Author: James Williams

Taping the Canvas

After the padding is completed, lay the lapels out flat, canvas side up, and press them over a tailor’s ham. This will help smooth out any puckers or slight wrinkles, and generally firm everything up.

After padding the lapels, the edges of the canvas need to have linen stay tape applied, to provide a firm edge for the cloth to roll over, and also to prevent the fronts from stretching over time.

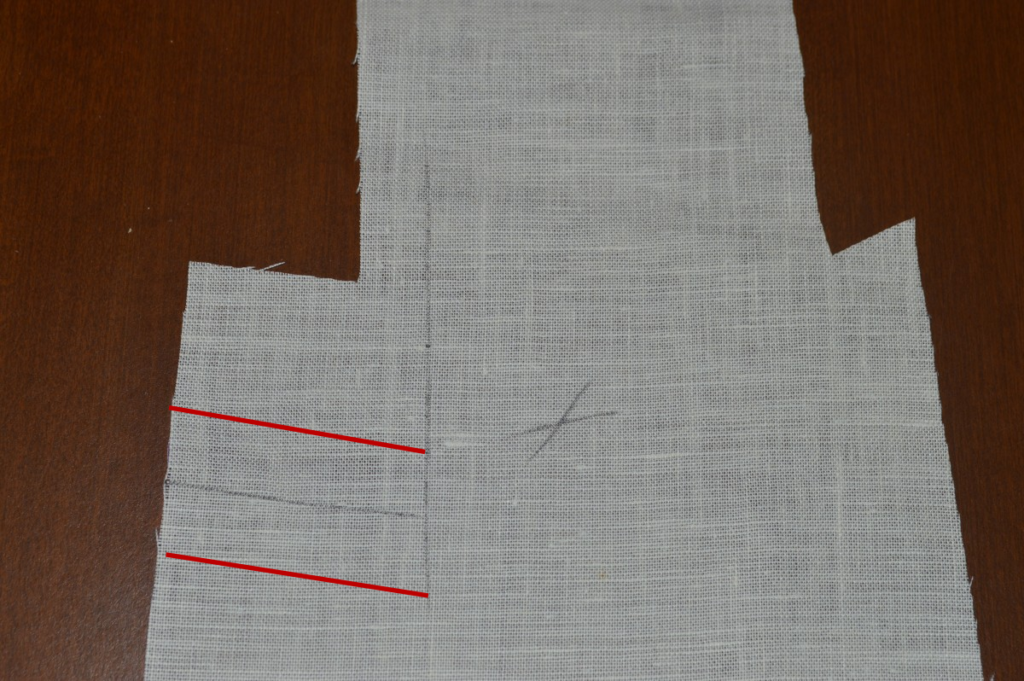

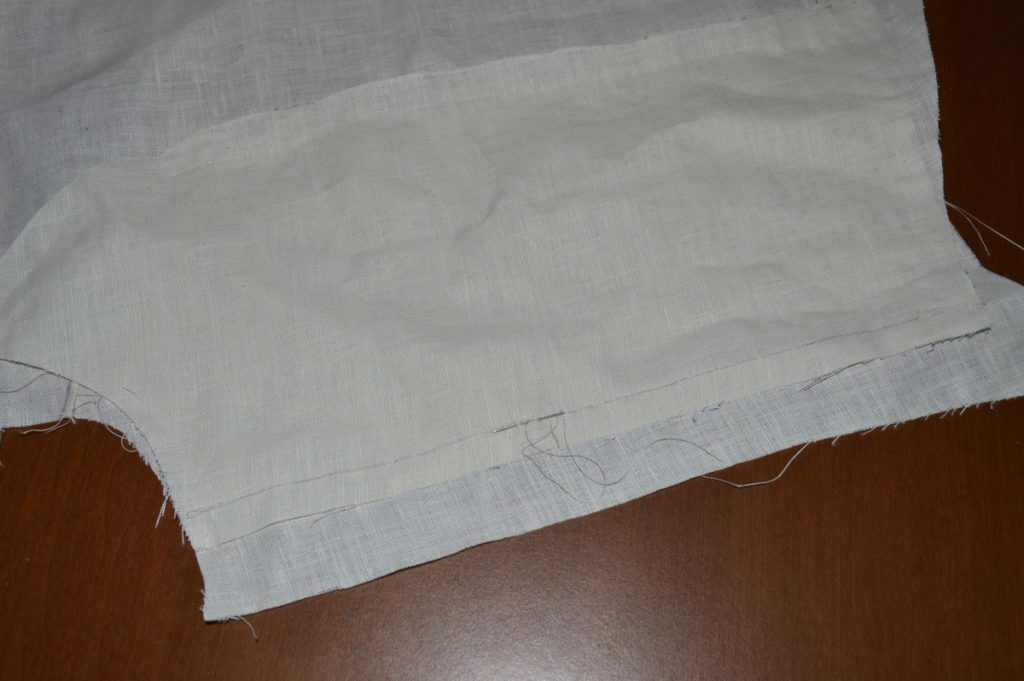

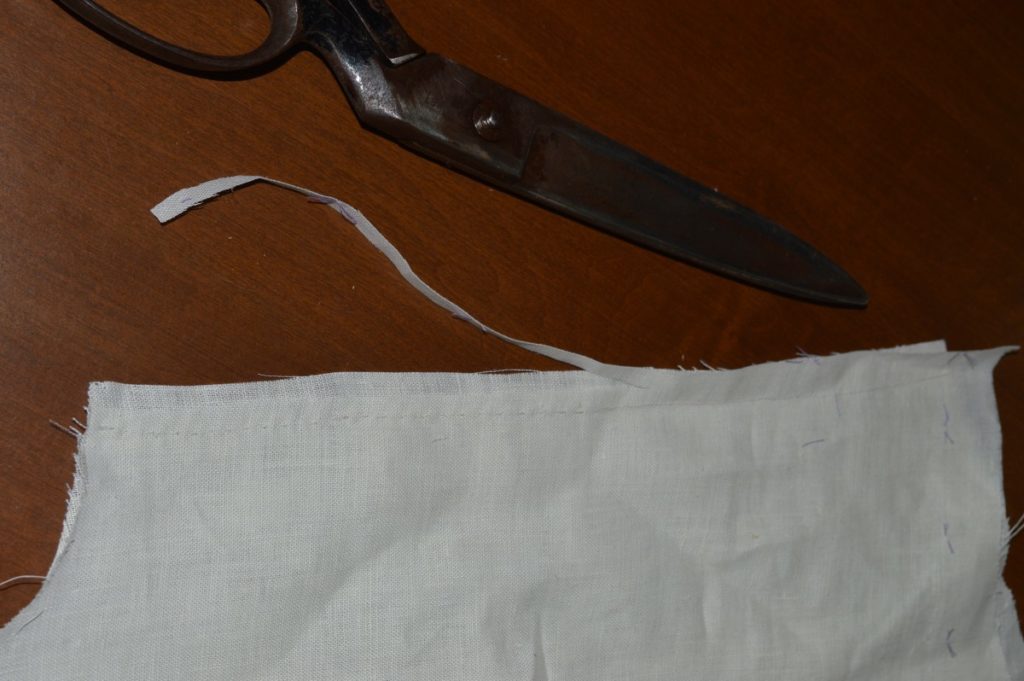

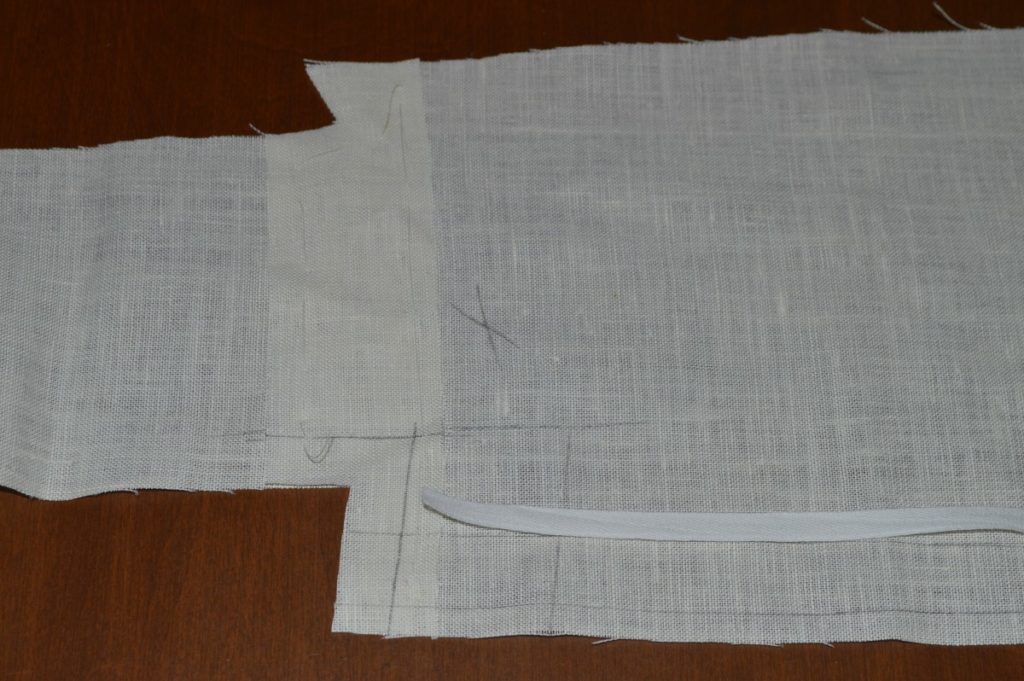

First, the seam allowance of the canvas needs to be trimmed very carefully. This should be 1/4” away from the marking stitches, or 3/4” from the edge of the wool, assuming you used a 1⁄2 inch inlay there. Begin trimming at the top of the lapel, right in line with where it is sewn to the body. As you were pad stitching, the seams on the canvas and wool underneath may have moved out of alignment. If this is the case, the canvas must be trimmed directly in line with the wool piece, or you will end up shrinking the size of the lapel. Mark the trim line with a pencil, then trim this piece as shown.

Trim down the front of the canvas, from the lapel to the waist line, by the same amount as above.

After the canvas has been trimmed, you must continue the line down the front of the skirt. The line should be continuous with the canvas, and be an equal distance from the front edge of the skirt, all the way down. You may notice that the line extends slightly in a direction away from the body, forming a very obtuse angle at the waist line. When the coat is finished, you’ll find this helps to keep the fronts of the skirt closed, with no gap showing.

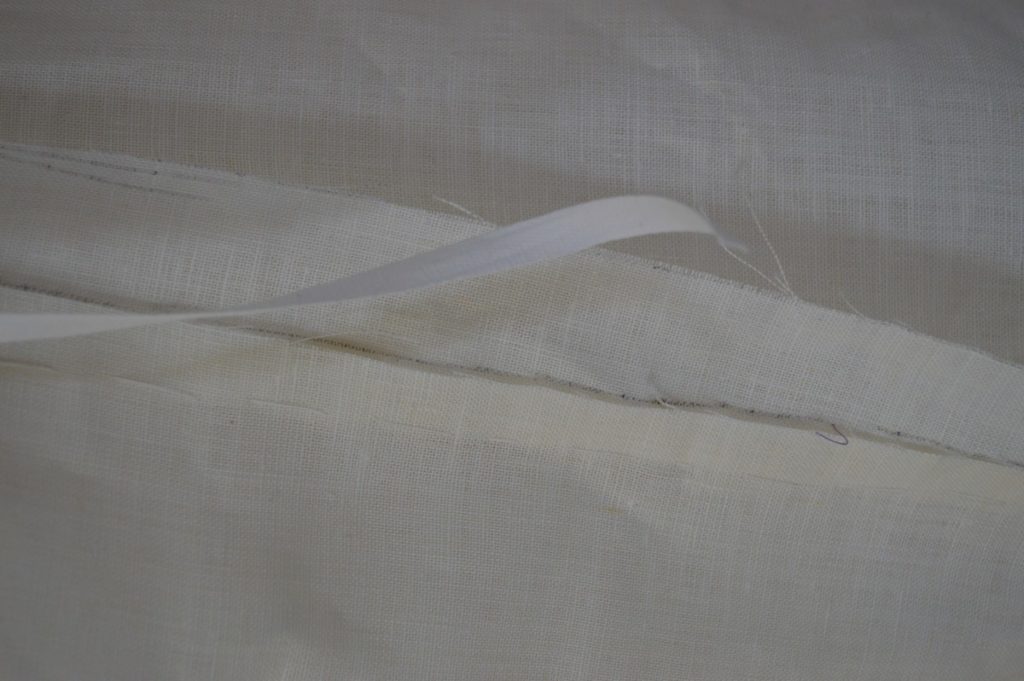

Starting at about a 1/2″ above the bottom of the skirt, add stay tape to the inside of the chalk line, basting it down. You may hold the tape on slightly for the first 8 inches (only about a 1⁄4 inch of tightness is needed), to help the skirt front stay towards the body.

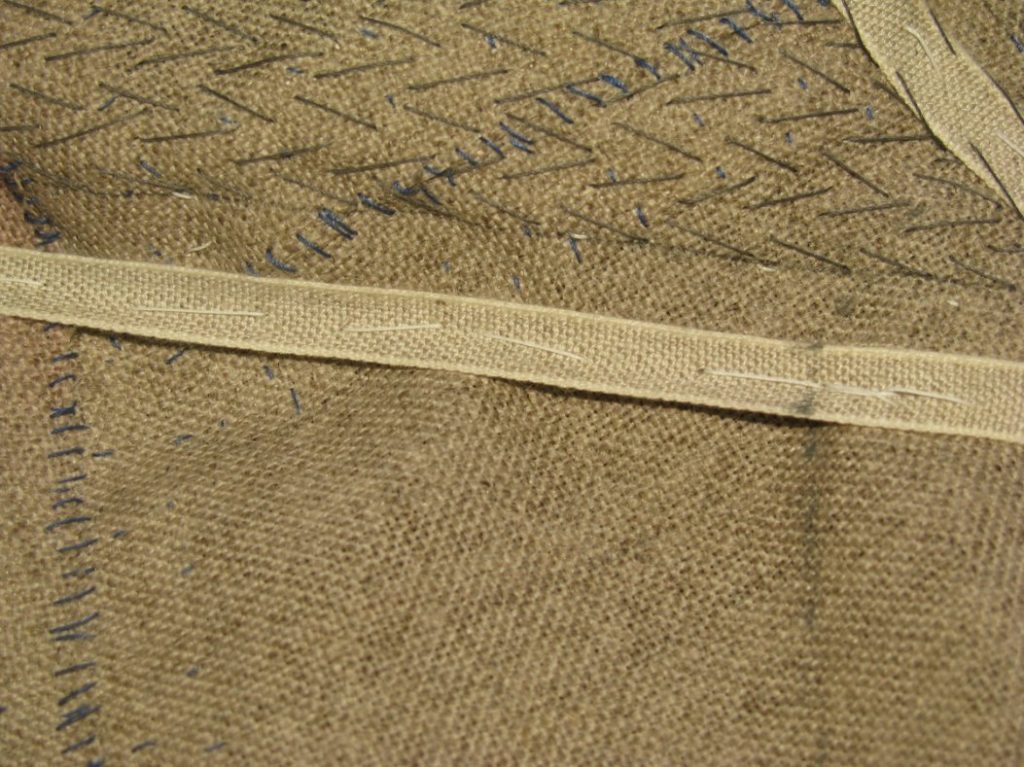

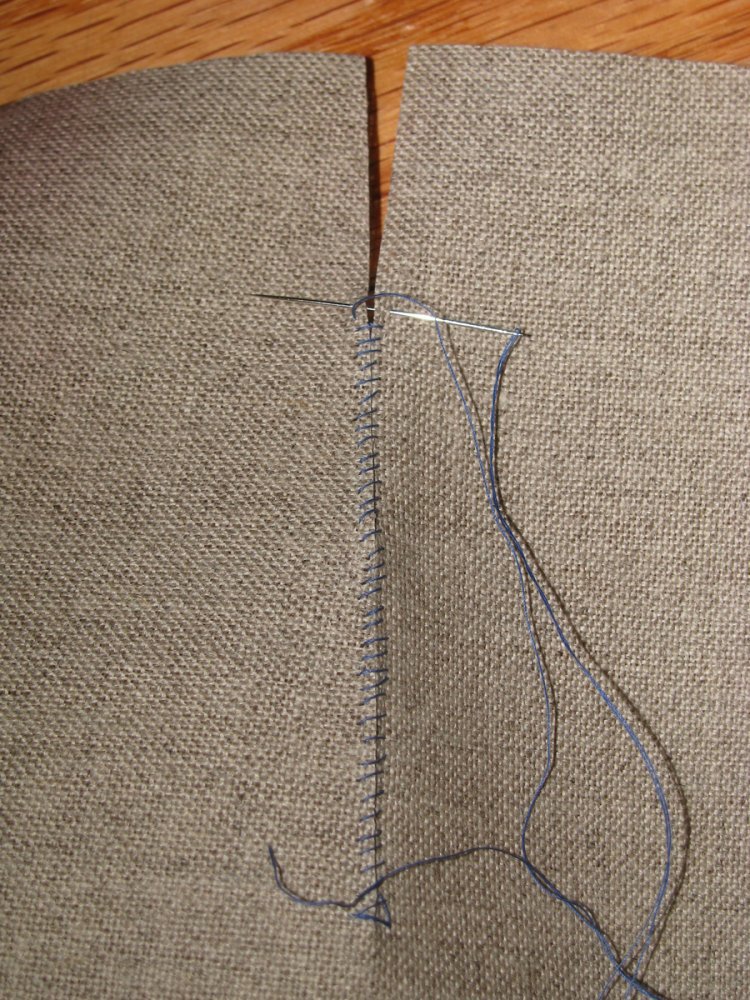

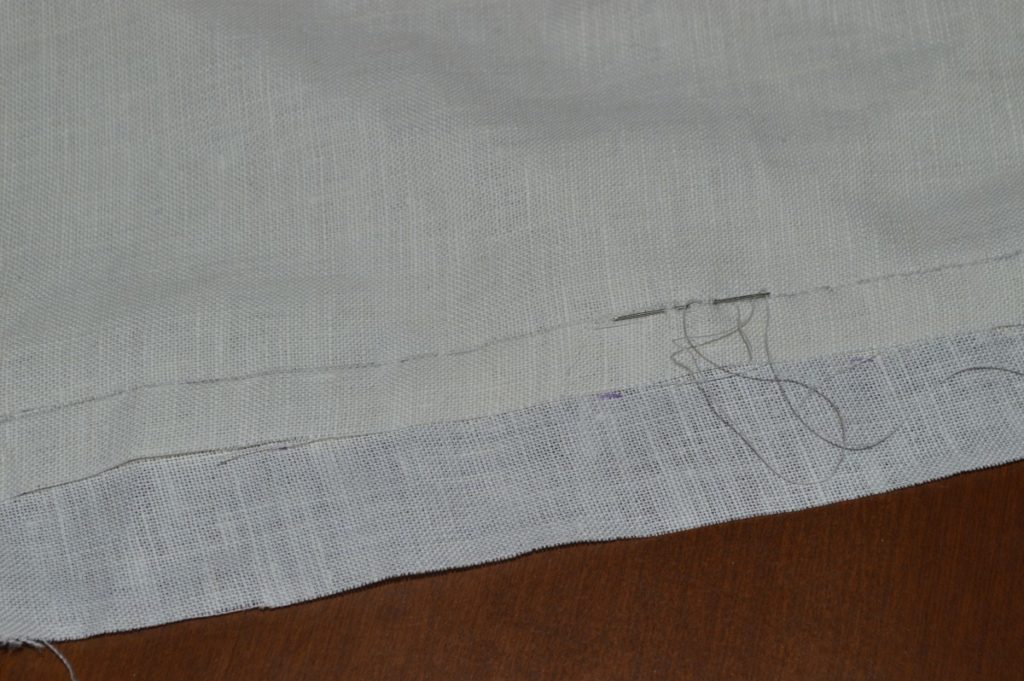

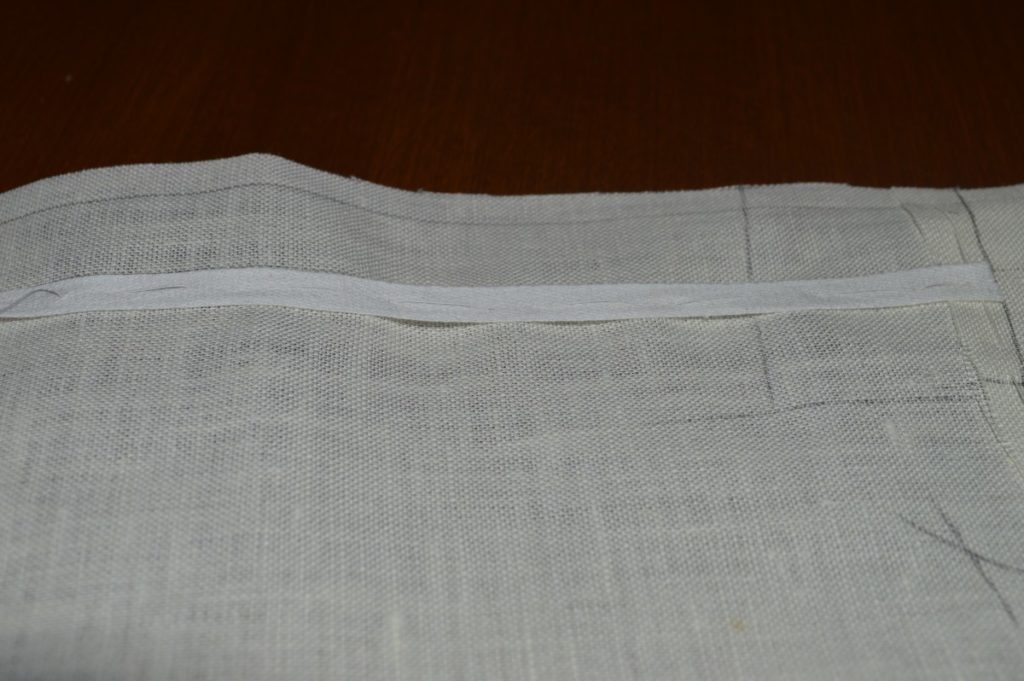

Continue laying the tape on top of the canvas. The tape should extend 1/16” off the edge, to reduce bulk.

When you get to the roll line, add 1⁄4” of ease in the tape, so that the lapel may roll freely. If this step is forgotten, the lapel will end up staying away from the body, giving an unsightly look.

Continue taping until the top of the lapel. Here you have a sharp angle, which must be mitered to avoid bulk in this area. First trim at an angle through the stay tape, leaving just a small bit untrimmed. You should aim for the very tip of the lapel.

Next, fold the tape along the top of the lapel, and trim away the overlapping section.

Continue basting along the top of the lapel. When you get to the center front seam, make another snip in the stay tape so that you can continue basting the stay tape along the gorge line. Note in this photo how the seam of the canvas is not aligned with the seam of the wool body, as discussed previously. This is an issue I need to do more experimentation with.

Continue basting the stay tape on until half an inch beyond the roll line. Note how the stay tape is laid against the seam allowance, not the inlay marks.

Now slip stitch the stay tape to the coat along both sides, being careful the stitches do not show through to the right side.

The Bridle

The bridle is a controversial addition in an 1860s frock coat. Of the original frock coats I’ve personally examined, I haven’t found this feature yet. It may be that they were just exceptionally rare – even today, you only find them on the higher end suits. In any case, it is up to you to decide whether or not to put the bridle in.

The bridle helps with the roll of the lapel, by tightening up the chest area just outside the roll line. This has the effect of putting in another dart, which in turn makes the lapel inclined to roll more naturally.

Starting at the top of the roll line, and 1⁄4 away from the roll line baste down a length of stay tape for about three inches. At this three inch mark, make a couple of stitches in place.

For the next three or four inches, depending on the length of your roll line, hold the tape on tightly, pulling the canvas and wool into a smaller space. At the end of this section, again make a few stitches in place to prevent the ease from escaping.

Finally, for the next section, hold the tape on with a neutral tension, ending about 3 inches above the bottom of the roll line, to allow the lapel to roll freely.

Using a cross stitch, stitch down the bridle. You should see the excess ripples of fabric disappear as you go along.

After the bridle is sewn down, you can press the lapel over the roll line. The iron should stay away from the bottom of the lapel, or you’ll remove the roll and end up with a crease instead.

Padding the Lapels

Now is the last chance to adjust the roll line of the lapel. If you wish, baste together the coat again, reinforcing the neck and armscye with stay tape, and double check the roll line. You may wish to adjust the depth. This is a completely optional step. When satisfied with the position of the roll line, chalk along the outside of the coat, staying in line with the tailors tacks. Then baste along the edge, pushing any excess upwards as you go.

On the canvas side of the coat, use a pencil to mark the roll line on the canvas. I like to use a pencil here because it is more accurate than the tailor’s chalk.

On the outside, chalk and baste along the inlays from the neck at the top of the roll line, to the edge of the lapel.

Transfer this line to the canvas side, marking in pencil, then mark in another 1⁄4 inch for the seam allowance. This is chalked only because the darts may affect the position of the neckline slightly. Along the front edge of the lapel, draw a chalk line 3⁄4 from the edge (inlay plus seam allowance). This area in between is where you will pad the lapels.

Also, draw a line continuing the neck seam line, across the bottom of the lapel ‘peak’. This will not be padded yet, but saved for afterward, as you will see.

Continue drawing the seam line all the way down the front of the coat.

Beginning at the edge of the lapel, directly next to the roll line, begin pad stitching up along the line. The needle is always pointed in the same direction, you simply work towards and away from you. The stitches should be about 3/8 inches in length, and show just a pin prick on the right side of the coat.

For the first few rows, pad the lapels while flat with the rest of the coat. As you pad, the thumb slightly pushes the canvas closer in the direction of the roll line, while the wool underneath is pulled by the fingers in the opposite direction. This is such a minuscule pull in each direction, that you shouldn’t even try it. If you’re thinking about it, you’re pulling too hard.

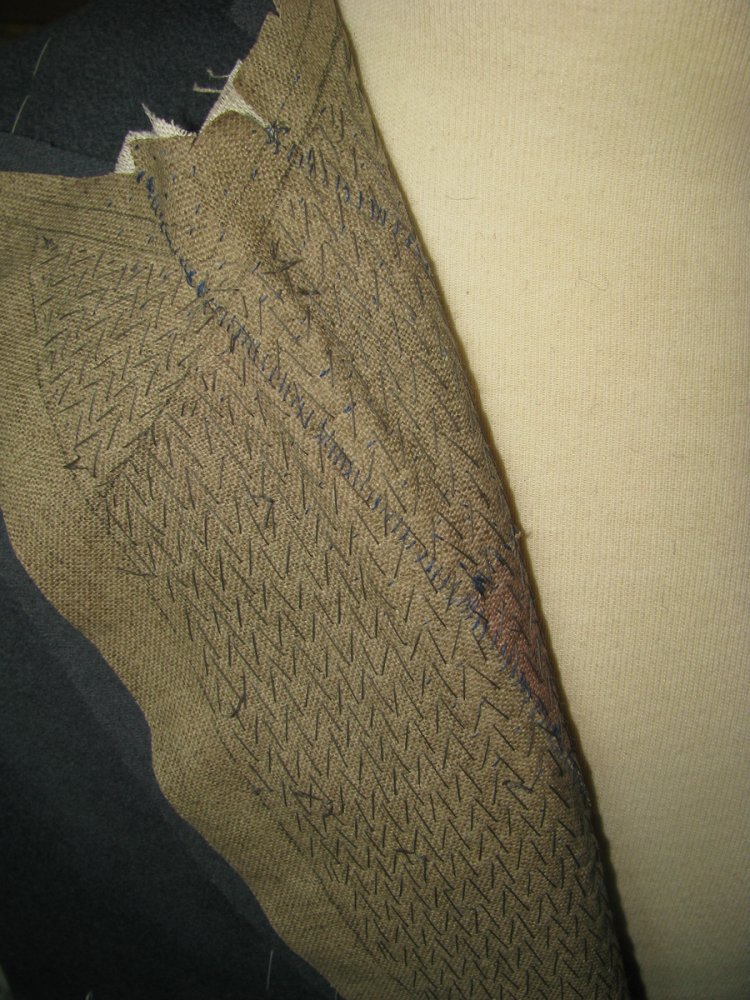

After the first few rows of padding, turn the coat over, and pad the rest of the lapel in the position that it will lay on the finished coat.

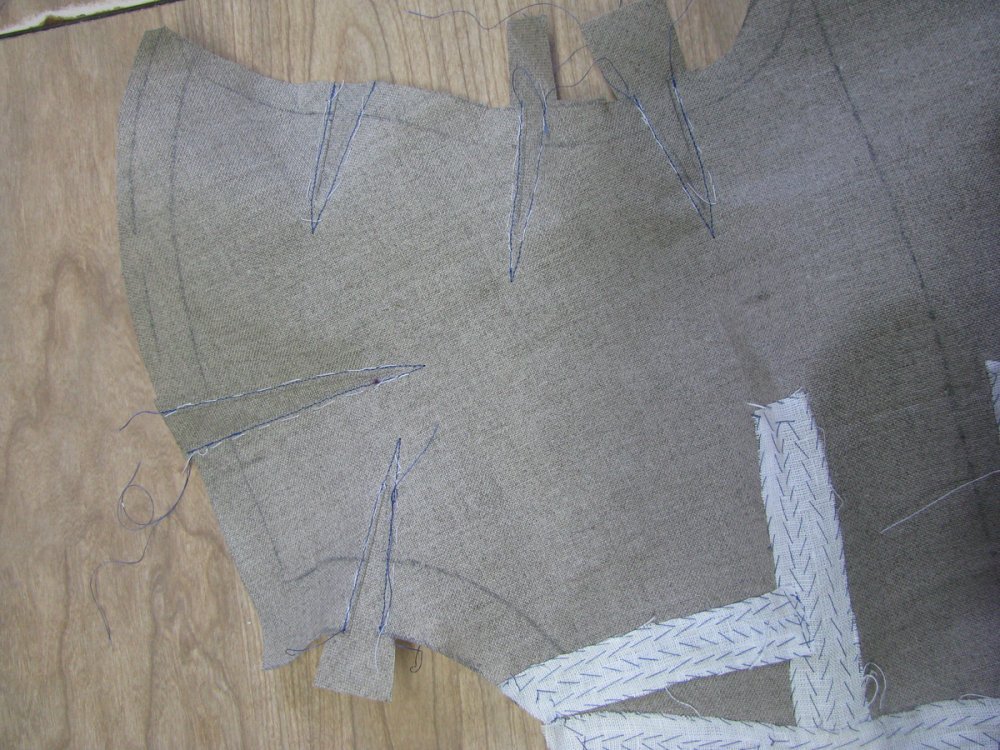

Note how the peak of the lapel has not been padded yet, and how the padding stops about 1/8 from the pencil lines. This is because we’ll be trimming the canvas on the pencil lines soon. When padding, you may have noticed that the canvas became shorter than the lapel underneath. This is because the canvas has to travel on the outside of the curve, thus taking up more material. To make up for this, you should redraw the pencil line, measuring the proper distance from the edge of the wool, not the canvas. Add an extra row or two of pad stitching to fill up this new space if necessary.

Padding the Lapel Peak

If you have peak lapels, as often found on double breasted coats, it must be padded separately, to ensure it stays against the body of the coat. Turn the peak over onto itself, wool sides towards each other, and pad in the direction of that line you drew. Think of it as a secondary roll line. These pad stitches should be smaller than 3/8, and get even smaller as you get towards the very tip of the lapel.

When complete, the lapels, properly padded, should want to roll over and towards the body almost naturally. The darts in the canvas should aid in this, as well.

Next, we’ll tape the canvases and finish the front edge of the coat.

Installing the Canvas

Installing the canvas is a very important step. As you baste the canvas in place, all slack in the wool forepart must be eliminated, or it will show up in the finished coat.

First, lay the forepart over the canvas, with the linen side of the canvas against the wrong side of the coat, so that the center front seams of each are precisely aligned with each other. Baste from the roll line, along side the center front seam, to the waist, pushing the excess fabric downwards as you go (in the direction of the arrow). Stop about half an inch from the waist seam.

Next, from the middle of the chest, basted down, parallel to the center front, pushing the fabric downwards and towards the side seam as you go. Ensure there is no excess between the two lines of basting stitches.

From about the same height, basted down along the edge of the canvas smoothing downwards and again towards the side seam.

From the level of the second basting stitch, and midway to the first row of stitches, baste upwards, straight to the roll line, and then follow the roll line and the neck, staying out of the inlay and seam allowance, until you get to one inch below the shoulder. Since this is the fullest part of the coat, it can be the most difficult to get correct (and took me two tries). Hold one hand underneath to support the fullness as you baste. It takes some practice to get a feel for the technique.

Starting at the same level, but this time between the second and third rows of stitching, baste upward through the center of the shoulder, pushing any excess towards the armscye as you go.

Beginning at the shoulder, baste downwards along the edge of the armscye, smoothing the fabric down and out as you go. Continue basting under the armscye along the edge of the canvas until you meet the third row of stitching you basted in. There should be no excess fabric anywhere in the forepart, except for the area above the roll line. If this is not the case, you’ll need to go back and redo your basting.

Finally, baste from the roll line, down along the center of the lapel, to half inch above the waist. This completes the process of basting in the canvas. You should carefully hold the coat up at this point and look for any excess that you missed, and redo the basting if necessary.

Once you are satisfied with the result, trim off the extra canvas from the center front, neck, shoulder, and armscye. Once this is done there is no room for adjustment, so be sure you are happy with the results first.

Turn the coat to the inside, and observe the waist seam. There should be about an inch extra inlay, which will need to be trimmed off carefully so that the end of the canvas is flush with the seam line.

With your scissors in the ‘ditch’ of the waist seam, carefully cut away this extra canvas. Cut a little bit at a time, and check between each cut that you are cutting accurately. If you cut too much away, the coat front will be pulled upwards and give an unsightly appearance. It’s okay to leave about 1/16 inch extra canvas. The extra fullness in the canvas will keep the wool in shape.

Using a cross stitch, secure the canvas to the waist seam of the coat. This will hold it permanently in place. Stitch from the inner edge of the canvas, to about two inches from the center front, where the tailor tacks are. You can use the basting stitches holding the canvas in place as a guide.

Canvas Construction

We will now begin construction of the canvas – a large amount of work even by itself. Allow at least eight hours for constructing the two halves of the canvas.

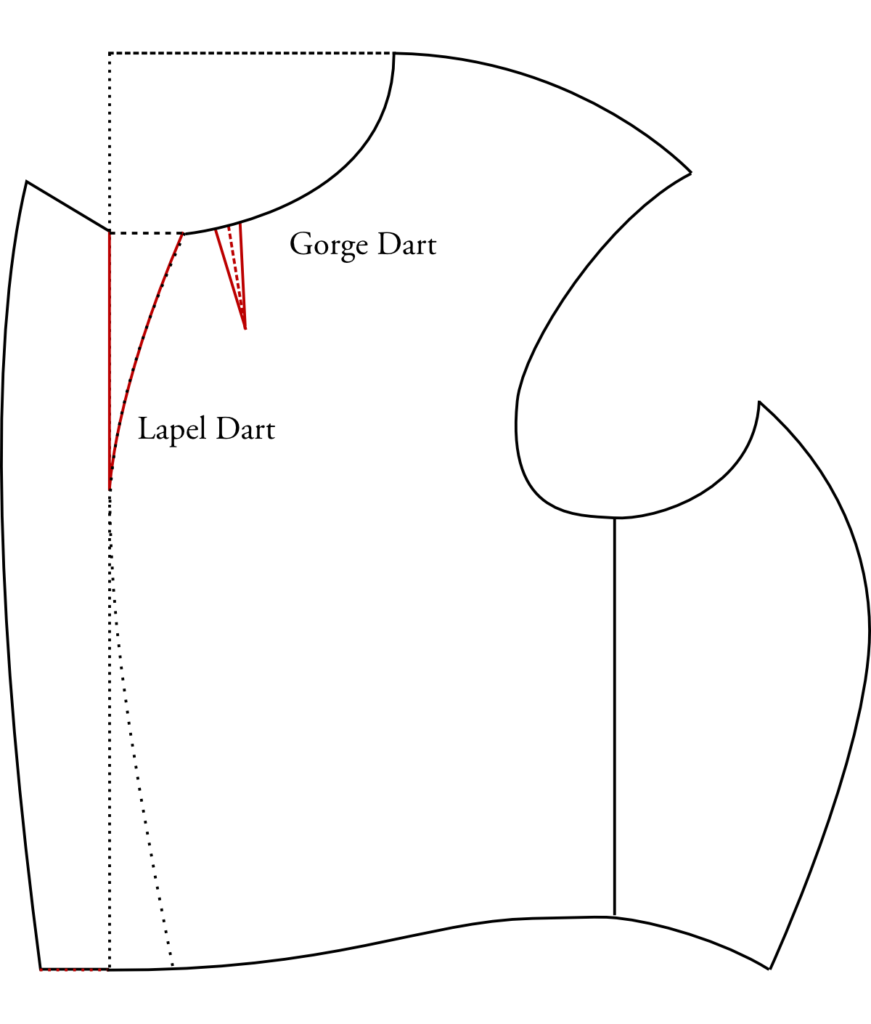

Cut out the two center front darts, as well as the lapel dart, directly on the construction lines you drew.

Stoat each dart closed, holding the edges together with your thumb and fingers as you go. The edges must butt together, but not overlap. Because the canvas is thin, and hidden in the finished coat, it is perfectly fine to have the stitches show through to the other side.

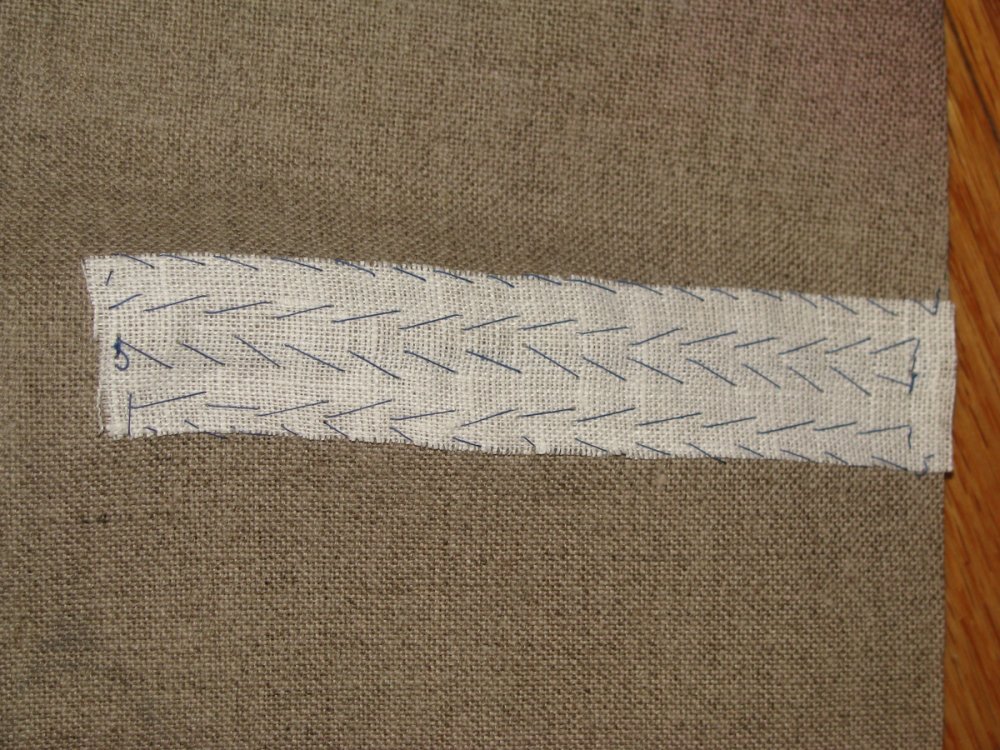

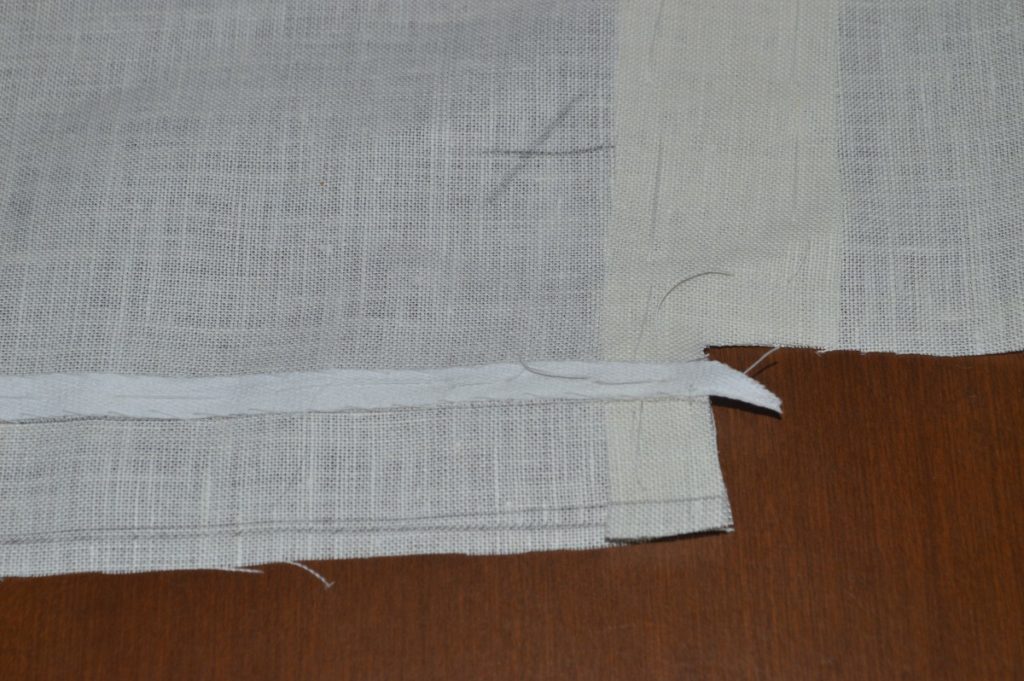

Cut a piece of linen 1 inch by the length of the dart plus one inch. Stretch the linen to prevent sizing issues later on, and place it squarely over the dart you just stoated closed. Using a padding stitch, pad down the middle of the linen, catching both edges of the dart underneath.

Then pad down the middle of each half of the linen, then along the edges. When complete, you will have a very strong canvas, with almost no movement. The padding also adds a little more shape to the canvas, making it less pointed, and more round.

Repeat the process for the other dart, as well as the gorge dart.

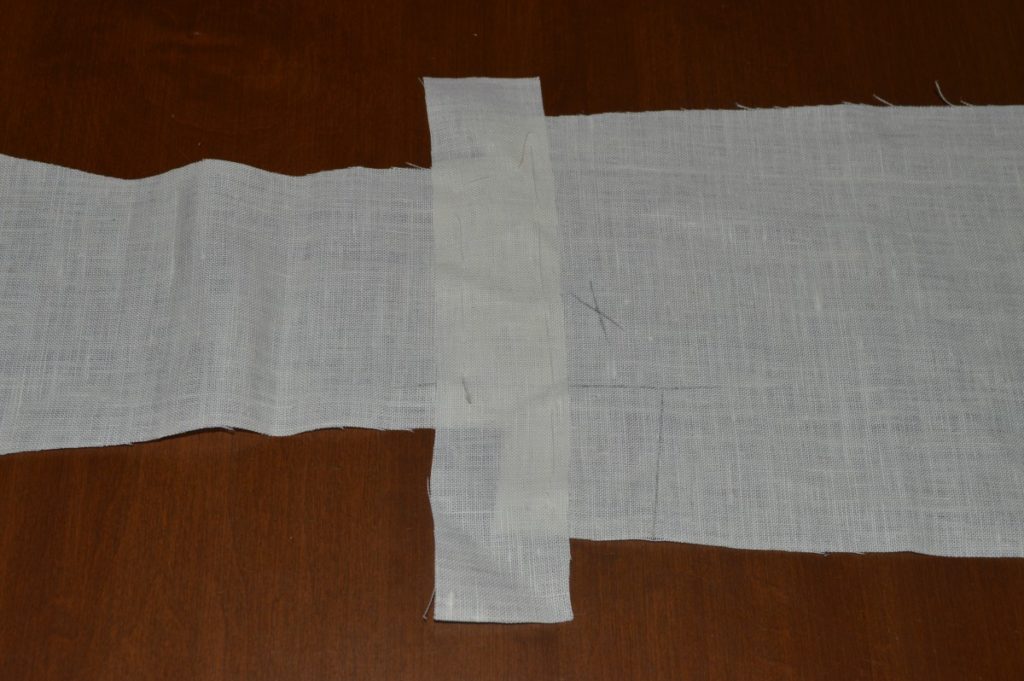

Next, join the lapel canvas to the body along the center front seam, using the same stoating method. Start at the top to make sure it’s properly aligned. Because of the darts you added to the canvas, the body will now be about an inch shorter than the lapel. If you added the correct inlays to the canvas, however, this will not be a problem. Note in the photo the completed gorge dart, as well.

After all darts and lapels are sewn, it is time to make the cuts in the canvas at the shoulder, neck, and armscye. Clip directly on the lines.

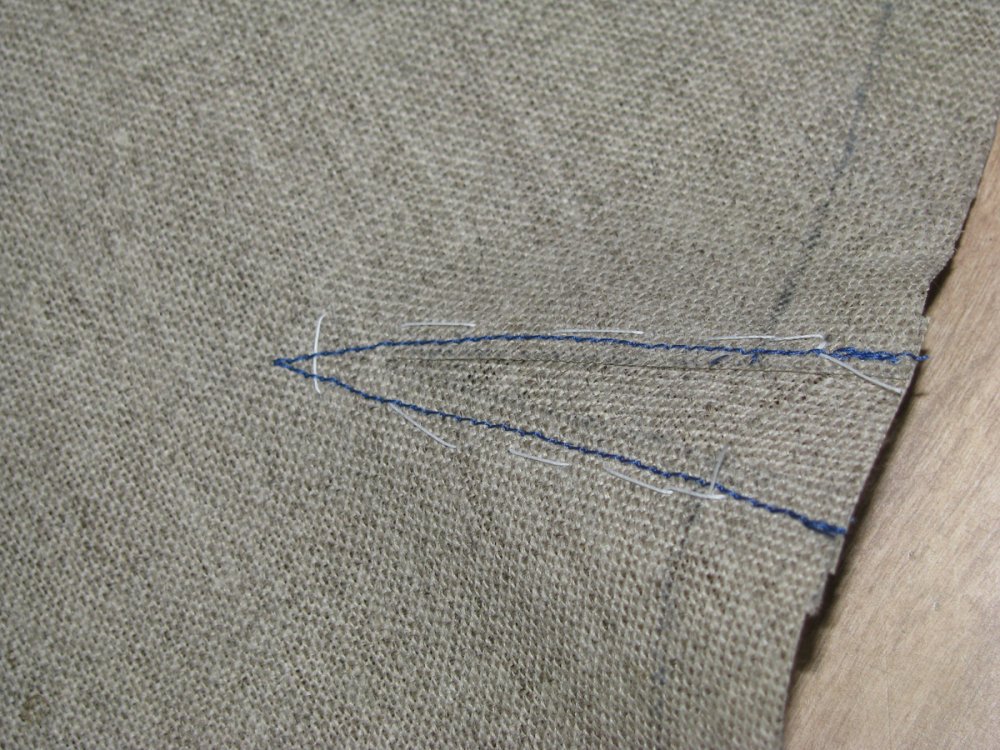

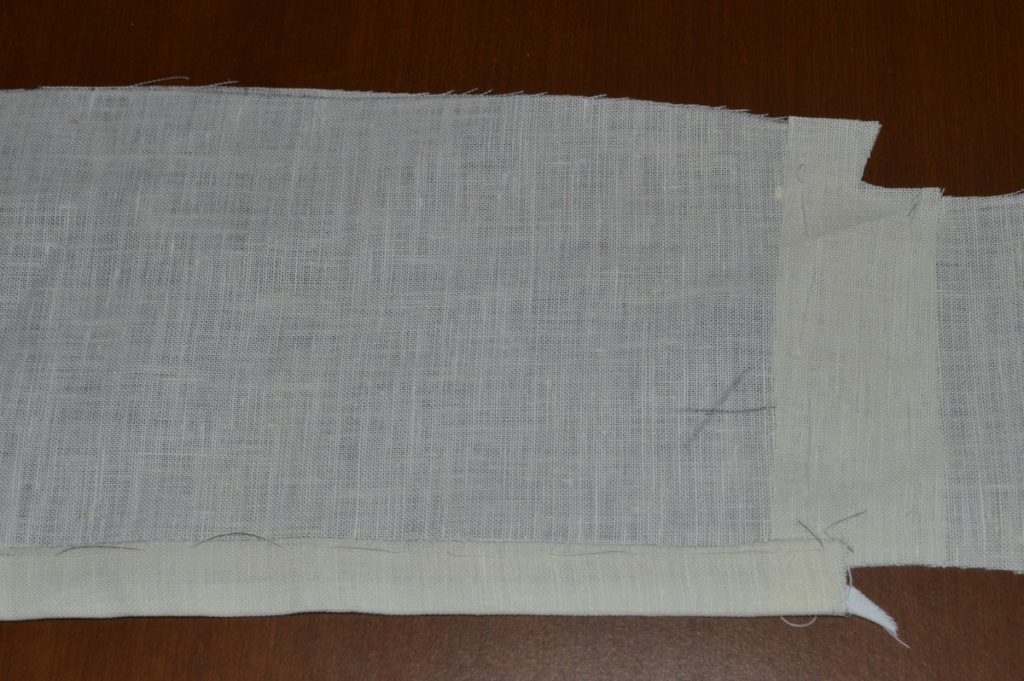

On the bias, cut 10 strips of canvas, 1 1⁄2 inch wide at the top, by half an inch at the bottom, and four inches long.

On the wrong side of the canvas (the opposite side of linen covered side), baste one edge of the bias canvas strips to one edge of the cut.

Open up the cut about 1⁄2 an inch, and baste the other side closed. This forms a gusset, copying the ironwork we put into the forepart.

Machine or side stitch the edges of the gusset closed. If using a side stitch, the stitches must be close together and pulled tightly, or there will be too much movement and the gusset may weaken over time.

Repeat the process for each of the gussets, on both canvas halves.

Trim the edges of the canvas inserts flush with the canvas itself. The canvas at this point is completed, and will now be installed into the foreparts of the coat.

Side Seam

The first thing to do is complete the side seam. Begin by basting 5/8″ from the edge, right sides together, and sewing with a back and fore stitch, with the right side of the stitches being on the side-body.

Trim off the unused inlay from the forepart. You can do this before basting if you wish, I just ended up doing it now.

Trim the seam allowance on the forepart down to 1/4″, or slightly smaller.

Press the seam towards the forpart. The discrepancy in lengths is due to me forgeting to add an inlay to the side-body.

Press and baste the 1/2″ seam allowance under the forepart seam. I basted it because the seam is slightly curved at the bottom, and it gives me more control and less to worry about while sewing. Fell down the folded edge.

Remove the basting stitches before you forget. Here is the progress on the coat thus far.

Second Fitting

Before assembling the coat permanently, it’s a good idea to baste together all of the pieces to ensure that everything fits properly. In this particular fitting, we’ll be most concerned about checking the side seam, and the height of the waist seam. Normally, the muslin sleeves would also be fitted here, but we will leave those out for now to simplify things. This fitting also serves as a ‘dry run’, so that there are no surprises when it comes time to sew things together.

Begin by basting the coat together, wrong sides together, in the same manner as you did the muslin toile during the drafting process. The end result will be a coat with all of the seam allowances on the outside. This makes it extremely easy to have someone fit you while you’re wearing it. Remember that everything has a 1/2″ seam allowance.

Before trying on the coat, it’s a very good idea to baste a length of stay tape around the neck seam and the armscye. This will prevent any unwanted stretching.

Here’s the side seam, showing the inlay next to it. Remember to treat the tailor’s tacks as the edge of the cloth. If necessary, you can use this inlay to expand the fit now. That’s a piece of stay tape hanging down from the armscye, if you were wondering.

Here’s the back seam and the vent area. Baste the left side of the vent over the right side to secure it and prevent tearing of the fabric. For the back piece, feel free to sew it right sides together with the rest of the coat to make things easier.

Here’s the shoulder seam, again showing the inlays. We will not be fitting the shoulder seams at this point, so don’t worry too much about them yet.

When the skeleton baste is complete, try it on, and besides the side seam, take a close look at the waist in the front. It should be about an inch below the natural waist, or just slightly below the waist coat. If it’s too low, that is most likely a balance issue – the front of the coat is too long – and you may want to add add a gorge dart, and move the waist line up slightly. As long as you’re just basting, it’s a good time to experiment with both of these. Post a photo of your fitting in the forum and I’ll help you determine what to do.

Right Back Skirt

The right side of the skirt is even easier to construct. This time, no diagonal cut is made at the top of the step. Begin by marking out your lines 1/4″ and 7/8 or 1″ from the edge. Lay out the stay tape from the top (it can extend off the edge here), to 1/2″ from the bottom and baste as before. Be sure to add the same amount of fullness to ensure the two sides are the same length.

Fold over the raw edge, and then fold over at the stay tape as before, press, and finish by felling.

That completes the back skirt construction process. This is exactly the same as for a wool coat, except that there is no lining. Here are the two pieces next to each other from the wrong side for comparison.

And the view from the right side. The left side will eventually overlap the right in the finished coat.

Left Back Skirt

Begin by marking about an inch or two of the back seam allowance, at the waist, and also mark the seam allowance across the ‘step’ at the center waist, as shown. This will give you the positioning for making a small cut, later on.

Along the edge of the skirt, at what will be the center back, draw out a line 1/4″, which will be turned under to hide the raw edge. Draw another line 7/8″ to 1″ from this first line, which will be the fold line for forming the back vent.

Add a length of stay tape along the inside edge of this second line, beginning just at the seam allowance at the top, and extending to about 1/2″ from the bottom.

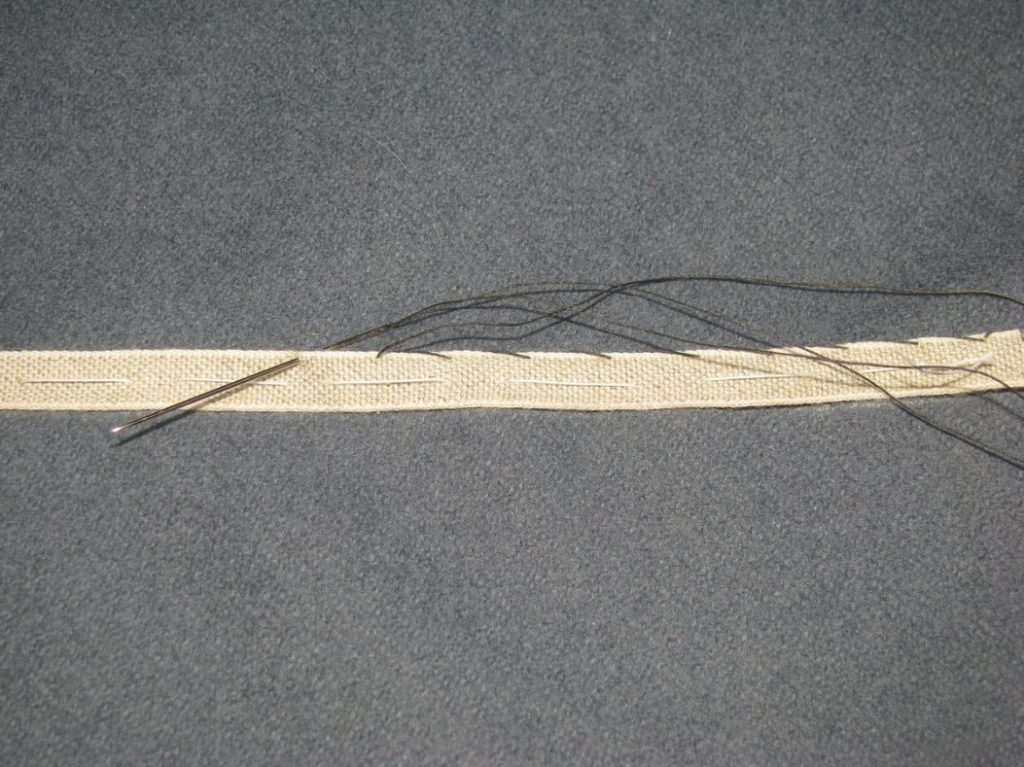

It’s a good idea to treat the stay tape for shrinkage prevention before using it. I like to put mine in a bowl of hot water, let it cool, and then press it dry with the iron. If you do a bunch at once you can get it over and done with for a good long while!

Baste down the stay tape. For the first 6 inches from the top, hold the tape slightly tight with your thumb in relation to the cloth. This will cause some visible ripples in the cloth. The purpose is to take the excess we added with the curved edge and move it towards the fuller part of the seat.

The tightness introduced is very slight, maybe 1/4″ over the enter six inches. This is about as much as we can get away with in linen or cotton, which does not shrink. This minimal fullness will not be noticeable, however.

Now fell down the stay tape with a slip stitch. Try to catch only a thread or two of the linen, as it does show through. I make my stitches about 3/8″ apart, slightly closer together when stitching down the shortened tape at the top.

Hopefully you can see this!

Now, carefully snip through all layers at the corner of the ‘step’ just to the seam allowance you marked earlier. This will help the seam lay nicely when completed.

Fold over the edge at the center back skirt 1/4 inch. I usually just press it with my fingernail as I go, but you could use the iron as well.

Fold over the seam allowance at the step by 1/2 inch. If you look carefully, you’ll note that this seam line is at a slight angle. You may wish to adjust this to make it perpendicular to the center back of the skirt, or it will produce some extra fullness in the next step. On a wool coat it’s not an issue – the fullness can be shrunk away – but it’s troublesome in linen or cotton.

Baste across this fold to secure it temporarily.

Secure the folded edge with a cross stitch.

Fold over and baste the center back of the skirt just next to the stay tape. Press from the right side only, being sure to use a curved tailor’s ham near the top.

Here’s that fullness I warned you about earlier. I had forgotten about this little issue, so had to go back and redo that.

Fell along the folded edge, being careful to catch only a thread or two of the right side.

Back Skirt Construction

The center back of the coat, where the two halves meet at the back vent, is probably the weakest part of the entire coat. The forces pulling on this area while sitting or walking can be quite a strain on the fabric, particularly when it’s very thin.

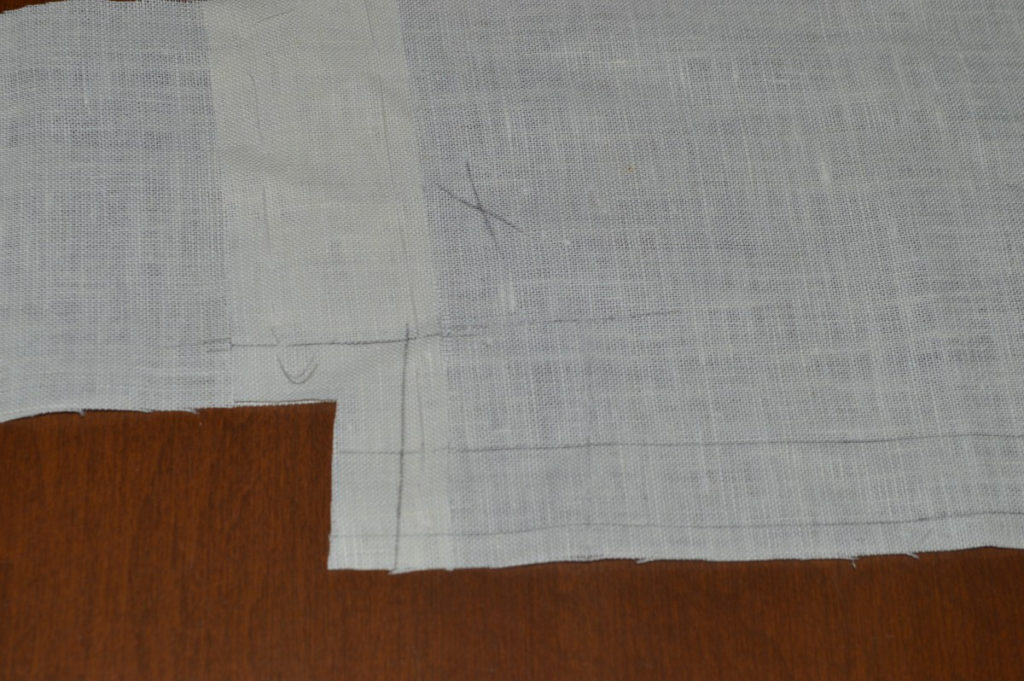

To help with this problem, we add a strip of linen over this area to distribute the stress and provide a firmer area for the stitching.

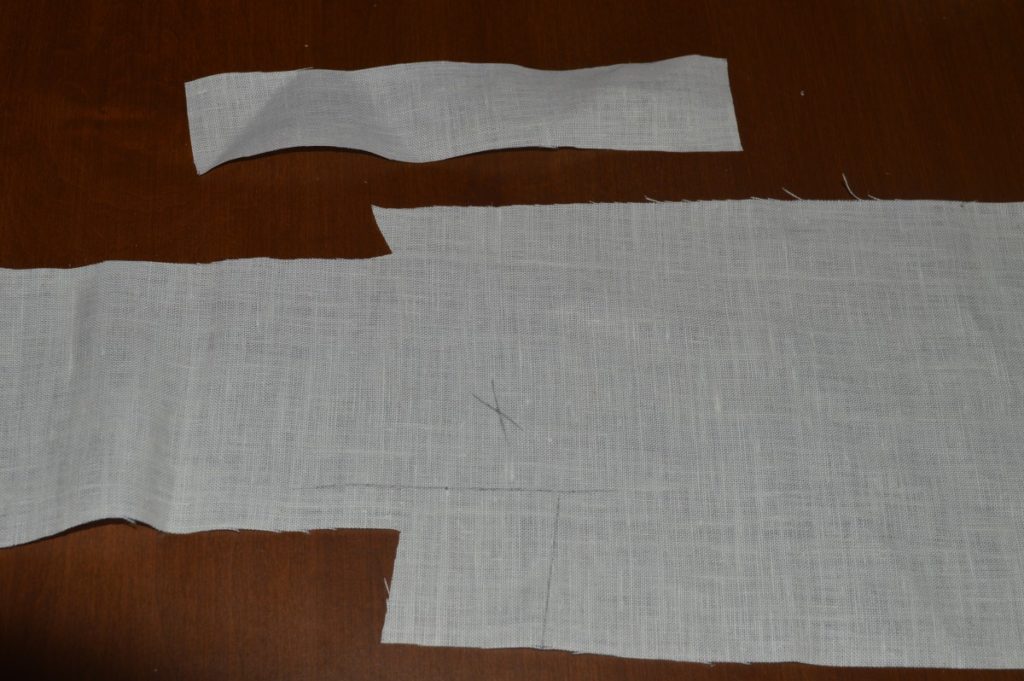

Cut two strips of linen about 1 1/2 inches in width and a little longer than the width of the back piece at the waist area.

Place the linen on the wrong side of the back piece, centered at the waist or even slightly below, and baste it firmly in place.

Trim the linen flush with the back, from the right side.

Layout

This next step is seemingly simple, yet extremely important! You don’t want to get your two sides mixed up in the construction process, so this is a fairly foolproof way of knowing you are working on the correct piece.

Lay out both halves of the back, right sides up, next to each other. This is the same way they will be on your body, left is on the left, right is on the right.

Pick up the left half and set the right side away for now. The following steps apply to the left side only.

First Fitting

Before moving on to the construction of the back skirt, this is a good opportunity to check that the back plait buttons are at the proper location, by basting up the coat as you did for the full muslin. The buttons should be about one inch below the natural waist, or small of the back, for an 1860s era frock coat. This fitting is optional – if you were satisfied during the muslin fitting, feel free to skip this.

If you do find the need to adjust the height of the buttons, you can do so by use of the inlays, and redrawing the line above or below the original inlay as necessary. Then make the corresponding adjustment on the side body seam.