Author: James Williams

Waistband with Watch Pocket II

With the waistband and pocket facings all basted into position, we can begin to sew everything down permanently. Begin by sewing the pocket bag to the trouser front using a 1/4″ seam allowance, beginning and ending precisely at the pocket opening marks. Be sure to keep the side seam pocket bag out of the way by folding it back.

Sew the pocket facing to the waistband in the same manner, using a 1/4″ seam allowance, keeping between the pocket opening marks. The stitching ends should line up as close as possible to those of the pocket bag.

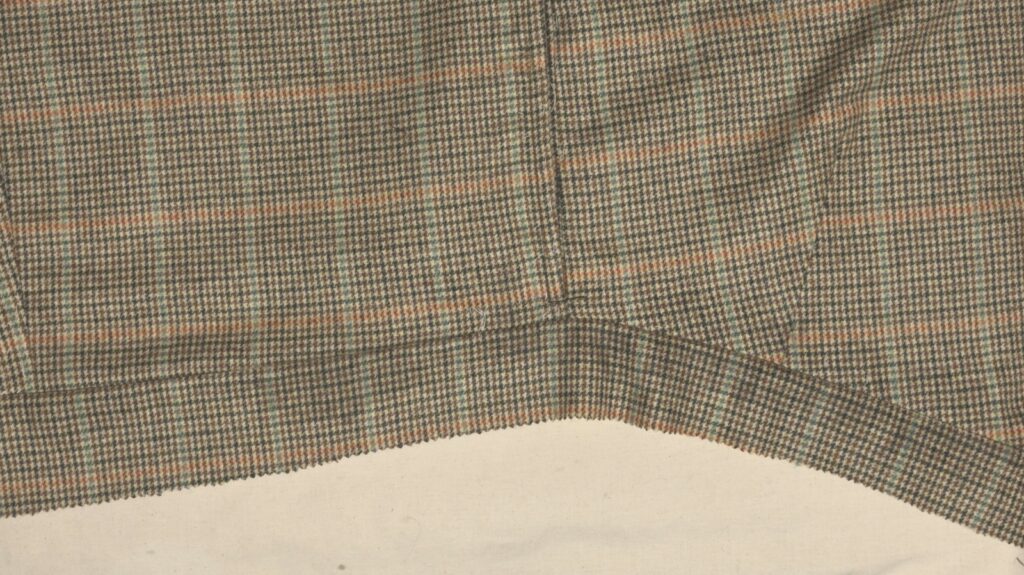

Remove the basting stitches from the facing and pocket bag. You should end up with something similar to this.

Now sew the waistband with a 1/4″ seam allowance from the back of the trouser, to the third mark you made earlier.

Remove (for the last time!) the basting stitches holding the pocket in place.

Fold the side seam pocket out of the way. Baste down the waistband again if necessary.

Carefully sew the waistband to the trouser front from the rear pocket opening to that third mark (it’s just an inch or so), or as close as you can to the folded back pocket edge without actually catching it in the stitches.

Just before sewing, be sure to move the seam allowances of the pocket facing and bag out of the way. We don’t want them caught in the seam at all.

Ideally, the stitches should meet at the pocket opening mark. It turns out my seam allowance was slightly off when sewing on the pocket bag, so they met about 1/8″ apart. I’ll be able to make it work, but it’s not ideal.

Finally, sew the front end of the waistband using a 1/4″ seam allowance from the front pocket opening to the front edge of the waist. Be sure to move the seam allowance of the pocket out of the way again.

The seams lined up much better this time!

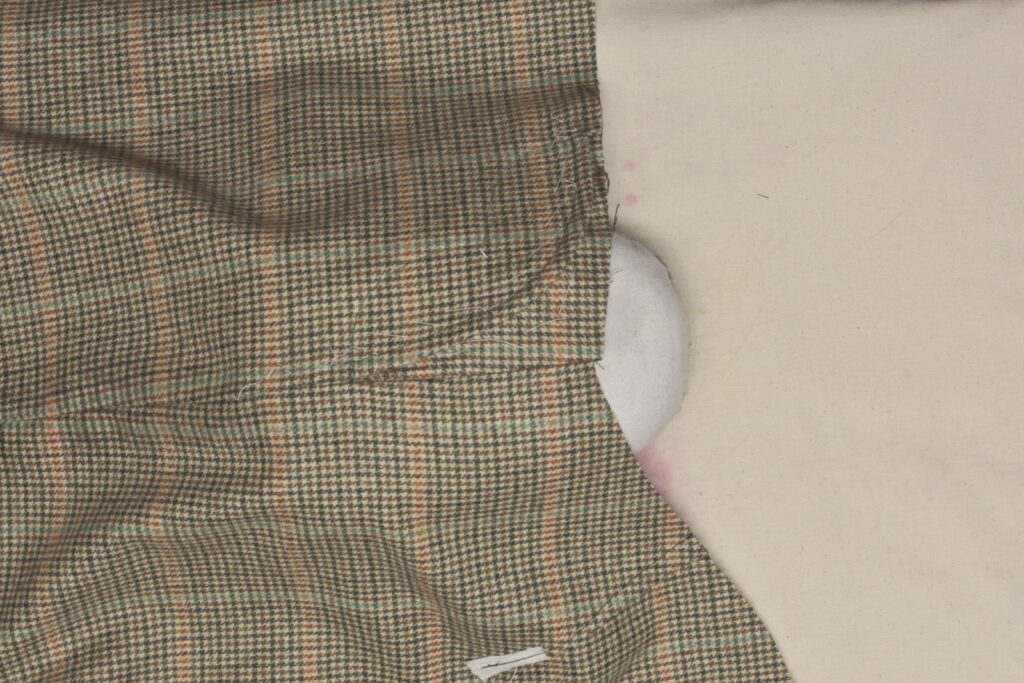

Here you can see how I’ve kept the 1/2″ seam allowances of the pocket bag and facing out of the waistband stitching.

You can see how I sew the waistband straight across the button catch rather than following the slight upward angle. It seems to align with the other half of the waistband just a bit better.

Pressing

With the wrong side of the trousers facing up, lifting the pocket so that the linen is exposed, clip the seam allowance of the trouser and linen pocket stay to the end of the stitch lines.

Press open the pocket bag seam as shown.

Now flip the pocket down into position, and press open the pocket facing seam.

Flip to the outside and press the inner pocket facing seam from the right side. It’s not really worth pressing the outside seam yet as the exact crease line has yet to be determined accurately.

Finally, press the remaining parts of the waistband seam up towards the waist as you did for the other waistband. This will enclose all the raw edges and make the seam stronger.

Waistband with Watch Pocket I

Adding a watch pocket to a waistband (usually on the right side) is not too difficult, but is somewhat involved with a lot of steps, so I will break the watch pocket into three sections. This first section will go over basting the pocket facings and waistband into place.

I’m adding this pocket to the trousers with side seam pockets. If you want one to trousers with the open top pockets, I’d suggest making a sample of each and then figuring out how best to combine them. I’ll try to add a tutorial for that combination sometime.

Besides the waistband, you’ll need the following pieces to construct a watch pocket. I like to make mine 3 1/2″ wide when finished, so all pieces should be cut 1″ wider, to give a 1/2″ seam allowance on either side. So for the pieces:

- 1 pocket facing 4 1/2″ x 1 1/4″

- 1 linen stay, 4 1/2″ x 1″

- 2 pocket bags, polished cotton 4 1/2″ x 4 1/2″

- 1 length of 1/4″ stay tape (not pictured) 4 1/2″

- Waistband

The pocket placement must first be marked – there are three marks total. The first two indicate the position of the pocket and are spaced 3 1/2″ apart (indicated by the two marks coming from the left). I like to place my pocket just in front of the hip bone so there is no interference. To the right (or towards the side seam, in other words), make a third mark an inch or two away from the pocket. You’ll be basting and sewing to this third mark, so it is fairly important.

Flipping to the wrong side, remove the basting stitches holding the pocket in place from the mark to the inside folded edge. Reinforce the basting at the mark with a couple of stitches in place if necessary.

Baste the linen pocket stay in place on the wrong side along the waist seam, flipping the pocket out of the way. Be sure to align it properly with 1/2″ allowance on either side of the pocket opening marks.

Baste the pocket back in place from the third mark to the edge of the pocket, keeping the stitches at least 1/2″ from the edge to give you some room to work with.

Baste the waistband into position in the same manner as the pocketless waistband, again keeping the stitches about 1/2″ from the edge. However, stop your stitching at the third mark, make a couple of stitches in place, and start a new thread to continue the rest of the basting.

I’m pointing here to the position of the third chalk mark, where I’ve started and stopped my basting stitches. This is so we can move and manipulate the pocket bag underneath without the entire waistband falling off.

If you made the side seam pockets earlier, this method will look very similar. Open up the waistband seam, exposing the right sides in between the layers. Transfer and mark the pocket openings on all pieces if you haven’t already.

With right sides together, place the pocket facing into position on the waistband. Be sure that 1/2″ allowance extends beyond the pocket opening marks on both sides.

Baste the pocket facing into position with a straight basting stitch, keeping the stitching out of where the seam will be sewn (1/4″ from the edge).

So far, you have the pocket facing basted right sides together to the waistband.

Now fold the pocket facing and waistband out of the way, exposing the right side of the trouser front underneath.

Place the pocket bag into position, right sides together with the trouser front, aligning it as you did the facing.

Holding the pocket bag half in position, fold the top of the side seam pocket that’s underneath out of the way.

Baste the pocket bag half to the trouser front, being sure not to catch the pocket that’s underneath. Mark the pocket openings.

This completes the basting process for the waistband and pocket facings. If you open yours up it should hopefully look similar to mine!

Attaching the Waistbands

Finally, it’s time to attach the waistbands, which close up the top of the pockets, in a sense completing them. If you are planning to insert a watch pocket on one side, please see the next section on attaching the waistband with a watch pocket.

Lay the waistband, wide end at the front of the trousers, right sides together. There should be two or three inches of extra fabric at either end to turn back later on. Baste securely.

As you get to the center of the waistband at the side seam, you’ll have to full in a little excess of the waistband fabric to help it get around the curved seam.

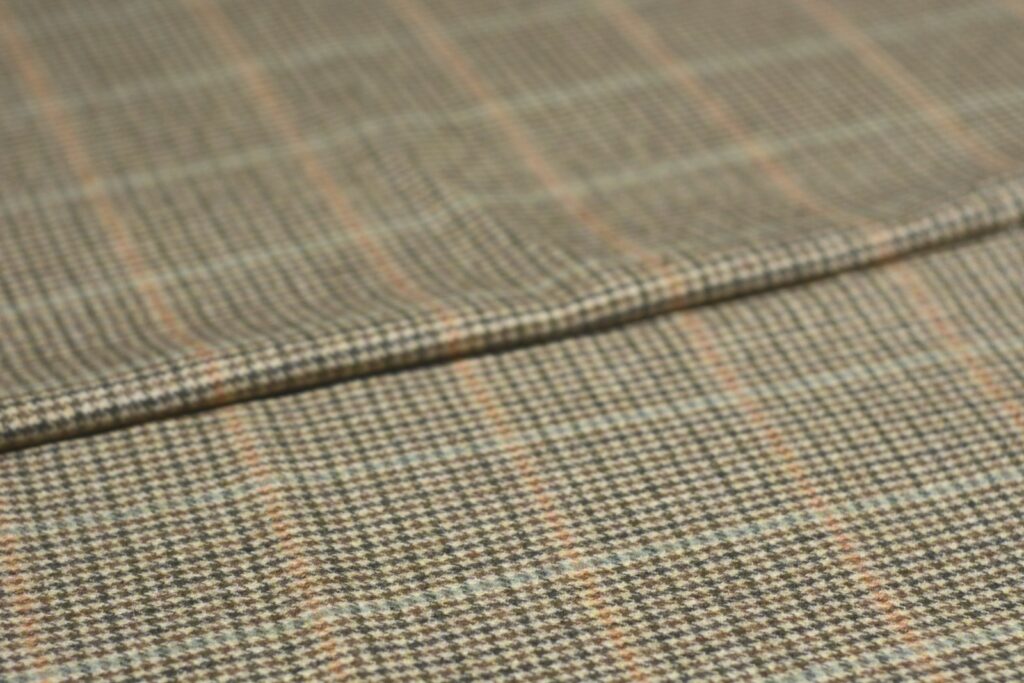

As you baste, check to make sure that the stripes are aligned between the waistband and the front of the trousers. As you get to the back of the trousers, it becomes impossible to match the stripes due to the angle of the cut.

From the underside, make sure the basting stitches catch the pockets and all layers, and that everything lays flat.

Sew the waistband seam through all layers with a 1/4″ seam allowance from end to end of the trousers.

Now, when you get to the end of the waistband at the button catch side, I like to go straight across with my stitching rather than following the slight upward angle of the button catch. It seems to give a better fit with the left side of the trousers.

Press the waistband up. The seam itself is not opened, rather the seam allowance and the waistband should both be pressed towards the top of the trousers.

Around the side seam area I like to use a tailor’s ham since there is usually a bit of excess fabric here.

A final view of the underside showing the seam allowance pressed towards the waistband. This gives the strongest possible seam to the waistband.

The Side Seam

It’s now time to attach the trouser fronts to the backs. Lay out the front on the table, and lay the back over the top, right sides together.

Now pin the very top of the side seam at the waist, ensuring that when we baste the side seam, the tops will be aligned properly.

Now, starting from the bottom hem, baste to the position of the knee (you can be precise about this and lay it out on the pattern, or just estimate).

Be sure to match the plaids as you’re going, if necessary.

Now baste from the knee to the waist, positioning the trousers so that the back piece is underneath and in an orientation that is most comfortable for your you.

As you’re basting, you’ll notice that the underside has a bit more fabric than the top side. This needs to be distributed evenly, moreso around the pocket opening, with the remaining excess distributed just below the pocket and tapering off to an even tension by the time you get to the knee.

When you get to the pocket, baste through all layers, ensuring the pocket notch is properly aligned 1/4″ from the edge.

It’s a good time to check how the plaids are aligned, and if necessary, redo them. Really depends upon how fussy you want to get. Also check that the pocket is properly aligned.

When you’re happy with how everything looks, sew the side seam using a 1/4″ seam allowance. Take care near the pocket area, as the presser foot has a tendency to skew off course due to all of the layers.

Remove the basting stitches, open the seam up, and press.

My plaids got slightly out of alignment here, alas. Hopefully yours turn out better!

Drafting the Pleated Front

Drafting the pleated front can seem a little tricky at first, but after you get the first pleat or two down it all starts to make sense.

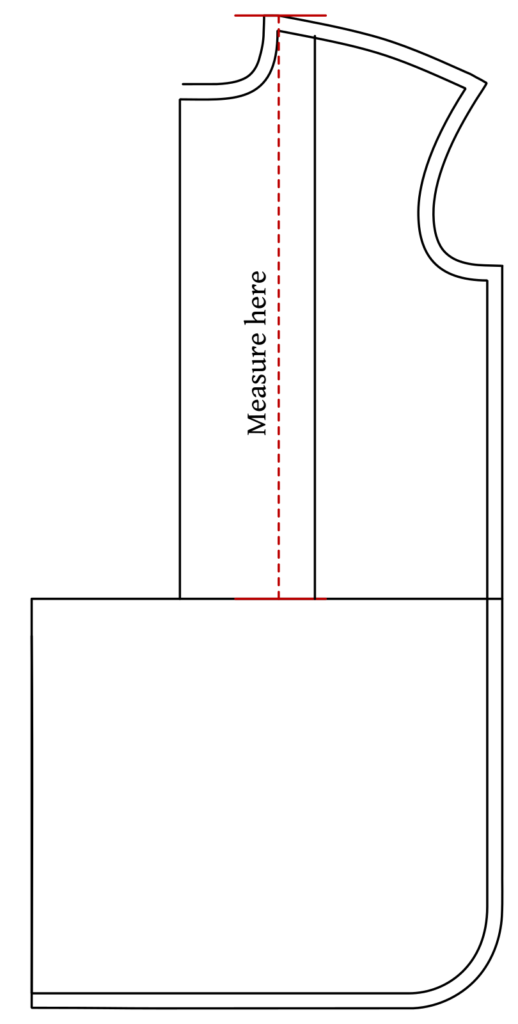

First, you need to measure the distance between the top of the pleats at the shoulder, including the seam allowance and the bottom of the pleats. Add 3″ or 4″ to this measurement, giving us the height of the pleats we will draft. When constructing the pleats, it’s easy for things to get out of alignment, so the extra inches give room for error.

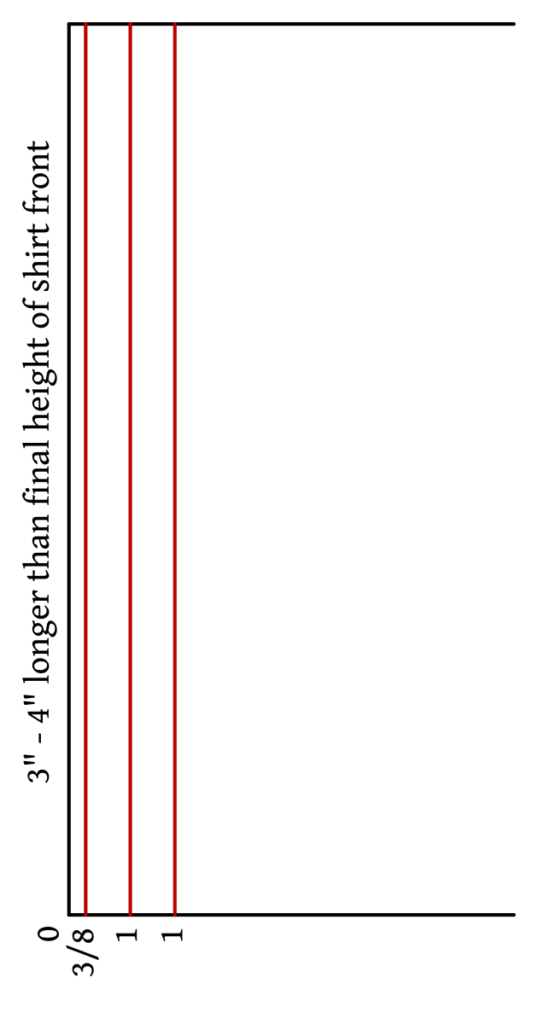

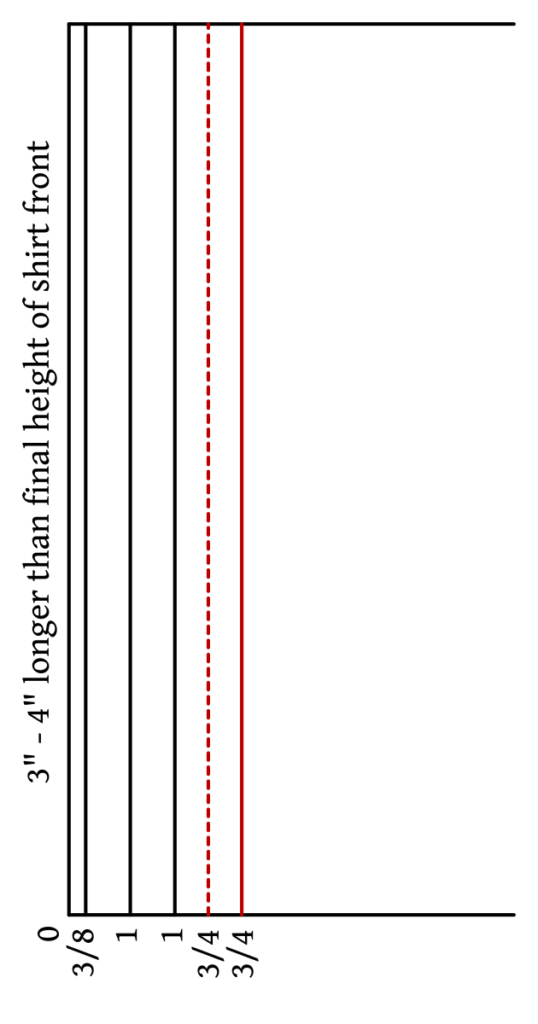

On a fresh sheet of paper, draw a vertical construction line 3″ to 4″ longer than the total height of the pleat length.

Square out at the top and bottom of the line. These horizontal lines should be around 20″ or so in length so that you don’t need to redraw them later.

Draw a vertical line parallel to the construction line at 3/8″ from O for the seam allowance of the center placket. I use 3/8″ to give some room for error and at the same time keep the seam allowance out of the buttonhole area.

Next, draw another two lines at 1″ from the previous to mark the outside and inside of the placket at the center front of the shirt. The one inch width can vary according to the style you’re going for or the specific shirt you are reproducing.

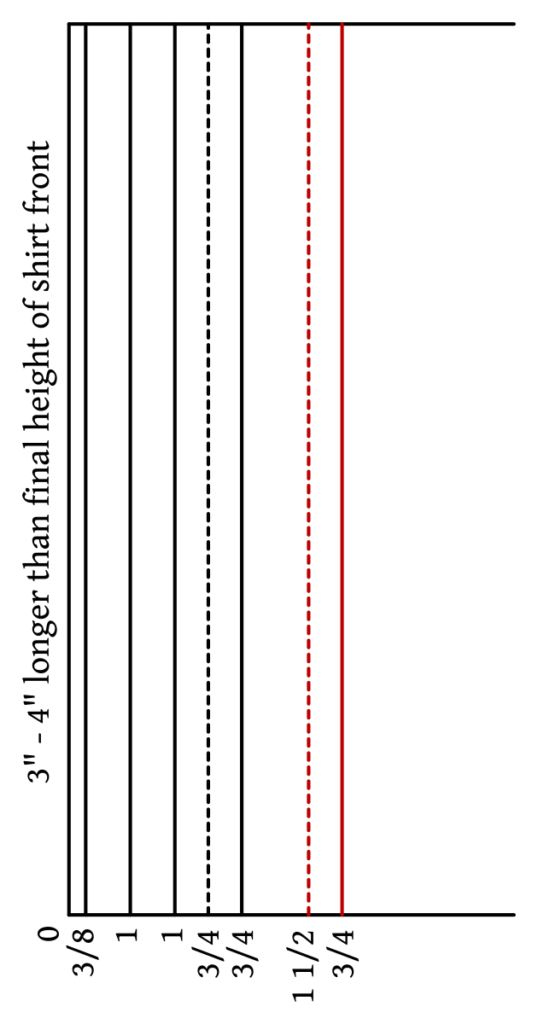

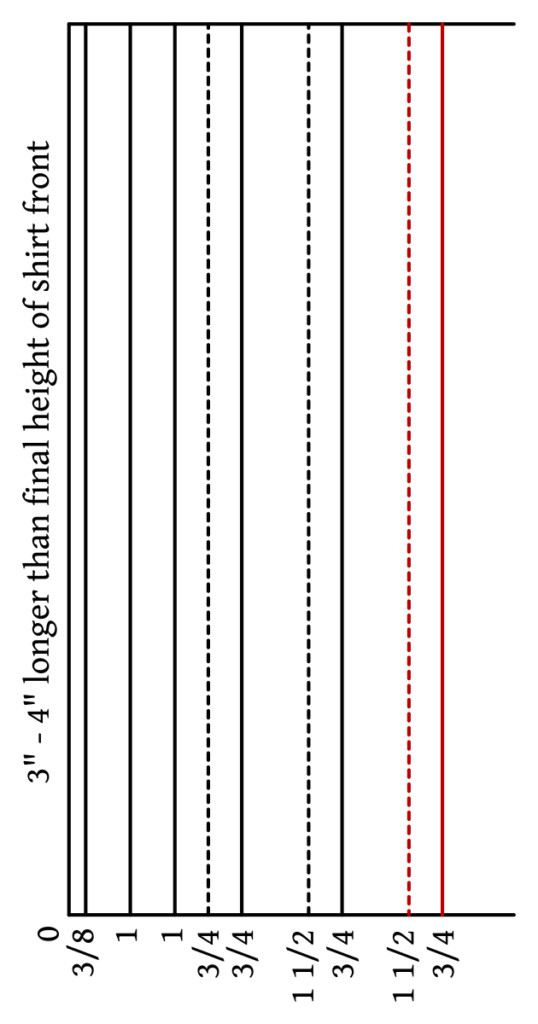

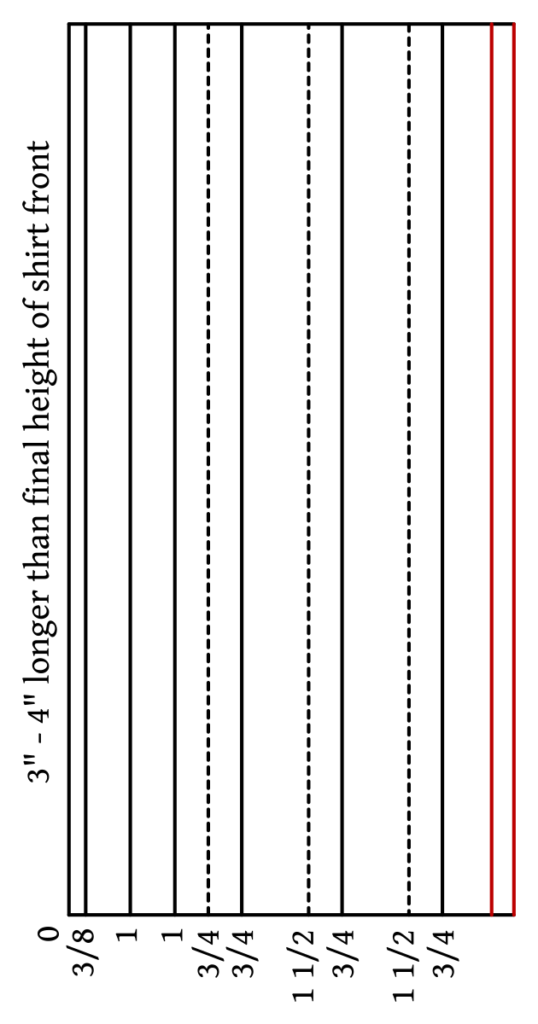

You should have determined your pleat width when drafting the front. I’ve decided to demonstrate here with 3/4″ pleats, but again, that can vary from less than 1/2″ to 1″.

Draw a dashed line 3/4″ from the previous line. This indicates the fabric is folded in the opposite direction as the other lines. Then draw an additional line 3/4″ from the dashed line.

This gives us our first pleat.

The next dashed line is double the width of the pleat in distance from the previous line. So in my case with a 3/4″ pleat, this dashed line is 1 1/2″ away.

Follow that with another solid line 3/4″ from the dashed line. This is our second pleat.

Continue adding pleats as shown until you have the correct number as determined in the draft of your shirt front.

To complete the draft at the inside edge of the placket, add one final line the width of the pleat plus any additional remainder you added. You may want to experiment with exactly the look you are going for at this point on a sheet of paper, so you can see exactly how the folds look.

Finally, add a 1/2″ seam allowance.

I do highly recommend copying the pleats to an 8 1/2 x 11 sheet of paper and folding it into position so you can wrap your mind around how it works, as well as compare the pleats to your pattern to ensure they fit properly. It also makes a great reference as you’re ironing and basting the pleats themselves.

Your Progress

[columns gutter=”0″]

[col]

[progressally_objectives]

[/col]

[col align_text=”center, middle”]

[progressally_progress_pie_chart size=”100″]

[/col]

[/columns]

Drafting the Yoke

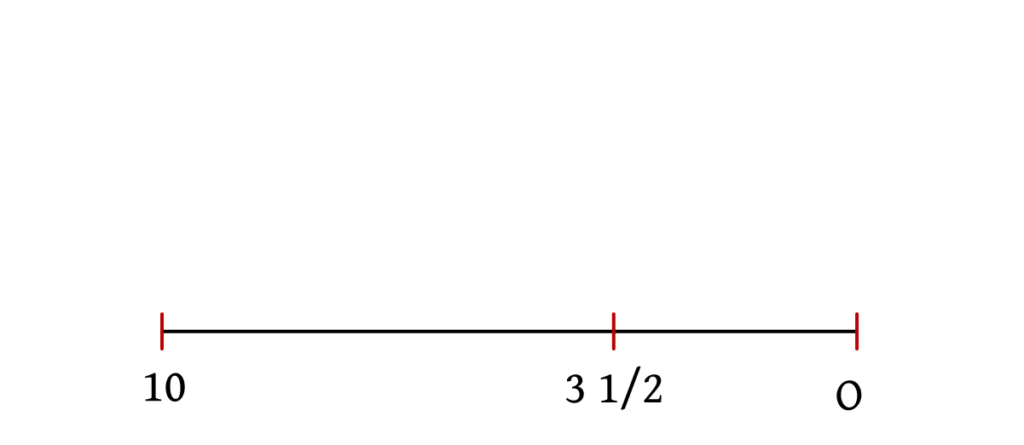

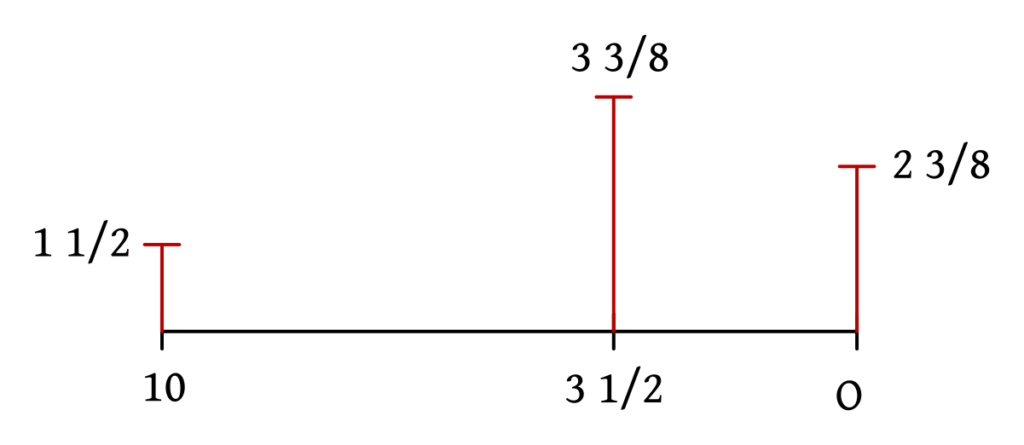

To draft the yoked back, first draw a horizontal line, marking off the following points with your graduated ruler.

- 0

- 3 1/2

- 10

Depending on your size, you can shorten the width of the yoke by moving point 10 to the right an inch or two as necessary. You could also adjust the position of the neck at 3 1/2, but that is an advanced operation.

Next square up the following points to get the heights of the various points:

- 2 3/8 from 0

- 3 3/8 from 3 1/2

- 1 1/2 from 10

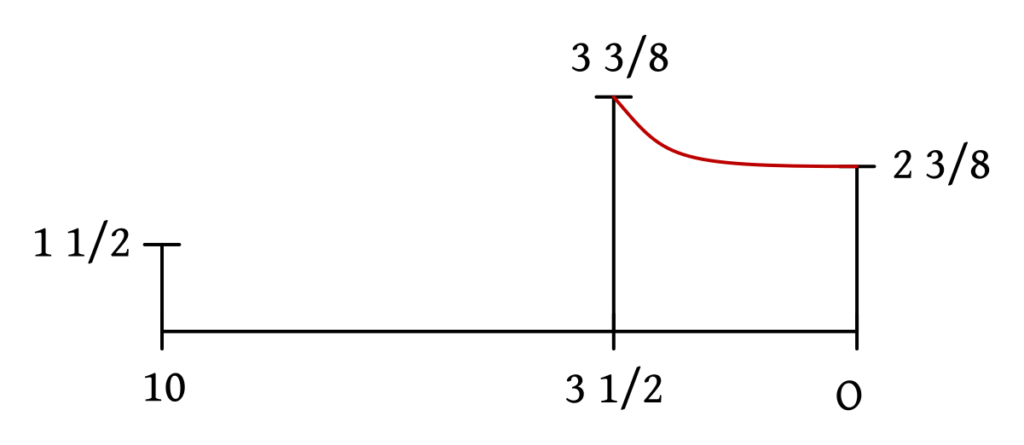

Now draw in the curve of the back neck. This should be pretty much horizontal from point 2 3/8, then curve somewhat sharply up to point 3 3/8.

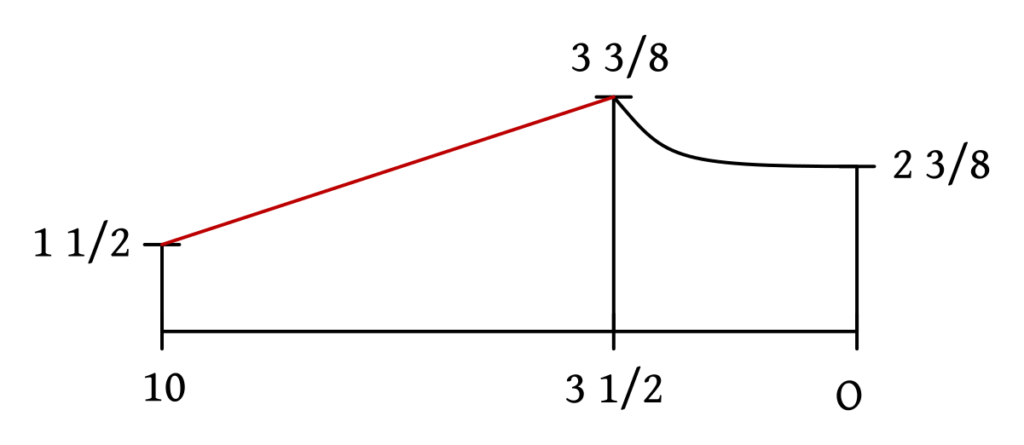

Lastly, draw the shoulder seam from point 1 1/2 to 3 3/8 with a straight line.

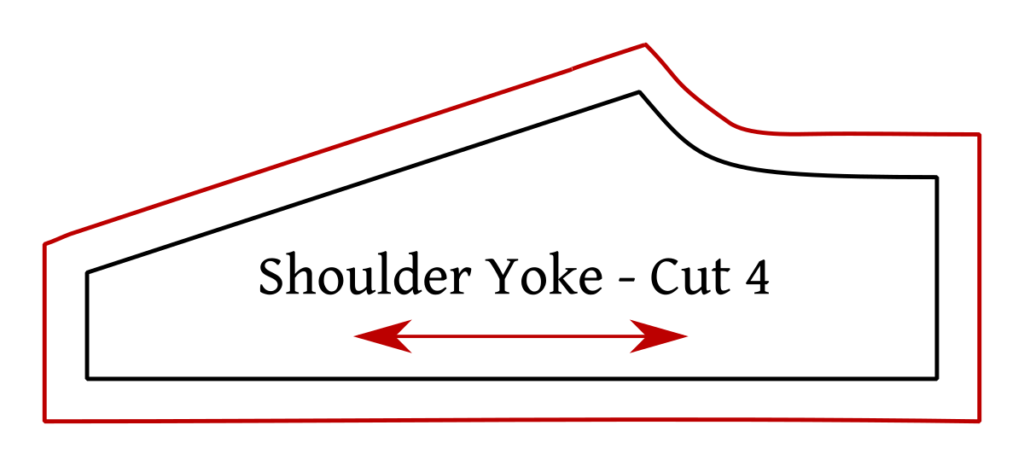

Finally, add a 1/2″ seam allowance all the way around the shoulder yoke. You’ll cut four of these from the fabric, as two are used for the lining pieces.

Your Progress

[columns gutter=”0″]

[col]

[progressally_objectives]

[/col]

[col align_text=”center, middle”]

[progressally_progress_pie_chart size=”100″]

[/col]

[/columns]

Drafting the Shirt Sleeves

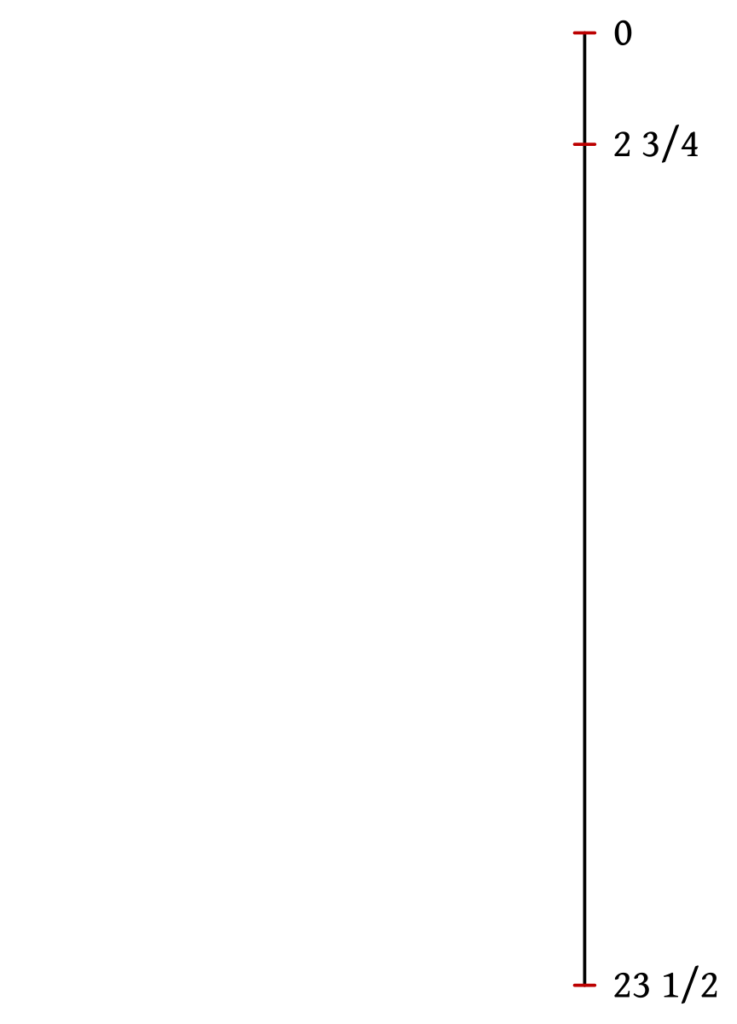

Drafting the sleeves is a very simple matter. Start with the usual vertical construction line, marking the following points with your graduated ruler:

- 0

- 3 2/4

- 23 1/2

For larger sizes, you can compare the length of the sleeve from 0 to 23 1/2 to your actual measurements, and shorten as necessary.

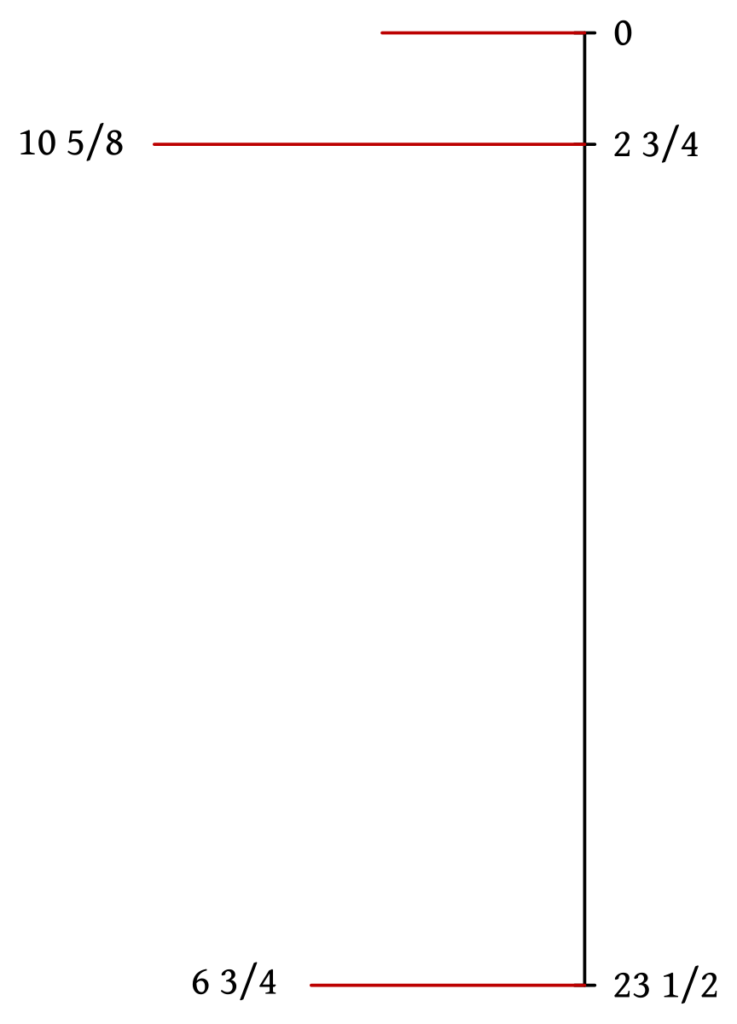

Square out from each of the points as follows:

- From 0 is just a construction line for the sleeve head, 2 or 3 inches works well.

- 10 5/8 from 2 3/4

- 6 3/4 from 23 1/2

Points 10 5/8 and 6 3/4 dictate the width of the sleeve. For the average size of 37 1/2″ chest, it’s already over 20 inches in diameter, so for larger sizes I recommend reducing the width at these points as necessary.

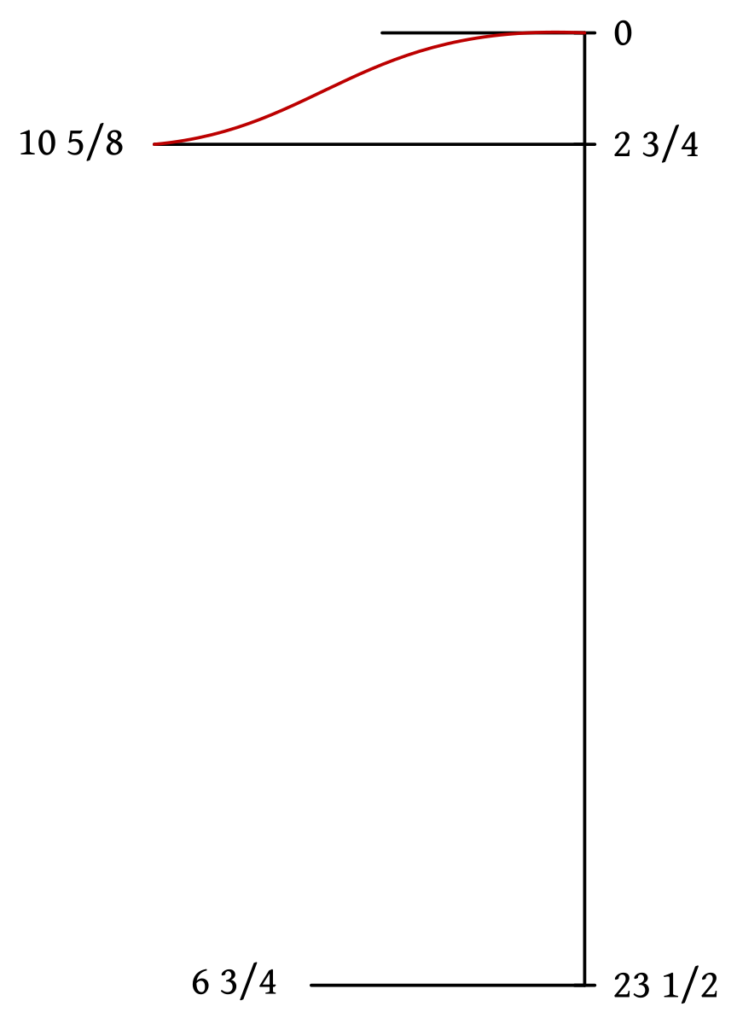

Now draw the sleeve head curve as shown. At 0 it follows the construction line for an inch or so, before falling into a gentle ‘S’ curve through to point 10 5/8.

You should measure the length of the sleeve head with a tape measure and compare it to the diameter of the armscye. The sleeve will definitely be a lot larger, but excessively large sleeve heads get more difficult to fit into the armscye.

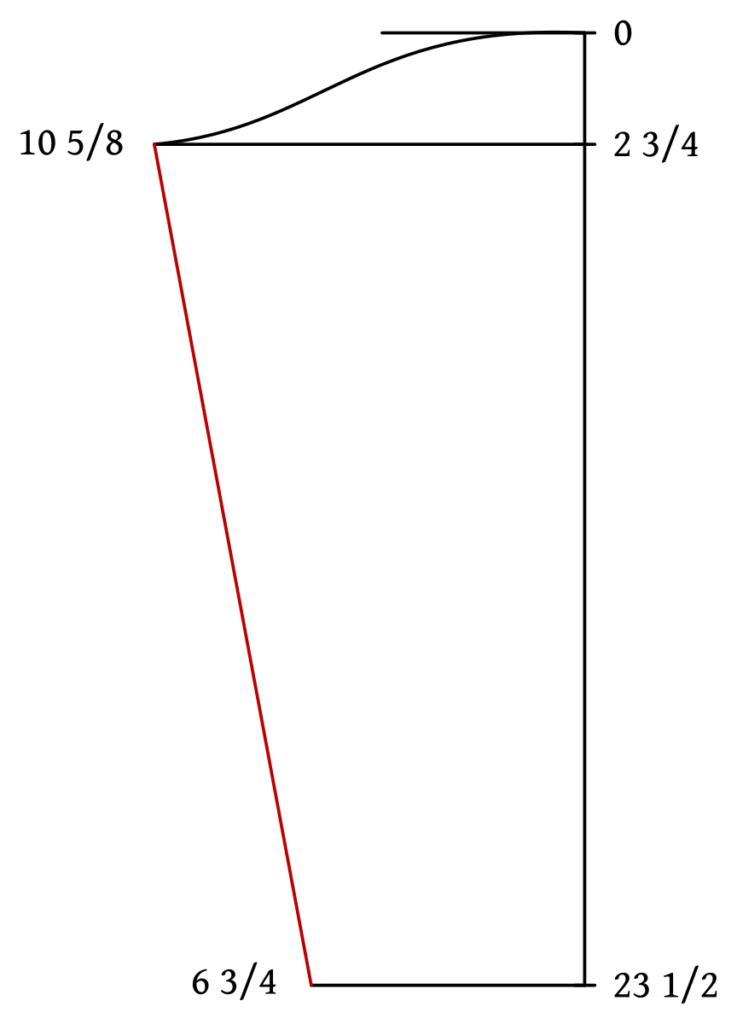

Finally, draw in the sleeve seam from 10 5/8 to 6 3/4. This completes the sleeve draft.

Now add a 1/2″ seam allowance along the sleeve head, the diagonal sleeve seam, and the cuff. The horizontal edge of the sleeve is cut on the fold.

Your Progress

[columns gutter=”0″]

[col]

[progressally_objectives]

[/col]

[col align_text=”center, middle”]

[progressally_progress_pie_chart size=”100″]

[/col]

[/columns]

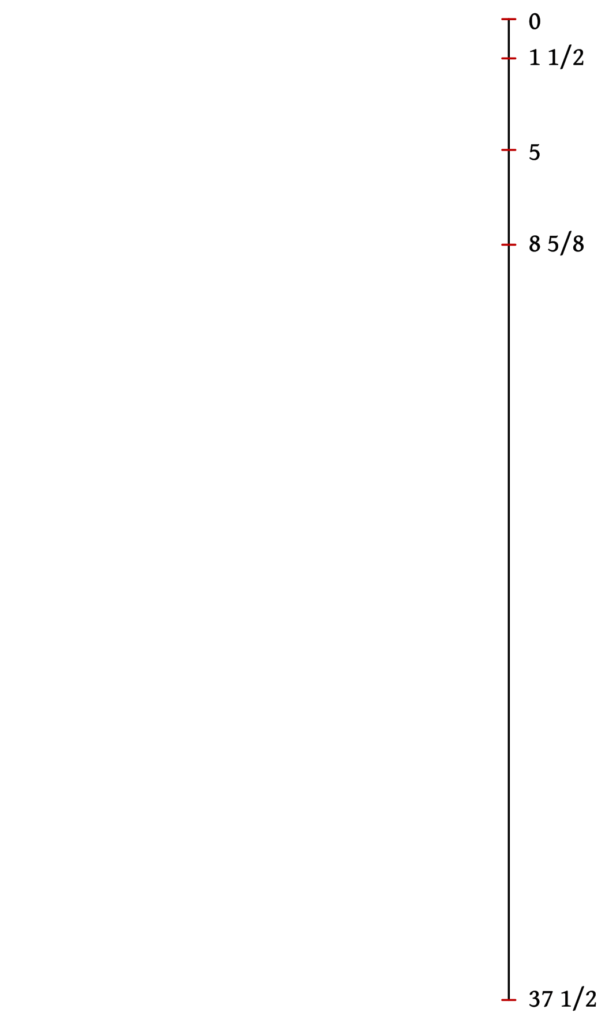

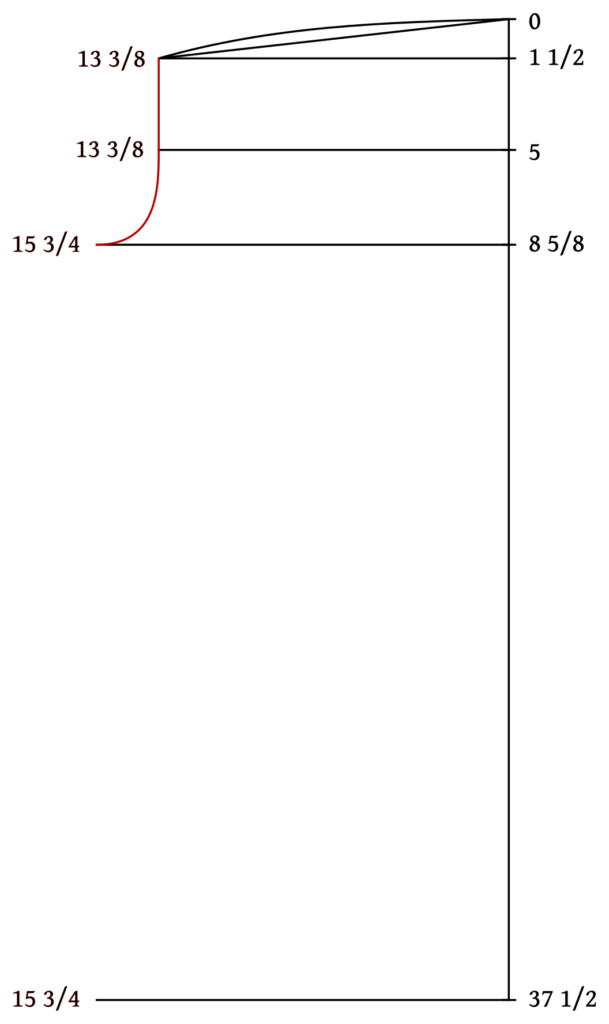

Drafting the Shirt Back

The draft for the shirt back starts in much the same way, with a vertical construction line. Mark out the following points starting with zero:

- 0

- 1 1/2

- 5

- 8 5/8

- 37 1/2

If you shortened the length of the front, you’ll want to do the same for the back length. It should be about 3 to 5 inches longer than the front ideally.

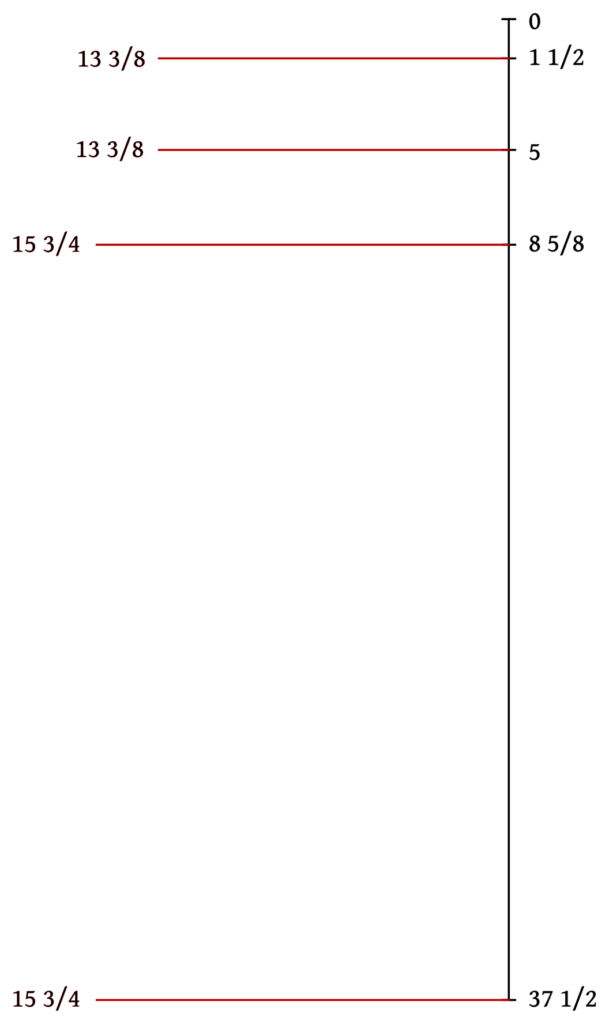

Square out the following lines and points:

- 13 3/8 from 1 1/2

- 13 3/8 from 5

- 15 3/4 from 8 5/8

- 15 3/4 from 37 1/2

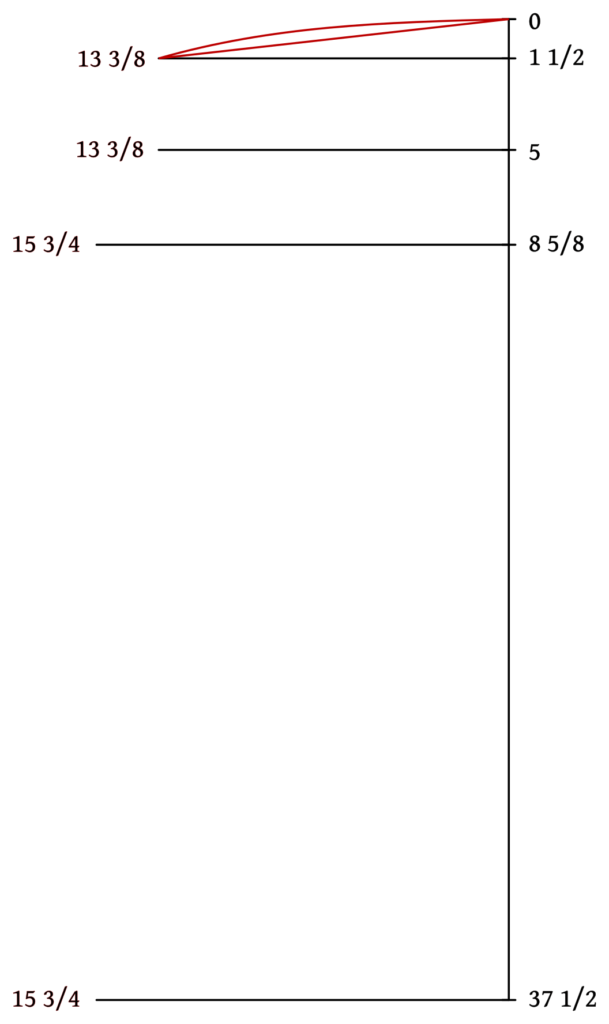

Begin drawing in the curves with the top edge. This is not actually the shoulder, but the bit below the shoulder, which will be gathered into the shoulder yoke.

I drew a construction line from 0 to 13 3/8, followed by a curve, almost perpendicular to 0 gently sloping into point 13 3/8.

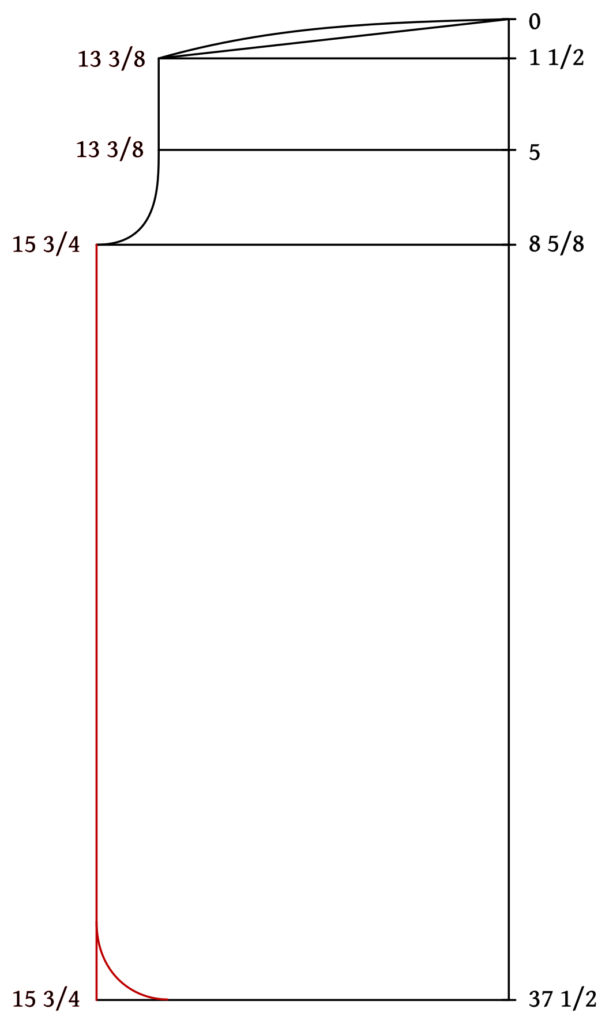

Next, draw the back armscye, starting with a vertical line from 13 3/8 to 13 3/8, curving deeply into 15 3/4.

Finally, draw the side seam, curving into the bottom hem as you did on the front draft.

One last alteration to the shirt body: if you are a larger size and find the back is just going to end up ridiculously large, you can remove a couple of inches from the center back as shown. Redraw the curve in the shoulder area as necessary.

I’d advise drafting the shoulder yoke in the next step before doing this alteration, however.

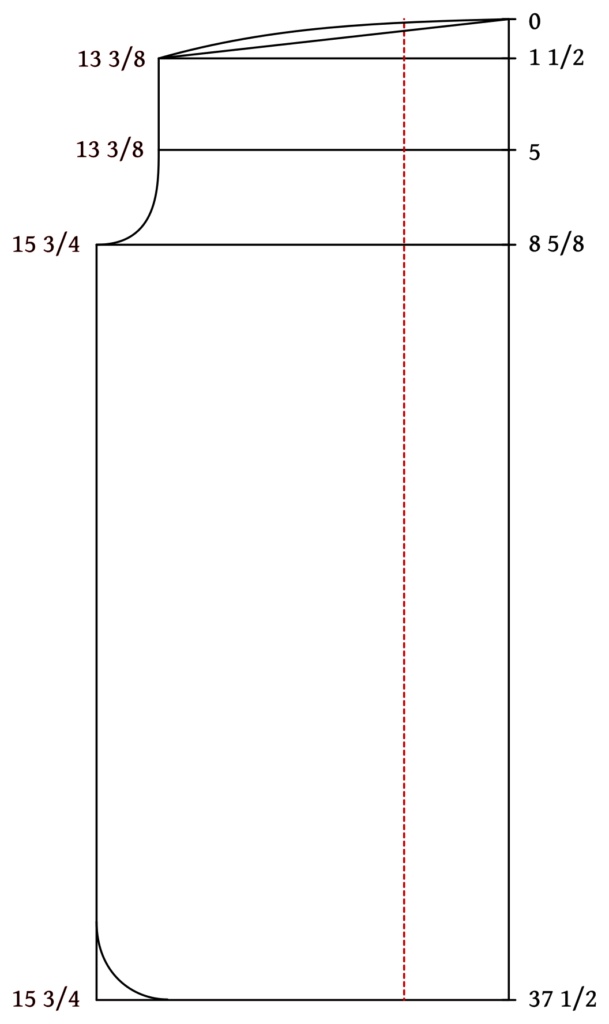

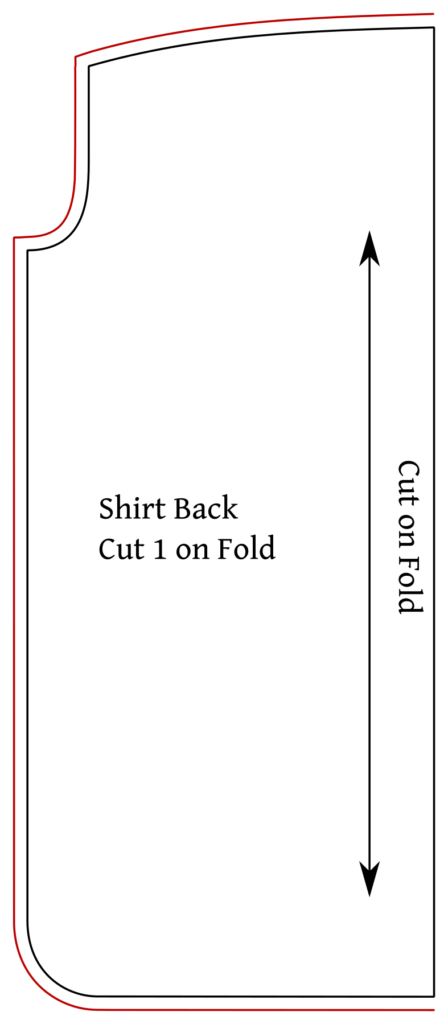

Finally, add seam allowances around the shoulder, armscye, side seam, and hem. The center back is left without a seam allowance and will be placed on the fold of the fabric.

Your Progress

[columns gutter=”0″]

[col]

[progressally_objectives]

[/col]

[col align_text=”center, middle”]

[progressally_progress_pie_chart size=”100″]

[/col]

[/columns]

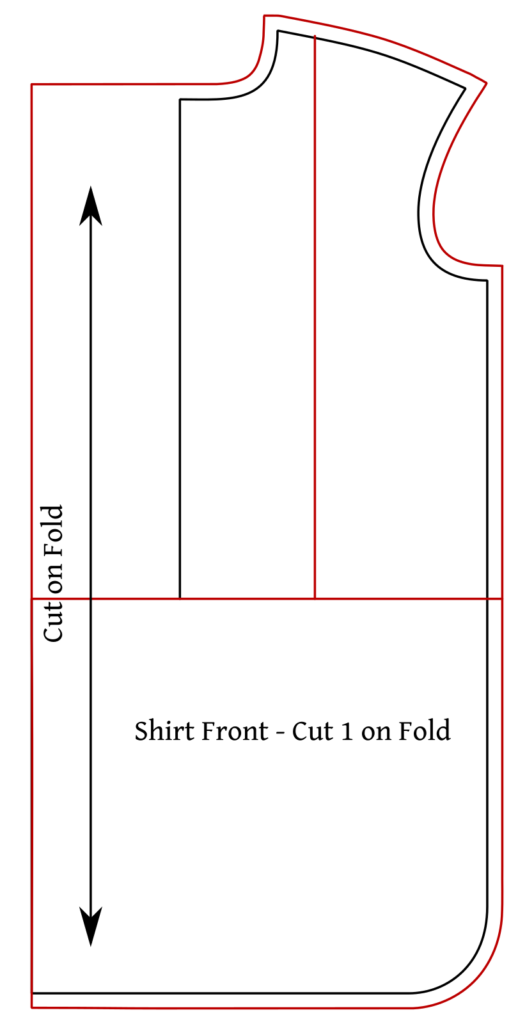

Drafting the Shirt Front

Before you begin with the drafting, you’ll need to print out a set of graduated rulers (or at least your correct-sized ruler) to use for the draft. These are based on those used by Louis Devere in his drafting manual and allow you to scale a pattern up or down to the approximate size of the person.

Your ruler sized is based directly on your measurement. So if you’re a 42″ chest, choose a size 42 ruler, and so on. This measure is used for the entire draft. You can then use a regular measuring tape to check for fitting issues, which I’ll explain as we go along.

When printing out the rulers, the most important thing is to print them at 100%, else the scale and your draft will be off. If you have to print on regular 8 1/2 x 11 paper (as I usually do), the ends of the rulers will be cut off, so just use the bit you have and measure things out in multiples of 5 or whichever is easiest for you.

I’m drafting on a roll of poster paper, 36″ wide, that I got from Hobby Lobby. You may be able to find similar rolls at Staples, Amazon, and other such stores, or you could use something like the back side of wrapping paper.

You’ll also need a longer straight edge such as a tailor’s square, yard stick, or quilting ruler, and a sharp pencil.

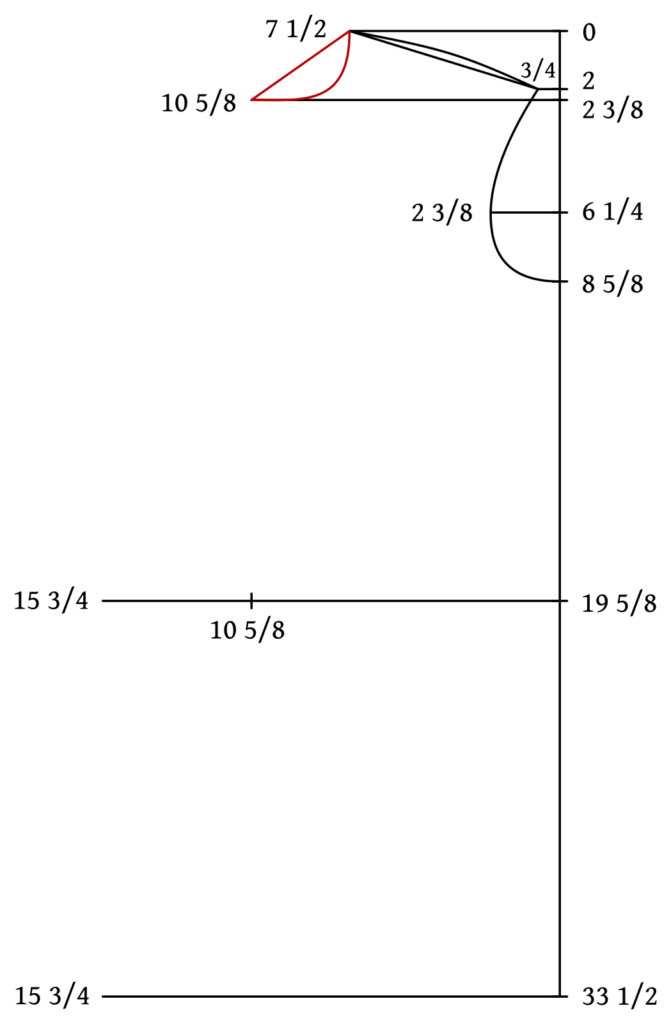

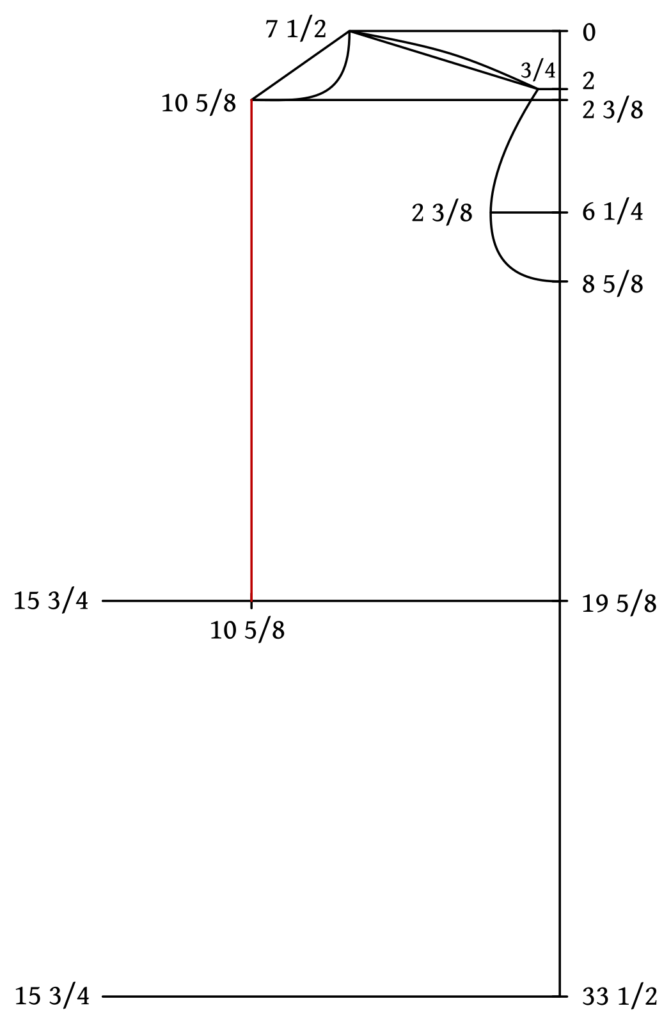

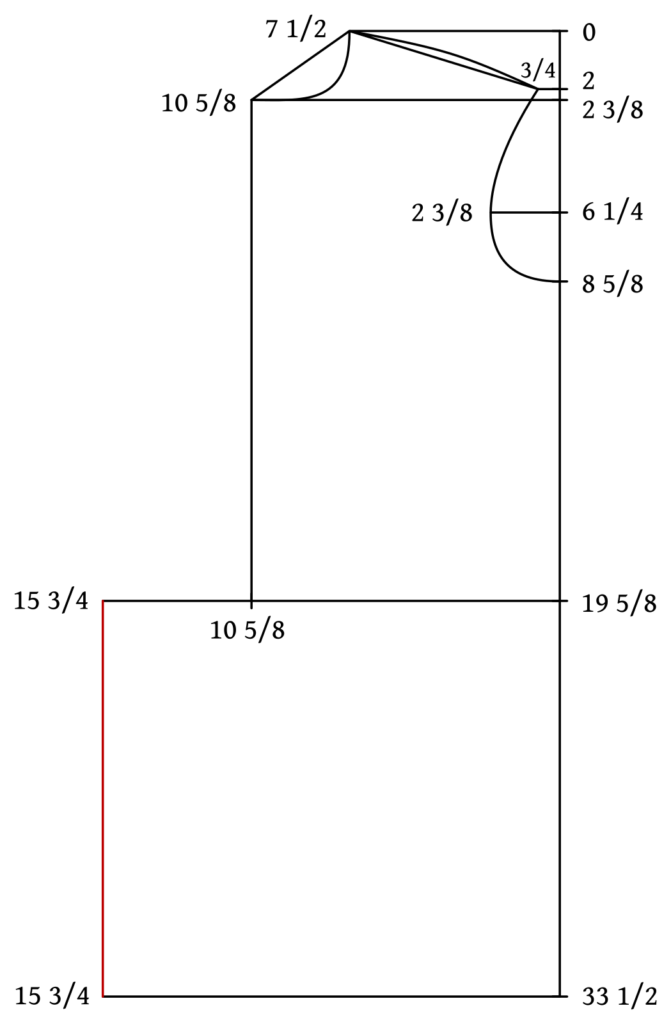

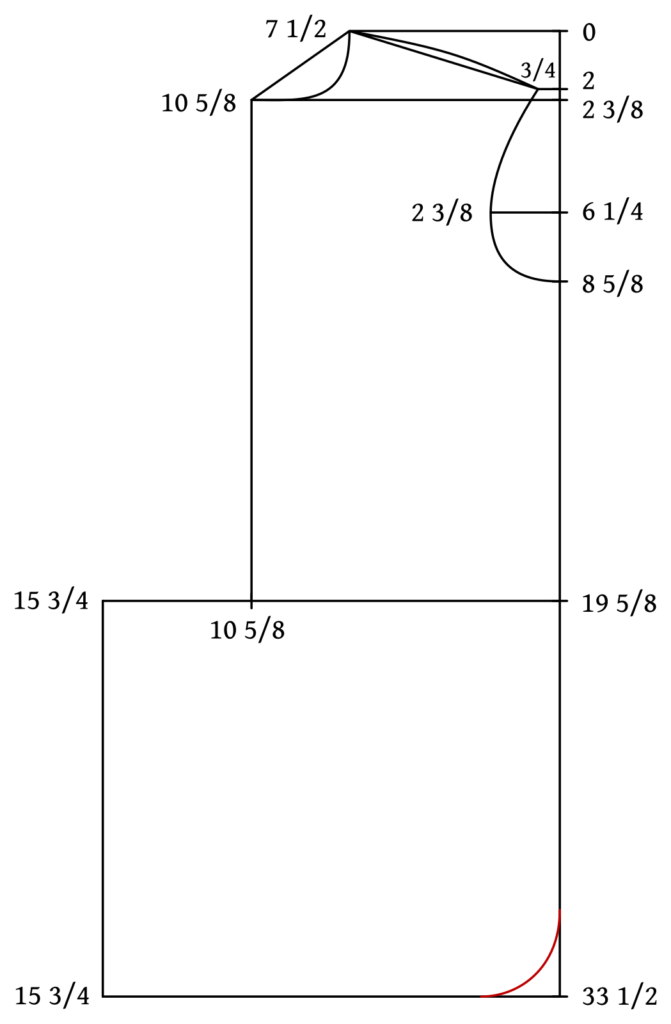

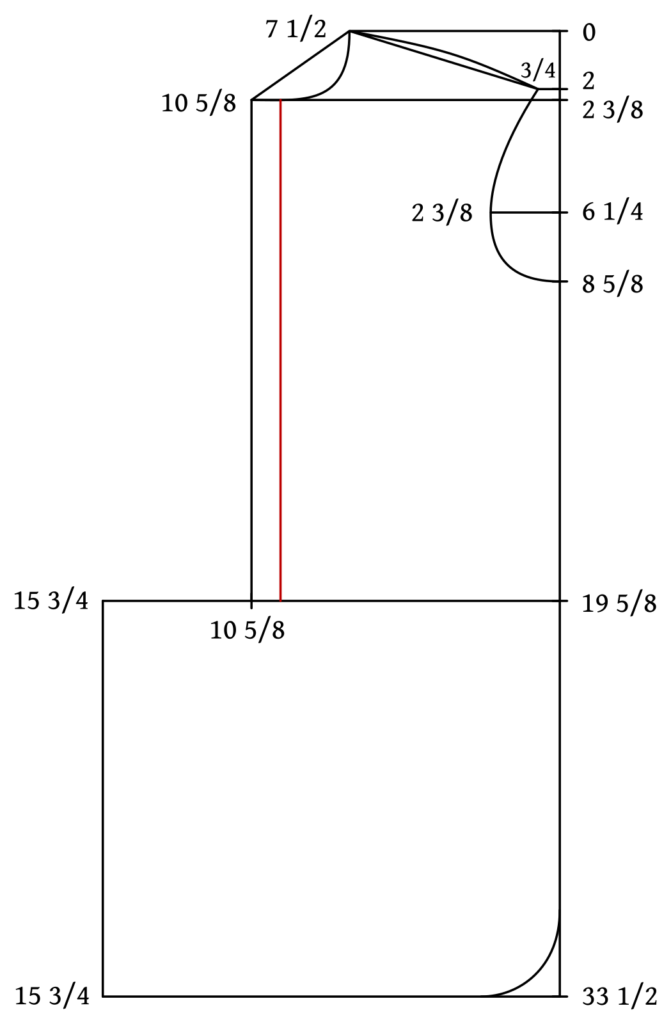

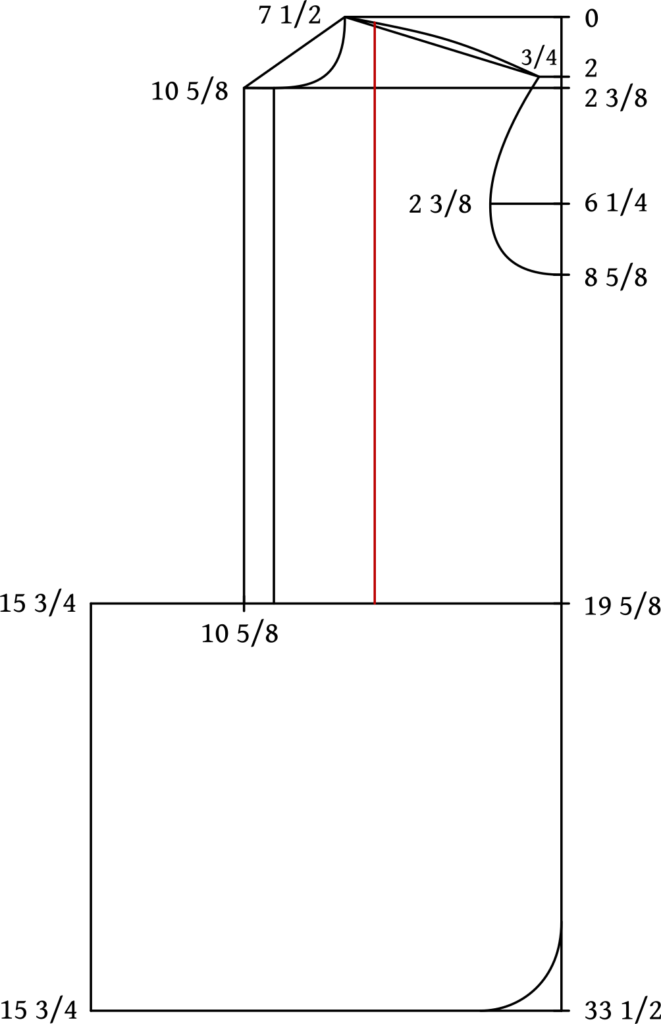

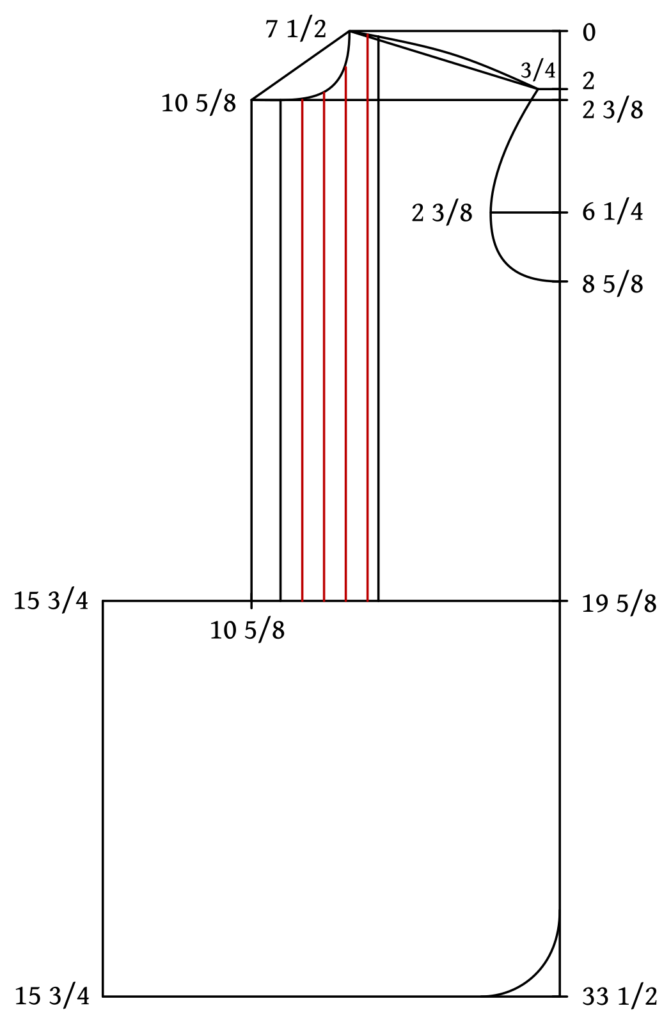

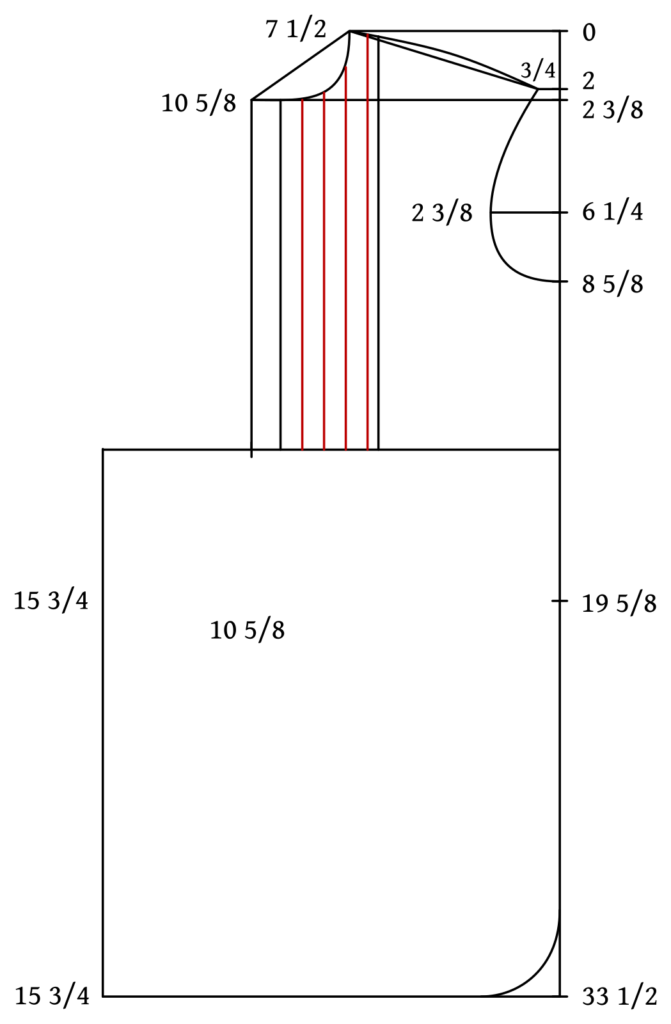

Drafting the Front

Begin by drawing a vertical line on the right side of the paper (you may need to work sideways to get everything to fit).

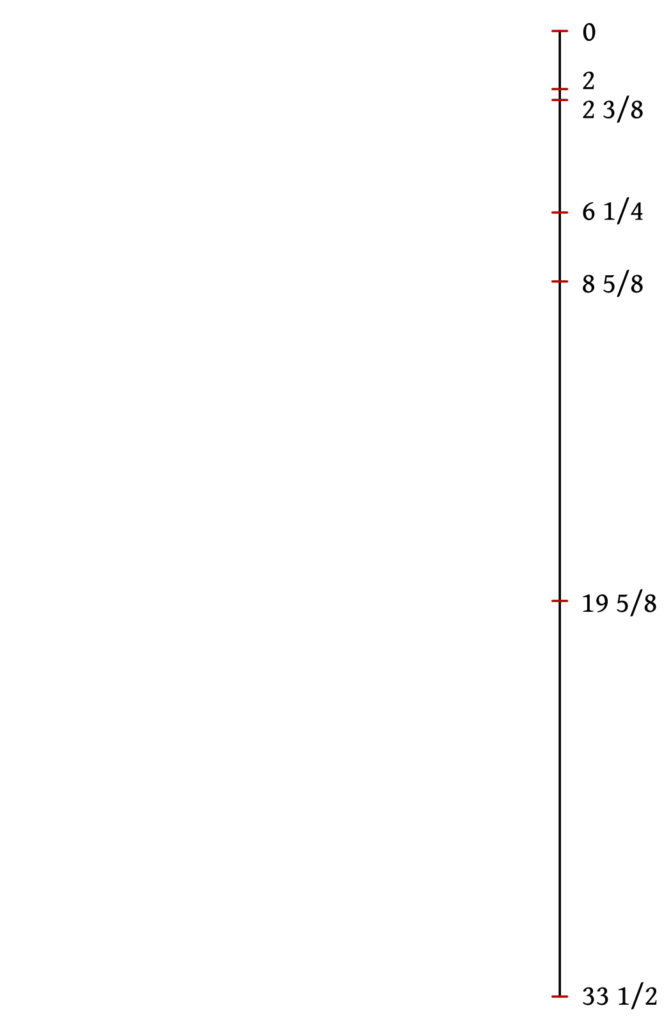

Mark the top of the line as 0. From this 0 point, mark out the following distances along the line using your graduated ruler:

- 2

- 2 3/8

- 6 1/4

- 8 5/8

- 19 5/8

- 33 1/2

Note

This is the first area in which you can double check the length with a regular tape measure. Sometimes, if you are a larger size than around a 42 – 44″ chest, the proportions start to be thrown off substantially. For an extreme example, imagine someone who has a 60″ chest and is only 5 feet tall. If you left the draft as is, the bottom of the shirt would most likely be touching the floor, at least!

So take the Length measurement you took in the last lesson and compare it to the actual length between points 0 and 33 1/2. If there is a large difference you’ll want to adjust it accordingly by raising point 33 1/2 to where it corresponds with your length measurement.

With larger sizes, other things such as the armscye depth at 8 5/8 may also be off, so please send me a message if you need help so I can get you straightened out before things get too out of place!

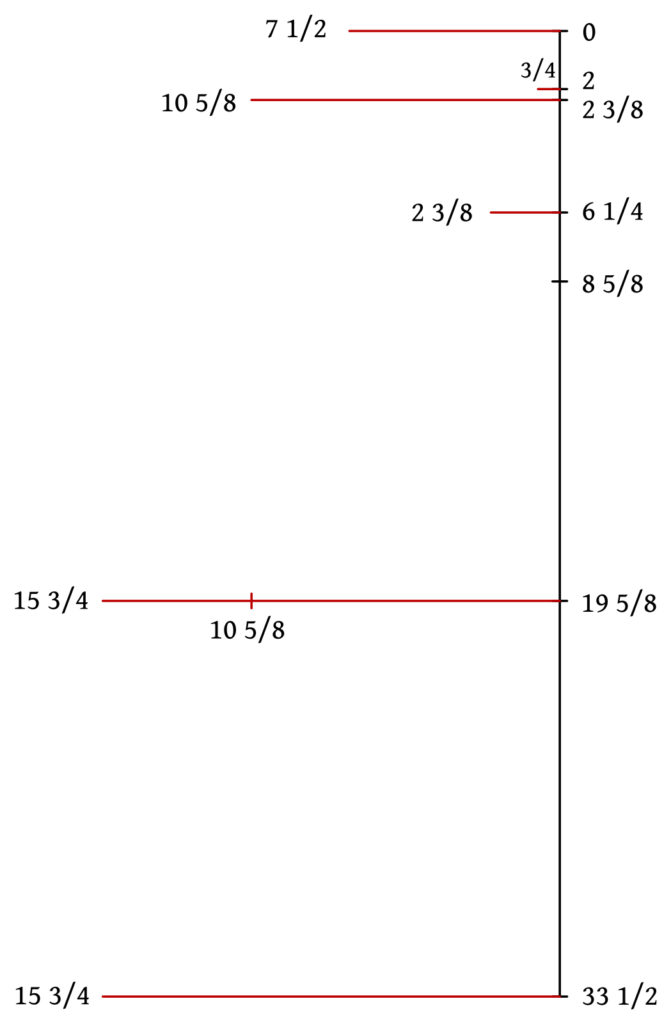

Next, ‘square out’, or draw lines at right angles to the original line, at each of the points you just marked out. Then measure the following distances on each of the squared out lines:

- 7 1/2 from 0

- 3/4 from 2

- 10 5/8 from 2 3/8

- 2 3/8 from 6 1/4

- 15 3/4 and 10 5/8 from 19 5/8

- 15 3/4 from 33 1/2

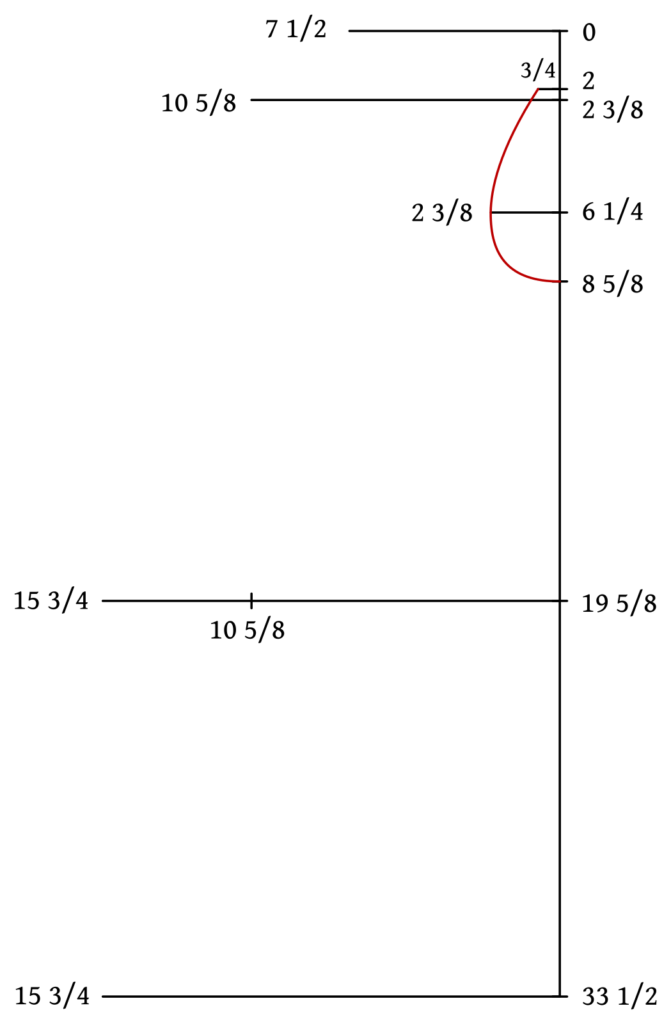

With the numbers all plotted out, it’s time to draw in the curves. You can do this free hand, or use something like a French curve or bendable drafting ruler to get the curves you like.

First, draw in the armscye from 3/4 through 2 3/8 down to 8 5/8 as shown.

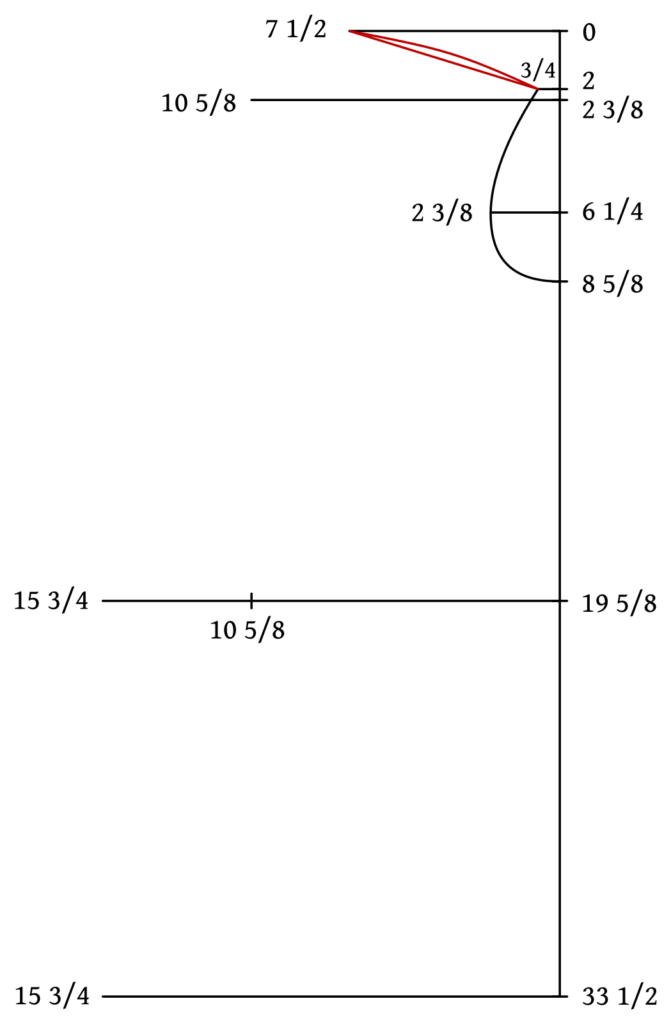

Draw in the shoulder seam now. I like to first draw a straight line from 7 1/2 to 3/4, then follow that with the curved seam line itself, in order to more accurately tell how deeply I am curving the line. Devere doesn’t give an exact depth to the curve, so something like 1/2″ should work well in most cases.

Next is the neckline, with a construction line drawn first from 7 1/2 to 10 5/8. The curve should be drawn rather deeply, it’s almost vertical at 7 1/2, and the last bit closer to 10 5/8 follows the horizontal line for almost 2 inches.

Draw a vertical line from 10 5/8 to 10 5/8. This gives the front edge of the opening placket.

Draw one more vertical line at 15 3/4 for the center front edge of the shirt – this will actually be placed on the fold of the fabric later on.

Here is another area where you can adjust the fit if necessary for larger sizes. On a sized 37 1/2 chest, where the graduated ruler is equal in size to a regular inch ruler, the shirt at the bottom is 31 1/2″ across the front, over 60 inches around if you include the back! So it is very roomy (and comfortable). If you are a larger size however, this can get unwieldy, so you may want to move the front edges at 15 3/4 and 10 5/8 at the neck back slightly.

Every case is different, so if you think you might need to do this, please take a photo of your draft as well as your self and send those to me so I can advise on a more individual basis.

The last bit of the draft’s curves is at the bottom of the side seam. Make a small curve here – mine started at about 3 inches from point 33 1/2 on either end. You could also use a can or plate here, anything that fits and is pleasing to your eye.

Draw a line parallel to the 10 5/8 line, about 1″ to 1 1/8″ inch away, depending on your size and preferences.

This next line is quite important, as we’ll be cutting various pieces based on this line later on. It is made parallel to the original construction line and should be placed about 1″ to 1 1/2″ in from the shoulder point. This forms the outer edge of the pleated front area.

Finally, draw in the desired pleat width parallel to the other lines. The spacing of the pleats is up to you – I’ve done 1″ and 1/2″ sized pleats in the past. Half inch pleats and smaller tends to get very tedious so I do recommend a larger pleat if this is your first attempt at a pleated front. The smaller pleats are also a pain to press!

The pleats should be spaced equally from the front placket area. As you can see, the outer pleat closest to the armscye is a lot smaller – you can either leave it, as it’s not very noticeable in the finished shirt, or move that outer line outwards to make all of the pleats equal in size.

Just a note, the pleats we’re drawing on this pattern are just to get an idea of what our chosen pleat size will look like. We’ll draft out the actual pleated section later on.

Finally, one last adjustment you may wish to make for the depth of the plackets themselves. I’m not sure, but I think the original draft was meant for wear with a very low cut dress waistcoat, so the placket is very long if you leave it at 19 5/8 depth.

Instead, you can apply your opening measure from the neck to the desired placket opening depth and adjust the heights of the various lines involved as necessary. Here’s what that might look like.

All that’s left to do is add a 1/2″ seam allowance, using a quilting square or similar device, around the neck area, shoulder, armscye, side seam, and bottom hem.

Rather than add a seam allowance to the front, which will be cut on the fold, continue the front seam vertically as well as extend the neck seam allowance horizontally until the two meet. The front edge will be cut on the fold of the fabric, and this makes certain steps a little more manageable.

Finally, make sure the bottom edge as well as the outer edge of the pleats is marked on the pattern. These need to be transferred to the fabric later on.

Shirt Measurements

The shirt pattern we are using is from Devere’s Gentleman’s Monthly Magazine of Fashion, July 1859, and is cut extremely loose in the fit. It’s not quite an ‘on the square’ shirt as there are some refinements to the shoulder and neck area, but it’s close. If you’re of a size greater than around 40 – 42″ chest, you should take the extra measurements and compare them to the shirt to ensure you do not create a balloon of a shirt.

When measuring, you or the person being measured should wear a dress shirt or period shirt ideally.

Breast

Measure around the fullest part of the chest. This measurement is written down as half for the sake of the draft. So a 38″ chest becomes 19″ when drafting. This measurement also determines the size of graduated ruler you should use for drafting.

N.B. The shirt is so unfitted that no waist measurement is necessary.

Neck

The neck should be taken fairly tightly around the neck, including the collar (stand it up). When you’re drafting, compare the neck size of the draft to your measurement to make sure you’re on the right track.

Length

Taken from the back, measure from the base of the collar down to the desired length. The draft we are using produces a very long shirt as was the style, and so if you are a larger size, it’s quite possible your shirt will touch the floor if you do not adjust the measurement! Ideally should be a few inches above the knees.

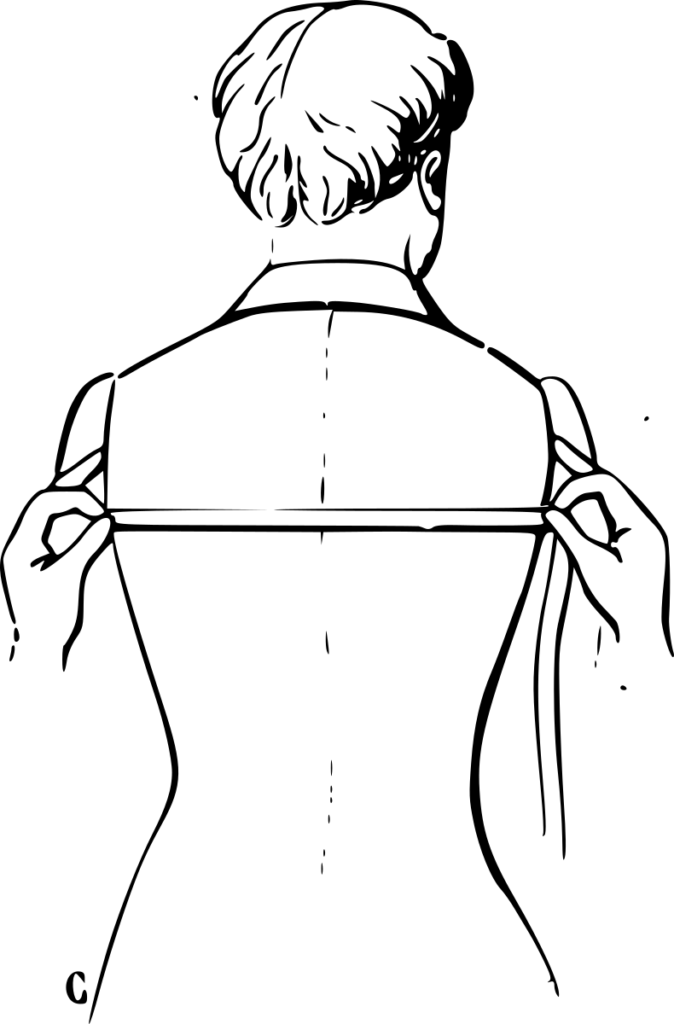

Back Width

This is basically a check measurement to ensure the back of the shirt does not become too wide. While the shirt has 4 – 6 inches of ease in the back shoulder area, if you are a larger size this will end up too wide. Measure from armpit to armpit (not under, just to the armpit) across the back.

Sleeve

The sleeves are more difficult to measure due to the looseness of the shirt – they don’t end at the same point as on a coat. So stand with your arm and elbow both held at 90 degrees, and measure from your armpit along the back of the arm to just past the wrist. Then compare with your draft as necessary.

Opening

To help determine the depth of the pleats at the front, measure from the bottom of the collar at the neck to the desired opening of the pleats. Generally, I like to make my pleats end at about 3″ below the opening or top button of my waistcoat. If you don’t yet have a waistcoat, just estimate where you’d like it to open and then add the 3″ to that.

There may be some other measurements that are of use in very rare cases, but these should certainly cover most drafts. If you need any help or have any questions, please post your questions in the support forum!