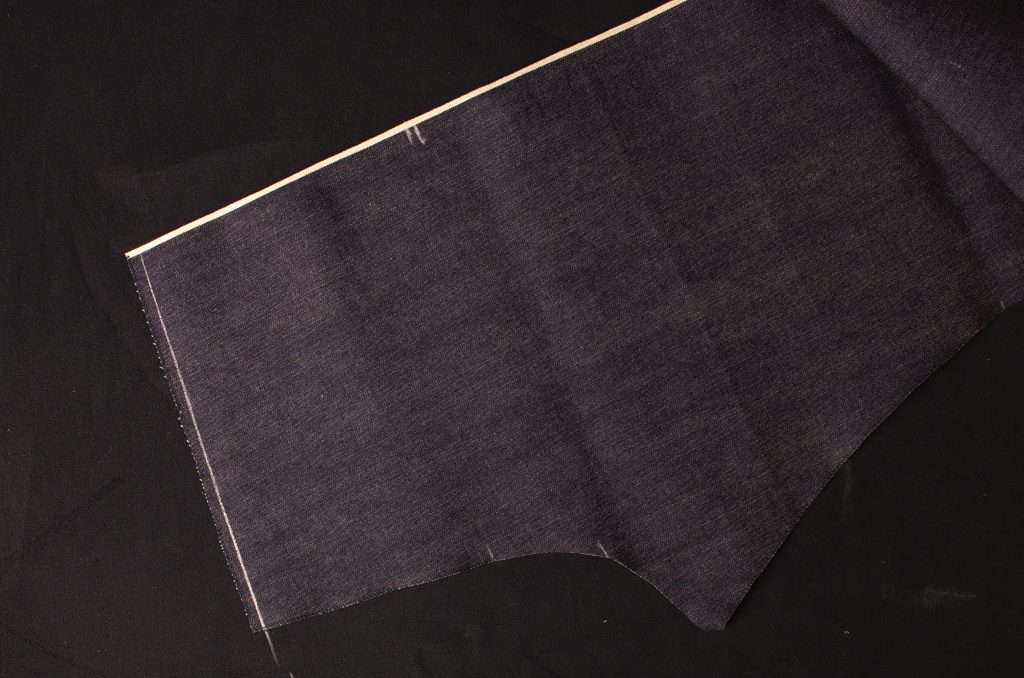

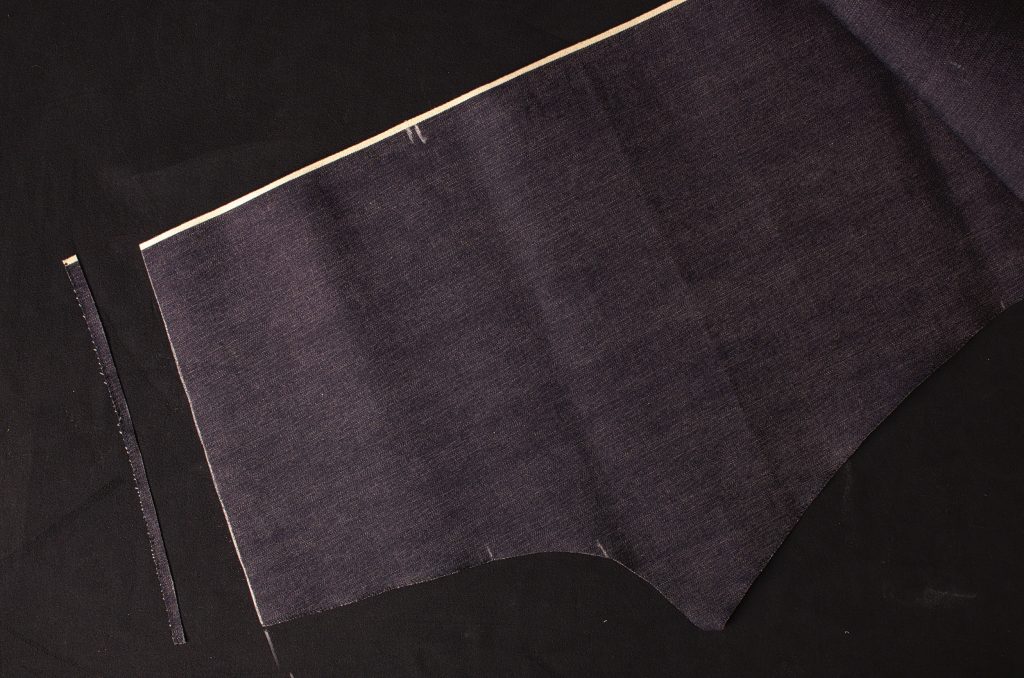

On the back legs, at the yoke seam, mark a line 3/8″ from the edge.

Trim this 3/8″ off, it’s only necessary if you’re doing the full modern construction with the flat felled seams.

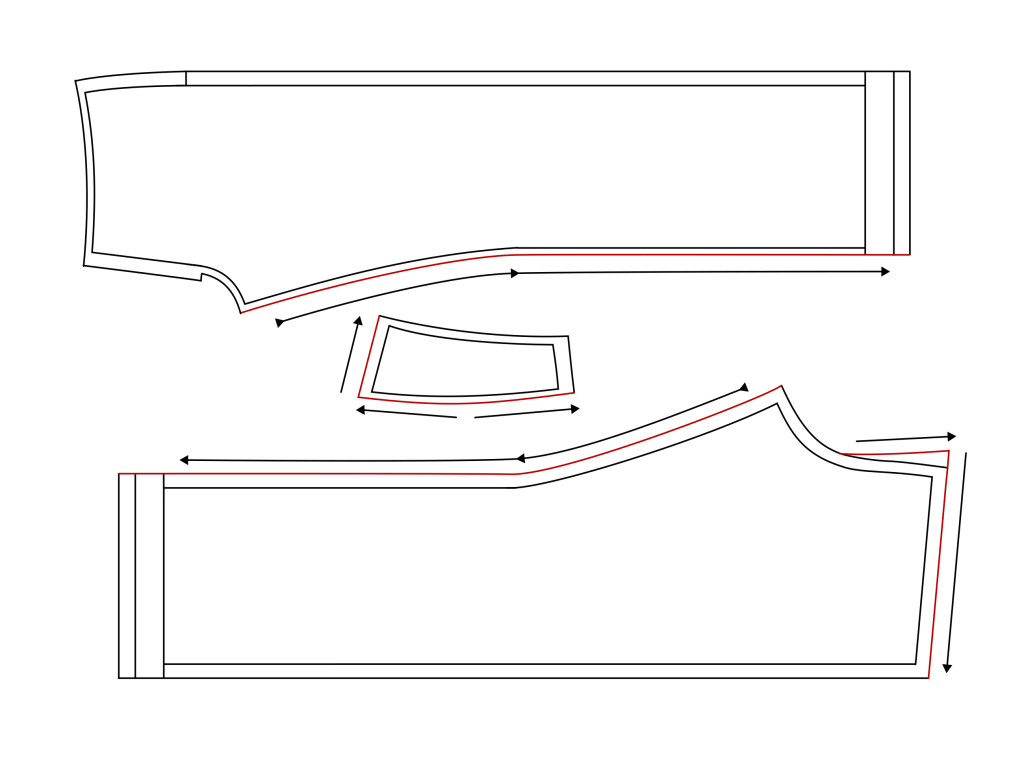

You’ll need to overcast the following areas. The rest will be covered up by pockets, fly, or waistband and can be left raw.

Front Leg

- Inseam

Back Leg

- Inseam

- Seat Seam from lower hip line to yoke

- Yoke seam

Yoke

- Yoke seam (go straight across in one direction if using the 1873 pattern)

- Seat seam (longer side)

Now starting at the ‘uphill’ part of each seam and working ‘downhill’, overcast the raw edges, keeping about 1/8″ in depth and distance between stitches. By working in this ‘downhill’ manner, you avoid the thread catching at the raw edge and causing it to unravel, in addition to making the sewing process a lot easier.

Use the finger behind the cloth to help guide the thread, making a neater stitch.

Here’s my overcasting stitch from the wrong side. This really does take a while, about 40 – 60 minutes per leg, but it’s also kind of mindless and you can turn on a film or podcast or music to help pass the time.

Finally, give everything a good pressing. The denim has a tendency to curl up or perhaps stretch out of shape slightly while overcasting.

Cutting the Jeans

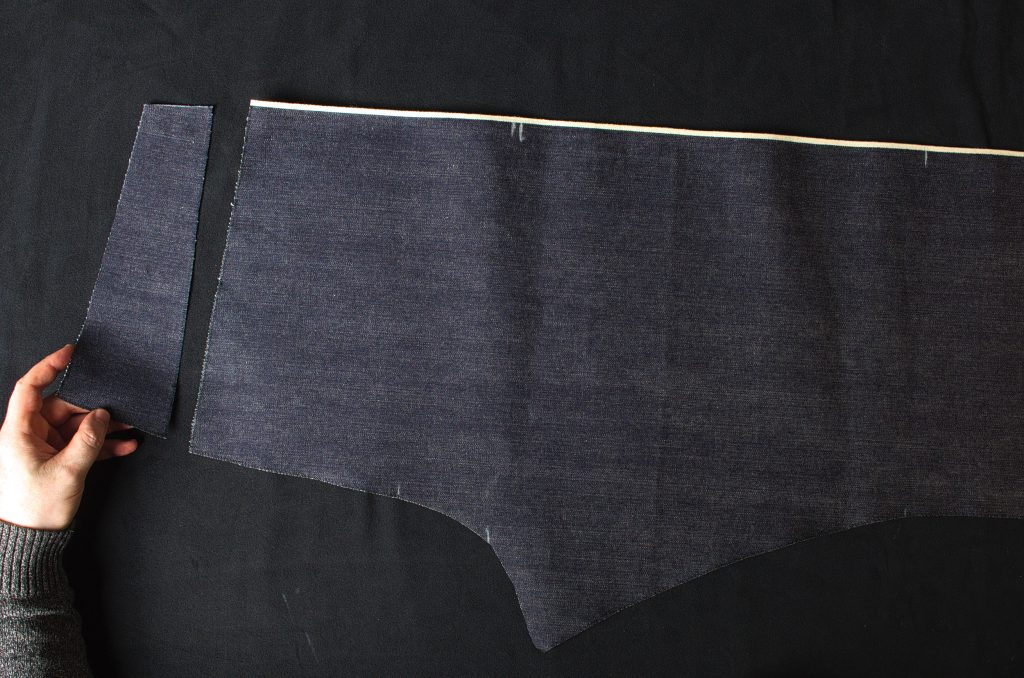

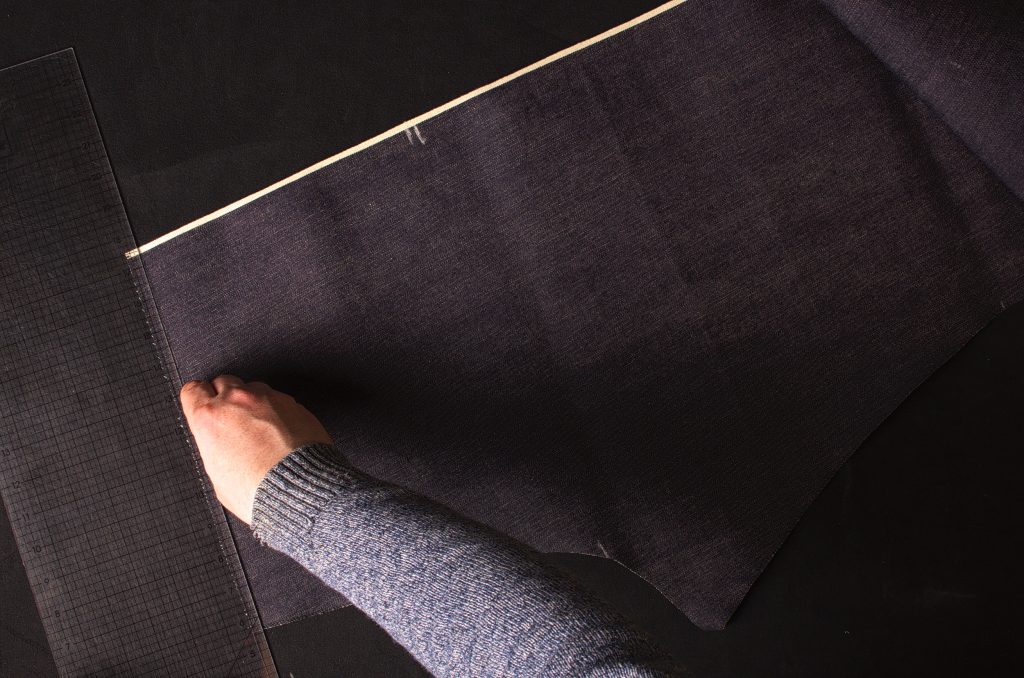

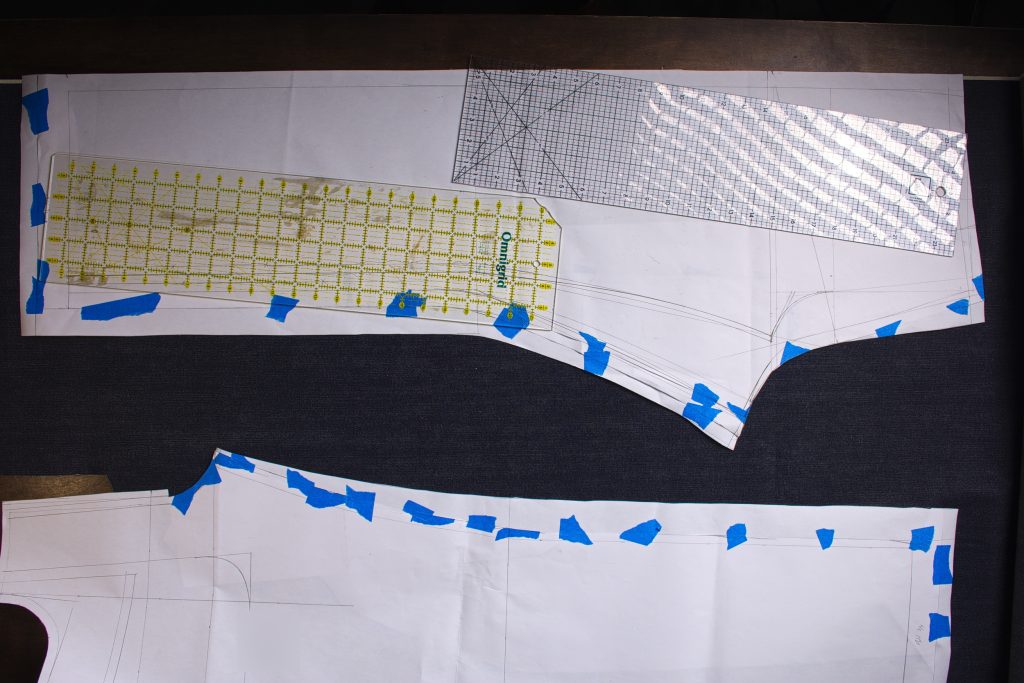

When you’re satisfied with your pattern and have all the pieces ready, it’s time to finally cut out the denim! I’m assuming you’re adept at cutting out clothing patterns already, but I’ll give a few pointers pertaining to the jeans below.

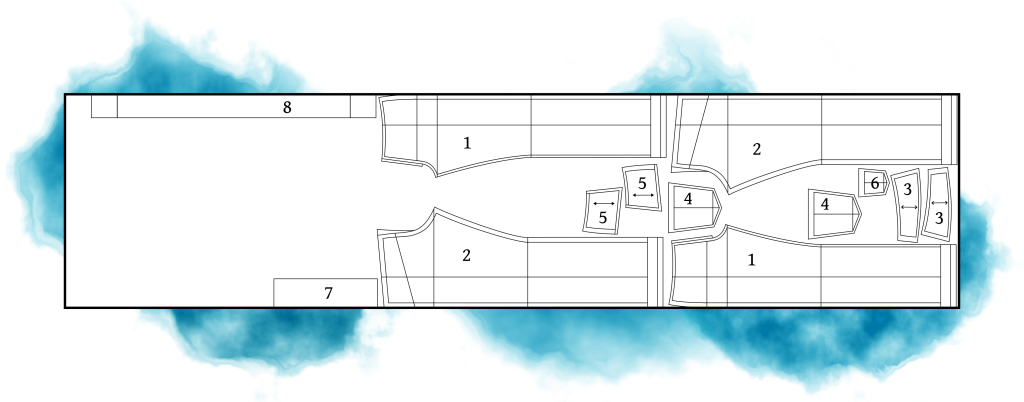

You’ll need the following pieces out of denim. The legs are cut on the selvedge. The waistband and fly can be cut on the selvedge as well if you have enough fabric, but as you can see, it does waste a lot of fabric. I’m not sure what they would have done with the extra back then, but you can use it for other denim projects like bags, vests, etc.

Also save any leftover selvedge to use for belt loops if you want them (for modern pairs).

Because of the nature of selvedge denim, you’ll want to trace out one pattern piece, flip it, and trace out the second side on the reverse, rather than cutting out both pieces at once. Try to keep the pieces facing the same direction if you can. While there’s no nap in denim, particular weaves may have a directional pattern to them. And depending on the width of your denim and size and shape of your pattern, your layout will look slightly different than mine.

Denim Pieces

- Front Legs

- Back Legs

- Yoke (straight or curved depending on your pattern)

- Back Pockets (only one for 1873 jeans)

- Front Pocket Facings

- Watch Pocket

Pocketing Pieces

- Pocket Bags

- Back Pocket Linings (cut the same as the back pockets

Some Tips

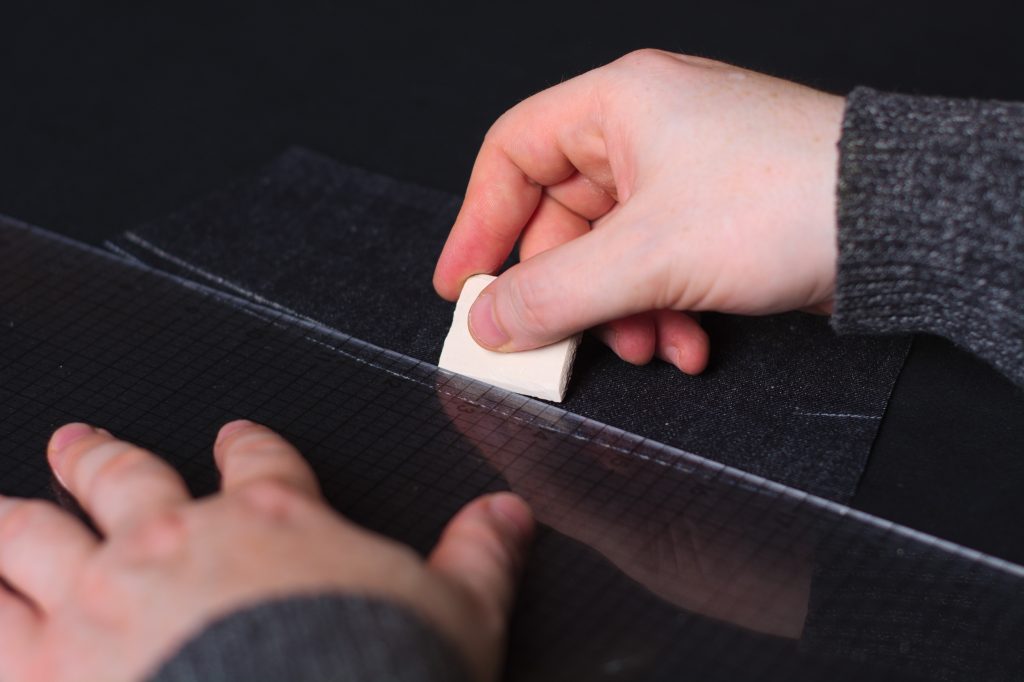

Weigh down the pattern pieces and use chalk to mark the edges for the most accurate cutting.

Lay the long side seams directly on the selvedge edge. This will keep those seams from fraying.

Make a small mark with chalk at the hem, knee, crotch, and hip lines just to aid in construction later on. I don’t recommend clipping notches as that will ruin the selvedge, and the marks are easy enough to add again if they fade.

Cut the smaller pieces out of the areas between the legs.

The originals were cut with selvedge waistband and fly, though this does waste a lot of fabric. Worth it though if you want to keep as close to the original as possible.

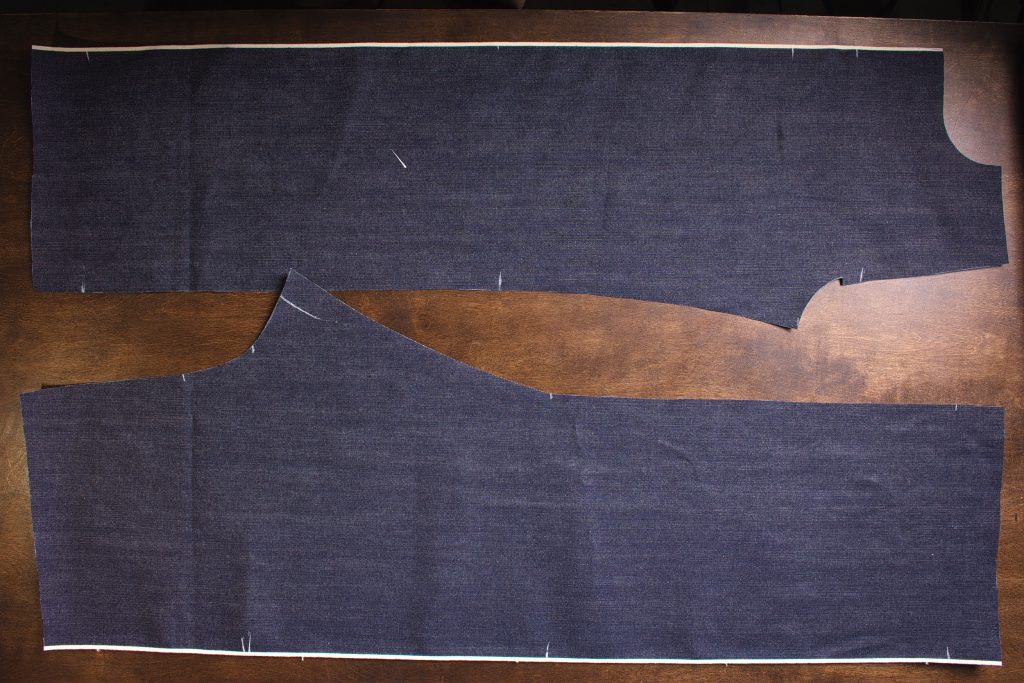

Here are all of the pocket pieces. The pocket bags are cut on the fold as indicated in the pattern. I’m not sure if the original jeans from 1873 had lined back pockets but I’ve cut them just in case (though we only need one pocket for the 1873 jeans). And the watch pocket I cut here with a selvedge top opening that I’ll fold under (more on that later).

Here are all of the pieces after cutting them out.

I like to roll everything up into a nice little package. This avoids creases, especially if you won’t be working on the project right away.

Restoring the Yoke Pattern

Sometimes during the process of altering the pattern, you need to restore the original yoke pattern or the entire back leg with yoke. If that’s the case for you, here’s how to do it.

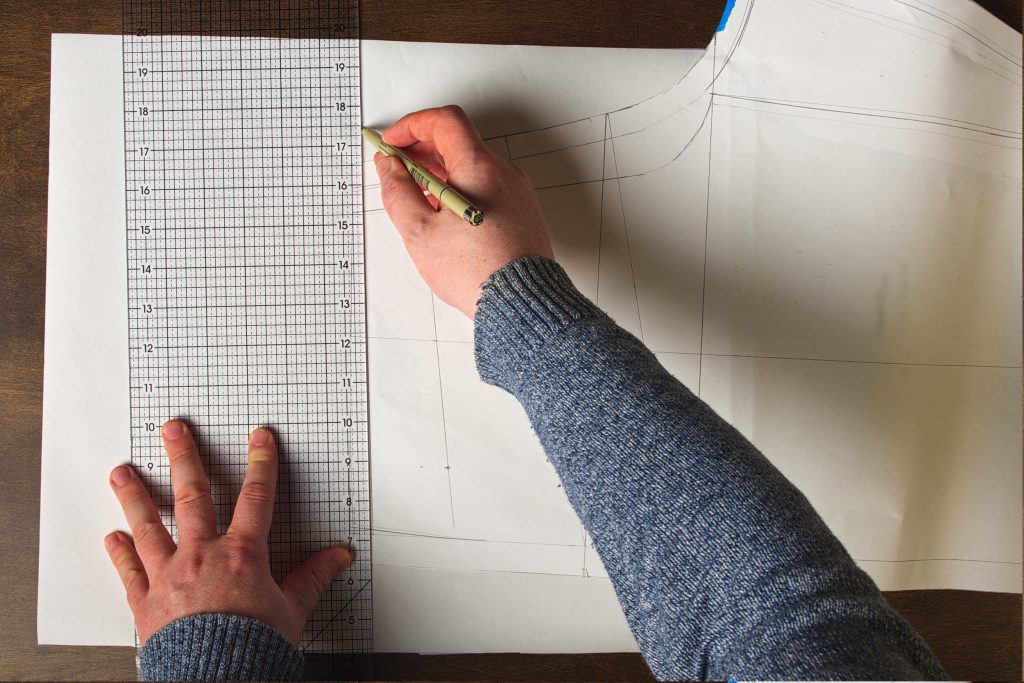

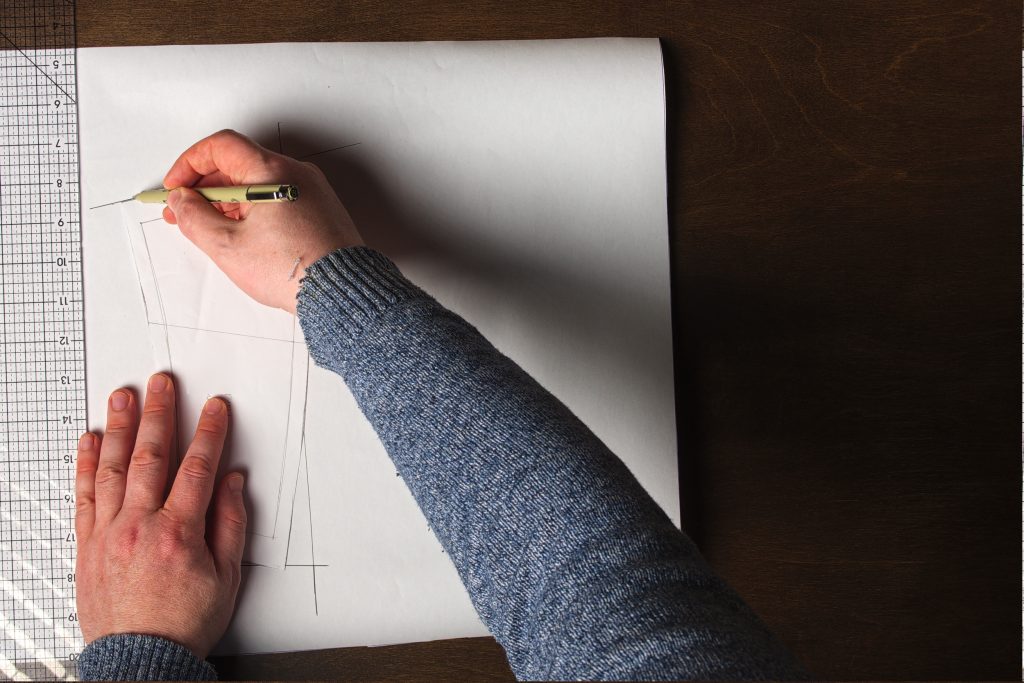

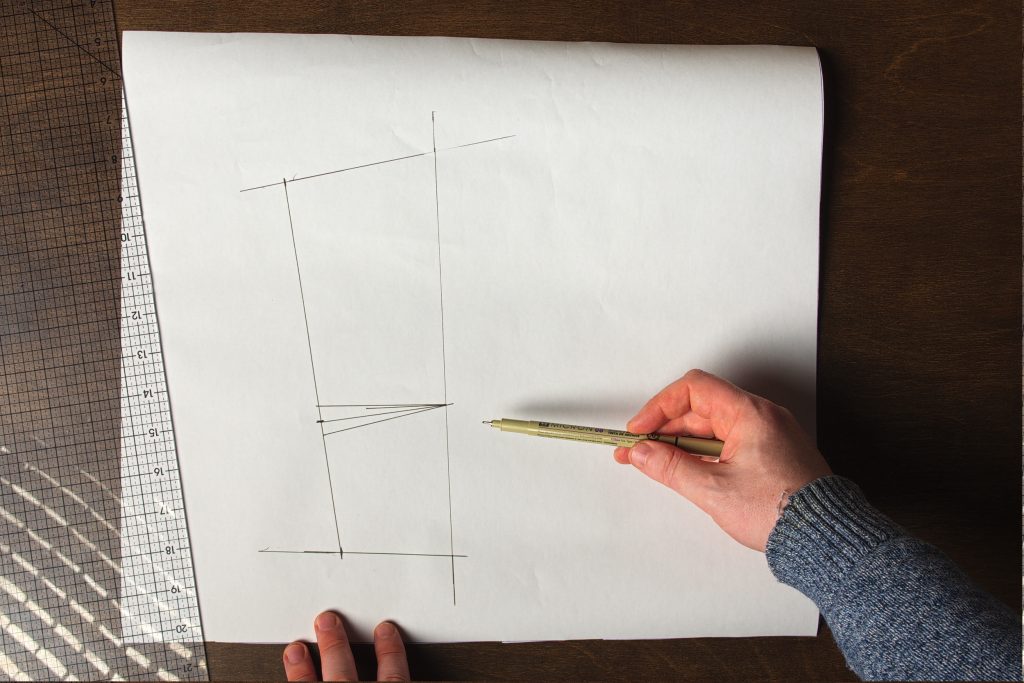

First, lay your back leg pattern on a fresh sheet of paper. Tape it if you’re trying to restore the entire back leg.

Then use a ruler to mark the yoke seam line (not the seam allowance) onto the fresh sheet of paper.

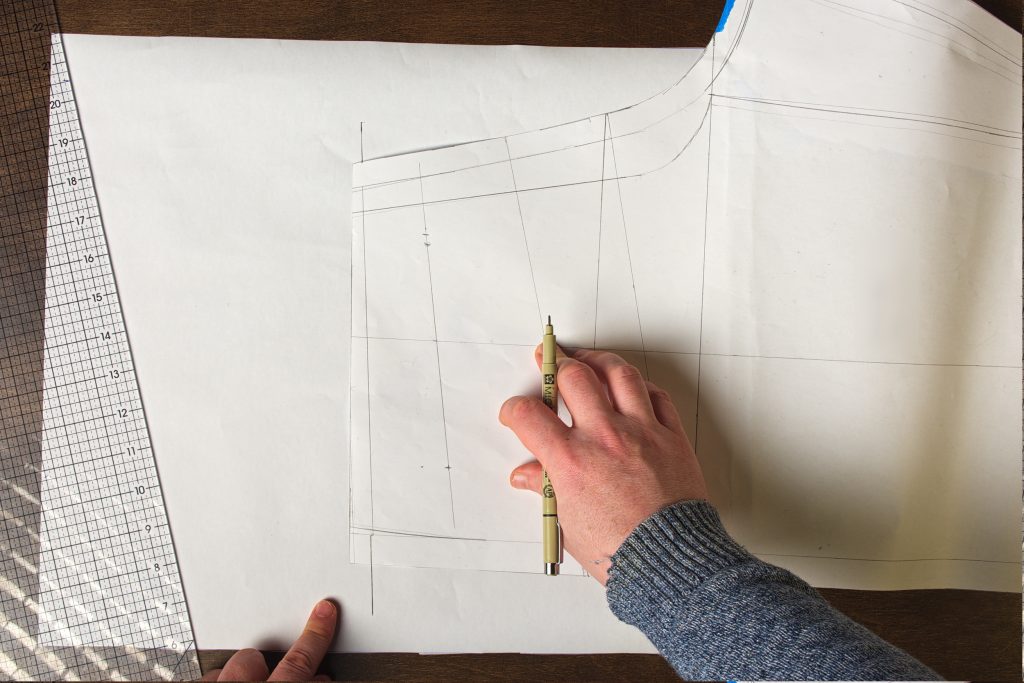

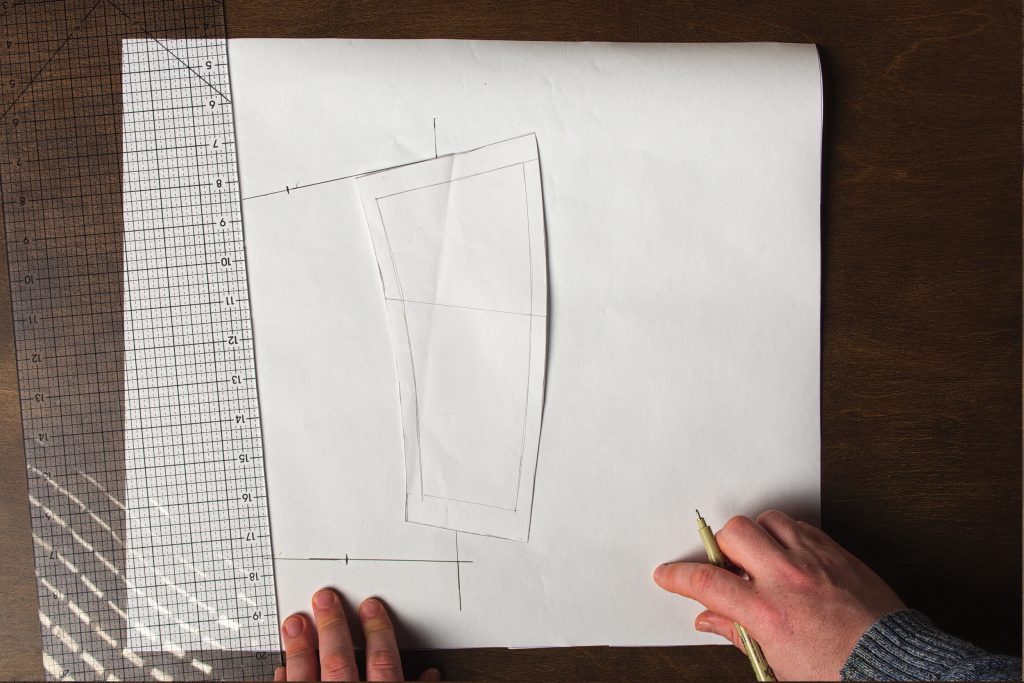

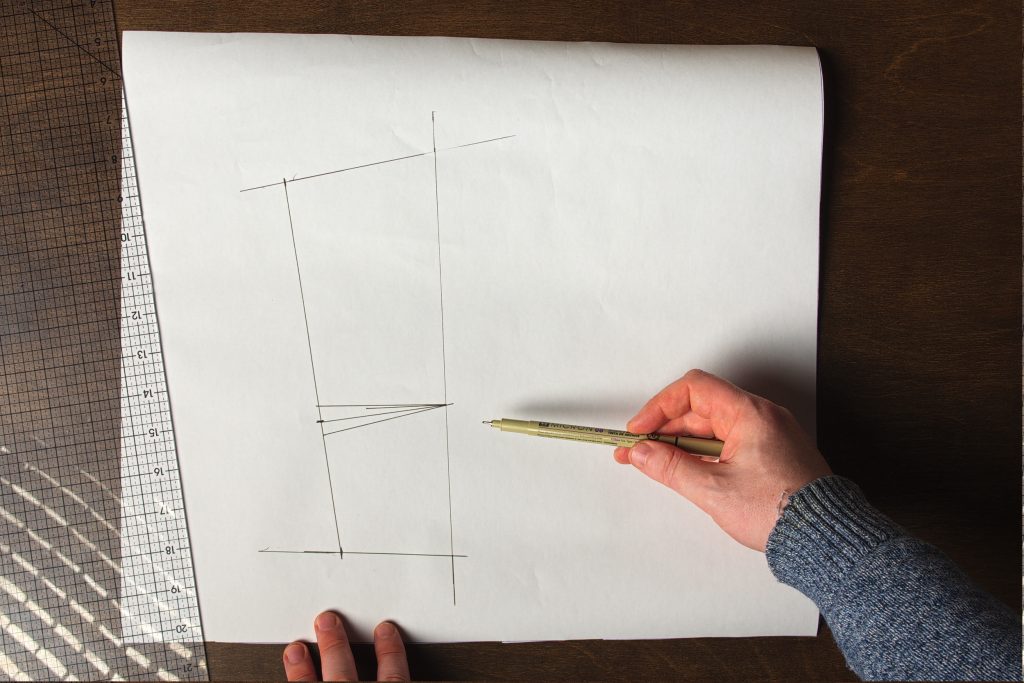

Then extend the side seam a little bit farther than you’ll need it.

And do the same for the seat seam line.

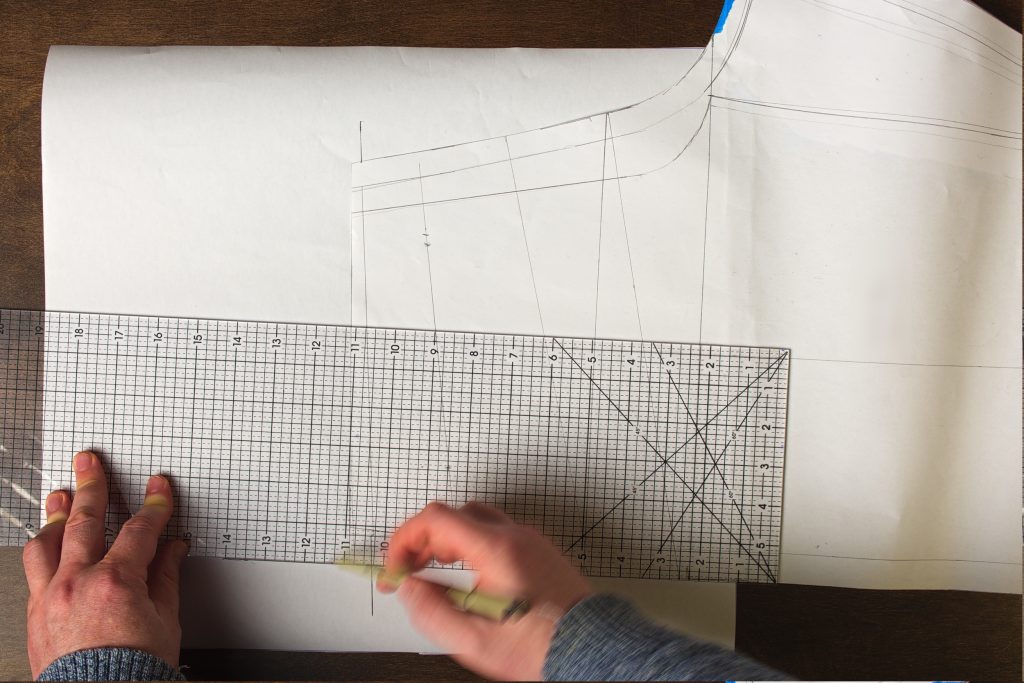

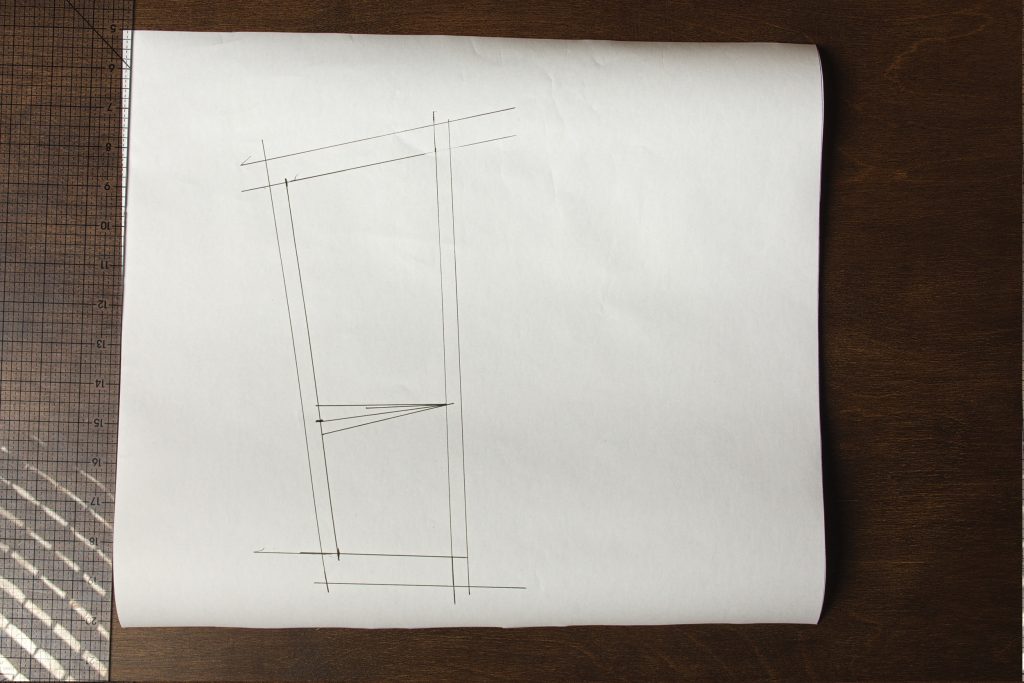

Lay your current yoke pattern on the new pattern and mark the lengths of the seat seam and side seam with the yoke pattern, not including the seam allowances. Or, you could simply measure and transfer the lengths.

Then draw the waist line, connecting the two points.

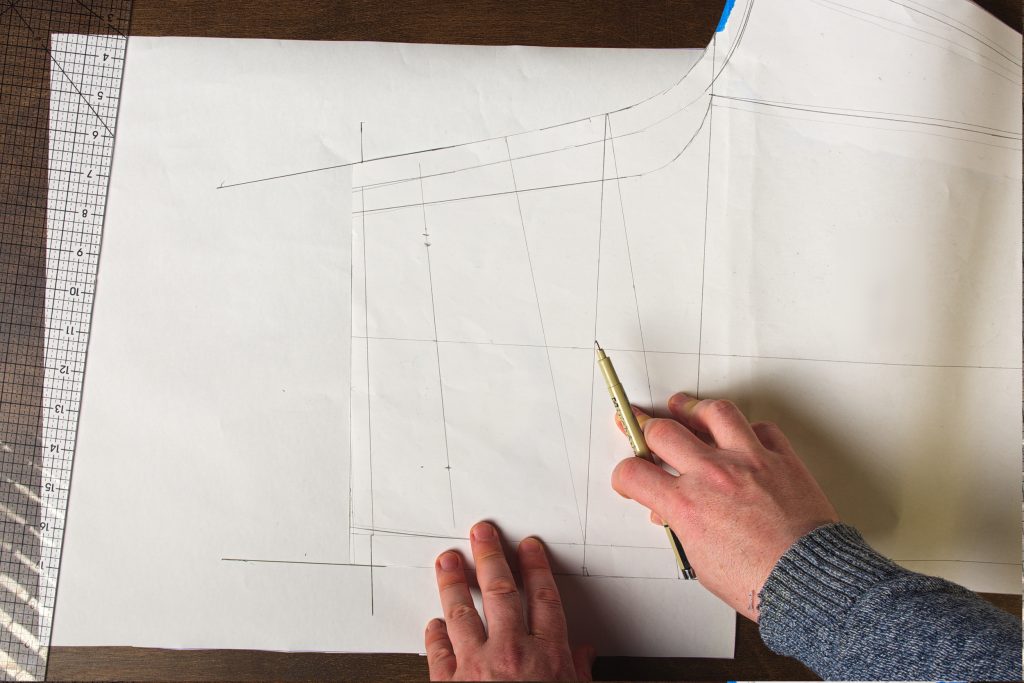

Then simply divide the waist line into thirds and add your darts in as appropriate (covered in the previous two lessons).

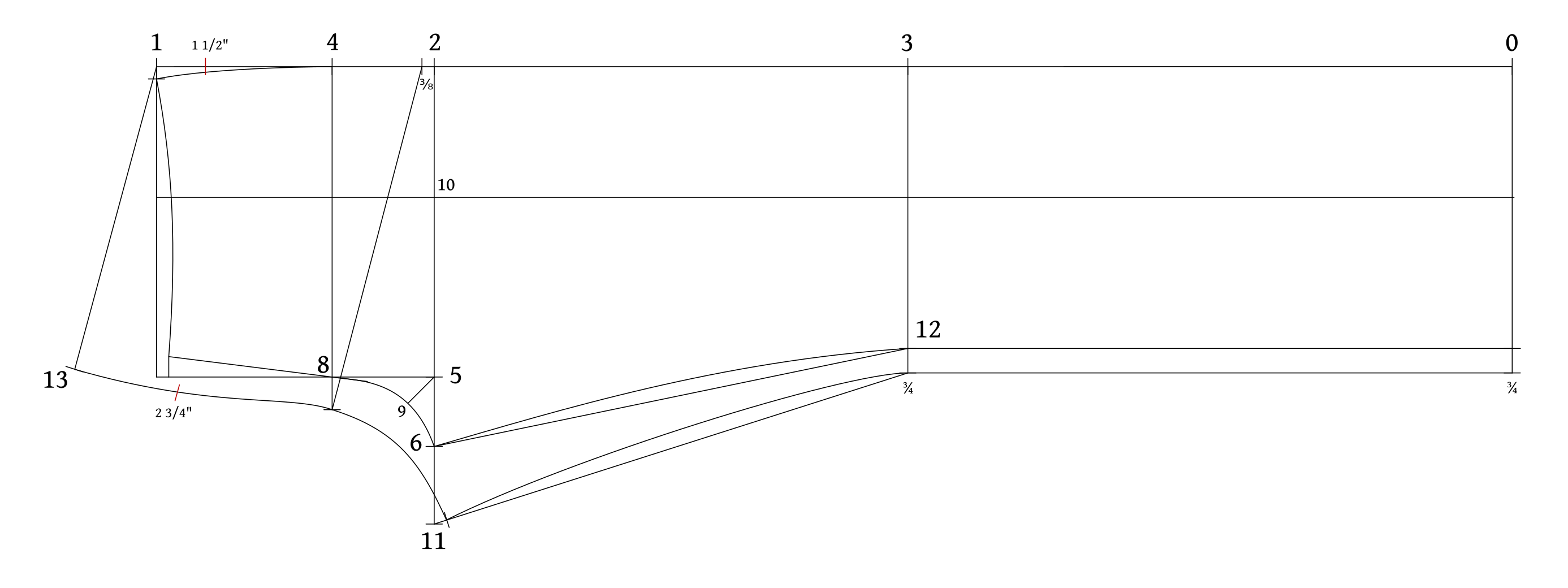

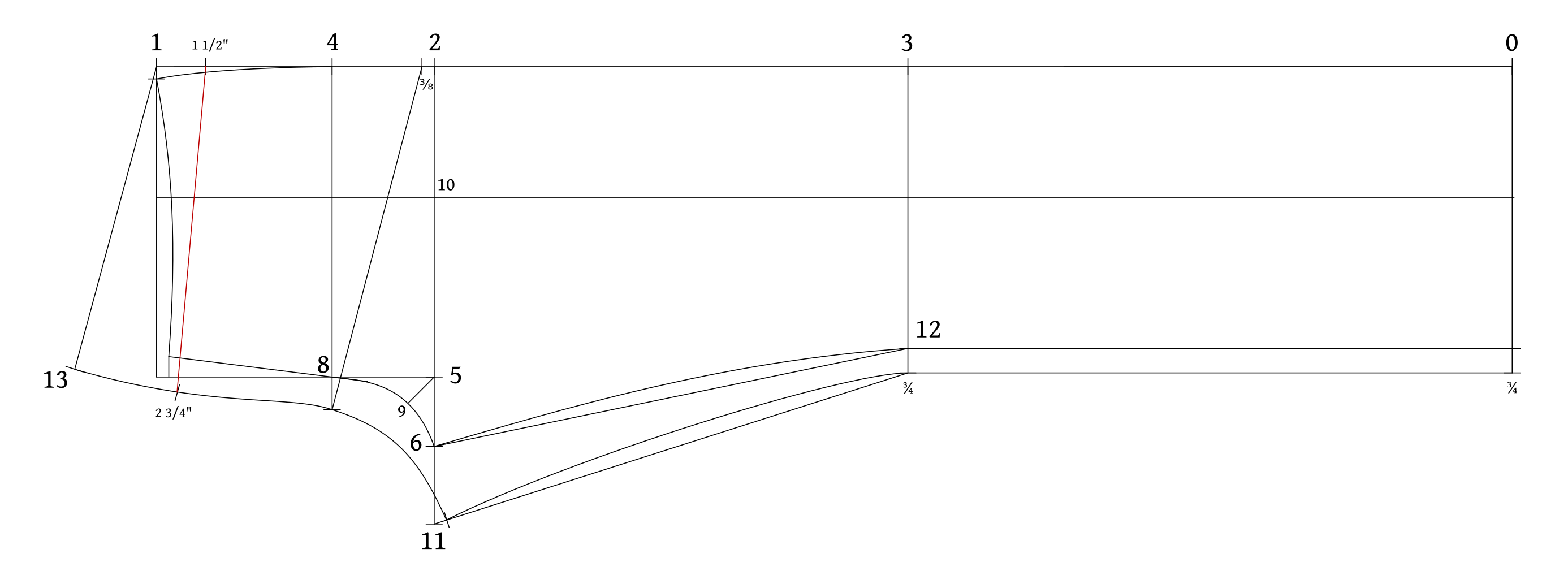

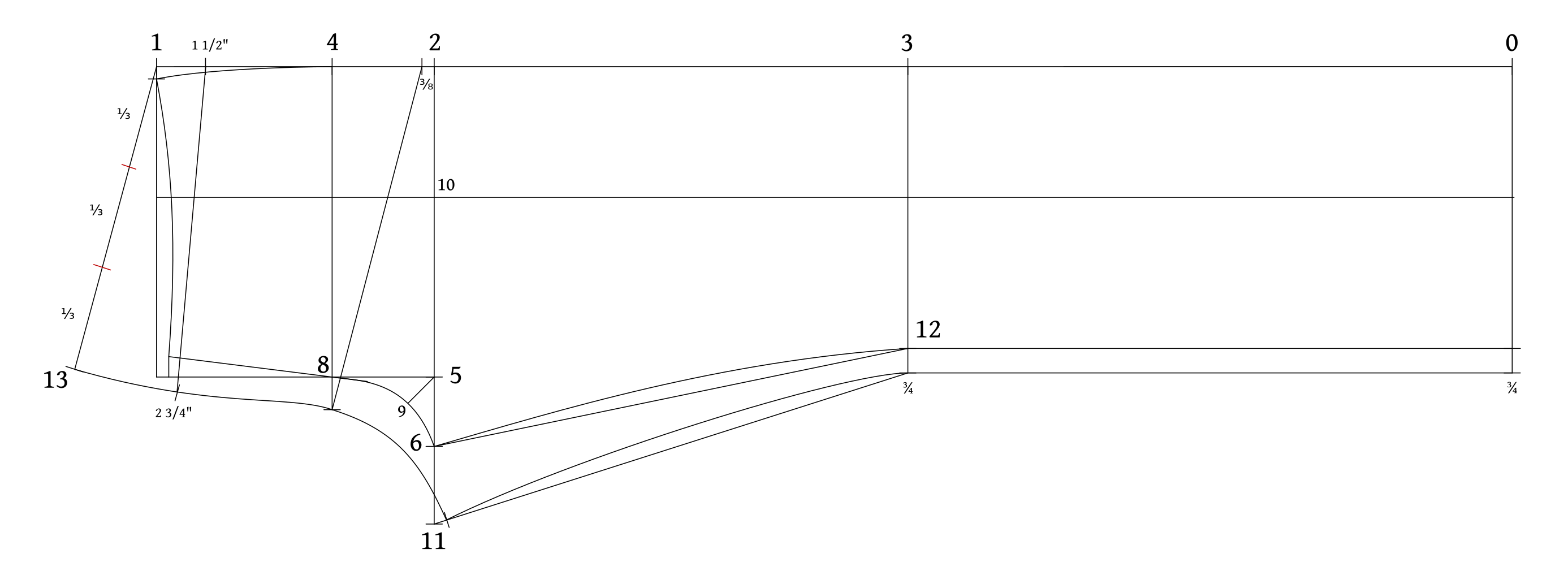

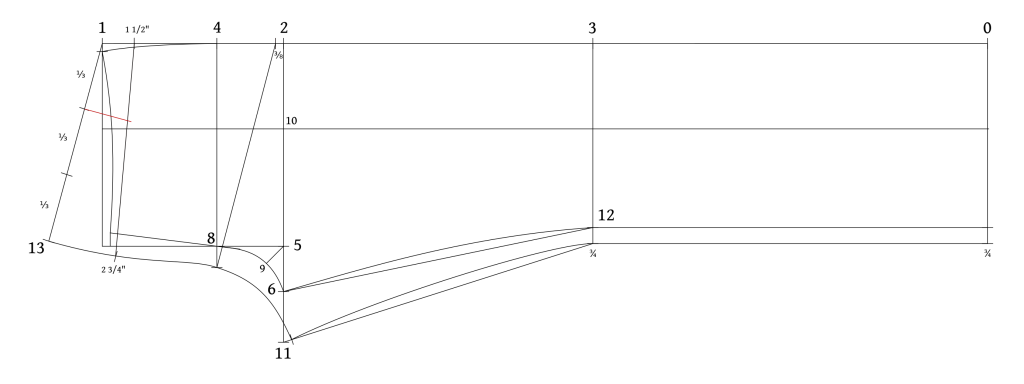

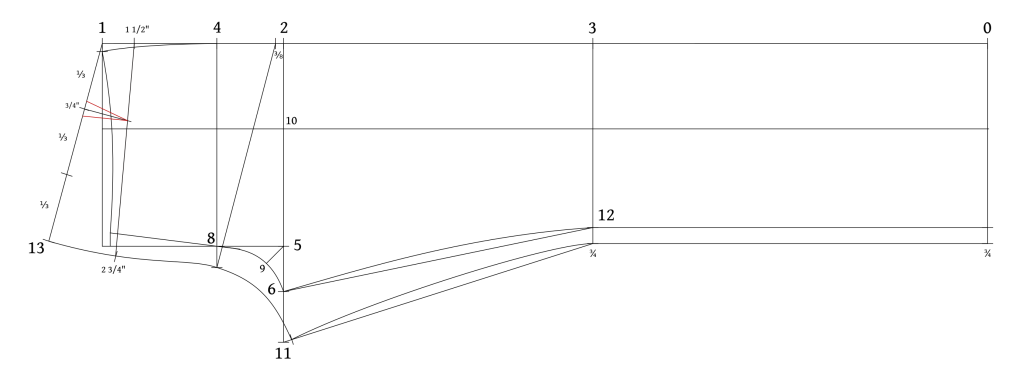

Drafting the Yoke – 1873

With the back complete, we’ve got to draft the yoke before cutting everything out and adding seam allowances.

- First, measure about 1 1/2″ from 1 on the side seam and mark that.

- Mark 2 3/4″ from 13.

These widths are just a good place to start. If you have very high rise jeans, you may need to deepen the yoke for example. But this is best determined after your first fitting.

Draw a line connecting the two yoke points.

Now divide the waistband into 3 equal sections, marking the two division points as shown. These will give the position of the dart used to shape the yoke.

Draw a line square from the waist at the point closest to the side seam to the yoke line.

Draw in a 3/4″ wide dart centered on the guideline – 3/8″ on each side.

From what I can tell, the 1873 jeans were made in a couple of sizes and the size of the waist was determined by the size of the dart here. Though it won’t be a dart in the finished jeans, more of a simple pleat.

Trace out the yoke piece and dart (sorry mine is backwards!).

Seam allowances are now added and the yoke is cut out.

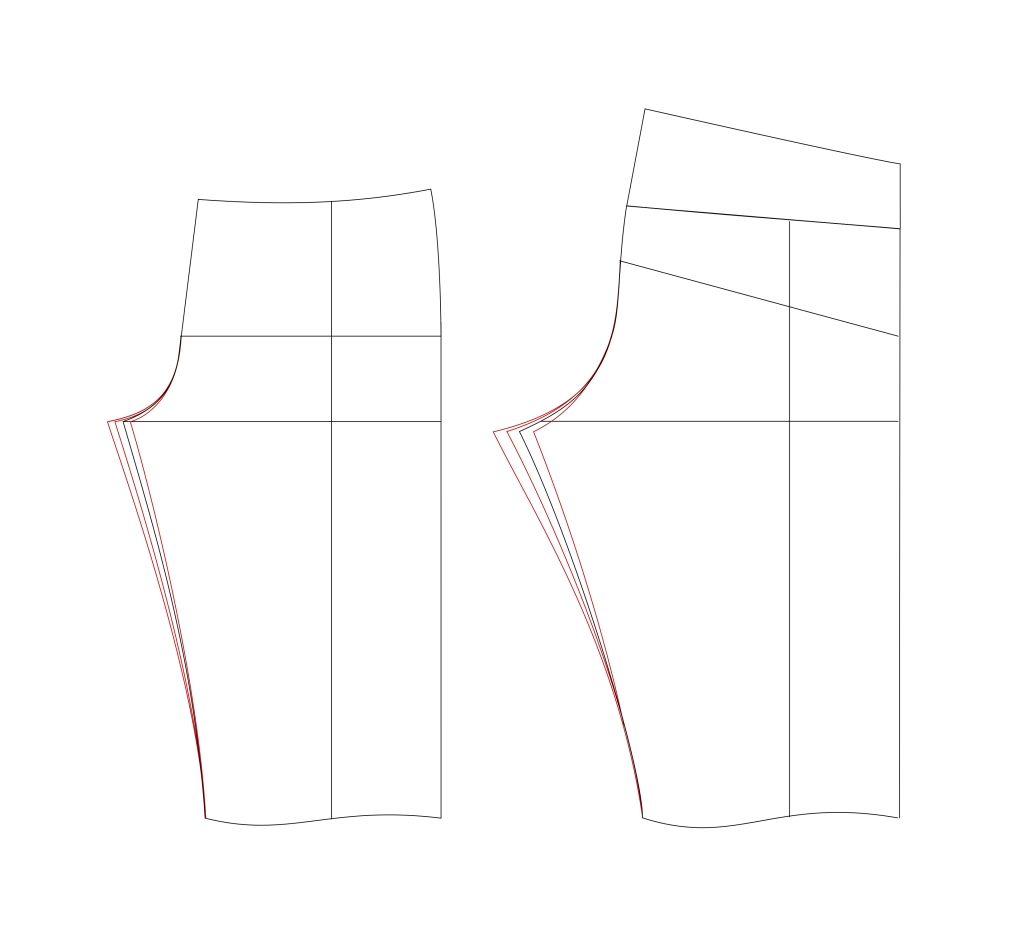

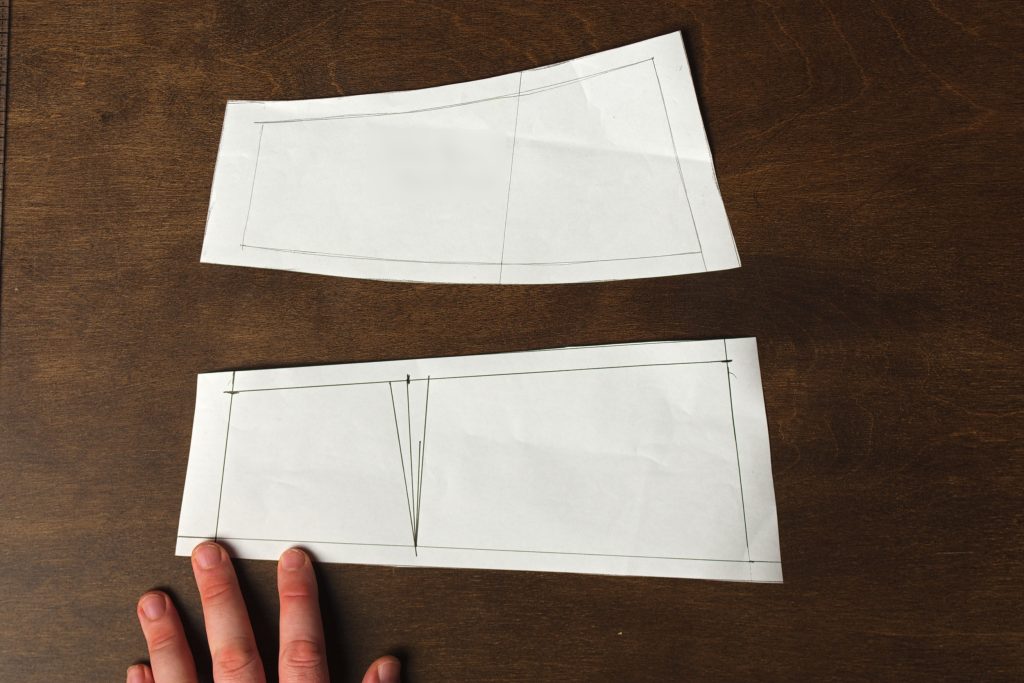

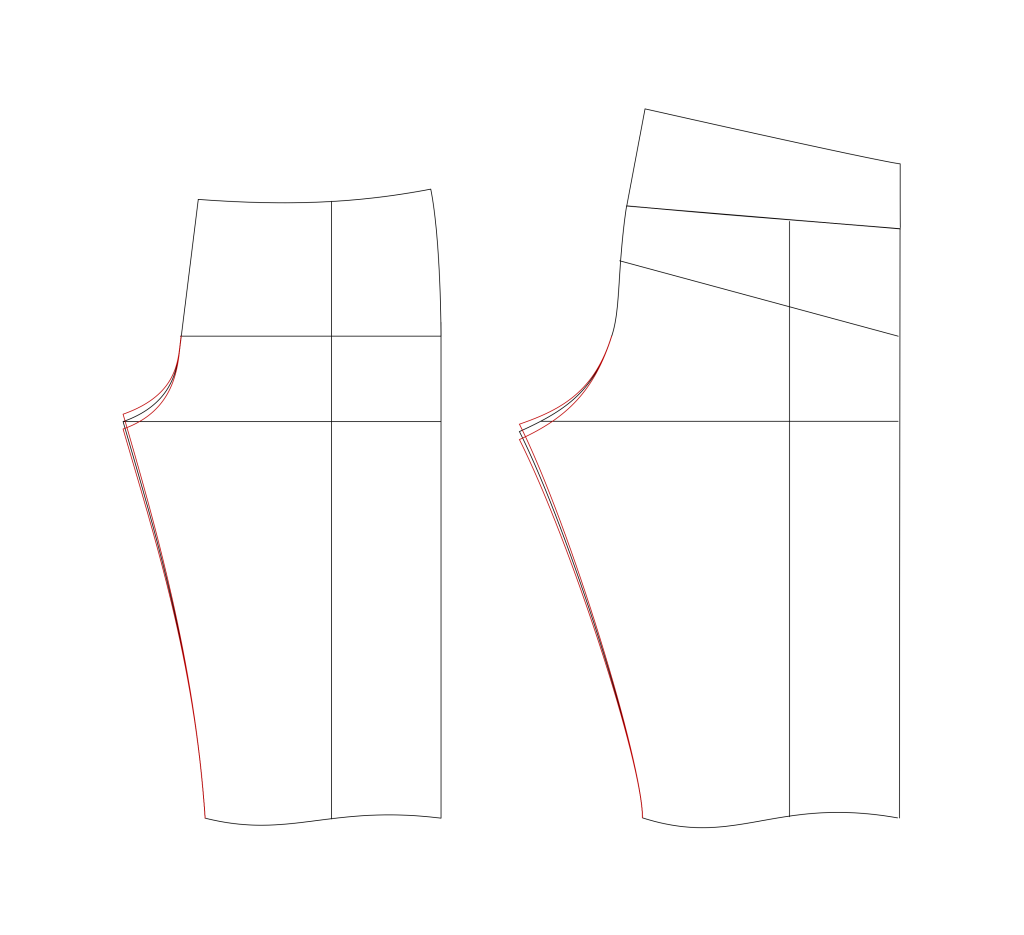

Here are the finished yokes, the modern one on top and the 1873 version on the bottom. It’s interesting to compare the two, and how the shape is already worked into the modern version as compared to the more basic 1873 yoke.

In the end though, both versions technically yield the same result – just how we get there is different.

Crotch Height

Adjusting the crotch height is fairly straight forward, and becomes necessary when your inseam measurement is slightly off. Usually, it’s only a matter of adjusting by 1/4″, maybe 1/2″ in either direction.

Simply lower or raise the crotch point by an equal amount on both front and back legs, then redraw the curves as necessary, maintaining that right angle.

Crotch Width

In my experience the crotch width is the most common alteration. I’ve tried to minimize it in the jeans draft, so we’ll see what happens after you all have drafted yours.

The problem is most often shown as a tight seat, almost a ‘wedgie’ affect, and potential tightness in the front.

To fix, move the back crotch point as necessary (usually to the outside). Then redraw the curves, maintaining that right angle. I’ve needed to alter this as much as 1 1/2″ in the past – hopefully you won’t have to do that but it’s there just in case.

On the front, I’d be much more careful in the adjustments, moving 1/4″ at a time. Then redraw the curves as necessary.