Month: November 2019

The Top Collar

It’s now time to install the top collar, which must be basted into place much like the front facings were, in order to ensure that it drapes correctly.

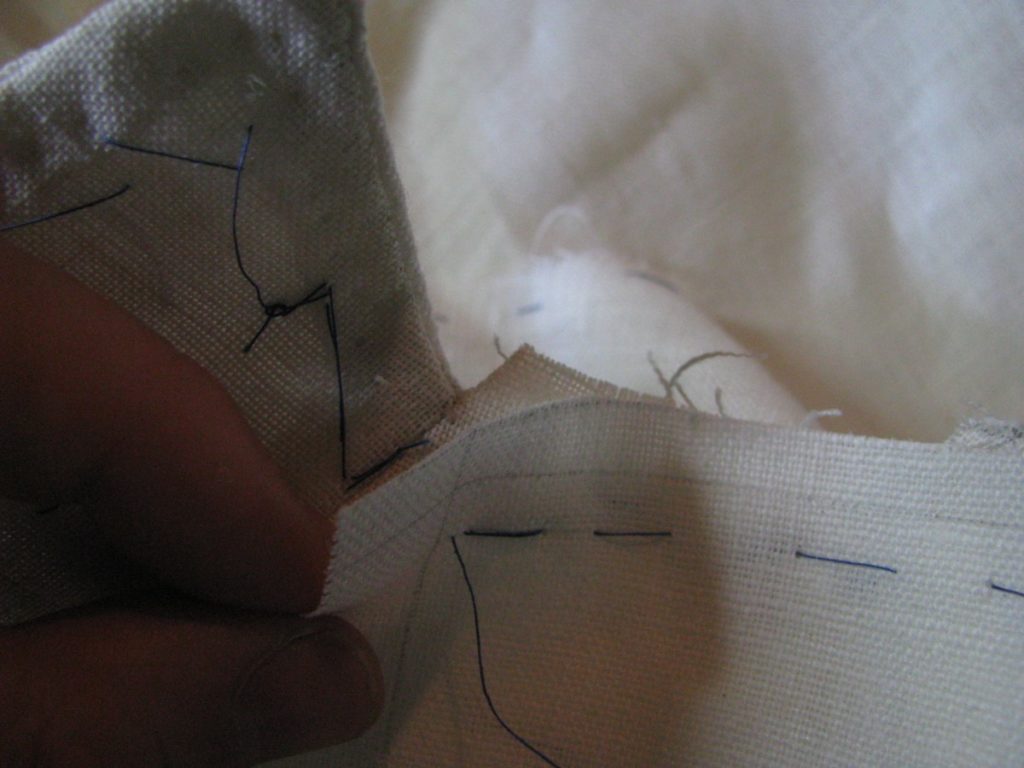

Begin by pressing and basting the under collar seam allowance 1/2″ along the top edge.

Do the same thing to each end. By doing the ends second, you ensure that the folded seam allowance angles inward so that it will not be seen in the finished collar.

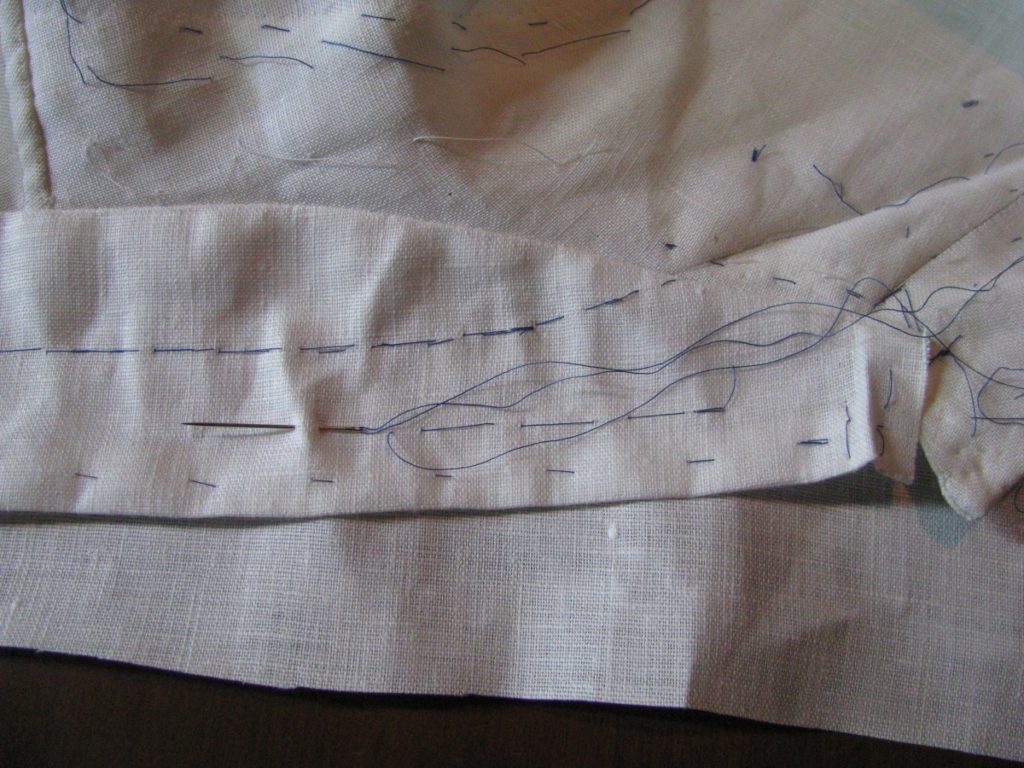

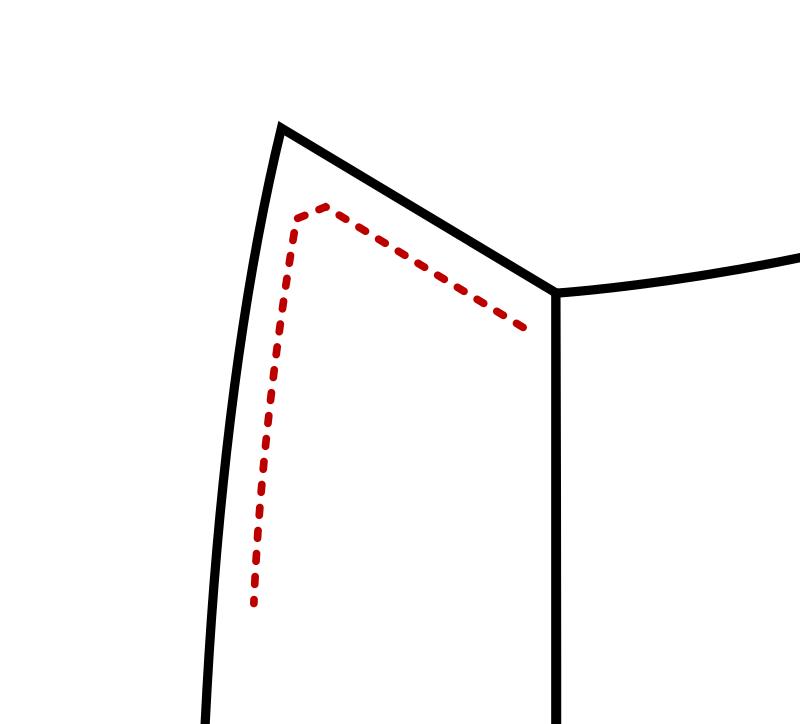

A view from the right side showing the seam allowances basted in place. You want this to be as neat as possible as it gives you the finished position of the collar.

Also note how the lapel, coat body, and collar all meet precisely at the same point.

It’s time to cut out the top collar, with the center line on the fold. Lay the pattern down, and then mark a line 1″ all the way around. Cut out the collar. This extra material gives you room to fit the top collar properly.

Lay the top collar wrong side up on the table and lay the coat wrong side down, on top of it. Make sure the flat edge of the top collar is positioned towards the top of the collar.

Not really much to photograph here, but starting about an inch from the edge of the collar, baste along the roll line of the under collar, catching the top collar underneath.

Stop 1″ from the other side.

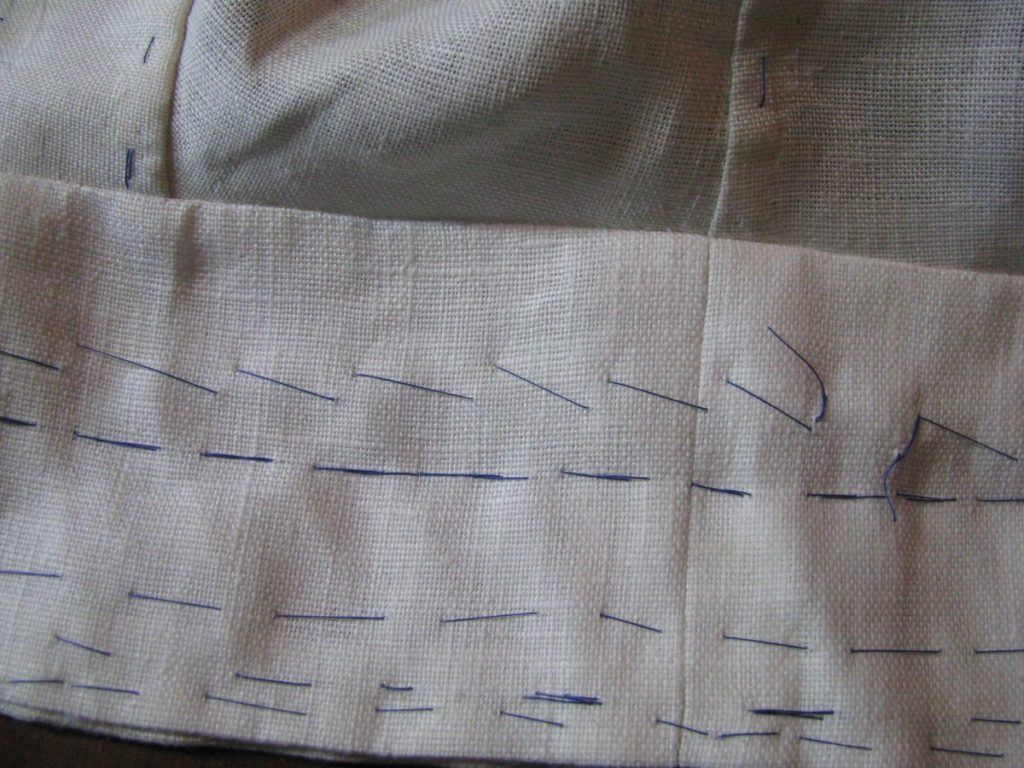

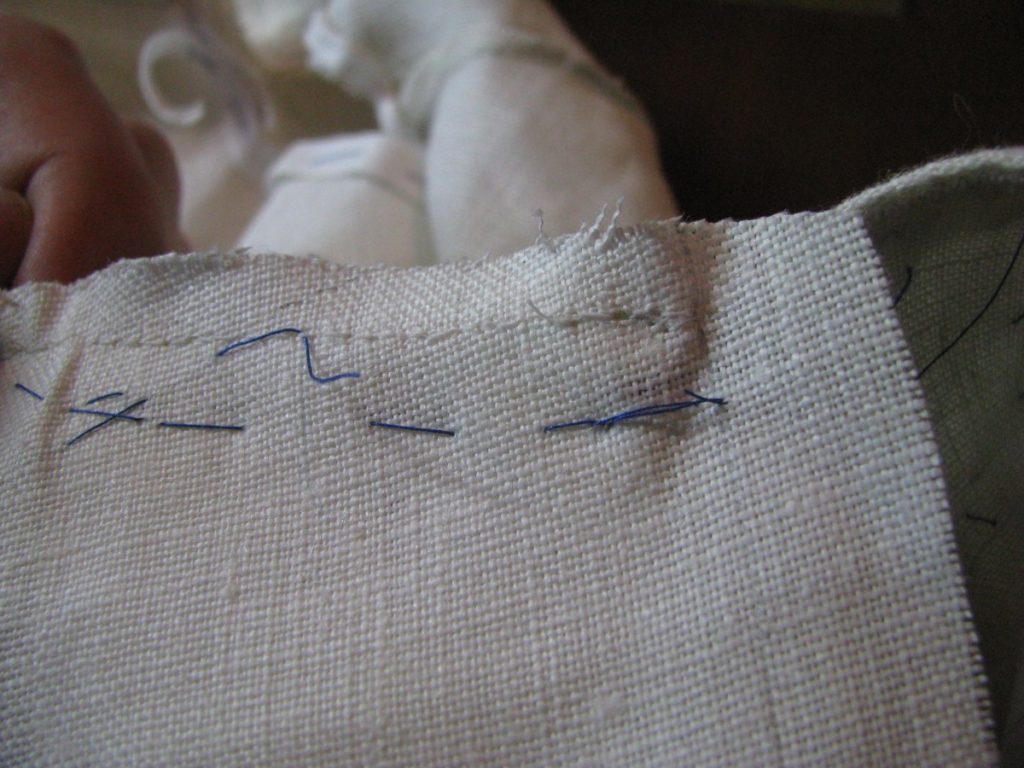

Again, about 1″ from the end of the collar, and about 3/4″ from the folded seam edge of the collar, baste along the collar catching the top collar beneath it.

Keep the entire collar flat on the table as you work to ensure the correct tension.

Stop 1″ from the other side of the collar.

Now carefully trim the excess away, leaving 1/2″ at the edge of the collar, and 1″ at each end. The hidden edge of the top collar is not touched at this point.

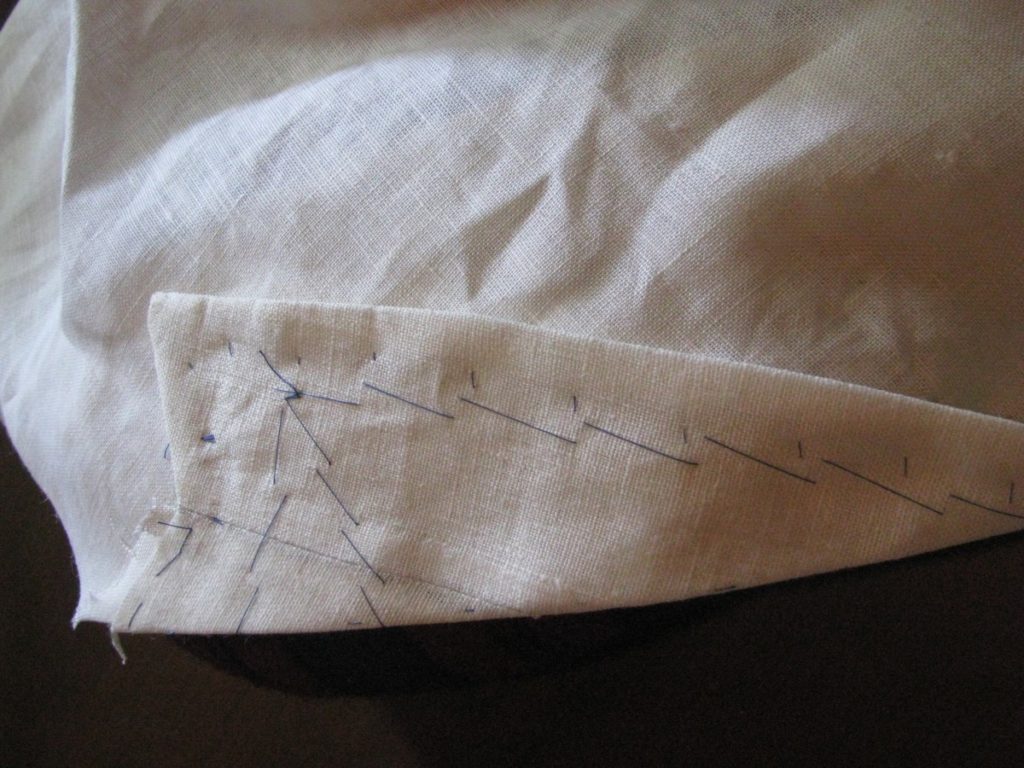

Fold under the ends of the top collar and baste, leaving 1/8″ of the top collar showing underneath.

Do the same thing for the other end, then along the outer edge of the collar, keeping that same 1/8″ of the top collar visible.

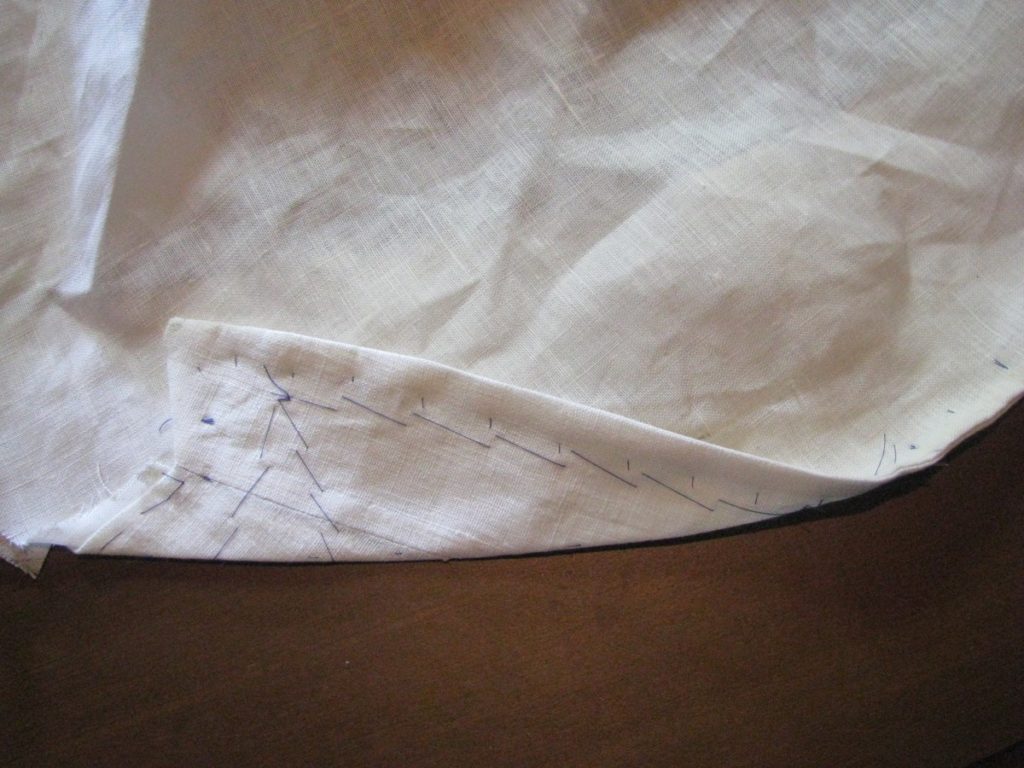

Turn the coat over so that the top collar is fully visible. At each end, crease the top collar back along the gorge line just to give you an idea of where to trim in the next step.

After both gorge lines are creased, continue the crease along the middle of the collar, so both creases meet up.

Keeping 1/2″ away from the crease line, trim off the extra fabric from the top collar.

Now fold under the 1/2″ seam allowance at each gorge line and baste securely closed.

Turn the coat back over so that the top collar is next to the table again. On the inside of the roll line, beginning about an inch from the edge of the collar, baste across the under collar, again catching the top collar underneath. This row of basting is about 1/2″ from the roll line.

Continue all the way across.

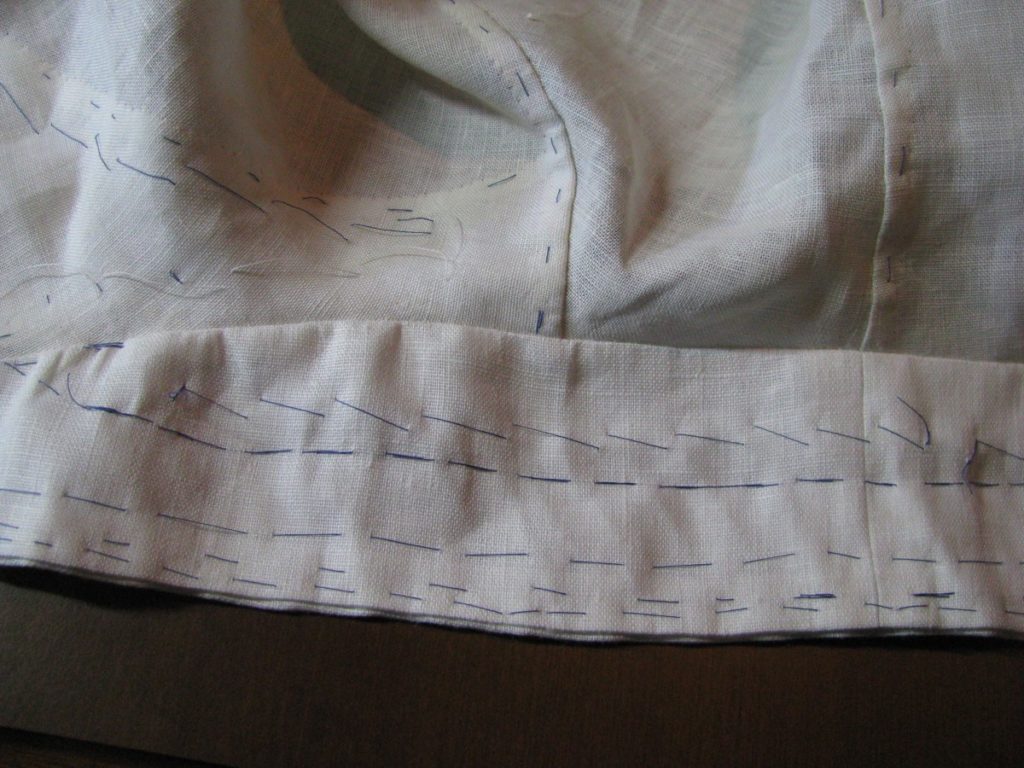

Turn the coat over so that the top collar is again facing you, and fold under the remaining raw edge of the collar so that it aligns with the stitching holding the under collar in place. Baste securely.

Working from the underside of the collar, carefully fell the top collar to the under collar, beginning at the outside edge of the collar, across the top, to the other end.

At one end of the collar (depends on whether you’re right or left handed, your preference), make about 4 or 5 backstitches in place at the point where the collar meets the lapel. This just firms up the area and prevents tearing.

Pass the needle and thread through to the top side of the collar. We’re in position now to start the ladder stitch, which is used to close up the collar and lapel along the gorge line.

Here’s a video demonstrating the ladder stitch:

Start by taking a stitch just above the crease, on the top of the lapel.

Then do the same to the collar side, entering the collar just across from where the last stitch exited. Repeat the last two stitches.

Every four stitches or so, take a stitch through the under collar, in between the two folded edges that you are sewing together. This holds everything more firmly in place. Pull the thread taught (but not too tight), right after you make this stitch.

Continue the entire process until you reach the end of the gorge line (which is where that snip was made in the facing).

When you reach the end of the gorge line, simply continue by felling the top-collar down to the neck along the shoulders and back. Continue until you reach the other gorge line.

And then continue with more ladder stitching, finishing up with another bar tack on the underside, as before.

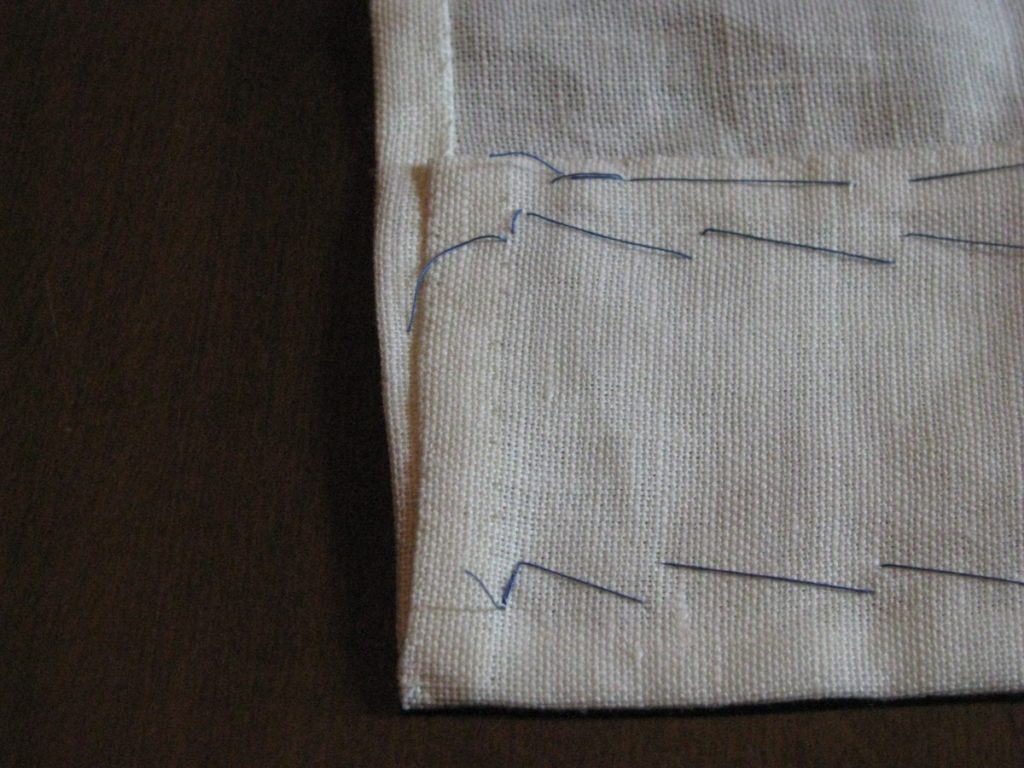

Here’s a photo of the stitches before they are pulled tight.

The last stitch before passing the thread to the other side for a bar tack.

Finish the collar by top stitching using a side stitch, 1/4″ from the edge, just as you did with the facing.

The Under Collar

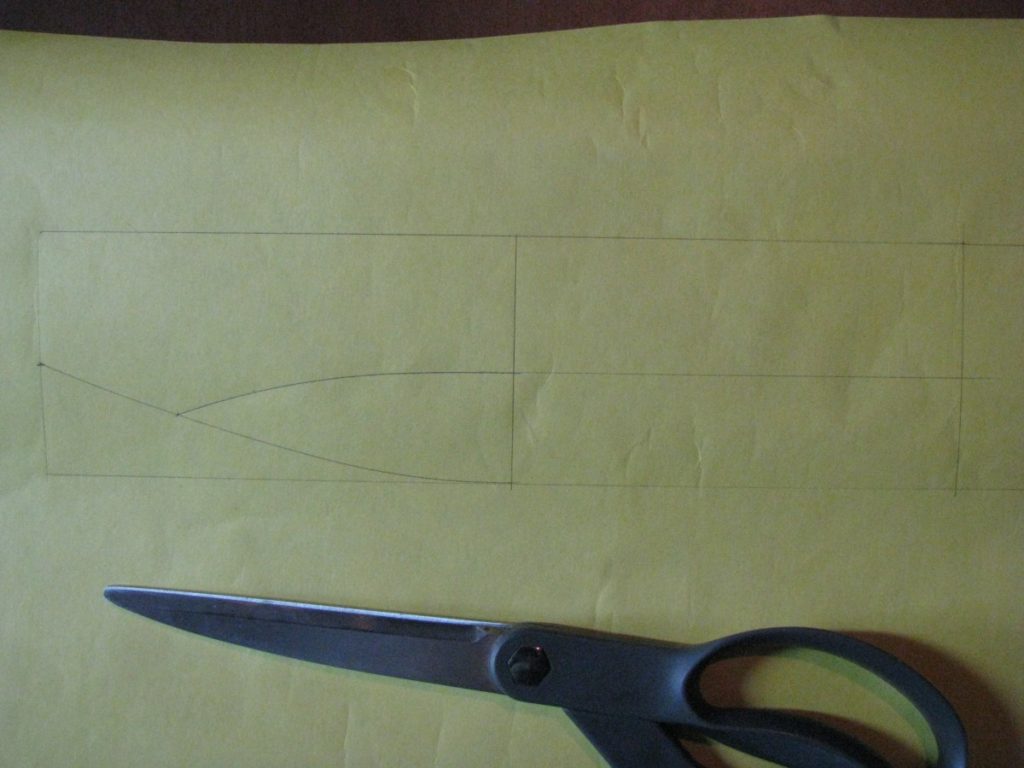

If you have not done so yet, now is the time to draft your collar pattern using my guide in the Frock Drafting series. Here is my pattern, freshly drafted:

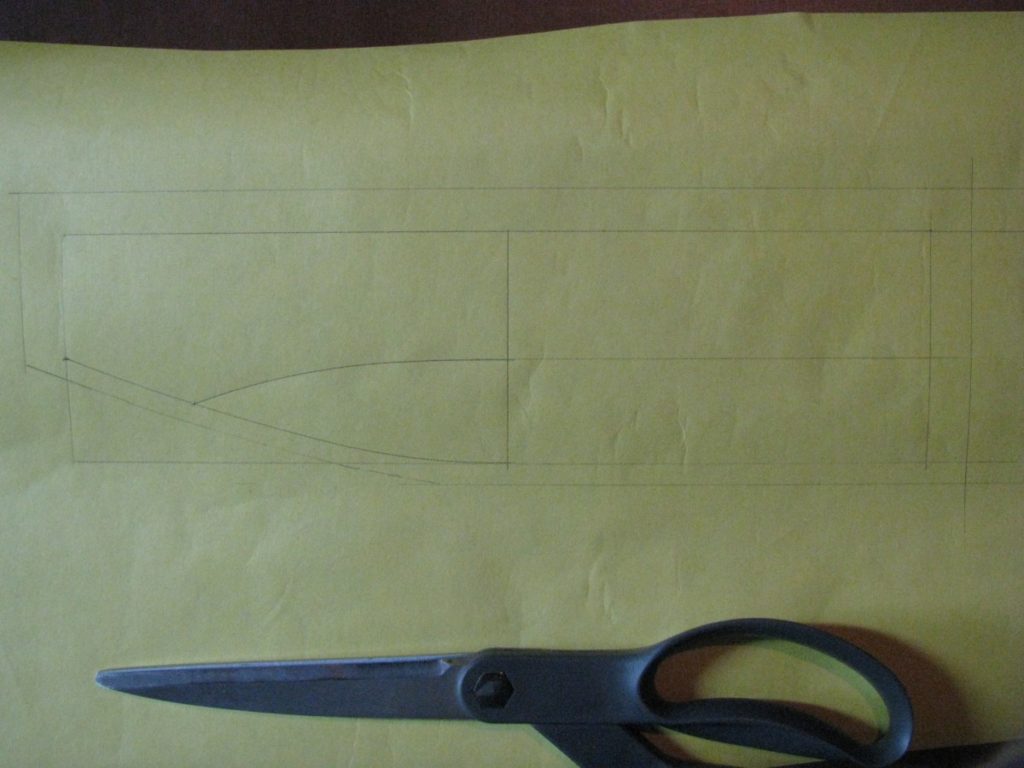

Before cutting out the pattern, add a 1/4″ seam allowance along the bottom curved edge (or whatever you used for the neck seam allowance). Add 1/2″ seam allowance along the top edge, and two sides. This simply makes it easier to finish later on.

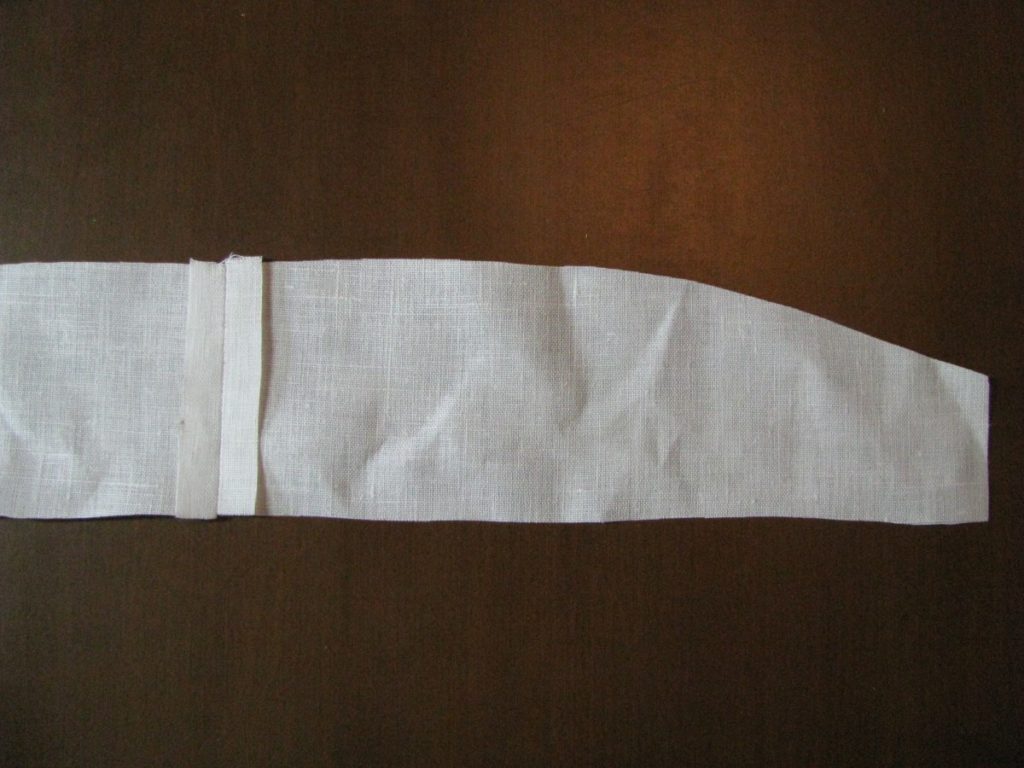

Cut out the pattern, and then the undercollar, which is made of two halves. Draw in the 1/2″ seam allowance along the center back (which is the wider side).

Stitch the under coller halves together using a backstitch. The collar is often under stress so it’s best to use a back stitch.

Press open the seam allowance. This can be trimmed to 1/4″ if you wish.

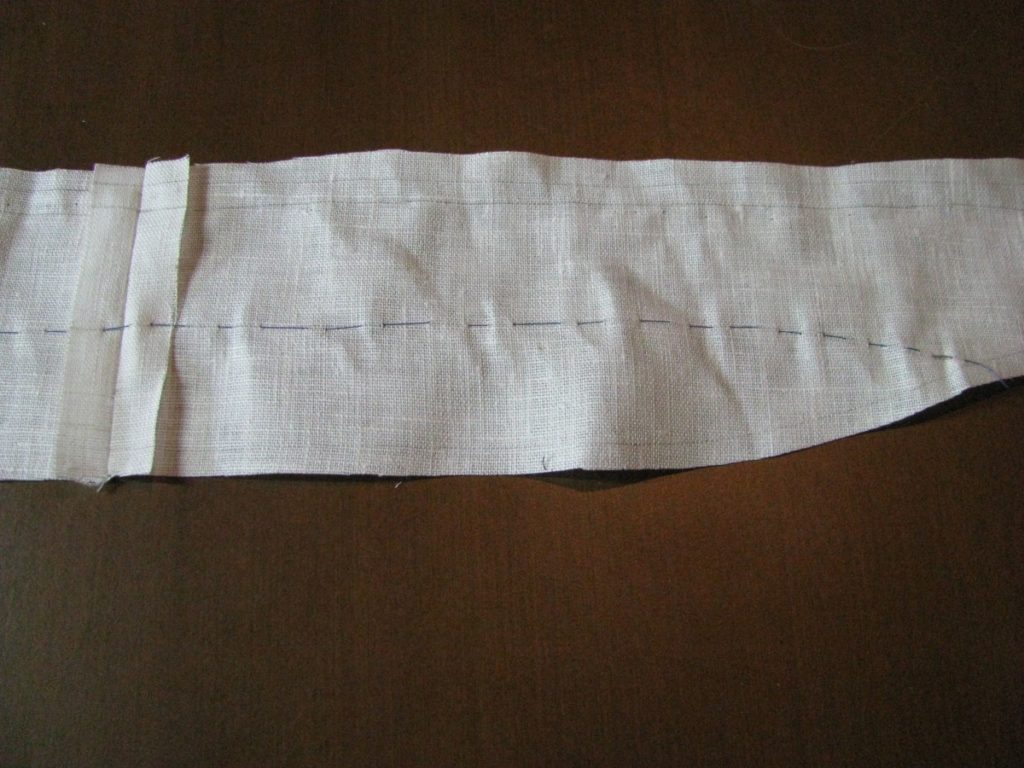

Transfer all seam allowances to the collar. Note here I accidentally put the 1/4″ seam allowance on the top of the collar instead of the curved bottom seam where it belongs. Figured that mistake out as I was basting the collar onto the coat.

Also very important, is to transfer the roll line to the collar. I find it’s easiest to just cut the pattern in half along the roll line and use that to mark it on the under collar.

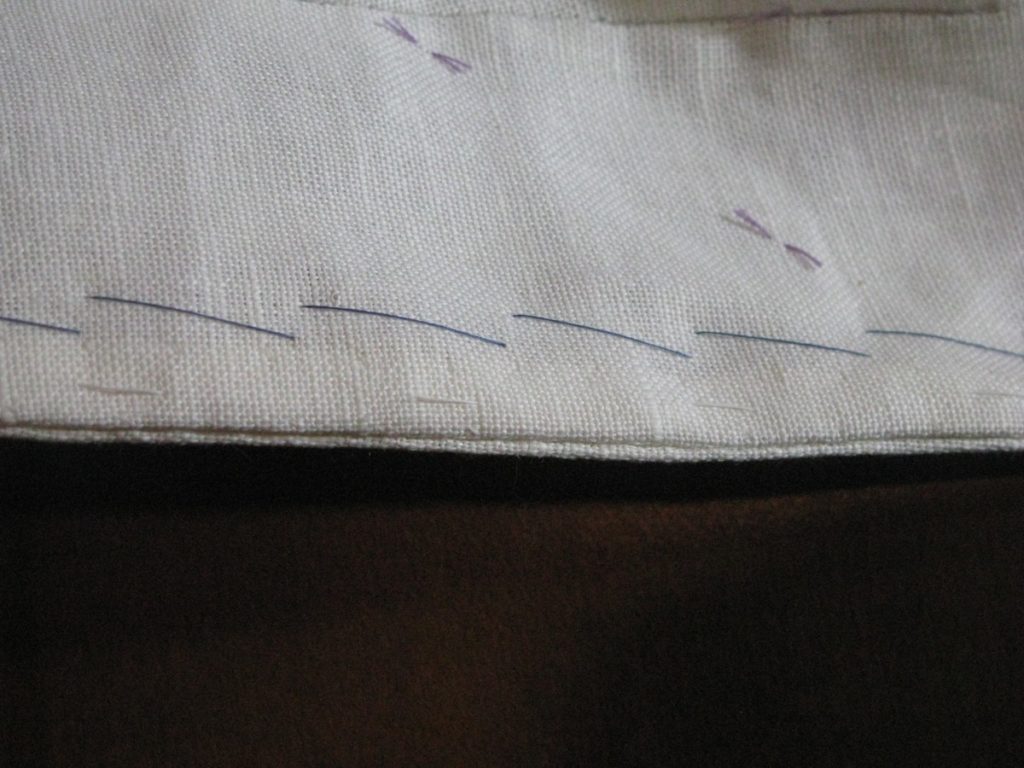

Mark the under collar more securely in thread, so that it shows through to the right side.

With right sides together, line up the curved bottom seam of the collar with the neck seam at the center back.

Baste securely together, starting at the center and working your way out (the direction depends on if you are right or left handed).

As you get to the curved part of the neck seam, you’ll find that the collar will naturally full itself in with about 1/4 – 1/2″ of extra fabric. This will help the collar roll properly.

The most crucial point of the entire process, you want to make sure that the roll line of the forepart and the collar align exactly, 1/4″ from the edge.

Continue basting to the front edge of the collar, aligning the cross hairs of the seam allowance with the top of the lapel dart directly underneath.

Repeat the basting process for the other half of the under collar. Here’s what the entire under collar should look like when basting is complete.

Beginning on one edge of the collar, at the crosshairs formed by the seam allowance, use a back stitch to secure the collar to the neck of the coat. At each end, it’s a good idea to reverse the back stitching on itself to give an extra secure finish to the ends of the collar.

Backstitches continued along the center back.

And finishing up at the other side.

Using a tailor’s ham, press the collar upwards along its entire seam. Note here how the roll lines align perfectly between collar and lapel. If they’re off, you’ll have issues trying to get things to lay properly.

Here’s a view of the inside of the coat showing the back seam, shoulder seam, and center back of the collar, and how the seam is pressed up towards the collar – not opened up.

Drafting the Collar

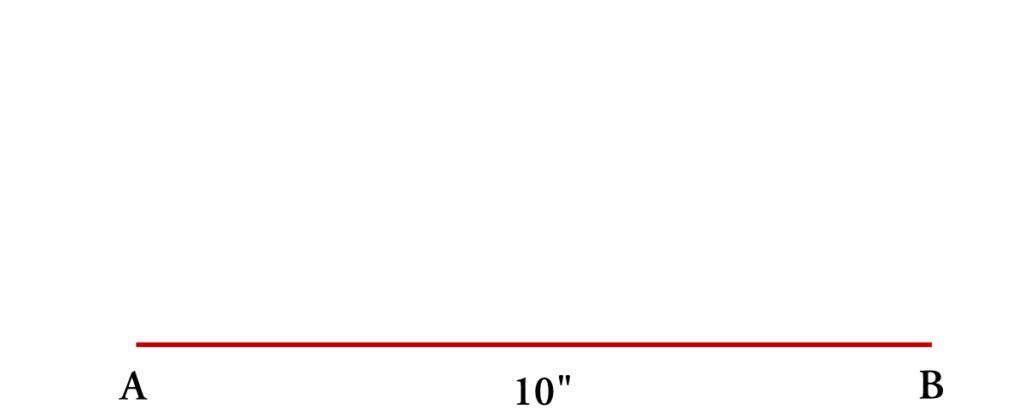

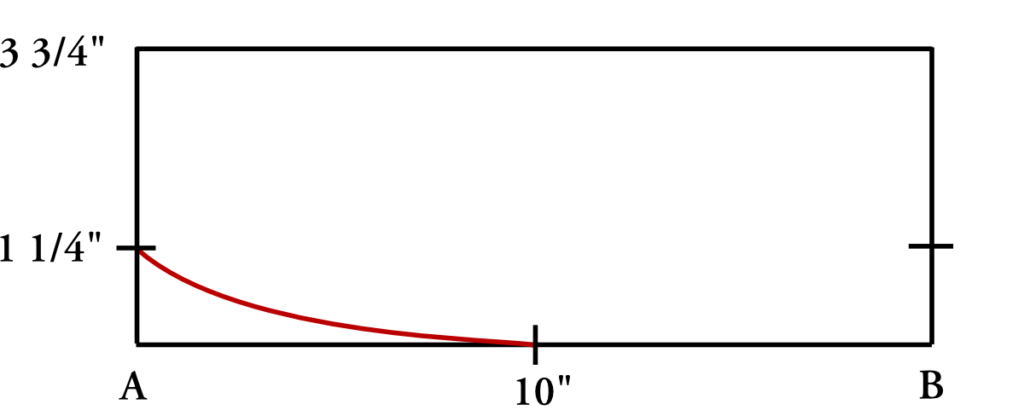

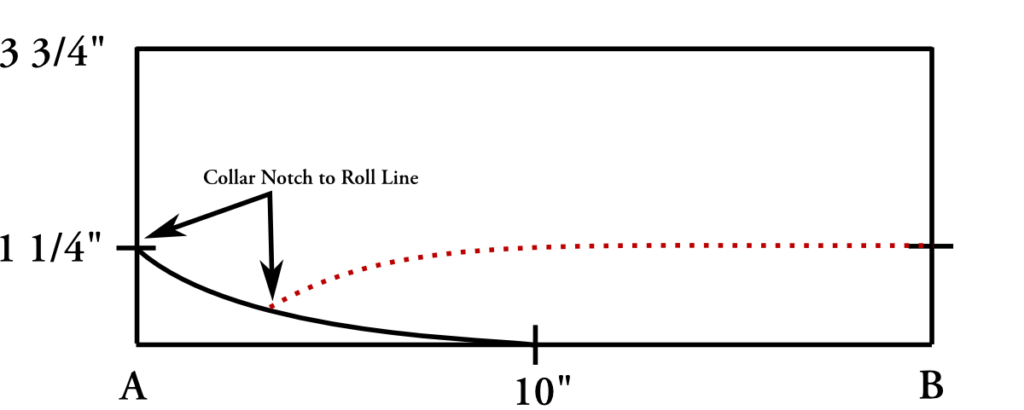

The first step in drafting the collar is to draw the baseline. This should be 10 graduated inches in length, or the length of the collar from the collar notch (edge of the neck dart) to the neck and shoulder point, plus the width of the back neck.

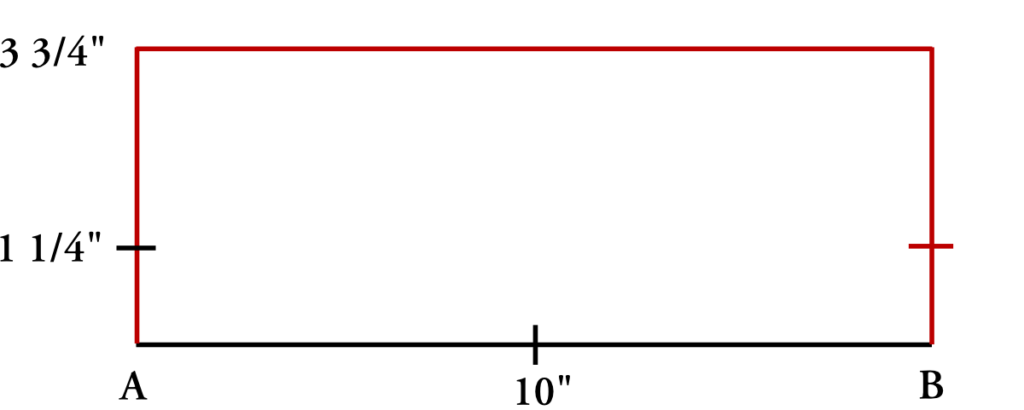

The next step is to square up from points A and B, and mark the appropriate distances. These are subject to fashion – Devere’s 1866 manual gives 1 1/4″ height for the collar stand, and 3 3/4″ for the collar fall. For an earlier type collar, say from the 1850s, Devere recommends 1 1/2 for the fall and 4 inches for the stand, giving a much higher collar.

Mark halfway between A and B. Draw a curved line from the mark at 1 1/4″ to this halfway mark. This is giving some curvature to the collar, which will give tension to the area and help it stand properly.

Next, measure the distance from the collar notch to the roll line. Measure that distance out on the curved line, and from there, draw the rest of the roll line on the collar. At about the half way point, the curve of the roll line straightens out.

Seam allowances are added all around for the undercollar. The canvas is cut the same size as the pattern, and the top collar has 2 inches seam allowance all around.

Long Turn of the Collar

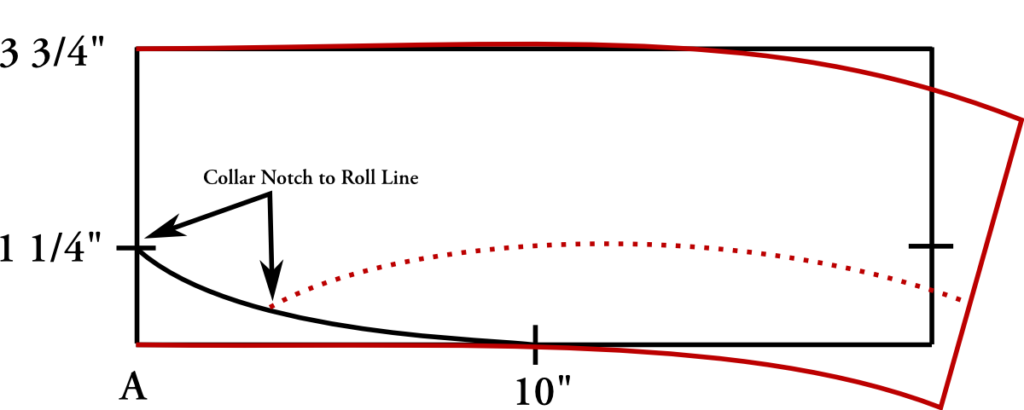

If you have a high buttoning coat, you will have to edit your collar pattern slightly. This is due to the fact that more fabric is needed on the outside to get around the longer curve.

To do this, move point B downwards, up to half an inch, and to the right, about 1/4 inch. Form a right angle from the new baseline at B, which will curve outward now. Measure up the appropriate distance, and redraw the top of the collar. Also be sure to redraw the roll line on the collar, it must curve as well.

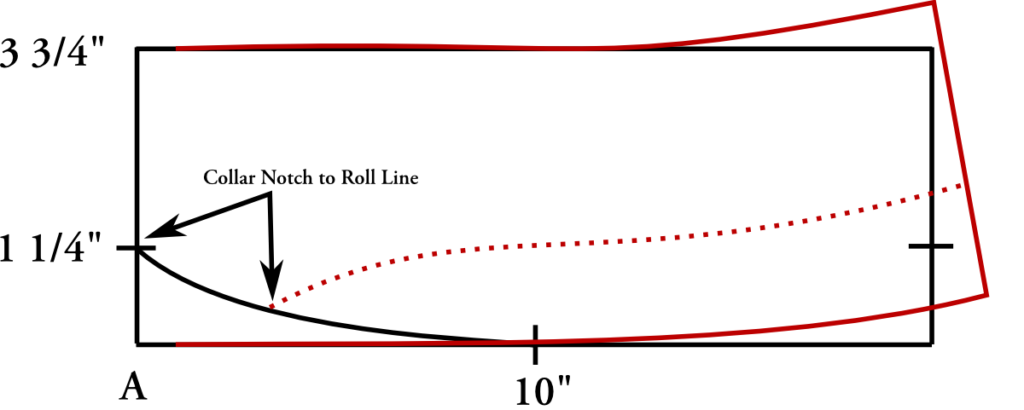

Short Turn of the Collar

On the other hand, if your coat buttons rather low, the curve will be less severe at the collar, and you will need less fabric there. Raise point B up to half an inch and outwards slightly, redrawing the bottom seam in pretty much a straight line. Draw a right angle up the same distance as the original collar, and redraw the top curve as shown. Redraw the roll line as well.

For Both of these instances, there are no set numbers on how far to adjust the collar. Rather, it’s up to your fitting skills, which will only get better with more practice. Usually 1/4 – 1/5″ will suffice for the alteration. I highly encourage you to practice with some scrap canvas the different cuts of the collar, and see how they affect the fit of the coat.

The Back Facing

Before moving on to the collar and sleeves, it’s a good idea to get the back facing out of the way. This facing hides the top of the plait pockets and the vent, and also provides a little structure and stability to the back of the coat.

Begin by measuring the inside of the coat, from the center back, to the far edge of the plait pocket. Add 2″ or so to this measurement for seam allowances and for some extra room to work with. Also measure the height of the area that needs to be covered and add two seam allowances to that measurement.

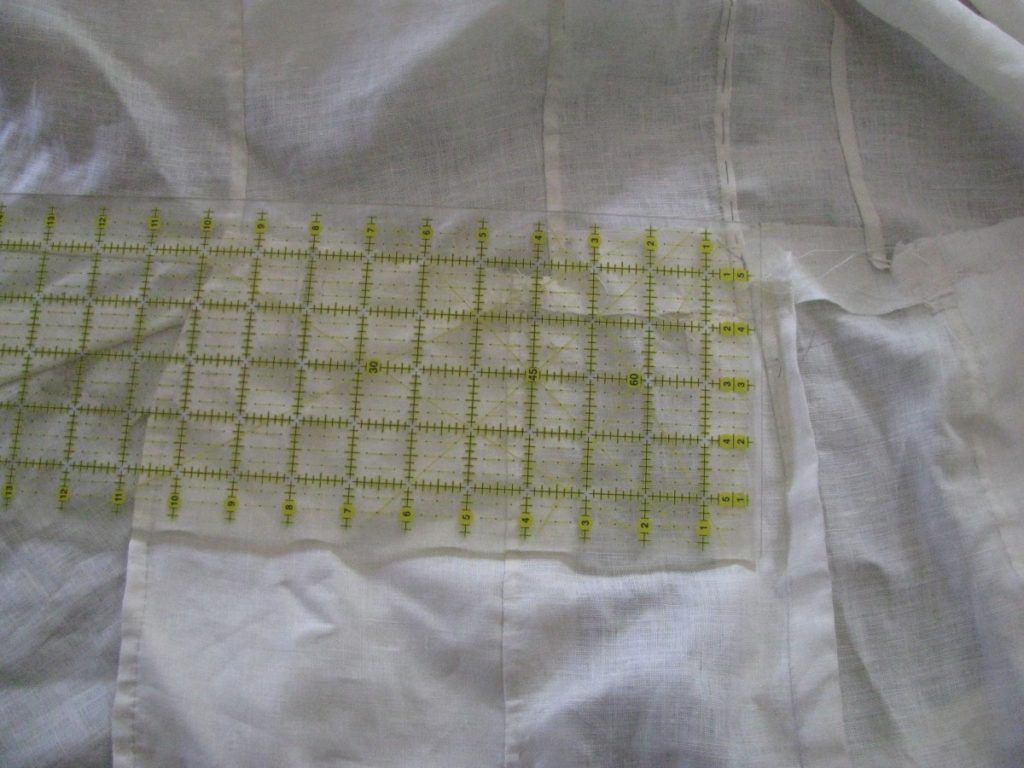

Using these measurements, cut out two facing pieces, one for each half of the coat. Mine turned out to be 3″ by about 13″ in length.

Place both halves together, and lay them on one half of the coat, covering the messy raw edges. When you’re happy with the positioning, lay a ruler along the back seam, and draw in the seam line for the back waist facing. It will most likely be at a similar angle to mine.

Stitch along this line with a back stitch, for extra strength.

Trim the seam to 1/4″.

Press open the seam.

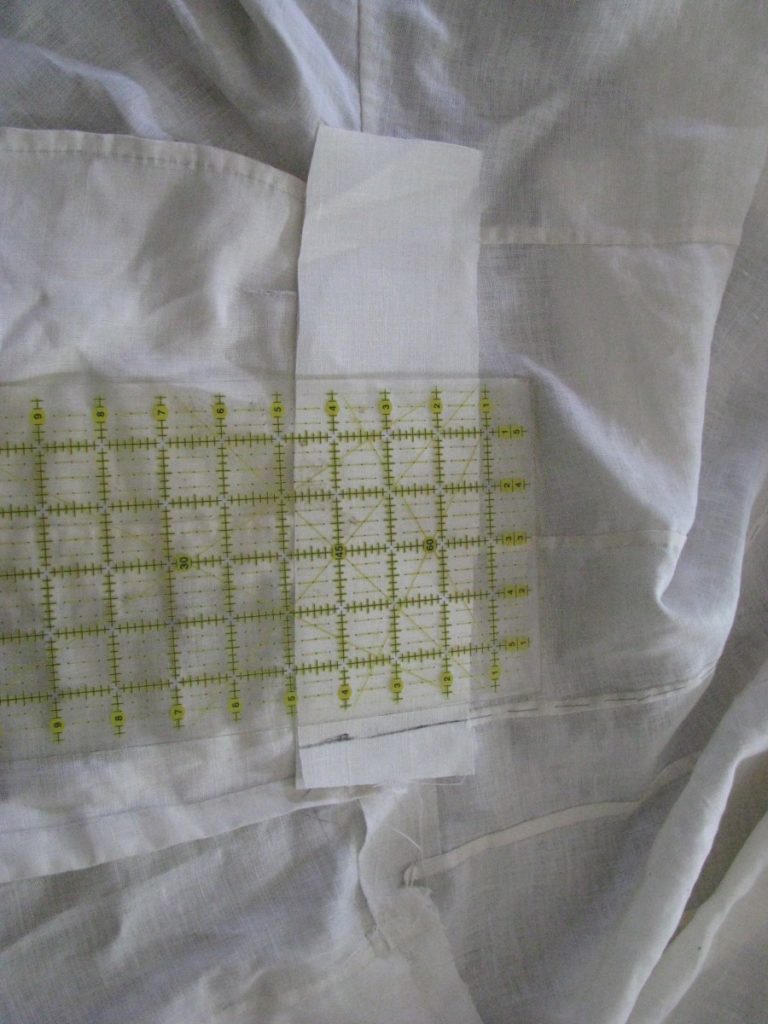

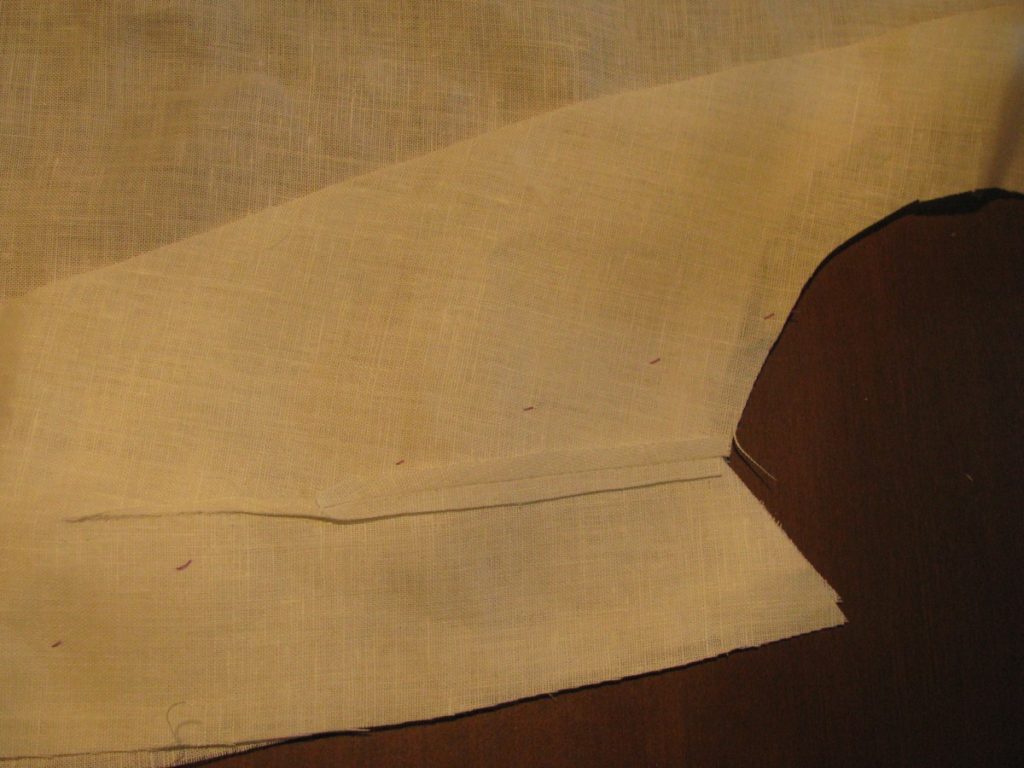

Lay the facing, wrong side down, on the inside of the coat, aligning the center line with the center back seam.

Baste from the center line, along the middle of the facing, towards one end.

Repeat for the other side.

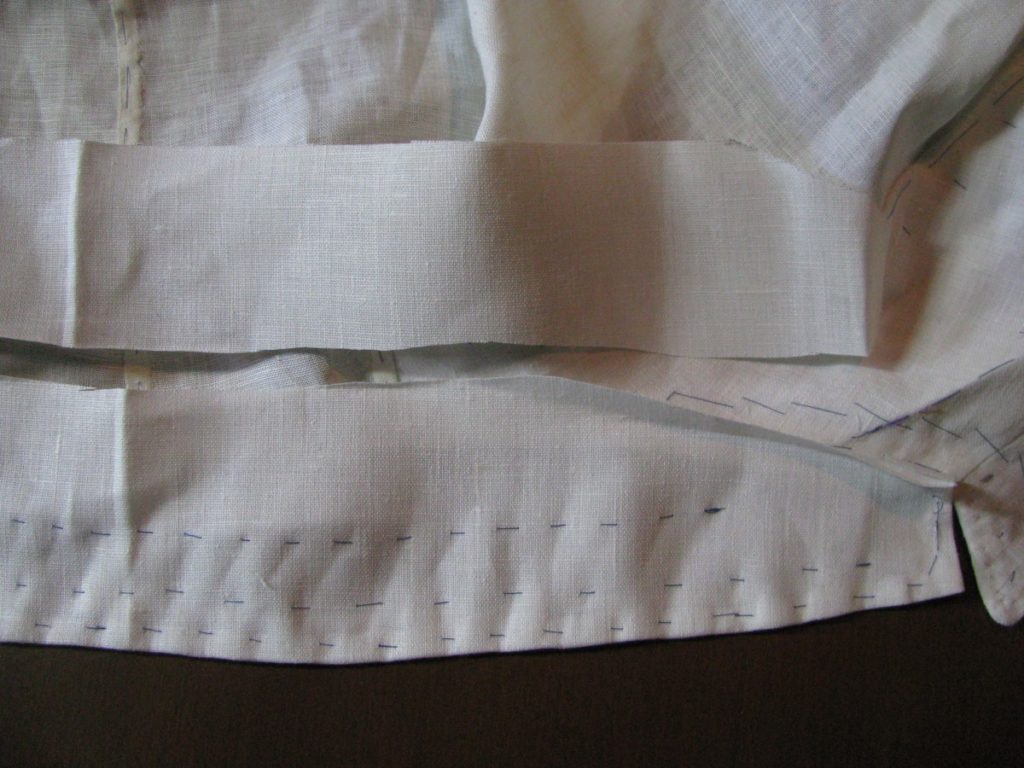

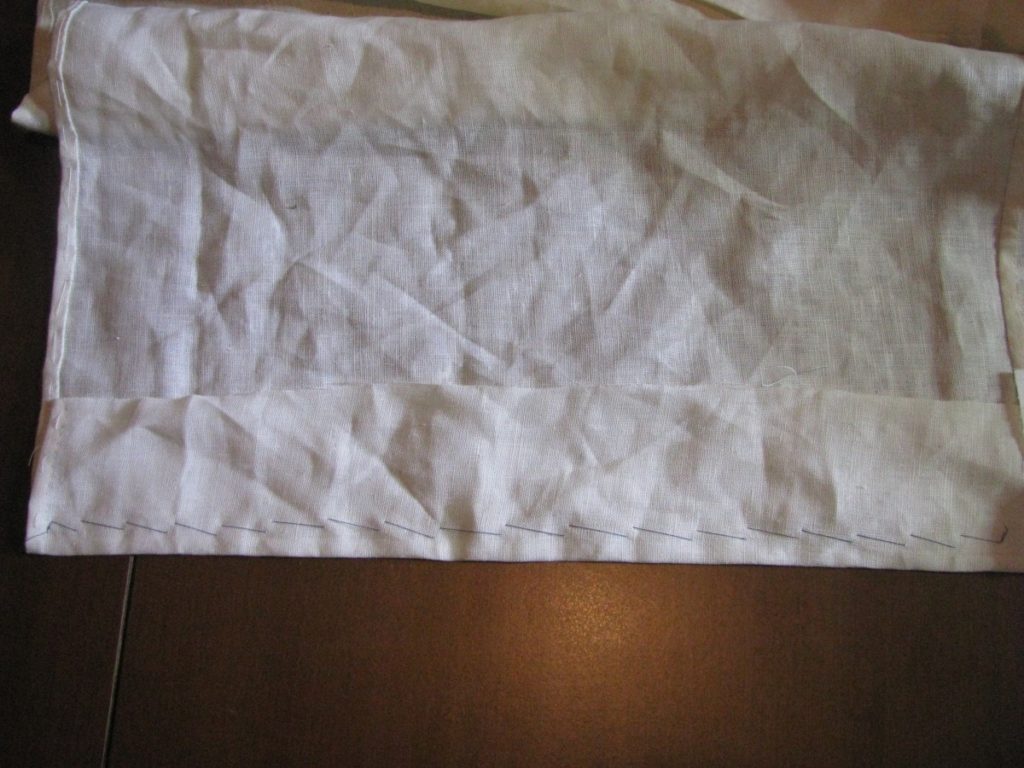

Fold under the raw edges and baste the facing down along the entire edge.

Using a felling stitch, fell the facing to the coat all the way around. Make sure you are only catching a couple of threads of the coat, as these stitches are visible from the outside.

The Back Vent

As soon as you finish the back seam, you’ll want to immediately begin work on the back vent, to prevent any tearing in the area. The left vent should overlap the right side of the coat. The exact position can be very difficult to figure out. It depends on the wearer’s posture and sometimes the default position will leave gaps in the vent. So I highly recommend doing a fitting and getting the position exactly. You want both halves of the vent to fall parallel to each other.

When you are happy, pin the vent in place and then remove the coat in order to baste more securely. Baste up the right side of the vent.

Across the top, and down the other side.

If you look closely, you’ll notice a little fraying at the inside corner of the vent. This is due to fraying during the construction process and not being accurate enough while sewing the back seam.

To fix this, and help secure the top edge of the vent, fell across the top edge of the vent, hiding any loose threads as you go. You can continue a short ways up the back seam if necessary.

The back vent must now be top stitched to permanently secure it. I’m going to use a box stay here, which is probably most secure. Draw a rectangle just below the top of the vent. Mine is about 1/4″ in depth and slightly narrower than the vent in width.

Using a side stitch, secure the back vent around the rectangle you just drew, using stitches about 1/8″ apart at most. On the right edge of the vent, fell the right edge of the vent from the top to the depth of the box stay.

Completing the Back Seam

It’s now finally time to sew the two halves of the coat together. Lay the two halves, right sides together, on the table and align the back seam.

Baste along the seam about 5/8″ from the edge, just outside of the seam allowance.

At the bottom near the vent area, the top of the diagonal cut on one half of the back should align with the square edge of the other coat half.

The inside point of the angled cut is the precise location that you want to end the stitch line on.

Transfer that point to the other half of the coat and mark the point with cross hairs. This should correspond with the 1/2″ seam allowance of the back seam.

Continue drawing the seam allowance along the edge of the coat to the neck.

With the ‘right’ side of the stitching on the half of the coat without the diagonal cut, sew the back seam using a back stitch or back and fore stitch.

As you get to the bottom two inches, switch to a back stitch. This is one of the most stressed areas of the coat, and so any extra strength in this area is most welcome. Note how the stitching stops at that point.

Here’s the view of the back vent area from the other side. I was off with my stitching by about 1/32″, which is workable. The fraying linen sure doesn’t help!

Trim the seam allowance of the back to 1/4″ inch on the side with the diagonal cut.

Turn the coat over and make a small diagonal cut, this time just a hair over 1/4″ in depth. This will allow you to fold the seam over, baste, and whip stitch as with the other seams. For some reason I did not photograph the felling, but you should be able to figure it out by now.

The Shoulder Seams

It’s finally time to move on from the facings! We’ll begin sewing the shoulder seam by first removing any unnecessary inlays. Feel free to have a fitting beforehand if you want to fiddle with the fit more closely.

With right sides together, line up the neck edge of the shoulder seam on the forepart with the corresponding point on the back. You want the seam allowances at the very edge of the neck. to meet perfectly. Hold in place with a pin. If you’re feeling brave and want to experiment with techniques, you can hold this between your pinkie and the palm of your hand, allowing your other fingers to manipulate the fabric – this takes some practice though.

Line up the other edge of the shoulder seam and the armscye of the back at their seam allowances, and baste across the shoulder seam. You’ll notice that the back seam is longer than the forepart, which will give added room for the shoulder blades. Just gradually ease it in as you are basting.

On the back, mark in the .5″ seam allowance if you wish. The right side of the stitching should be on the back of the coat body, so that the seam allowance can be folded towards the forepart.

Sew the shoulder seam with a back stitch or back and fore stitch, and then turn the coat to the forepart side and trim the forepart seam allowance to 1/4″.

Fold over the remaining seam allowance and fell in the usual method. Note that by folding the seam allowance towards the forepart, we preserve the width of the back at the armscye. If we had gone the other way, it would look much narrower.

Repeat for the other shoulder.

Finishing the Facings

Working from the outside of the coat, baste the facing to the forepart, about 1 inch from the inner edge of the facing. By working from the outside, you can ensure that the tension between the coat and the facing below are neutral, which will avoid any pulling or stress when the coat is finished.

Fold under the raw edge of the facing and baste it securely, as you did for the front skirt facing.

Leave about an inch of the facing free at the bottom, which should overlap the skirt facing.

Felling the Edges

Starting at the waist seam, fell down the folded edge of the skirt facing. These stitches will be visible on the outside, so try to catch only a thread or two of the skirt fabric.

Continue felling all the way to the bottom of the skirt, and continue around the bottom of the facing.

Now that the skirt facing is complete, you can basted down the bottom of the forepart facing. Fold the raw edge under about 1/4″, or whatever looks best in your particular case.

Baste the facing down along the raw edge, starting at the shoulder seam . . .

. . . and continue to the waist seam, felling along the bottom edge, and then the first 1/2″ or so of the front seam (remember you had stopped the backstitches about 1/2″ to 1″ above the waist).

Now it is time to top stitch the edge of the coat facings, which serve to give a firmer edge to the coat, and also to prevent the seam from rolling out of its position. This could be done with either machine stitching or by hand, depending on your preference. I’ve chosen to use a side stitch here.

Begin at the top of the lapel, just at the lapel dart, and about 1/4″ from the edge. Ideally, you’ll catch the edge of the stay tape in your stitches. Work from the right side of the lapel at this point, as this is what will be seen when the coat is worn.

When you get to the roll line, turn the fabric over so that you are still working from the outside of the coat.

Continue stitching past the waistline, all the way to the hem of the coat.

If you wish, you can do the same thing to the facings on the back of the coat. I usually do not, as they are thinner in width and tend to stay in their proper position.

Basting the Facings

Since this coat will not have any of the pad stitching used normally to ensure a good roll of the lapel, we must take extra care in the basting of the lapel. Begin by trimming off some of the excess material at the tip of the lapel. Try to keep at least 3/8″, as linen ravels easily.

From the facing side, put in a row of shirring stitches. These are just running stitches, secured at one end with a few backstitches, used to help gather material.

From the coat side, pull the end of the shirring thread, gathering the excess material around the point of the lapel. Since it is linen, it may be slightly troublesome, just persevere. Press from the coat side when you are happy with the result. Be sure not to pull too tightly and end up with the crease on the inside of the sewing line.

Remove any basting stitches and the shirring thread, and turn out the lapel to the right side. You can use a pointed but blunt object to help smooth out the tip of the lapel. At the top of the lapel dart, you’ll want to remove any stitches from above the stay stitching you put in both the coat and facing.

Starting at the bottom of the roll line, from the coat side, baste about 1/2″ from the edge. As you go, roll back the coat edge slightly, so that 1/16″ of the lapel is visible on the outside edge. Baste to the lapel dart.

With the facing side up, baste from the bottom of the roll line to just above the waist line, about 1/2″ from the edge. This time, roll back the lapel so that the coat is visible by 1/16″ underneath. What this is all doing is ensuring that when wearing the coat, all you see is a nice finished edge, with no facing visible underneath.

As you’re basting near the roll line, keep the facing and coat exactly even for about 1/2″ above and below the roll line. This gives a smooth transition from below the roll line to the lapels.

On the skirt, fold back the facing over the stay tape, making sure to not pull too tightly. Baste about 1/2″ from the edge from the waist to the hem.

At the hem, the facing will probably skew upwards a little, which is okay.

At the waist, allow the forepart facing to overlap the skirt facing.

About 3/4″ away from the raw edge, baste down the inside of the skirt facing.

Turn under the raw edge and baste closed.

From the facing side, baste along the edge, just inside of the first row of basting stitches, from the bottom of the lapel to about an inch beyond the top of the roll line. At the top of the lapel, stay about an inch away from the edge.

Holding the coat with the lapel held in its final rolled position, make a row of basting stitches from the tip of the lapel, diagonally towards the roll line, stopping about 1/2″ beyond the line.

On the coat side, draw in the roll line lightly with chalk or a pencil. This is the last chance to make sure it all lines up properly. Baste using a running stitch from the bottom of the roll line to about 1″ from the top.

On the facing, draw a line from the top of the lapel dart, about 1/2″ from the top, to a point 1/2″ from the roll line. This should follow the top of the stay tape underneath. Make a mark to denote the end point.

Make a cut through the facing only from the neck to that point, as shown.

Fold the facing under from the cut to the lapel dart. The folded edge should be just above the top of the stay tape. Baste in place.

Lay the coat facing side up on the ironing board and press the lapel flat. This will give just the right amount of tension to the lapel, helping it to roll over nicely.

Hold the lapel into it’s position, creasing along the roll line, and press from the top of the roll line to two or three inches above the bottom of the roll line. This area is not pressed, but allowed to roll freely.

Attaching the Facings

It’s now time to attach the facing to the coat, which will give us a firm, crisp edge and help the lapel roll properly. To start off with, lay the facing onto the right side of the coat, right sides together. The outside edges should line up, and the bottom of the facing should extend about 1/2″ below the waist line.

Baste along the front edge of the facing, catching the stay tape underneath. Baste from the waist line to just below the top of the lapel.

At the top of the lapel, lower the facing vertically with your thumb, and baste in place across the top edge. This should give some extra fullness at the top of the lapel, and will allow the lapel to roll freely when it is completed. If you think about it, the length between the inside of the lapel, and the outside will be different, due to the curve. This step will achieve that.

I didn’t photograph this, but it’s a good time to make a stay stitch, or a few stitches in place, at the top of the lapel dart on the facing, at the seam line, to keep the dart from raveling. These stitches will be positioned right over the top of the stay tape underneath.

Stitch the facing onto the coat using either a back stitch or back and fore stitch. The stitching starts precisely at the dart, around the corner of the lapel, and ending about 1/2″ to 3/4″ above the waist line. The stitching should be 1/16″ away from the edge of the stay tape.

At the corner of the lapel, instead of making a sharp corner with the stitches, make two stitches on the diagonal to allow room for the seam allowance when it is turned right side out. See the diagram below for more clarity. Use backstitches in the corner area for extra strength. Also, note that the stay tape should indeed come right up to the corner. I had a slight mishap and lost about 1/8″, hence the gap at the corner.

Continue sewing to to about 3/4 above the waistline. This will later be finished by felling after all of the facings have been turned right side out – we need some room to move things around at this point.