Category: Federal Enlisted Frock Coat

Felling the Lining

It’s now time to permanently sew down the lining. At the shoulder, baste about 1 inch from the shoulder seam. Then turn the raw edge of the seam allowance over, and baste that down as shown.

Along the waist line, and diagonally up towards the side piece and armscye, turn the raw seam allowances over as well, and baste. The basting and turning over ends at the armscye, which remains as it was.

Finally, catching only a stitch or two of the lining, fell the lining down using 8 to 10 stitches per inch. The stitches should be almost invisible. Remember not to let the stitches show through to the right side of the coat.

Pocket and Vent Facing

Enlisted frock coats had a strip of cloth covering the tops of the pockets and vent. This served two purposes: one, to cover the untidy areas of the coat, and two, to aid in the drape of the coat back.

To begin, measure the distance from the center back seam, to the end of the pocket, then add one inch. In my case, I my measurement was 8 inches. On wool fabric, draw a rectangular piece 1 1⁄2 inch wide, by your measurement in length. These should be cut on the bias if possible, or at least semi bias. Use up those scraps of fabric you indubitably have.

Cut out both pieces, and with right sides together, lay both pieces on top of the waist seam. There should be some extra space on the vent side for a seam allowance. Now draw a chalk mark continuing in line with the center back seam, on the facing piece. This is the stitching line, and should be at an angle corresponding with your waist seam.

Sew this seam, trim the seam allowance to 1⁄4 inch, and press the seam open.

Next, lay the facing piece wrong sides together on the coat, centering the center back seams. Starting from the center back, baste one side to the coat. When you get to the end, the lining may be in the way. Remove a few basting stitches from the lining if necessary, and ensure that the facing will lie beneath the lining.

Repeat the basting for the other side.

Carefully fell the facing to the coat. When sewing, be sure your stitches do not show on the right side of the coat. Also, when you get to the edge of the pocket facings, it’s a good idea to take a few extra stitches in place, for strength. You don’t want the stitches tearing open when reaching into your pocket.

If you have any bubbles or loose areas that appear in the facing piece, you can very carefully shrink those away with the iron. Don’t use too much pressure, as you don’t want to affect the coat body.

Securing the Piping

At either end of the collar, where the piping meets, you may have noticed that the stitching does not meet. Yyou need to sew a bar tack there for extra strength. Knot your thread, insert the needle between the layers of piping, and sew about 5 or 6 stitches in place, catching both layers of piping, and the collar fabric itself. This will be very difficult to see later on, and will be further strengthened when the facing is attached.

Piping Ends

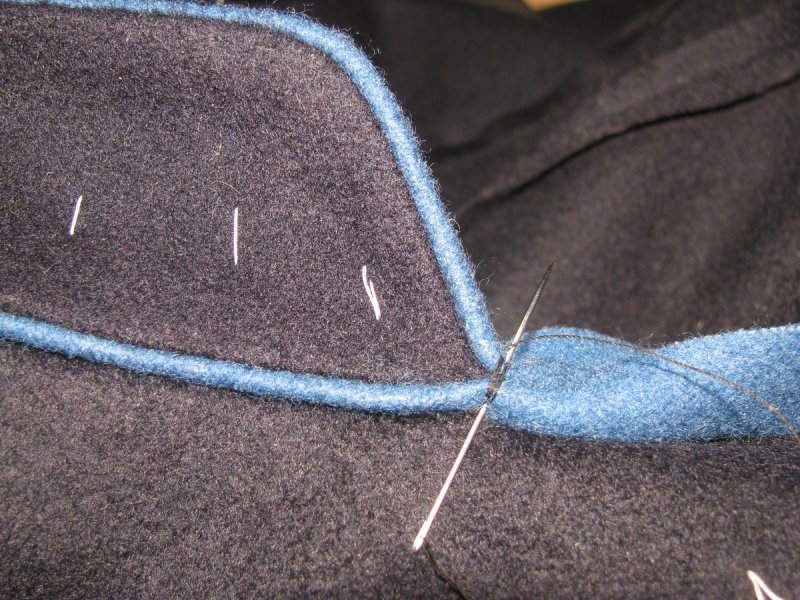

The loose ends of the piping must now be sewn down to the canvas with a cross stitch. Sew down one piping, then the other, catching only the canvas, not the forepart. Again, do not allow any tension to form here, or it will be noticeable on the front and collar.

On the left side of the coat, where the buttonholes will be, you need to leave room for them. I try to cross stitch these ends as close to the collar as possible, and only from the top edge of the piping. This allows me to move the piping later on if it is in the way of the buttonhole. Sewing buttonholes through multiple layers of piping is not fun to do.

The Collar Canvas

There is more work to be done on the collar at this point. First, you must trim the seam allowance off the canvas at the neck, and shoulder seams. The best way is to measure and draw out the seam allowance with pencil on the canvas, then carefully cut away. On the shoulder seam, you can either rest the scissors ‘in the ditch’ and cut carefully by feel, or you can fold the canvas under the seam, creasing well. Then just cut along the crease line. Either way, the canvas must end just about right on the seam line. It’s probably best if it’s a 16th of an inch off, to allow the wool to turn in though.

Using a tailor’s ham, press open the collar and neck seam from the wrong side of the coat. This needs to be pressed well, or you will have a collar that pulls up the neck area. Press carefully, as you don’t want to shrink or distort the neck area.

Place the canvas flush against the neck and shoulder seams, and baste to hold it in place. Using a cross stitch, secure the canvas from the ends of the collar, to the shoulder seam, across to the armscye. End the stitch just before you get to the inlay that should still be in the armscye.

Next, find the collar pattern you drafted without seam allowances. To test the fit, put it inside one half of the collar, underneath the piping. Take note of any adjustments that are needed.

Lay the collar on your canvas, following the grain lines as with the wool collar. It should be placed with the center on the fold. Trace around, but this time, keep the corners square. You’ll trim them after to get a perfect fit.

When cutting out the collar canvas, cut on the outside of the chalk lines, to make the canvas slightly larger than necessary. This is to prevent making it too small, which would cause issues with the collar stance.

Mark the center line of the canvas, and insert the canvas into the collar underneath the layers of piping, as well as the trimmed and turned edge of the collar (you trimmed that very close to the piping seam line). Starting from the center, baste to one side, then do the same for the opposite. When basting, you want the bottom side of the canvas to be perfectly flush with the bottom row of piping. This way, you only have to trim the top.

With your scissors ‘in the ditch’ of the upper piping seam, carefully trim away the excess canvas, starting at the front, and working your way to the other side. The canvas should end up being 1/16th shorter than the seam line.

Using a cross stitch, stitch the lower piping down to the canvas. As you are doing this, try to keep a neutral tension on the canvas and collar. You don’t want pulling or pushing of the canvas, or the collar will not stand straight. Also, catch only the canvas, and try not to go through to the wool, or it will be seen.

After the bottom piping is cross stitched, move on to the top piping. It’s helpful to flip the piping layers around at the ends so that the upper piping is overlapping the bottom piping. Cross stitch along the top piping, again keeping a neutral tension.

Attaching the Collar

Fold the collar in half, right sides together, to find the center of the collar. Mark this with chalk.

The center back of the collar is placed over the center back seam of the coat. Make sure that the piping extends 3/8 of an inch below the top of the coat. This will put the seam line at 1⁄4 inch – our seam allowance. Baste a few stitches in place here, and working towards the left side, baste the collar in place, stitching just above the piping.

Make sure that when you are basting and sewing the collar to the coat, that you fold the lining and canvas out of the way. These cannot get caught in the stitching.

When you get to just past the shoulder line, hold the collar on loosely while you’re basting, so that you can baste in about 1⁄4” inch of fullness into the collar. This again will help the collar stand up nicely. After you get past the most curved section of the neck, hold the collar on normally, with no tension.

The front of the collar should meet just behind the center front basting marks – not past them.

Now baste on the other side of the collar, starting at the center and working your way to the other side of the coat. Baste some ease into the collar in a similar manner, and ensure the ends meet at the same place on both sides.

After ensuring the collar fits and is in the correct place, proceed to sew it down.

For most control and accuracy, hand-stitching is the way to go. Use a pricked side stitch, placed ‘in the ditch’, right where the fabric meets the piping. Stitches should be 8 to 10 per inch, and should go straight through the piping, 1/8” from the edge. On the underside, make sure the stitches line up at 1⁄4” away from the edge. If they are uneven, you will have trouble pressing open the seam allowance there later on.

Also, while taking each side stitch, pull snuggly on the thread. This will pull the collar a miniscule amount inward with each stitch you take, giving more shape to the collar area, and helping it hug the neck.

The side stitching should be pretty much invisible, save for some slight indentations in the piping, perhaps. Technically, you should be able to use a hot pink thread and still not see it. Try it as a good exercise!

If you prefer to use the sewing machine, this can be tricky in its own way, in that the foot is apt to slide off of the piping. You’ll need to use a zipper foot so that the needle can get in snug to the collar fabric.

With either method, start sewing the collar on at the point where the upper piping meets the bottom piping.

Pressing the Collar

Begin by pressing the entire collar flat, using a press cloth and a lot of steam. Then turn under the bottom piping a little section at a time, pressing it as you go. Weigh it down with a heavy iron or clapper if you can.

Press the entire collar again just to get some steam into it before you begin pressing the top piping under.

To press the top piping, start with one end and press that corner under. Then do the same with the other end. You can then press the middle section with more ease. Turn the entire collar over, wrong side up, and gently press out the ripples in the upper piping at the curved areas.

Finally, turn the collar right side up, and using a press cloth, give the whole collar a final pressing.

Constructing the Collar

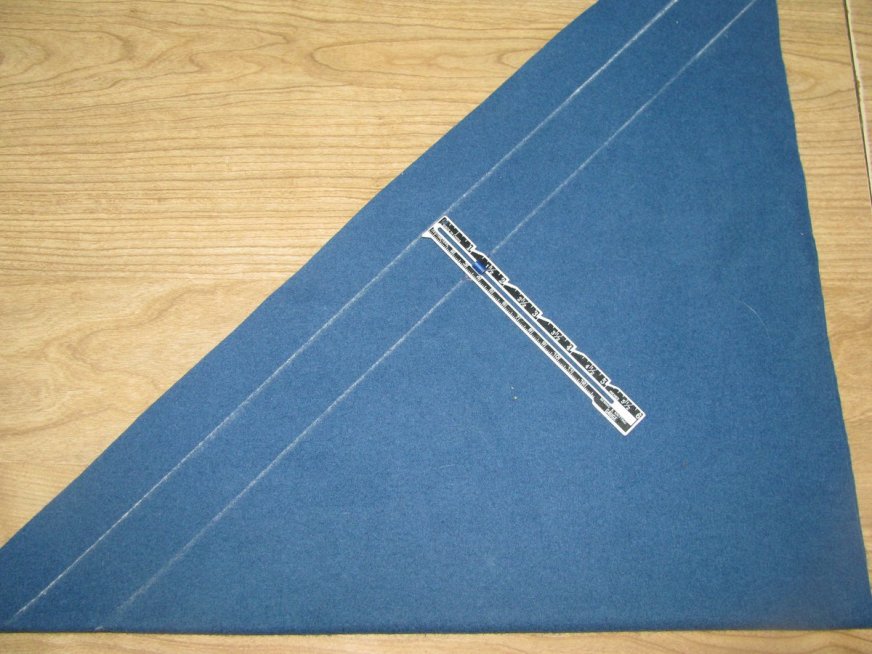

Begin by cutting some bias strips of light blue wool. These should be at a 45 degree angle to the selvage, allowing them to stretch easily. Each strip should be 1 1⁄4” wide. You should cut four pieces so that you have enough for the collar and sleeve cuffs. 24” is a good length.

Cut out these strips, fold them in half, and press well, so that they retain their shape. The finished piping should be 5/8” in width.

Baste one strip of piping, with the folded edge facing the inward side of the collar, to the bottom edge of the collar. The edges should be lined up with the edge of the collar. Using a ruler, mark half an inch from the edge of the collar on both ends of the piping. You will stitch to and from these chalk marks.

Make sure to leave about 2″ of extra piping at either end.

Mark a line on the piping about 5/8″ from each end of the collar to help guide the next piece of piping into place and to mark the end of the stitching line.

Carefully stitch down the piping, using a half inch seam allowance. This will give you piping that is 1/8 inch wide when finished. This can be tricky to do, so go slowly, turning the wheel by hand if you like. If you make the piping too narrow, it will not be able to fold under, and will disappear from view. If it is too wide, it will look bulky and flap around on the finished coat. Definitely not elegant.

Baste on the upper piping, making some extra stitches around the curved areas. You’ll have to stretch and gather the piping in this area as you baste, with your hands. After basting, carefully sew again a 1⁄2 inch seam. The stitching should start and end at just past where the upper piping overlaps the bottom piping. You don’t want to catch the bottom piping in the upper piping seam.

At this point, the sewing is done, and you should remove the basting stitches.

Turn the collar to the wrong side, and carefully trim away the entire seam allowance of the collar fabric. If you angle your scissors in, you can get very close to the seam without worry about cutting through it.

Next trim the upper layer of piping, about 3/16” wider than the collar fabric. This is ‘stair-stepping’ the fabric to reduce bulk and make pressing a lot easier. Finally, trim the bottom layer of piping so that it is just 3/16” wider than the upper layer of piping.

Drafting the Collar

To begin drafting the collar, measure the length neck seam allowance, from center line to center line, then divide by two. Write down that number to use when drafting the collar.

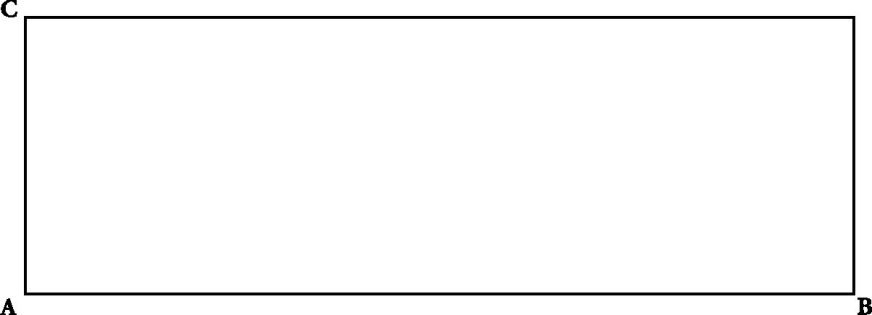

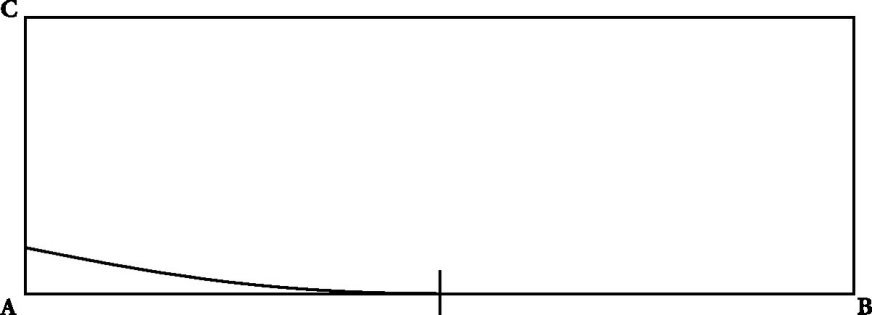

A–B

First mark a construction line from A – B, equal to half the neck length that you just wrote down. In my case, it was 9 inches.

A–C

Mark from A – C the height of the collar. The average collar was about two inches in height, but they became shorter as the war went on. I find that two inches is too high on some client’s necks, and move it down to 1 3/4 inches. That is the minimum that will look good, however.

Complete the rectangular shape as shown.

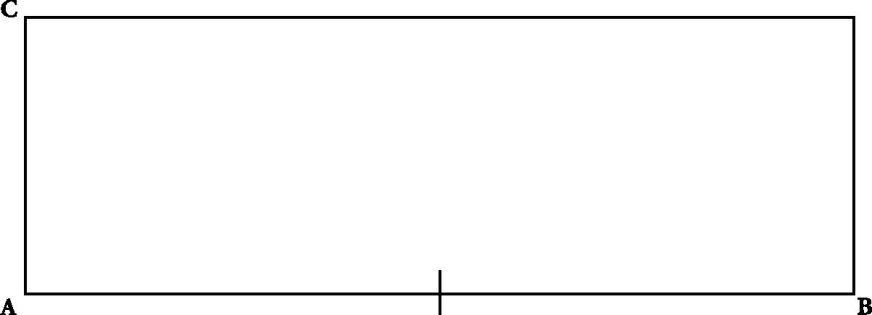

Midpoint

Mark the midpoint between points A and B.

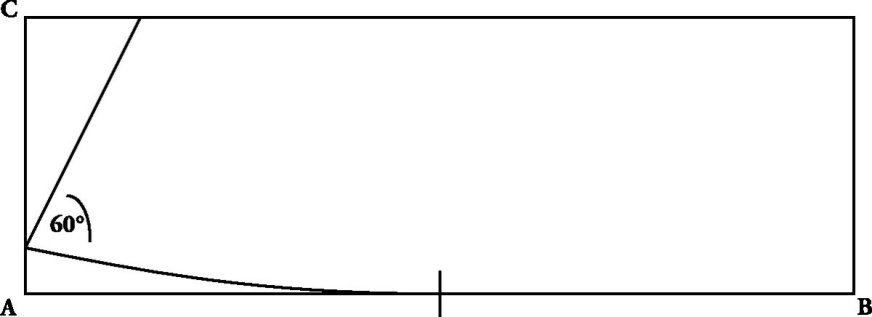

Bottom Curve

Draw a shallow curve, starting from the midpoint, and ending at a point half an inch above point A. The purpose of this curve is to give the collar a little tension, making it stand up and hug the neck more naturally.

Front Edge

Draw a line at a sixty degree angle from the front of the collar. When finished, this will leave a 60 degree gap between the collar halves as per regulations. This line should be a quarter inch shorter than the height of the collar.

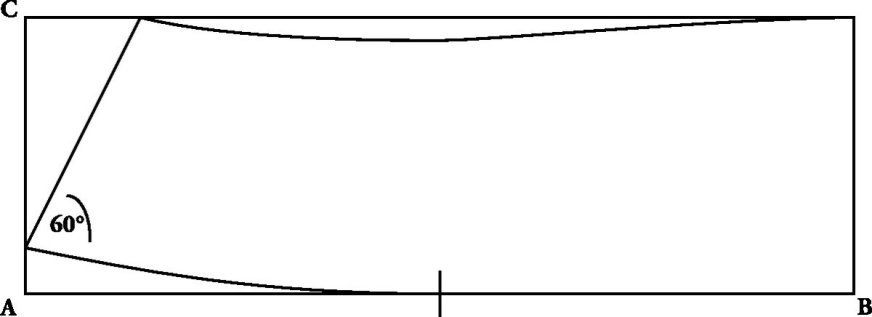

Collar Top

Draw a curved line along the top. When you get to the midpoint, the line should curve back up and reach the end in a right angle with line B.

Curve

Draw a nice curve along the top front edge of the collar. This will make it easier for the piping to be attached in this area.

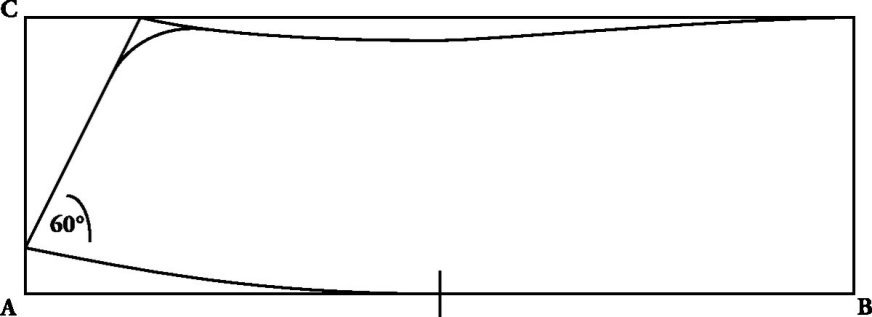

Seam Allowances

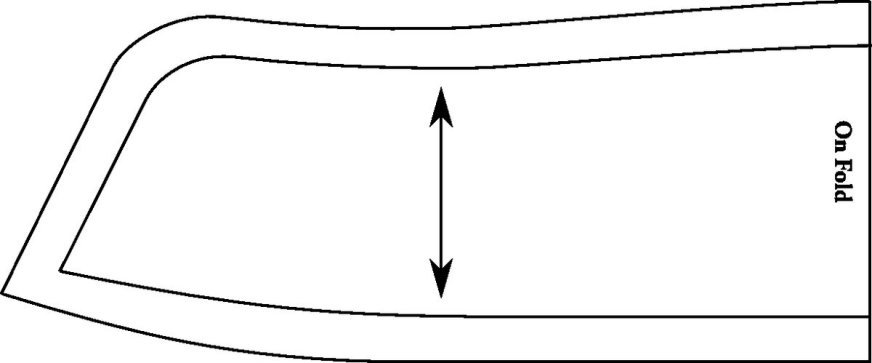

You’ll need two copies of the pattern – one with seam allowances, and one without. Add a 1⁄2 inch seam allowance around the entire collar, except for the middle, which will be placed on a fold. Note the arrows for placement on the cloth.

Place the pattern with seam allowances on the wool, carefully lining it up so that the folded edge will be at right angles to the bottom and top of the collar.

The Back Vent

From the right side, place the left, finished vent over the right side, and carefully line it up so that the vent falls straight and square to the pleats. If possible, have a quick fitting, and pin the vent in place. Then thoroughly baste the vent in place, ensuring no movement.

At this point, you can sew by hand the vent in place from the inside, using a series of backstitches in a rectangular formation. The stitching should not show through to the outside of the coat. This gives a very nice appearance.

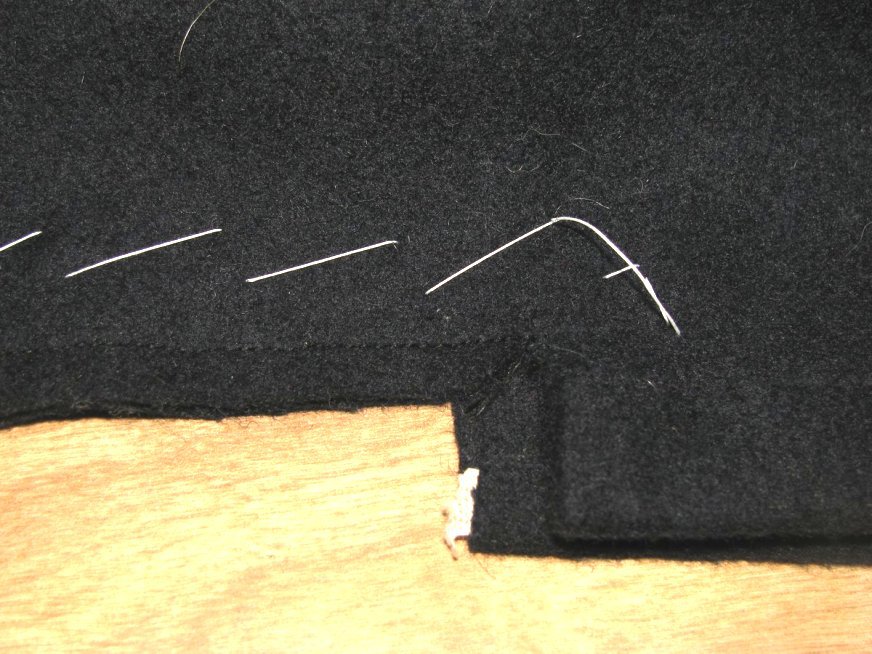

Alternatively, you can sew a box stay on from the outside, to match the finish of the pocket stays. I recommend drawing the rectangular box in black chalk first, then very carefully stitching. This is very difficult to do properly, and the results can easily be lopsided and uneven, as demonstrated in the photo below – one of my earlier attempts. I prefer the first method now.

Center Back Seam

Take both halves of the coat, right sides together, and baste the center back seam together. At the top, the ends should be flush together. At the bottom, remember there are two differently made vents. Finished vent should be a quarter inch below the top of the unfinished vent. You can also line it up by using the cut corner area as a guide.

Sew the back seam with a quarter inch seam allowance. At the bottom, make sure to sew exactly to the end of the clipped corner.

Any further, and the fabric will pucker. Any less, and there will be a hole.

Let the right, unfinished vent come to the inside of the coat, while the left side goes to the outside.

Press as usual. When pressing this seam at the bottom, you will need to have the seam allowance roll over to accommodate the unfinished vent. By doing this, instead of clipping the corner, you add strength to this area.