Category: Federal Enlisted Frock Coat

Plait Pocket Construction

Place your pattern on your brown polished cotton, lining up construction line A – B with the grain. I find that by rotating the pattern piece for the second pocket, you can save some space. You will need two pockets, for a total of four pieces. Keep the pocket halves together after they are cut out.

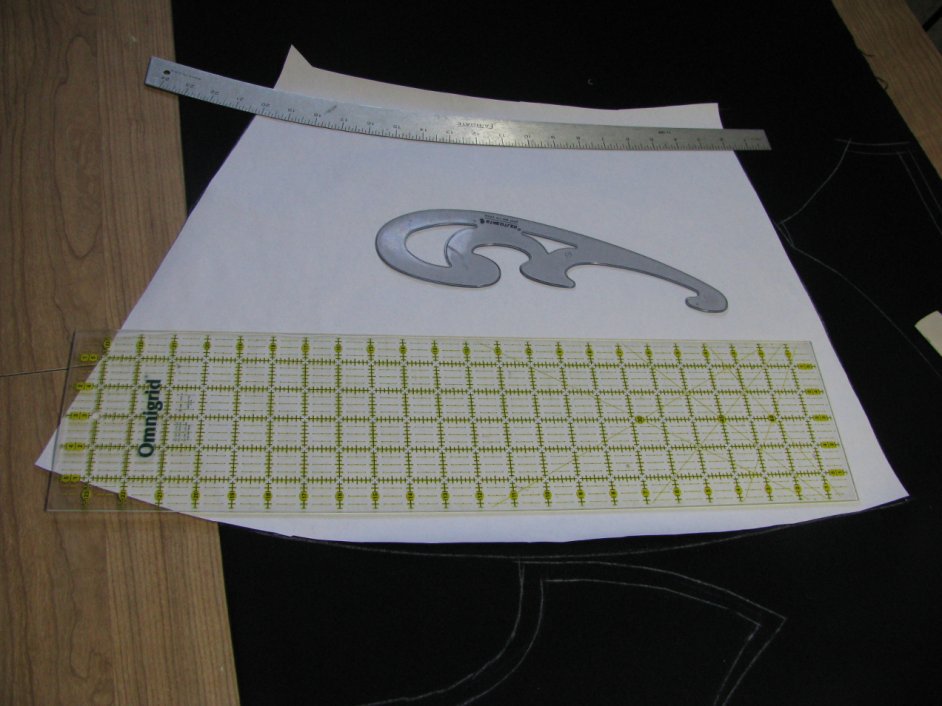

For the facings, cut out a 2 by 8 1⁄2 inch rectangle of wool. Make sure the grain is lined up, and the nap is facing downwards.

After cutting, press each facing precisely in half, right side out. You may want to baste the halves together first to ensure accuracy and avoid movement from the iron.

Check to see which end is the bottom, by running your hand along the nap. At the bottom, using a french curve, chalk a small curve, starting at the bottom of the folded edge, running up about an inch to the cut edges. Lay both facings on top of each other, and trim along the chalk line, ensuring each piece is identical.

Pocket Construction

To begin construction, take the top halves of each pocket, and set aside the bottom halves so that you do not get them mixed up. As we go step by step, you should be doing both halves at once, the second half being a mirror image of the first.

On the wrong side, measure out a line 1⁄2 an inch from the edge, along the A – B line of the pocket.

Fold and press over the fabric so that it just meets this line.

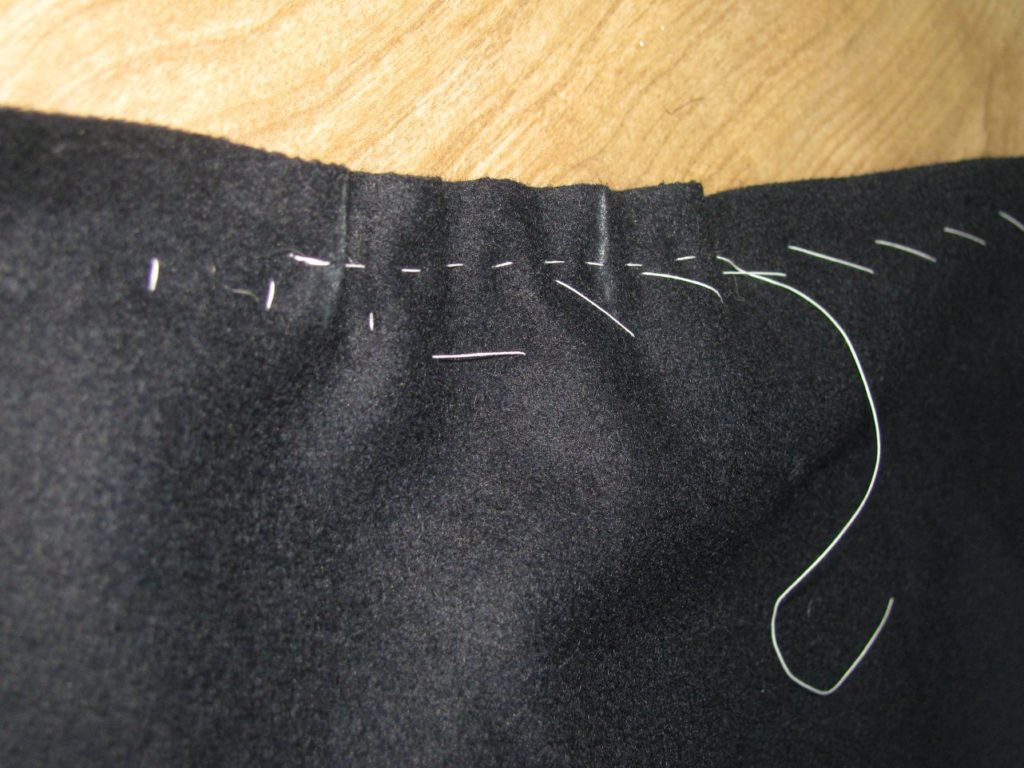

Take a facing and insert the pocket between the folded layers. Ensure that the pocketing is snug into the fold of the facing. Baste carefully, checking as you go, that this is still the case.

Starting at the top of the outer edge, machine sew a line of top stitching, 1/8 inch around the facing. At the bottom, I recommend turning the sewing machine wheel by hand for maximum control. If you wish, this top stitching may also be done by hand, using a side stitch.

After top stitching, press the facing well to remove any excess that may have entered into the facing while sewing. Press both sides.

At the bottom of the facing, draw a small mark on the folded edge of the pocket fabric, directly below the facing. Snip the seam allowance to the fold, but no further, and press the bottom of the pocket open again.

Now place the pocket backs and fronts right sides together, and baste along the outer edge. Make sure each piece lies completely flat, with no tension. Then sew a 1⁄4 inch seam along this edge, using brown cotton thread. Remove the basting stitches, press to set the stitches, and at the bottom curve, trim the seam allowance to 1/8”.

Turn the pockets right side out, and baste just around the outside edge. As you are basting, hold the bottom piece under by 1/16th of an inch, to keep it hidden from view. Then top stitch a mere 1/8 inch from the edge, using the sewing machine foot as a guide. Alternatively, use a side stitch to finish the pocket by hand. Remove the basting stitches. At this point, the pocket construction is completed.

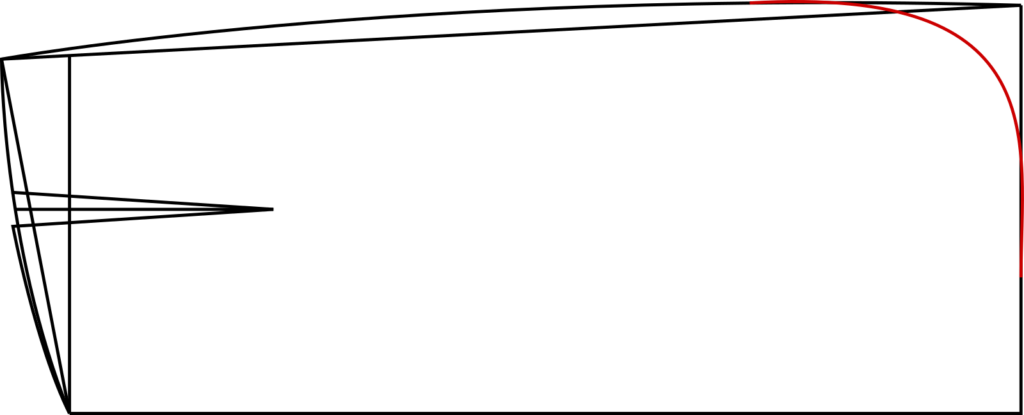

Drafting the Plait Pockets

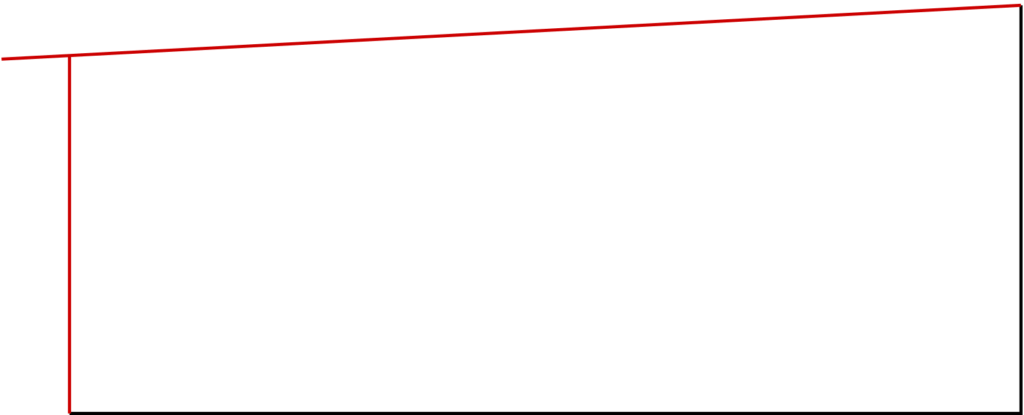

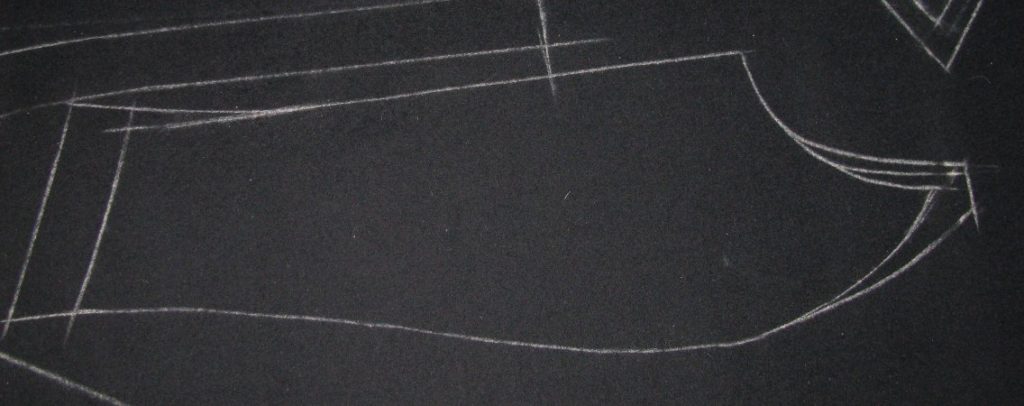

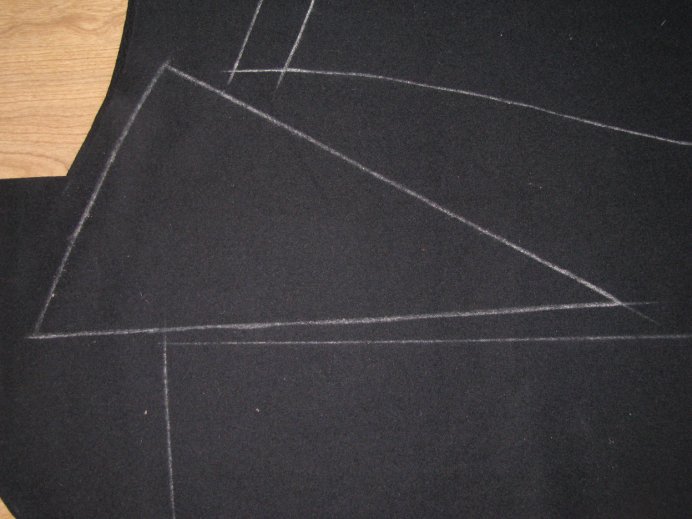

Begin by drawing a vertical line 14 inches long. On the right, or bottom of the pocket, square out another line 6 to 7 inches wide. These numbers are both variable according to how long your skirt is, and how large your coat is, but this is a good starting point. Also include the seam allowances in this measurement, so an extra 1/2 inch total.

On the left, or top of the pocket, draw a line square across that is about 1/2″ to 1″ smaller than the bottom width. Connect the two end points with another line, extending this line past the top of the pocket.

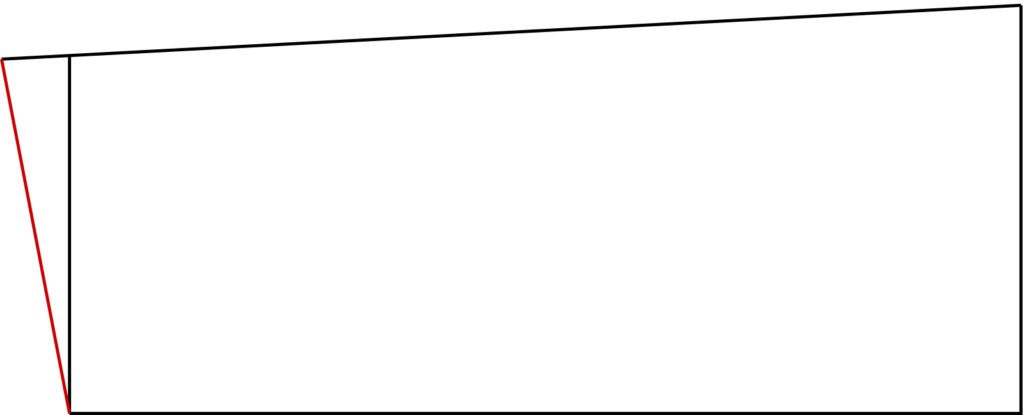

At the top, extend the first line about 1 inch, and redraw the top line at an angle.

At the top and right sides, add curves to each. This will add fullness to the pockets, and allow them to hang freely without affecting the drape of the skirts.

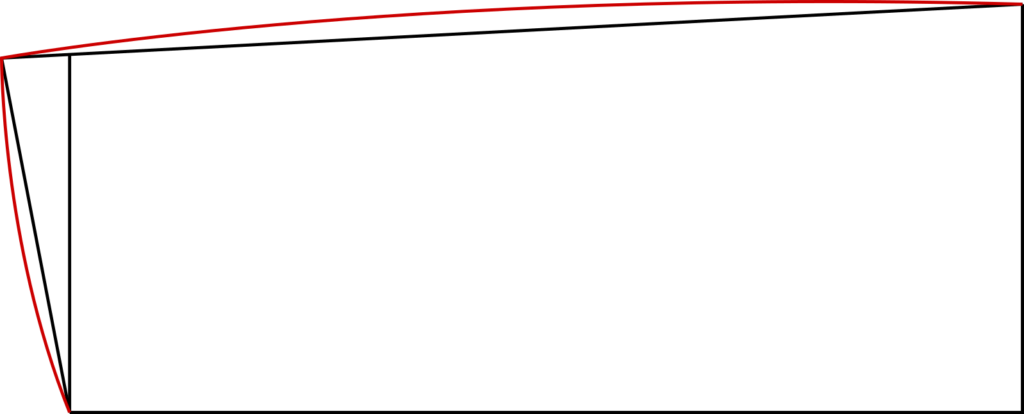

Again at the top, add a dart to the pattern. This should be placed roughly in the middle of the pocket. The construction line of the dart comes down vertically about 2 to 4 inches. The total width is 1/2 inch. Finally, redraw the top seam so that the seams of the dart agree in length.

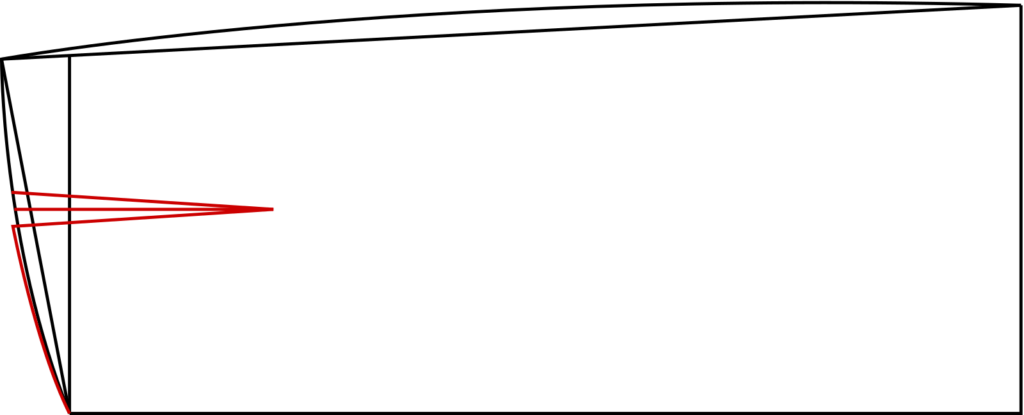

Finally, round the bottom outer corner to give a pleasing look and make it easier to retrieve items from the pocket.

Constructing the Body Halves

Now that the back vent facing is complete, it is time to construct the body of the coat. This is much the same as when you made the full muslin, though we will go into slightly more detail now.

Side Body to Forepart

At this point, any unused inlays at the bottom of the forepart and side body should be trimmed off. If you made any adjustments, such as lengthening the skirt, then make sure you have marked that and do not trim off that area.

Begin by basting the side piece to the forepart, lining up the edges of the side piece to the edges of the tailor tacks. You should have stretched both of these seams by about 1⁄4 inch, and they should agree in length at this point. Sew with a back stitch or machine stitch, and press both sides to set the stitches. I suggest using a seam roll to press the top two thirds of this seam, as it will add a little more shape. At the bottom third, where the pieces spring out to make room for the hips, you will need to use a tailors ham.

The Skirt

If you have not placed any darts into the skirt, it is then necessary to full some of the fabric at the hip area of the skirt. Place the skirt, right sides together, onto the forepart assembly, and make note of where the side seam is. Make a chalk mark on the skirt, one inch behind where the side seam would be, and 2 inches in front.

Take up just the skirt. Using basting thread, start with two back stitches in place, just to the outside of the first mark. Make small, even running stitches just to the other mark, and snip the thread, leaving at least 6 inches extra.

Place the skirt again on the forepart assembly. Flip it over so that the forepart is on the top. The back edge of the side seam should extend 1⁄4 inch – the seam allowance width – into the inlay we gave to the skirt when drafting. It should not follow the spring upwards, however, but instead continue in a line with the rest of the skirt.

Baste this point in place, then turn over the whole assembly so the skirt is on top again. Baste until you get to the first chalk mark, using the padding type basting stitch for strength. When you hit this mark, gently pull on the thread you previously basted in, gathering in 1⁄2 to 3⁄4 an inch of fabric. Baste this down carefully so that the fullness remains evenly distributed. Feel free to use back stitches if necessary. The basting should be 3/8” away from the edge, to stay out of the stitching line later.

Continue basting the rest of the skirt in place. You should have about 1 inch extra at the center front of the skirt, which will be used later to self-face the skirt in the front.

With the skirt side up, carefully shrink out the fullness you put in. The iron should not extend more than 1⁄2 from the edge of the fabric, or you will shrink out all of the fullness, thus rendering all that work you did useless.

Sew the waist seam, skirt side down, from the front edge of the forepart, to the back edge of the side piece. Press to set the stitches on both sides. Open up the seam allowances on the wrong side, carefully using a tailor’s ham to press the curved areas. Press the right side.

On the back of the skirt seam allowance, carefully make a small snip in the seam allowance, 3/8 in from the edge of the back of the side body. This will enable the skirt inlay to lay upright instead of being folded over in a seam allowance, thus helping to make the back pleat area thinner.

Back Piece

Trim off the inlay at the top of the side body at the outside edge only, if you did not need it. With right sides together, line up the back piece to the skirt and forepart assembly. You can place a pin at the waist area to help hold it if you wish.

Line up the top of the side seam to the top of the back seam, making sure the side piece extends by an amount equal to the seam allowance. Baste in place 3/8 inches away from the edge, gently easing the back piece into the side piece. The pieces should line up correctly if you did your fitting stages and muslins correctly. Any mistakes should have been caught by now.

Continue basting the skirt to the back skirt. At the bottom, the front skirt should meet the back skirt at the inlay marks, but if not, it’s not a huge problem. It means that you stretched the skirt while making up though, so just be aware of it. Any length discrepancies will be dealt with later.

Now sew the seam with the back side down. This helps manage the fullness of the upper back area.

When you get to the waist line, determine how wide you want the pleats to be. Regulations stated no pleats, but you do need to have at least a 1⁄4 inch pleat (also known as a false pleat), to leave room for the pockets. If you are doing the 1⁄4 inch pleat, you’ll turn in at the waist and sew just a quarter of an inch before turning 90 degrees to finish sewing. It’s a good idea to chalk the line to ensure a straight seam. Trim off the extra fabric, leaving a 1/4 inch seam allowance.

If you wish to have the full pleats, continue sewing 1⁄4 from the edge, as you did in the muslin.

After sewing, clip the seam allowance of the back piece just above the point where you spring out for the pleat area. This enables you to press the upper back seam properly.

Press both sides to set the stitches. Press from the wrong side to open the seam, and press from the right side. Be sure to use a tailor’s ham at all times this upper back seam, as it is very important for fit. If you press it flat, you’ll shrink out all the ease that is there and end up with a ruined coat.

At the pleat area, press the pleat back. I generally press to one inch below the buttoning point, where all three pieces meet. If you’ve done everything correctly, there should be only four layers at this point. It took me a while to figure out this step. I remember having 6 or more layers here while I was learning. Hopefully the instructions have been clear enough to help you get to this point with less trouble. If not, please let me know. At this point you should have two nearly identical halves of a coat.

Rear Facings

I’ve always considered this step as the ‘first’ step in constructing a coat, as all the technical and fitting issues are finally behind us. As such it’s also one of my favourite steps. We are going to commence construction of the tail facings, which protect the edge of the garment from wear, and give some weight and body to the area as well.

Begin by laying both back pieces, right side up, as shown. The left side should overlap the right. Take this left piece, and set aside the right piece. It’s important because each side is constructed slightly differently. The following steps all pertain to the left side.

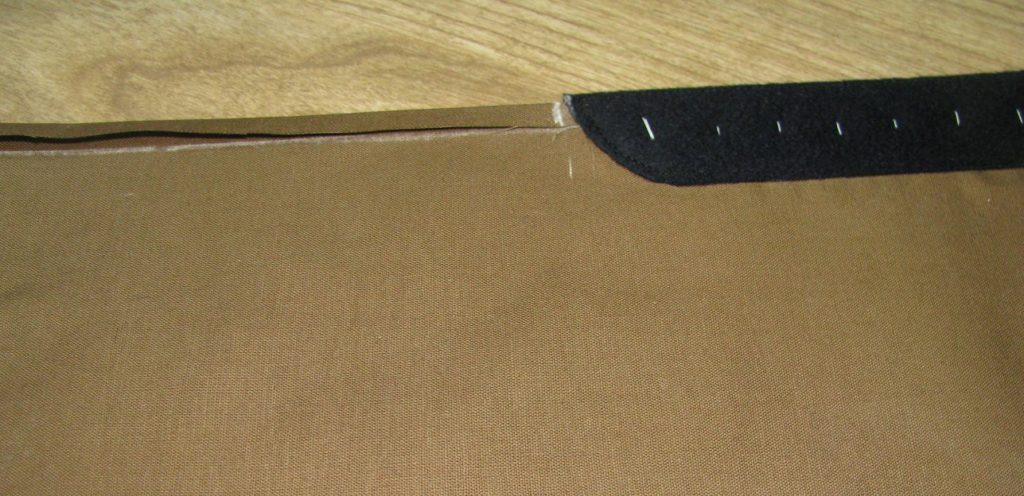

Turn the left side of the back so that the wrong side is facing up. Trim away the inlays around the waist area and center back, if you did not need them. If you made any adjustments to this area, then trim only the excess amount.

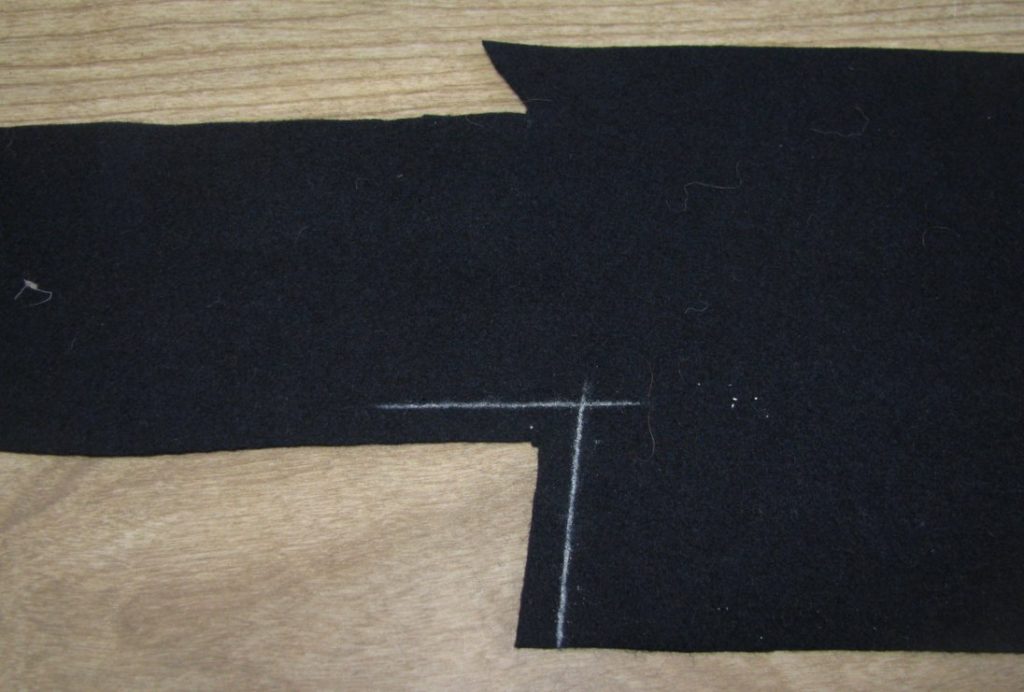

Measure and chalk a 1⁄4 inch line at the bottom of the center back, and across the top of the center back vent, as shown. Again, make sure you are working on the left side of the coat before you continue. Make a small cut from the corner of this area to the intersection of those two lines, as shown. The cut should be made just to the lines, not extending into it, as the chalk has a width to it, remember.

Next, mark a vertical line extending from the top of the back skirt to the bottom. I generally make this 1 3⁄4” wide, because the fabric will be folded to this point to make a 7/8” facing. This is adjustable though depending on your size. Generally, the line should be made 1⁄4 inch away from where the center back seam line will be.

At the top, baste over the fabric 1⁄4 of an inch, and press carefully. Then baste the fabric along the center back over itself, so that the edge lines up with the vertical line you just drew. Baste carefully. There will be a little fullness at the top, because you don’t want the facing to extend above the top of the vent. Press this fold as well, gently shrinking out the fullness.

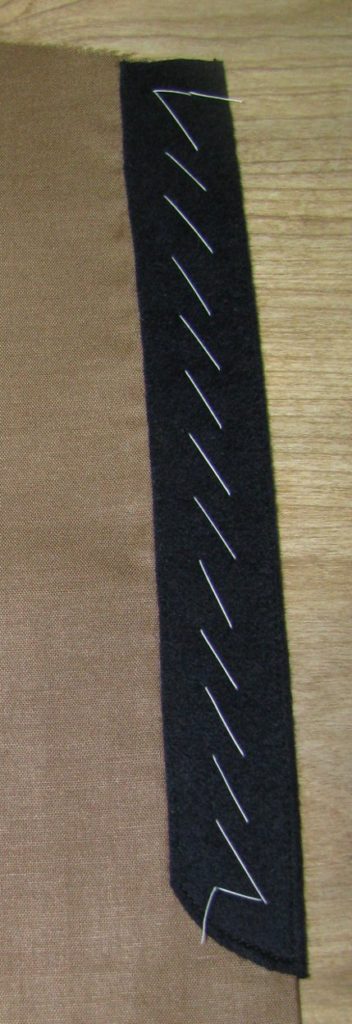

At this point, remove all basting stitches, and unfold the facing. You should have a nice crease along the edge, and top of the back vent. Use this as a guide to baste in the linen stay tape.

The tape should be placed right along this crease, starting at the top. Start with a back stitch with your basting thread to hold it in place at the top, and hold the tape where you want it as you baste.

About 8 inches from the bottom, make another backstitch in place. From this point on, hold the tape a little tight compared to the fabric until you get to the bottom. The tape should be about 1⁄4 inch tighter than the fabric, which is distributed equally along the 8 inches, as you baste. At the bottom, end with another backstitch in place. The stay tape should be trimmed 1/8 of an inch above the inlay at the bottom.

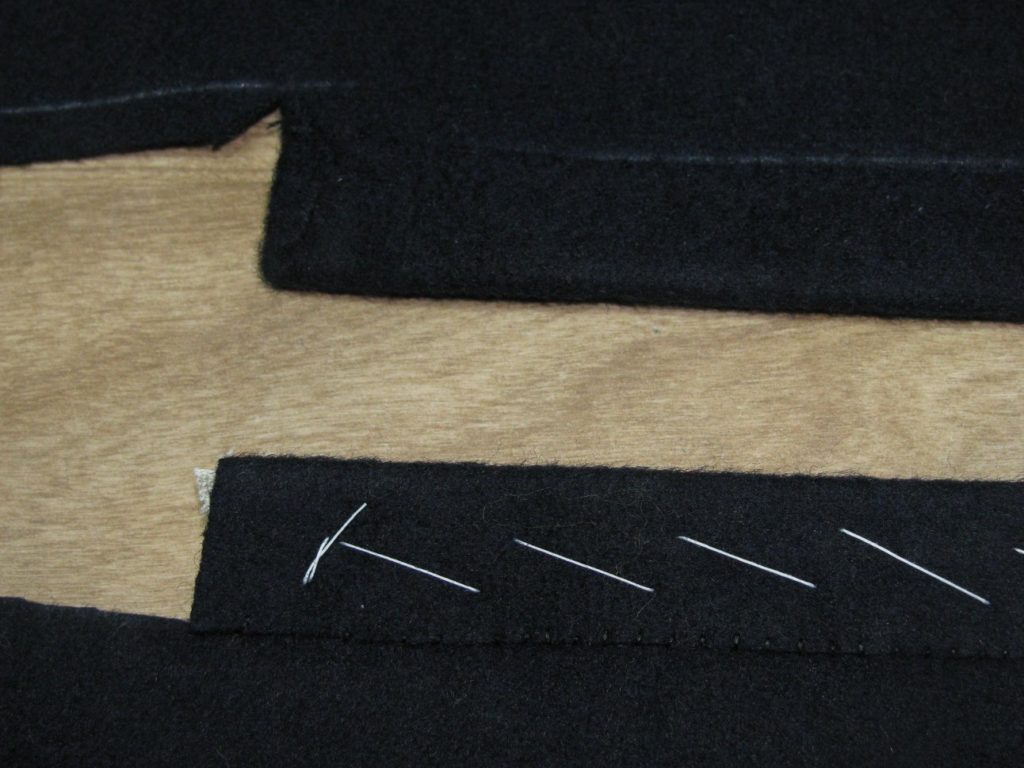

The stay tape is then slip stitched into place, making sure the stitches do not show through to the right side.

Baste the top of the vent closed again, and fell it down by hand,using 8 to 10 stitches per inch. These stitches should not appear on the right side of the fabric, and should be just little pinpricks on the wrong side of the facing. Catch only a few threads in the facing as you go.

Next, baste the facing closed again, and fell this as well, as just described.

Finally, press the facing from the right side on a flat surface, to remove any wrinkles and puckering. Do not press any further than the edge of the facing, because there should be a slight fullness here from holding the stay tape tighter. This is the same principle as when shrinking the front of the forepart. The result should be a back tail piece that curves slightly inward, and helping to avoid sticking out away from the body.

Pick up the right back piece. This time, do not make the cut, but proceed to making the 1 3⁄4 inch vertical line. Baste over along just this edge, insert the stay tape, and fell just as with the left side. It’s okay if the stay tape extends above the top of the vent a little.

The result should be two back pieces with facings, that are different only at the top of the back vent. This will add strength to the back vent, as we’ll see in a later step.

First Fitting

Congratulations, you’ve made it to your first fitting intact! The main things to check for at this fitting are the same as at the beginning of this module. If you need to make adjustments, do so now by marking the amount you need to take in or out with chalk (just draw a line), and then removing the basting stitches, and rebasting. Remember, you need to leave room for the padding and lining, so don’t fit the front too tightly. Be mainly concerned that the back hugs the back closely, that there are no unsightly creases or folds, and that all seam lines are in their proper place.

- Make sure you have lowered the waist seam of the pattern, as was the style in the 1860s. When you do that, the fabric then comes over the hips, so make sure there is a bit of spring added to the pattern.

- Try putting a belt on while you are wearing the coat. The bottom edge of the buckle should lay just above the point where the buttons will be. That’s where the skirt, back piece, and side pieces all meet.

- Ensure that the center front of the coat meets up and touches, without excessive tightness. If necessary, add to the front as previously discussed.

- Finally, make sure the front of the waist doesn’t dip down too much, and that the fronts of the coat do not fall away. If they do, raise up the front of the waist slightly (you can just use pins to test), and if that fixes the problem, you may leave it for now. Please post photos of this stage, for critique and helpful hints.

One important aspect of a good fitting coat is having a correctly balanced coat. Remember that balance is the length of the front compared to the back. As you are fitting your coat with the basted skeleton fitting, take a look at the front of the coat. Do the fronts swing away from each other? If so, temporarily remedy this by pinning the center front of the forepart until the fronts are even. Just take out an inch or maybe more as if you were putting in a dart.

Next, measure how much you had to take in to make the fronts hang evenly. If it was more than one inch, you’ll have to raise the waist seam manually. For example, if you had to pinch the front seams up 2 1⁄2”, the waist must be raised 1 1⁄2”. The remaining inch will be shrunk away with ironwork in the next step. Please keep in mind that 1 1⁄2” is just an example, and exaggerated. Hopefully you won’t have to take in that much. If the amount needed to balance the fronts is one inch or less, this can be achieved by ironwork alone.

The waist seam is raised by subtracting the amount from the bottom of the forepart. The skirt length remains the same.

Removing the Basting Stitches

After you have made all necessary corrections during the fitting, make sure you have marked the new seam lines with chalk, and that they all agree with each other. For example, the waist seam in front should be raised up equally if necessary. At this point, you will remove all of the basting pieces, and press the seam allowances flat again if necessary. Be sure not to undo your careful ironwork on the forepart though.

The Skeleton Baste

Darts

On the wrong sides, on both the skirts and forepart, mark the darts in chalk, carefully tracing the thread tacks you put in. If you don’t have any darts, then you may skip this step. Next, baste the darts, starting with a couple of stitches in place to hold, then using the basting stitch. Make sure the stitching aligns with the chalk lines on both sides of the dart as you sew.

The Skeleton Baste

At this point, you will baste together all pieces of the garment by hand, to test for fit one last time. Normally, in a skeleton baste, the tailor would baste in the padding, linings, and collar as well. Since you have yet to learn how to construct these pieces, we will forgo them for now. On your next project, you may put them in.

This is done just the same way as for the full muslin, except to not clip any seams. Treat the marking threads as the edge of the cloth, the inlays are there in case you need room.

When you are basting together the center back seam, sew from the top to 1/4″ inch past the bottom of the inlays at the waist seam.

Then you can get a good idea if the opening is at the correct height or not. Press each seam as you go, but only lightly. And when sewing each seam, stop when you hit the marking threads. You don’t want to include the inlays in the seam, as they are not technically part of the coat at this point.

The Skirt

Now we will actually commence construction, starting with the skirt. Find the small triangular pieces you cut. Also be sure you have separated the two skirt pieces by cutting carefully on the fold line. Next, figure out which side is longest on the triangular piece, and line it up, right sides together, to the skirt piece. It may take some fiddling to figure out which piece goes where, but I assure you, they will line up, providing you added double the seam allowance when cutting.

After they are lined up, baste together carefully, making sure there is no fullness on either side. Then, sew, using a 1⁄4” seam allowance, with either a backstitch, or machine stitch. If using the sewing machine, I recommend about 12 stitches per inch. Remember that machines of the period could not so backwards, so no back-tacking! Instead, leave about 4 inches of extra thread at the ends, pull the threads to one side, and tie in a secure knot. Remove the basting stitches.

Now, press the seam, using the following technique. After pressing, snip off the little triangular pieces that form at either end of the seam allowance.

Pressing Technique and Opening Seams.

The first rule of pressing is to not move the iron up and down the seam, as this has a tendency to stretch the seam and throw it out of shape. Begin by laying the pieces, still right sides together, on the ironing board. Go over with a hot iron, with steam, and press the seam. Flip both pieces over, and repeat this process. What this is doing is setting the stitches, which will give us a tighter press of the seam.

Next, open up the seam from the wrong side, and press the seam open. Take your time, and do just a small section at a time. Hold the iron for a few moments, remove, then press with a heavy goose iron, or clapper, to really set the seam. We’re trying to avoid that rolled look to the seams that one so often finds, especially in coats made of heavy fabric.

Turn the fabric over to the right side. Using a scrap of fabric as a press cloth, go over the seam again, with the steam iron, then the clapper or goose iron. When using the clapper, you may want to put the fabric seam on a hard surface such as a piece of wood. Make sure to use a press cloth whenever pressing the right sides of fabric, to prevent shine and imprinting the shape of the iron.

If you have the problem of the seam allowances showing through to the right side, press the seams with a piece of cardstock underneath each of the seam allowances.

Ironwork

Ironwork seems very intimidating to most people, as very few tailors, save the bespoke tailors on Savile Row, and some others, still practice it. The style of ironwork done in the period is almost unheard of. I know it was one aspect of tailoring that took me years to figure out. I didn’t have anyone to just show me though, and had to learn it through books and lots of practice.

It’s a good idea to do most of the stretching on your muslin wrapper. Even though it will not stay permanently, it will give you a better idea of how the final fit will be. Shrinking will not work on the cotton muslin, so you’ll have to train your eye to recognize the adjustments needed.

If you skip the ironwork, you’ll end up with long vertical folds near the shoulder and front of scye, and the chest will not be full enough to contain the padding we will be inserting. The front of the coat will drape open, a problem often seen.

The following text comes from Practical Tailoring, The Art and Craft Simply Explained for the Student and Apprentice, by J. E. Liberty. He gives the clearest instructions for ironwork I have found yet.

Shrinking to Shape.

The material should be laid on the board and a little water applied with the fingers of the left hand, the part to be shrunk being nearest the worker. Place the iron first at the back of the material at a part where the shaping will begin, and working it from right to left and towards the front, work round the part being shrunk with the fingers of the left hand while the iron is moving. It will be seen that the shrunk section probably has one or two small pleats formed by trying to shrink too much at once, and these should be smoothed out by putting a little water on the creases and passing the iron over them. It should not be necessary to go over the shrunk part more than twice to obtain the shape required, as too much shape will not hold in the cloth, and should be taken out be seams in the cutting of the garment.

Stretching.

In stretching the process is similar to that used in shrinking, except that the material is worked out instead of in. It should be remembered that in shrinking into shape, the material will, after a time, return to its normal shape, but with stretching, it seldom, if ever, does ; also that to obtain length by stretching naturally reduces the width, and this must be allowed for in cutting.

Forepart

We will begin our ironwork by taking up the forepart, and stretching the front of the armscye. The total amount of stretching should be about 3⁄4 of an inch. Hold the fabric at the shoulder point, and put pressure down with the iron, stretching as you go. Both layers of fabric should be stretched at the same time, to ensure they are stretched equally.

Next, stretch the shoulder seam, about a quarter inch total. This is one of those steps not explained in any book, but learned only through practice and critical thinking. If you measure the distance from the edge of the shoulder seam, and compare that to the edge of the back shoulder seam, you will see they are equal. If you add a seam allowance to that, there is no problem getting them to line up. This is what the majority of produced patterns do. Remember, we did not add a seam allowance, so instead, measure the distance of both seams, 1/4” from the edge. You’ll find that the back seam is 1⁄2” to 3⁄4” longer. By stretching the front shoulder seam, and shrinking the back shoulder seam, this distance is reduced, and the seams line up much closer. Now, stretch the hollow point of the neck seam only, about a 1/4” as well. This gives a little more shape to the shoulder area, and helps the neck hug the body more closely. Stretch the side seam as well, about 1/4”. This is not shown by Devere, but necessary to get the seam to line up with the side piece.

The center front needs to be shrunk, now. Notice how the center front is curved. You will need to shrink this carefully so that it is turned almost into a straight line. Please see the video for a demonstration of this and the other techniques.

Notice how the fullness is visibly in the center of the forepart now.

This will also leave room for the padding later on. The shoulder area should have a lot of shape to it as well.

Sidebody

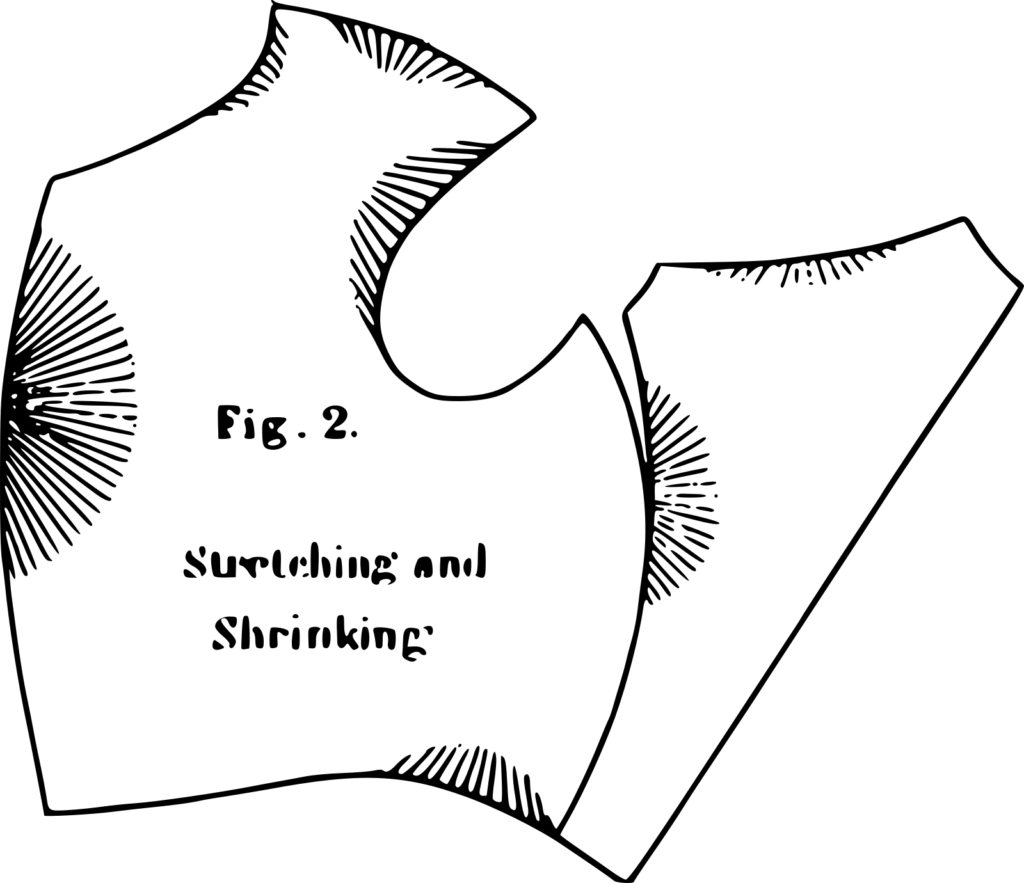

The goal of the ironwork on the side piece, is mainly to impart more shape into the coat. In this step you are basically folding the fabric over, and stretching the seams, while shrinking the middle. It will take some practice, but you will get it. Try not to crease the middle of the piece as you’re doing the ironwork, as it’s hard to get rid of.

The following is a description from The Art of Garment Making, by Phillip Dellafera.

Fold the sidebodies as indicated, then proceed by shrinking away all the ‘loose’ material that will show itself at the waist. This work must be done carefully, until a nice hollow is formed at the waist; it will then be seen that the outer edges will have become slightly stretched. This is exactly what is required, and it will be found that a well-defined waist is obtained by adopting this method.

Sometimes this effect is obtained by slightly stretching the seams in a downward direction only. This, of course, will certainly help to get the desired shape; but the best plan is to shrink the centre of the side body, which will automatically give the extra length to the seams.

Also, stretch the bottom of the side piece slightly, again about 1⁄4”.

Here’s a video of the entire process showing the ironwork I usually do on a frock coat.

Inlays

If you are not confident in the fit of your pattern, or perhaps just want some extra security before you cut into your expensive fabric, it’s a good idea to add inlays – little extra bits of fabric in strategic areas – to give you extra room to work with if necessary.

Add inlays to each piece as follows. As you are learning to do this, measure out each inlay carefully. With experience, you’ll eventually be able to do this freehand, and anticipate how much inlay to add

based on the figure you are fitting.

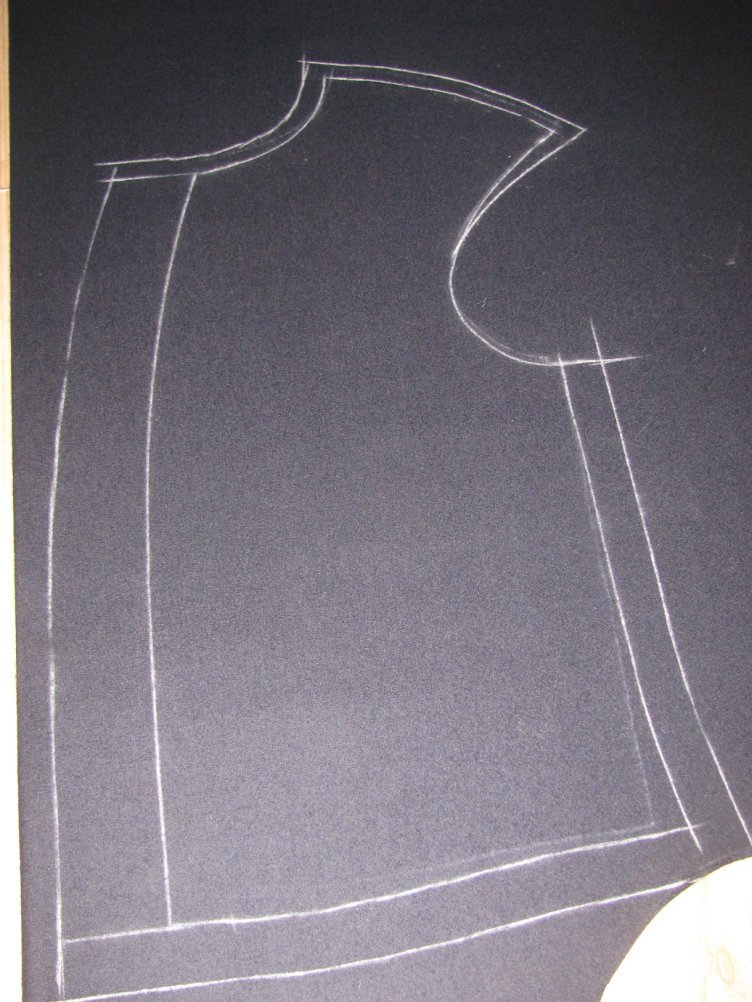

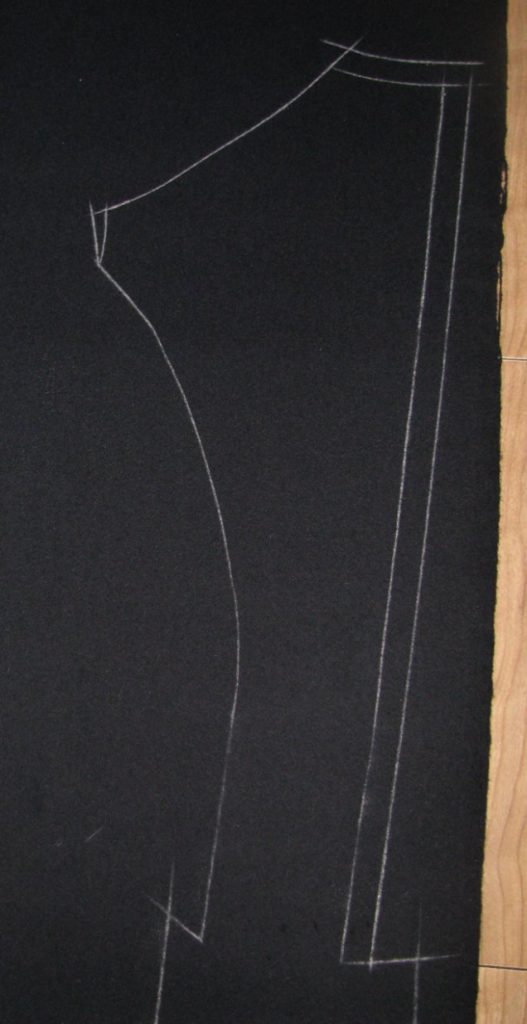

Forepart

At the side and bottom, leave 1” inlays. At the center front, leave 2 inches. This is very important, and if you forget, the coat will not button. At the neck and shoulder, leave 1⁄2 inch, and at the armscye, start at half an inch, tapering to nothing about halfway down the front of the scye.

Also, if your pattern has darts, chalk those, and then close the bottom of the dart by drawing a line as if the dart were not there. The edges of the dart represent the seams, not the cutting point.

Also, as you are laying out the forepart, transfer the chest line to the fabric. This will be helpful in aligning the front later on.

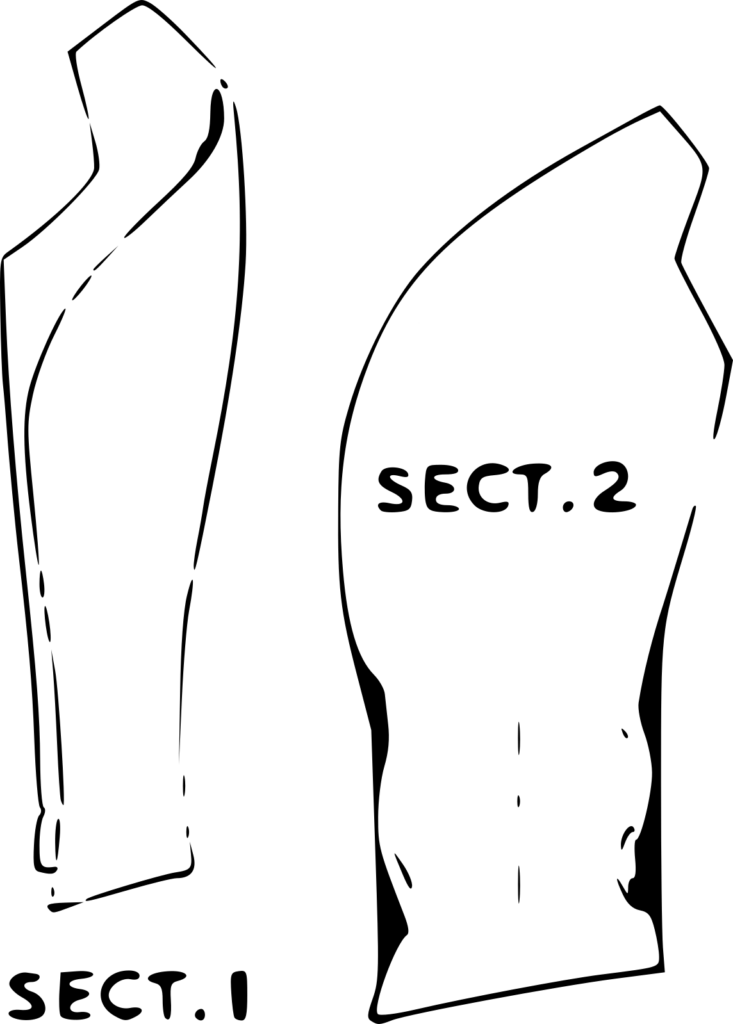

Side Body

At the bottom, leave a 1” inlay. At the top, leave a small inlay, 1⁄2 inch at the widest point, tapering down, as shown.

Back

Leave a 1/2” inlay at the top of the neck, as well as down the center back, as shown. At the top of the plait areas, add a 1 inch inlay, extending the height. This is in case you need to raise the back button points up. And finally, at the bottom, leave a 1⁄2” inlay, to allow for any stretching of the back of the skirt that may occur during making up.

When you’re laying out the back section, make sure the pattern is on the grainline. The center back should be on a slight diagonal when lined up properly.

The Skirt

If you haven’t already accounted for it in your draft, add about 2″ inlay to the front of the skirt. The skirt needs to be able to fold over itself in the front to form the facing, and you need the extra fabric to do that.

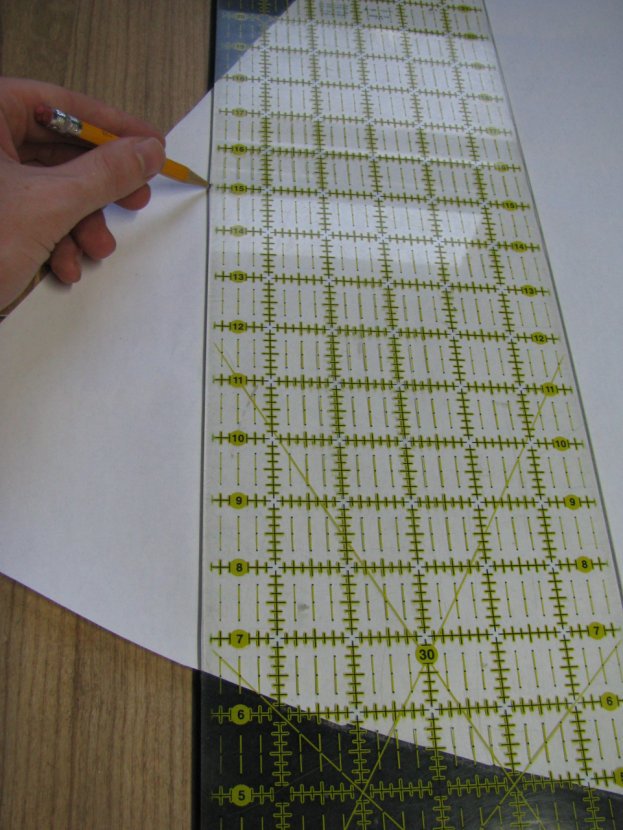

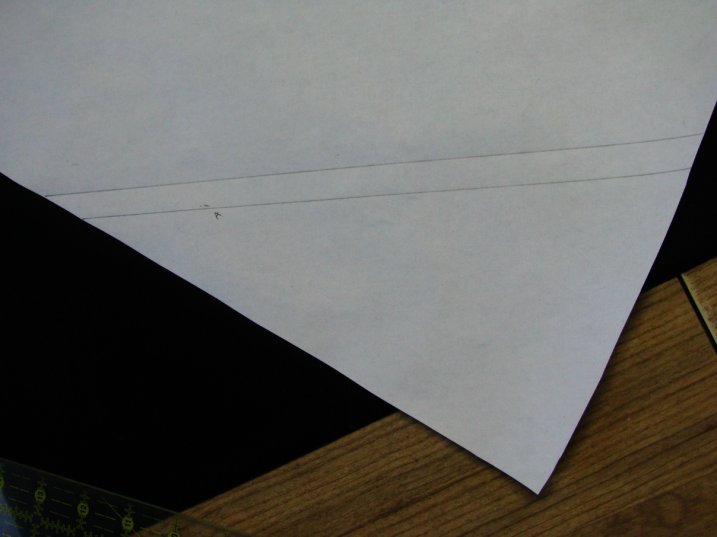

There is a special period technique for laying out the skirt pattern, that helps to save fabric. In the majority of cases, the skirt is too wide to fit on the fabric. Don’t turn it sideways or unfold the fabric! Instead, lay the pattern out, with the front of the pattern against the edge of the selvage. The back of the skirt should be hanging off the edge of the skirt. Take a ruler, place it on the edge of the fabric, on top of the pattern, and draw a line on the pattern, indicating the edge of the fabric.

Now, add twice the seam allowance to this small triangle, which would be a 1⁄2 inch in our case (we’re using 1⁄4” seam allowances, remember). Then cut out this small piece of the pattern, and place it elsewhere on the fabric where it will fit. Snug it up into those little spaces you have still. The longest edge, which has the seam allowance, should be on the grain line.

As you are chalking out the skirt, mark the darts, and then mark the tops, as if you had not cut out any darts in the pattern. This is important as you will not cut out the darts. They are just seam lines. Very important.

Cutting

This can be a nerve-wracking step for some people, especially if you are using expensive fabric like Hainsworth. It’s potentially hundreds of dollars down the drain if you make a major mistake. I remember reading about a tailor cutting an overcoat with fabric that was about $800 dollars a yard. He was very nervous as well! But if you are careful and check everything twice, you should be okay.

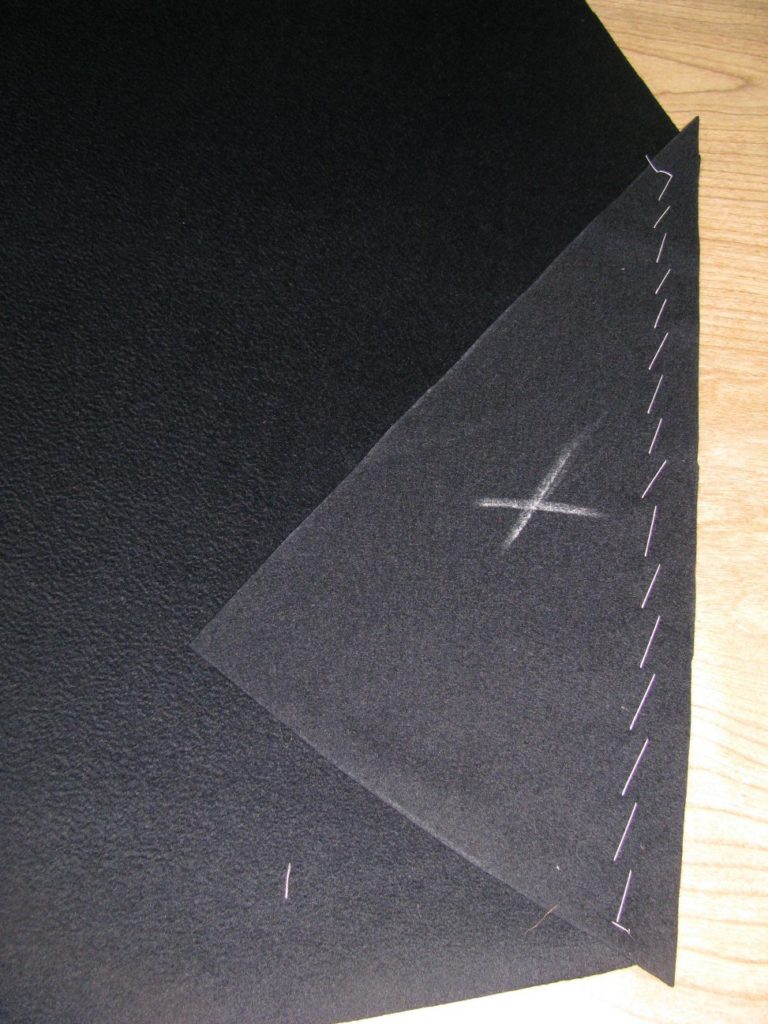

To cut, make sure the shears are held completely straight, not slanting to the left or right. This will help make sure both pieces are cut equally. Cut inside the lines, as the chalk line adds some width to each piece. Make sure you are cutting the inlays with the pieces! After a piece is cut, carefully move the pieces aside, keeping them together as one. This is necessary for the next step. It’s also a good idea to mark an X on the wrong side of each piece, especially if the right and wrong sides are similar in texture.

Tacking

Now, you must mark the inlays more permanently with thread, using tailor tacks. You learned the stitch in the previous module. Do the stitches, cut the threads, separate the pieces slightly, and then cut the stitches in between. I made a video of this process, sent to you in the email. Please view it if you are unsure. Make sure to mark any darts, as well as the chest line on the front of the coat, as well.

Keep the pieces together, still, for we have some ironwork to do.

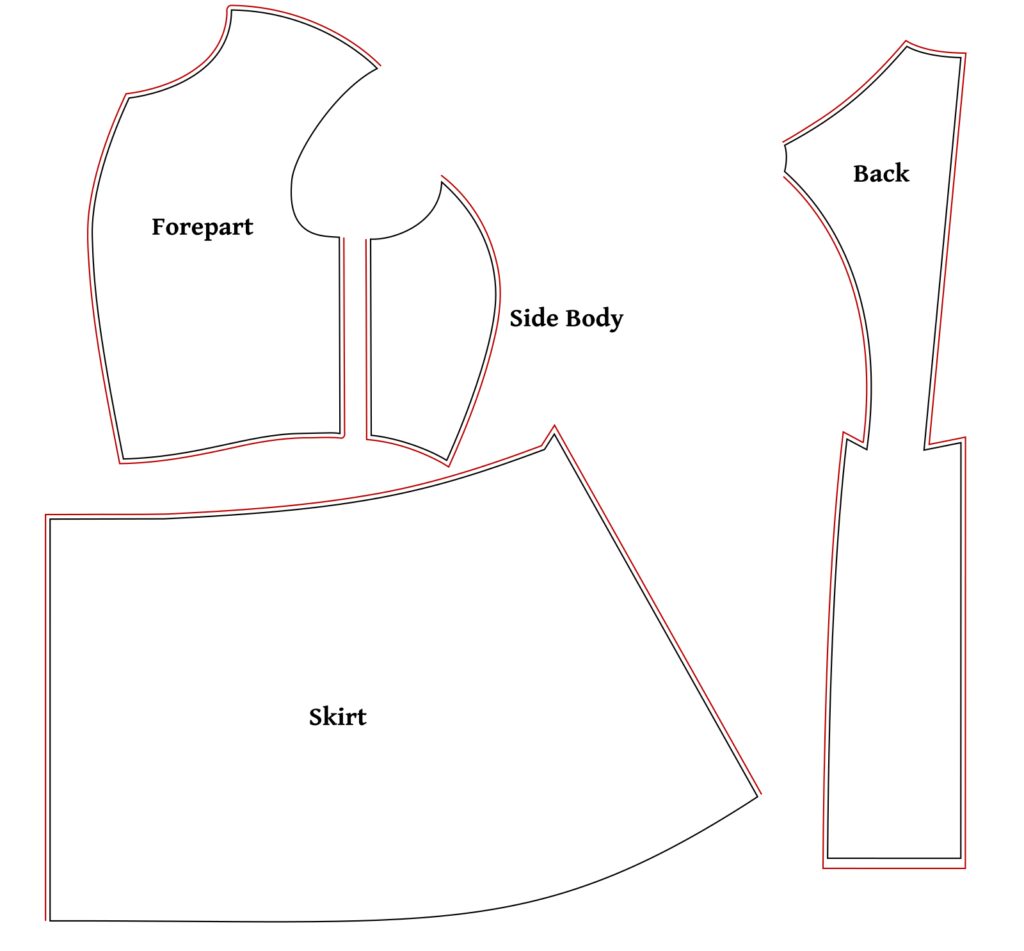

Pattern Details

Before starting on the construction of this Federal enlisted frock coat, it’s important to have drafted and fitted a basic frock pattern using the instructions found in my frock coat drafting course.

There are no major changes to the pattern needed, though one thing is you may need to raise the neck point up an inch or so, which you can check for during the fitting of your muslin toile.

Ensure you have the following before continuing:

Forepart

Should be drafted as normal. Add a 1/4″ seam allowance along the top of the shoulder, neck, front, waist, and side seam. No allowance is necessary in the armscye as Devere seems to account for this in his drafts.

Side

Add a 1/4″ seam allowance along the side, bottom, and back seams. No allowance necessary in the armscye.

Back

A 1/4″ is needed around the entire piece except for the armscye. A 1/2″ seam allowance is recommended along the bottom so that it is slightly longer than the skirt piece, to account for any stretching during construction. This can be trimmed off later.

Skirt

Add a 1/4″ seam allowance along the front, waist, and back seams. No seam allowance is necessary along the bottom because you’ll account for the total length in the draft and it’s left as a raw edge anyway. Also accounted for in the draft is an extra 2″ in width along the front edge, that will be turned in and used as a self-facing later on.